Ground Testing Technical Committee - AIAA Info

advertisement

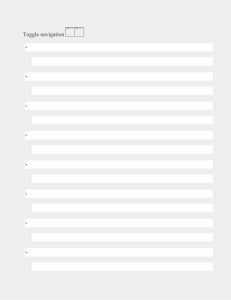

Vol 4 No 1 January 2001 Ground Testing Technical Committee Chairman’s Message Welcome to the newest edition of the newsletter of the American Institute of Aeronautics and Astronautics (AIAA) Ground Testing Technical Committee (GTTC). You will find that this publication, like the GTTC itself, is about taking action and getting involved, furthering the AIAA technical agenda, and making the most of AIAA contributions. The GTTC is dedicated to the advancement of ground testing in support of the aerospace sciences. The committee strives to be innovative in its approach and to continuously look for new areas to explore. Our membership represents the full spectrum of aerospace ground testing expertise and we pride ourselves on our ability to be open to new ideas. We rely on guidance from our members and from you to help us select the most relevant ground test topics for special consideration. Our main subcommittees are in the technical areas of aerodynamics and propulsion. Through an innovative working group structure, most of the technical work we 2 Outstanding Papers 3 Membership 4 Subcommittee News 6 Working Groups 8 Student Contest 9 Congressional Visits Day 10 Ground Testing News 17 Special Topics 18 Committee News 19 GTTC Calendar 20 Membership Information GTTC Newsletter GTTC Newsletter GTTC Newsletter do incorporates participation from outside of the GTTC membership. The subcommittees and working groups are active in six areas of study, completing products and/ or documents in the areas of • Experimental uncertainty • Internal balance technology • Wind tunnel calibration methodology • Test processes • Thrust stands • Flow quality To improve communication and to support a proactive approach to solving common problems, the GTTC maintains numerous liaisons throughout the AIAA and industry. The GTTC has made strides in improving the quality of our conference sessions with technical programs that focus on current ground testing problems and solutions. We have also been busy with numerous other activities to support our goals. These include the continuation of our Student Design Competition to recognize and encourage the work of AIAA’s collegiate members, the selection of Outstanding Papers from technical papers presented at last summer’s Advanced Measurement Technology and Ground Testing Conference (AMT/GT) (see announcement in this newsletter), the presentation of our National Ground Testing Award, and participation in the planning and execution of AIAA’s annual Congressional Visits Day. The GTTC provides a forum for its diverse membership to discuss new issues and ideas. The committee comprises a skills blend of 35 AIAA professionals from commercial, government, and academic sectors involved in ground testing of aerodynamics and propulsion systems. We benefit from the enthusiasm of members who are always seeking new opportunities and challenges. Through our associate membership and international programs, we Continued on pg 2 www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 1 Vol 4 No 1 January 2001 Ground Testing Technical Committee Continued from pg 1 also encourage young professionals (under age 35) to participate, as well as those who work outside the United States. Since we are always looking to increase our value to AIAA members and the aerospace community, I invite you to send comments or suggestions regarding any of our activities directly to me: Dan.Marren@arnold.af.mil If you wish to learn more about our technical activities, get involved as a member, or join an active and dynamic technical committee, you may visit our web site [www.lions.odu.edu/~dlandman/gttchome.html] or contact the committee chairman, Dan Marren, at 301–394– 1750 or chairman-elect, Allen Arrington, at 216–433–8551. Outstanding Ground Testing Papers from the 21st AMT/GT Conference The GTTC is pleased to announce the selection of three Outstanding Papers from the 21st AMT/GT Conference in Denver in June 2000. Five papers were submitted by the various session chairpersons for consideration. A review committee of five GTTC members ranked the papers. Three papers were selected as outstanding: “Langley Wind Tunnel Data Quality Assurance—Check Standard Results” (AIAA-2000-2201). Michael J. Hemsch, NASA Langley Research Center; John P. Grubb and William B. Krieger, Lockheed Martin Technology Services Group; and Daniel L. Cler, NASA Langley Research Center. 