Case Study

Flexible Energy Efficiency Program Reaps Massive Energy Savings

ComEd Smart Ideas for Your Business Incentive Program

Enables Industrial Facility to Fast-Track Lighting Upgrade,

Saving Over 1.2 M kWh Annually

®

As energy efficiency plays an increasingly important role in power management

strategies for the nation’s utility companies, incentive programs encouraging businesses

to save energy are gaining in importance. This is good news for the nation’s industrial

facilities, as upwards of 38% of their annual budgets are consumed by lighting, making

it a rich target for energy efficiency savings and incentive programs.

Yet the level of energy savings derived from lighting upgrades vary widely by manufacturer

and type, making a “one size fits all” approach to incentive programs ineffective

Best-practice utility companies, like ComEd, cater to this variety by offering a range —

from prescriptive, per-fixture incentives to custom incentives — designed to promote

maximum kWh savings. ComEd’s industrial customers are taking advantage of this

program to upgrade their lighting, as this represents the low-hanging fruit of energy

efficiency projects, with a quick payback and high return on investment.

C om E d CUSTOMER , SILVER BEAUTY, EVALUATES ITS OPTIONS

The management team at Silver Beauty, a warehousing management company that builds

and leases warehouses in the Chicago area, faced a dilemma. The metal halide lighting

in its 177,413-square foot facility,Warehouse #5, consumed too much energy and had

developed a persistent “hum” that was increasing in intensity to the displeasure of its

tenant. Operating under the principle that well-designed facilities result in satisfied,

long-term tenants, Silver Beauty decided to replace the lighting in Warehouse #5 —

a facility with year-round, 24 x 7 operations.

As the management team began investigating its lighting options, they also looked

into various ways of defraying some of the upfront costs associated with the lighting

upgrade. Working with energy efficiency consultant, Green Light Midwest, the effort

included reaching out to ComEd, an Illinois-based unit of Exelon Corporation, one of

the nation's largest electric utility companies. What the team learned about ComEd’s

award-winning “Smart Ideas for Your Business” energy efficiency incentive program

captured their interest and strengthened their commitment to the project.

INCENTIVE PROGRAM SUPPORTS HIGH EFFICIENCY LIGHTING DECISIONS

At ComEd, the most commonly utilized form of incentive for lighting, prescriptive

incentives, was not a good fit for Silver Beauty, as it effectively under-valued the

savings attainable for the intelligent lighting system they were considering. Prescriptive

incentives are paid out on a per fixture basis and are targeted at lighting solutions that

deliver strictly wattage-based savings. Alternatively, custom incentives are designed

for projects that deliver energy savings ‘far above and beyond’ commonly available

alternatives. For projects that meet the rigorous requirements, custom incentives

are paid out on a ‘per-kWh-saved’ basis.

“The Digital Lumens system that Silver Beauty was considering met all the criteria

we look for in a custom incentive offering,” said Randolph Harding, Energy

Efficiency Engineer for the Smart Ideas for Your Business team at ComEd. “With a

documented payback period of less than two years, it was well within our one- to

seven-year payback requirement; offered energy savings that comfortably exceeded

the 70% efficiency improvement the program requires; and, as importantly,

ComEd

UTILITY PARTNER

ComEd

PROGRAM

®

Smart Ideas for Your Business

INDUSTRIAL CUSTOMER

Silver Beauty

LOCATION

Chicago, IL

FACILITY SIZE

177,413 ft 2

OPERATIONAL SCHEDULE

24 x 7

ENVIRONMENT

Ambient Warehouse

PREVIOUS LIGHTING SOLUTION

1000-watt Metal Halide

PROJECT TYPE

Lighting Retrofit

INCENTIVE TYPE

Custom — $/kWh Saved

ANNUAL kWh SAVINGS

1,237,262

Figure 1: Using the integrated LightRules reporting

capabilities, the Silver Beauty management team

has detailed information on lighting use, such as

kWh used and occupancy patterns.

ComEd — Silver Beauty

was listed on the Design Light Consortium (DLC) Qualified

Product List (QPL) — a must-have for LED project consideration”

(see the next page for additional details about the Design Light

Consortium Qualified Product List).

ComEd's custom incentives are designed for

projects that deliver energy savings ‘far above

and beyond’ commonly available alternatives

At $.05 per kWh-saved, the custom incentive would defray up

to 50% of the up-front costs associated with the LED-based

system, making the decision to move forward with the project

just that much easier. Installed in mid-2012, the Intelligent

Lighting System has reduced the facility’s annual lighting budget

by 92%, from $78,000 to just under $6,000, while reducing

ComEd’s industrial load by 1,237,262 kWh annually.

REQUIREMENTS FOR A CUSTOM INCENTIVE

With a level of control over lighting that is unmatched within

the lighting industry, the Digital Lumens system easily met all

the criteria necessary to qualify for a custom incentive. The

next step, defining the parameters of the incentive, followed a

well-established process at ComEd that is used for all qualifying

lighting technologies. It involved:

• Establishing a baseline. Working with facility engineers and

Green Light Midwest, a lighting audit was conducted to gather

baseline information about the facility’s lighting use. The audit

was then used to estimate the amount of energy consumed

by the existing lighting fixtures within Warehouse #5 since,

like most facilities, lighting was not separately metered.

