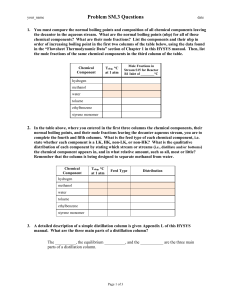

experimental simulations of distillation column profile

advertisement