2000-2521). Jonathan W. Naughton, University of Wyoming; and Mark Sheplak, University of Florida. We extend our congratulations to each of these authors who have made a significant contribution to the conference, the ground testing community, the AIAA, and the aerospace industry. The GTTC selects papers from each of its conferences to recognize important work in the field of aerospace ground testing that demonstrates outstanding research, documentation, and presentation. These three exceptional papers were selected after a rigorous review process from all papers presented in GTTC sessions at the AMT/GT. The primary criteria are technical quality and relevance to aerospace systems ground testing. Chosen papers are recommended for publication in the appropriate AIAA journals and the authors are presented with a certificate and a letter to their management announcing their achievement. Related Links The networking that we do to share ideas and information within the ground test community is vital to our success. This newsletter is just one way that the GTTC aids the community by providing updates on ground testing current events. There are a lot of other great sources of information on aerospace and ground testing news. Mike Worthey produces a fairly new newsletter called The Wind Tunnel Connection, together with a web site: http://www.worthey.net/windtunnels/ “Numerical and Experimental Investigation of CO 2 Condensate Behavior in Hypersonic Flow” (AIAA-20002379). P.J. Erbland and D.P. Rizzetta, Air Vehicles Directorate, Air Force Research Laboratory, Wright-Patterson Air Force Base; and R.B. Miles, Department of Mechanical and Aerospace Engineering, Princeton University. “Modern Skin Friction Measurement Techniques: Description, Use, and What To Do With the Data” (AIAA- This web site was established to provide useful information to aerospace professionals and engineers engaged in the design, testing, and fabrication of aerospace vehicles, hardware, and software. The newsletter provides updates on wind tunnel activities at various sites around the world (you can request the newsletter through the web site listed above, or visit GTTC (http://www.aero.odu.edu/ ~dlandman/gttchome.html) and look for the Wind Tunnel Connection under “Links”). 2 GTTC Newsletter GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html Vol 4 No 1 January 2001 AIAA / GTTC 2001 Membership Technical Working Groups 2001 GTTC Officers Chairman Daniel E. Marren 301–394–1750 Aerodynamics Subcommittee Nancy Swinford 408–743–1443 Publications Subcommittee David Minto 505–679–2133 Test Processes Mark R. Melanson 817–763–1760 Vice Chairman E. Allen Arrington 216–433–8507 Propulsion Subcommittee Susan T. Hudson 662–325–6602 Standards Subcommittee Susan T. Hudson 662–325–6602 Flow Quality Working Group Frank W. Steinle, Jr. 931–454–7716 Secretary Nancy Swinford 408–743–1443 Awards Subcommittee L. Brent Bates 931–454–4943 Steering Committee Daniel E. Marren 301–394–1750 Internal Balances David M. Cahill 931–454–6725 Conferences Subcommittee Frank K. Lu 817–272–2603 Student Activities Subcommittee Bonnie L. Johnson 316–978–3569 Wind Tunnel Calibrations E. Allen Arrington 216–433–8507 Thrust Stands Daniel Cresci 516–737–6100 ext. 109 Membership Subcommittee E. Allen Arrington 216–433–8507 Gregory Addington Thomas Aiken Dr. Stephen A. Arnette E. Allen Arrington L. Brent Bates Dr. Thomas J. Beutner Jean Bianco Richard Burrows David M. Cahill Julie Carlile Stephen Craft Daniel Cresci Mark Cross Jeffery Emdee Eric Ernst Thomas Fetterhoff John Hayes Dennis W. Hergert Dr. Susan T. Hudson Dr. Bonnie L. Johnson Dr. Jerry Kegelman Jeffrey Kirk Ray Knowis Dr. Drew Landman Dr. Jan Lepicovsky Dr. Frank K. Lu Dr. John Magill Daniel E. Marren Dr. Thomas McLaughlin Mark R. Melanson David Minto James Norton Mark L. Perry Dr. Mark Rennie Mathew L. Rueger Dr. Frank W. Steinle, Jr. Samuel Stephens Todd Sterk William A. Straka Nancy Swinford Niek Verhaagen Air Force Research Laboratory/VACA NASA Ames Research Center Manager, Aeronautics Engineering Research/Sverdrup Technology, Inc. Supervisor, Mechanical Operations/Dynacs Engineering Sr. Engineer/Sverdrup Technology, Inc. (AEDC) Program Manager/Air Force Office of Scientific Research PSL Facility Manager/NASA Glenn Research Center Sr. Engineering Specialist/Boeing Engineering