Because Silver Beauty’s facility used 1000-watt metal halide

fixtures operating on a 24 x 7 basis, a reasonably accurate

baseline value was easy to determine. In fact, the Silver Beauty/

Green Light team had previously estimated its baseline usage

via the Digital Lumens’ Energy Savings Calculator, a tool that

combines industry-specific knowledge with facility-specific

data (e.g., type of facility and size, fixture type and wattage,

operating hours…) to calculate potential upgrade savings

based on current costs.

• Estimating the savings. For planning purposes, it was

important to estimate the dollar value of incentives that

would be granted upon installation of the new system.

These calculations take into account the expected changes

in lighting use based on conventional factors, such as facility

size and fixture wattage, as well as behavioral factors, such as

workspace usage and occupancy patterns.

Through the Energy Savings Calculator, Silver Beauty already

had a rough estimate of the potential energy savings attainable

with the Intelligent Lighting System. For ComEd, the Energy

Savings Calculator provided an important data point and

comparative tool for establishing the estimated value of the

Silver Beauty energy efficiency incentive.

Case Study

Once the custom incentive was approved and the lighting

system installed, energy savings had to be validated before

payout, which normally occurs within 60 to 90 days of

installation. Naturally, the higher the energy savings, the better

the incentive for Silver Beauty.

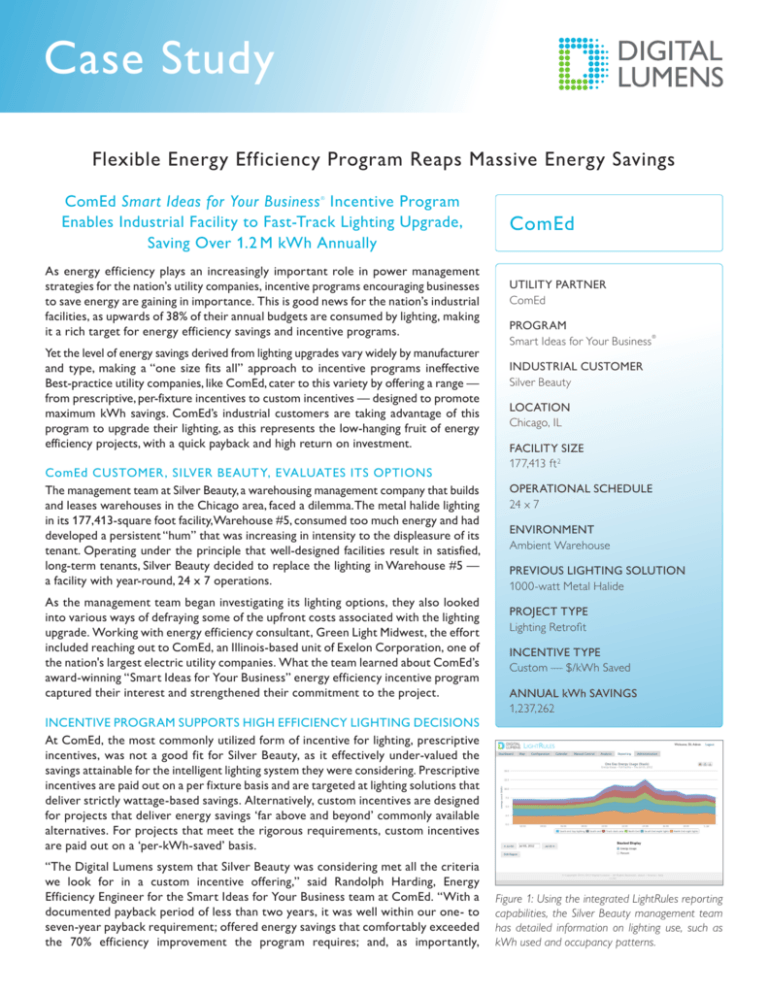

SILVER BEAUTY

LIGHTING ENERGY COSTS

Intelligent Lighting System Installed

$7000

$6000

$5000

$4000

$3000

$2000

$1000

March

April

May

June

Figure 2: Lighting energy costs at Silver Beauty before and after

installation of the Digital Lumens Intelligent Lighting System.

VALIDATING THE SAVINGS

To validate the energy savings, ComEd used one month’s worth

of actual usage data to estimate the annual savings. While this

is normally done by tracking billing changes and comparing it

to the baseline estimate, the validation process for the Silver

Beauty incentive was much easier and, importantly, completely

accurate. This is due to the metering and controls within the

Digital Lumens system, which provides detailed usage reports on

a facility’s lighting use, such as kWh used and occupancy rates,

for any timeframe needed.