Specialist/Sverdrup Technology, Inc. (AEDC) Air Force Research Laboratory NASA Langley Research Center Sr. Scientist/GASL, Inc. Sverdrup Technology, Inc. The Aerospace Corporation Cryogenics Testbed Manager/NASA Kennedy Space Center Arnold Engineering Development Center (AEDC)/XPV Pratt & Whitney Sr. Principal Engineer/Boeing Phantom Works Ass’t. Professor/Mississippi State University, Mechanical Engineering Director, Aerodynamic Labs/National Institute for Aviation Research NASA Langley Research Center Engineering Specialist/Lockheed Martin Missiles and Fire Control Sr. Vice President/Micro Craft, Inc. Old Dominion University Project Manager/Dynacs Engineering Assoc. Professor/University of Texas at Arlington Physical Sciences Inc. Wind Tunnel Projects Manager/White Oak (AEDC) Aeronautics Research Consultant/U.S. Air Force Academy Engineering Chief, Model Design/Lockheed Martin Aeronautics Holloman High-Speed Test Track/U.S. Air Force Director, Operations/Integrated AeroSystems Lead Projects Engineer/Lockheed Martin Aerodynamicist/Aiolos Engineering Corp. Sr. Project Engineer/Boeing Sr. Engineering Specialist/Sverdrup Technology, Inc. (AEDC) Lockheed Martin Stennis Operations Sandia National Laboratory Assoc. Research Engineer/Penn State Applied Research Laboratory Manager II PEL, Aero/Fluids Group/Lockheed Martin Space Systems Sr. Research Scientist/Vortex Aerodynamics and Acoustics GTTC Newsletter GTTC Newsletter GTTC Newsletter 937–255–8490 650–604–6855 931–393–6699 216–433–8507 931–454–4943 703–696–6961 216–433–8870 562–797–5651 931–454–6725 661–275–5098 757–864–4817 516–737–6100 ext. 109 931–454–5952 310–336–7704 407–867–2133 931–454–5870 561–796–4397 206–655–4253 662–325–6602 316–978–3569 757–864–8022 972–603–2419 615–455–2617 ext. 504 757–683–6008 216–977–1402 817–272–2603 978–689–0003 301–394–1750 719–333–2613 817–763–1760 505–679–2133 714–755–7427 770–494–5619 416–674–3017 314–232–2832 931–454–7716 228–688–7207 505–844–4923 814–863–3009 408–743–1443 31–15–278–6385 gregory.addington@va.afrl.af.mil taiken@mail.arc.nasa.gov arnettsa@sverdrup.com earnest.a.arrington@grc.nasa.gov brent.bates@arnold.af.mil tom.beutner@afosr.af.mil jean.bianco@grc.nasa.gov richard.burrows@west.boeing.com david.cahill@arnold.af.mil julie.carlile@ple.af.mil s.j.craft@larc.nasa.gov dcresci@gasl-usa.com mark.cross@arnold.af.mil jeffery.l.emdee@aero.org eric.ernst-1@ksc.nasa.gov thomas.fetterhoff@arnold.af.mil hayesjoh@pwfl.com dennis.w.hergert@boeing.com hudson@me.msstate.edu bjohnson@wsuhub.uc.twsu.edu j.t.kegelman@larc.nasa.gov jeffrey.kirk@lmco.com rknowis@microcraft.com dlandman@.odu.edu jan.lepicovsky@grc.nasa.gov lu@mae.uta.edu magill@psicorp.com dan.marren@arnold.af.mil tom.mclaughlin@usafa.af.mil mark.r.melanson@lmco.com dave.minto@46tg.af.mil jnorton.ias@dabico.com mark.l.perry@lmco.com mark@aiolos.com mathew.l.rueger@boeing.com frank.steinle@arnold.af.mil samuel.stephens@ssc.nasa.gov tmsterk@sandia.gov was@wt.arl.psu.edu nancy.swinford@lmco.com n.g.verhaagen@lr.tudelft.nl www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 3 Vol 4 No 1 January 2001 GTTC Subcommittee News The GTTC subcommittees are the backbone of our organization and create opportunities for the GTTC members to get involved with the workings of this AIAA Technical Committee. The GTTC is subdivided into two primary subcommittees, Aerodynamics and Propulsion. Each GTTC member is assigned to one of these primary subcommittees. Membership in other GTTC subcommittees depends upon the member’s interest (for the Liaison, Publications, Standards, Student Activities, and Awards and Upgrades subcommittees) or the office held within the GTTC (for the Steering, Conferences, and Membership subcommittees). If you have an interest in a specific subcommittee, please feel free to attend the next meeting. GTTC subcommittee meetings coincide with GTTC-supported conferences. Specific dates, times, and locations can be found in the conference registration materials. The Steering Subcommittee reviews GTTC policy, AIAA business, and all matters of general interest to GTTC members. The Steering Subcommittee is headed by the GTTC chair and includes the vice chair, secretary, and all subcommittee chairs. The success of our technical committee has been recognized by AIAA Headquarters. The GTTC has prepared and presented AIAA training sessions for new technical committee chairpersons. Daniel E. Marren White Oak (AEDC) 1999, “Assessment