“The incentive program is a significant component of ComEd’s

power management strategy, so once we grant a custom

incentive, it is important that the promised energy savings be

realized,” said Mr. Harding. “So not only do we need to verify

energy savings for our own purposes of creating and issuing the

incentive, we also need to be confident that the project savings

are delivered and can be independently verified by a thirdparty evaluator. Because the energy data in the Digital Lumens

LightRules reports match the energy consumption recorded

on our own meter, we’re confident that this will be the case.”

In fact, a third-party evaluator independently validated the

savings at Silver Beauty, which included placing several dozen

sensors around the warehouse to confirm lighting usage

and levels.

ComEd — Silver Beauty

EXTRAORDINARY ENERGY SAVINGS SURPRISE Com E d

In the month following the installation of the Intelligent Lighting

System, Silver Beauty’s energy bill abruptly dropped. In fact,the

savings were so extraordinary that ComEd assumed the meter

at Warehouse #5 had malfunctioned and sent a repairman out to

visually inspect — and presumably repair — the meter. Amused

by the situation, Gary Raymond, Managing Partner for Silver

Beauty, proudly demonstrated his new lighting system and the

detailed usage reports that documented the 92% energy savings.

These energy savings were the result of many efficiencies,

both large and small, enabled by the Intelligent Lighting System,

including:

• Occupancy sensing. Unlike LEDs, metal-halide lights cannot

cycle on and off as forklift operators pass through a work area,

forcing lighting to be on 100% of the time. With its built-in

occupancy sensors, the Intelligent Lighting System achieved an

additional 70% savings over wattage alone by instantaneously

raising illumination from security to working levels only

when needed.

(As Mr. Raymond discovered in one of his other facilities,

Warehouse #6, motion-sensor-controlled T5 fluorescents

were not a viable alternative, as frequently cycling them on and

off to save energy seriously degraded lamp life. Furthermore,

they could not cycle quickly enough in cold environments to

provide the necessary levels of illumination, even when using

cold-weather ballasts.)

• Daylight harvesting. Skylights provide up to 40% of the

lighting needed to illuminate the facility. Photo sensors

integrated into each fixture assess available ambient light,

enabling each fixture to continually adjust lumen output to

meet the facility’s 20 foot-candle target.

• Dimming and task tuning. Dimming and occupancy settings

can be modified easily to address changing operational needs.

When a space is unoccupied in Warehouse #5, for example,

lighting is dimmed to 30% in well-traveled aisles, and 10% to

15% elsewhere for security purposes.

• Integrated LightRules Intelligence. Provides the

information the management needs to continuously optimize

how lighting is used within the facility to safely achieve

additional energy savings. Includes the ability to evaluate

“what-if” scenarios.

• Wattage-based savings. With an equivalent foot-candle

reading — three feet off the floor — the previous metal

halide lamps consumed 149,040 watts of electricity each hour

versus 31,740 for the Digital Lumens 18,000-lumen fixture.

“When we first looked at the request for an incentive, the

claimed savings was higher than we generally see in most

occupancy sensor applications,” said Mr. Harding. “Because the

system had a reliable M&V analysis tool, typical to advanced

lighting systems, we were able to confirm the savings in

our analysis.” Thanks to a smartly designed incentive program

and the prudent property manager whom it helped to install

an intelligent LED system, ComEd gained a single source of

significant kWh reduction and a happy, satisfied customer.

Case Study

COMED: INVESTING IN ENERGY EFFICIENCY

ComEd’s Smart Ideas for Your Business ® program provides

a range of incentives to businesses investing in energy efficiency.

Available to all ComEd commercial and industrial customers,

these incentives are helping to defray up to 50% of the up-front

costs associated with projects that range from more efficient

lighting and refrigeration systems to industrial equipment and

data centers. The Smart Ideas program has been recognized

by the American Council for an Energy-Efficient Economy for

its leading design and practice in energy efficiency programs by

reducing energy costs, improving the environment, and boosting

the economy.

For more information about ComEd’s Smart Ideas for Your

Business programs, visit www.ComEd.com/BizIncentives. Smart

Ideas is funded by ComEd customers in compliance with Illinois

Public Act 95-0481.

ABOUT THE DESIGNLIGHTS CONSORTIUM'S QPL

The DesignLights Consortium (DLC) is a collaboration of utility

companies and regional energy efficiency organizations, with

a mission to ensure that high-quality, energy-efficient lighting

becomes commonplace in all areas of the commercial lighting

market. Only products that meet specific criteria, which must

be independently tested and verified, are added to its Qualified

Product List (QPL) and therefore eligible for incentives in

participating programs.

The QPL is a free tool available to utilities that are processing

incentive applications for industrial and commercial customers

who use products that are not currently covered by the U.S.

Department of Energy’s Energy Star ™ program. In 2011, Digital

Lumens’ Intelligent Light System became the first product to be

approved by the DesignLights™ Consortium (DLC) for its newly

created High-Bay Aisle category. To learn more or to download

the DLC’s QPL, go to designlights.org.

www.digitallumens.com

374 Congress Street, Suite 600

Boston, MA 02210

(617 ) 723-1200

All Rights Reserved © 2012-2013

Digital Lumens Incorporated

Subject to change without notice.

DOC-000137-00 Rev A 03-13