of Experimental Uncertainty with Application to Wind Tunnel Testing.” The subcommittee is now working on a related AIAA publication, “Guide for Assessing Experimental Uncertainty—Supplement to AIAA S071A -1999.” This document will provide additional information and examples to assist the experimenter in applying uncertainty analysis techniques and performing an uncertainty analysis. The information contained in the standard and this guide is not limited to wind tunnel testing and can be applied to a wide range of experiments. Susan T. Hudson Mississippi State University Mechanical Engineering Membership Subcommittee Aerodynamics Subcommittee The Membership Subcommittee, which comprises the vicechairs of the GTTC and of the Aerodynamics and Propulsion subcommittees, tries to provide a balance in technical background and represented organizations when reviewing applications for new members. Selected new members are notified in March. Applicants who are not selected in one year are eligible for consideration the following year. The large number of applications to the GTTC has created a considerable pool of eligible representatives from all arenas of the aerospace community. E. Allen Arrington Dynacs Engineering The Aerodynamics Subcommittee promotes the advancement of aerodynamic ground testing technology. Members of this committee serve as liaisons to several other committees, such as the High-Speed Civil Transport Coordination Committee, the Thermophysics Technical Committee, the Applied Aerodynamics Technical Committee, and the Institute for Aerospace Research of the National Research Council of Canada. Nancy Swinford Lockheed Martin Steering Subcommittee Conference Planning Subcommittee The Standards Subcommittee consists of members from both the Aerodynamics and Propulsion subcommittees. It promotes the understanding of ground testing, the standardization of uncertainty analysis methodology, and the widespread use of uncertainty analysis techniques. Recently, the subcommittee published a revision to AIAA Standard S-071A- The Conference Planning Subcommittee, as its name implies, plans and organizes GTTC conferences and sessions. The GTTC sponsors a biennial ground test technical conference and also supports two annual AIAA conferences with ground testing sessions. Beginning in 1996, the conference has also been supported by the AIAA Aerodynamic Measurements Technical Committee as the Advanced Measurement Technology and Ground Testing Conference. These conferences are typically 4 GTTC Newsletter GTTC Newsletter GTTC Newsletter Standards Subcommittee GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html Vol 4 No 1 January 2001 GTTC Subcommittee News colocated with other AIAA technical conferences held in the early summer months. The committee also plans and organizes the GTTC-sponsored sessions for the annual Aerospace Sciences Meeting in January and the Joint Propulsion Conference (on odd-numbered years only). Planning and organizing activities include electing conference chairs; selecting session chairpersons, the conference program, and the site and meeting room; preparing the Call for Papers; and planning of coordinated short courses, tours, luncheons, special exhibits, and so forth. Frank K. Lu University of Texas at Arlington outstanding achievement in the ground testing field. The 2000 Ground Testing Award was presented to Travis Binion (formerly of the Arnold Engineering Development Center) in June 2000 at the 21st AIAA Advanced Measurement Technology and Ground Testing Conference in Denver. The Outstanding Paper Award recognizes the technical quality, technical relevance, presentation, and readability of papers presented at the various GTTC sessions. Three papers from the 21st AMT/GT Conference were given this award. L. Brent Bates Sverdrup Technology, Inc. (AEDC) Publications Subcommittee Propulsion Subcommittee The Propulsion Subcommittee promotes the advancement of ground testing technology related to aeropropulsion systems. Members of this committee serve as liaisons to several other committees such as the Propulsion Technical Committee, the Turbine Test Facility Working Group, and the Turbine Engine Testing Working Group. Susan T. Hudson Mississippi State University Mechanical Engineering Liaisons Subcommittee The Liaisons Subcommittee was formed to foster communications with AIAA Headquarters, other AIAA technical committees, and independent societies and organizations. GTTC members are encouraged to become liaisons to groups that share their professional interests. Representatives of liaison organizations are invited to attend GTTC meetings and exchange information with members to our mutual benefit. These exchanges may include sharing of administrative methods, participation in joint endeavors and innovative projects, or information about conferences and technical programs. Liaison reports are summarized in a standard format and published as addenda to the GTTC minutes. Daniel E. Marren White Oak (AEDC) Awards and Upgrades Subcommittee The Awards and Upgrades Subcommittee coordinates and participates in the selection process for the annual Ground Testing Award presented by AIAA. This award is presented for GTTC Newsletter GTTC Newsletter GTTC Newsletter The Publications Subcommittee promotes the efforts of the various GTTC subcommittees through dissemination and publication of technical information, journal articles, and use of other forms of media. In addition to the annual Aerospace America Highlights article, the committee is responsible for preparing and publishing the GTTC Newsletter and maintaining the technical committee’s web site. Ground testing-related articles and news items for use in Aerospace America Highlights and the GTTC Newsletter are solicited from current and former GTTC members and others in the ground testing community. David Minto Holloman High-Speed Test Track/U.S. Air Force Student Activities Subcommittee The Student Activities Subcommittee coordinates a GTTC Engineering Contest each year for undergraduate and graduate students. The winners receive honoraria for their efforts, as well as the chance to attend an AIAA professional conference through a financial donation by Pratt & Whitney. Encourage students at your area universities to submit their projects by handing out the flyer included in this newsletter to your sections, and please volunteer to judge the projects after they have been submitted. The subcommittee also encourages interaction between GTTC members and their local schools. New ideas for experiments and/or testing kits for students who want to learn about flight and aviation are always needed. Please send your ideas to Drew Landman, along with any interesting web links on sciencerelated activities you may encounter. Bonnie L. Johnson National Institute for Aviation Research www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 5 Vol 4 No 1 January 2001 GTTC Working Group News Five Working Groups are currently operating in the GTTC. The working groups and chairmen are Internal Balance Technology, David M. Cahill; Test Processes, Mark R. Melanson; Wind Tunnel Calibration Methodology, E. Allen Arrington; Thrust Stands, Daniel Cresci; and Flow Quality, Frank W. Steinle, Jr. Recent working group progress is presented below. Wind Tunnel Calibration Methodology Working Group E. Allen Arrington, chair The Wind Tunnel Calibration Methodology Working Group held its 10th series of meetings in June 2000 as part of the Advanced Measurement Technology and Ground Testing Conference in Denver. At present, the 16 members are completing the first draft of a best-practices guide on wind tunnel calibration. During the June meeting, it was decided to include case studies on actual tunnel calibration programs in the guide to better illustrate how tunnel calibrations are conducted. Assignments for the remaining guide sections were also made. The current plan is to complete the draft for the January 2001 meeting in Reno. The Wind Tunnel Calibration Methodology Working Group was formed in 1996 to provide a forum for the exchange of ideas and information about wind tunnel calibration. Since so many topics are relevant to wind tunnel calibration, the initial scope of the working group was limited to the empty test section calibration of subsonic and transonic wind tunnels. Each member of the working group has made valuable contributions to the success of the group. The current membership is provided below: Dr. Steven A. Arnette Allen Arrington (chair) Dr. Thomas J. Beutner Alan Boone Colin Britcher Andy Garrell Jim Hallissy Dennis W. Hergert Dr. Bonnie L. Johnson Mark Kammeyer Mike Mills Mark L. Perry (vice-chair) Dr. Mark Rennie David Sanford Lew Scherer Dr. Frank W. Steinle, Jr. Jim Thain Sverdrup Technology, Inc. Dynacs Engineering, NASA Glenn Research Center Air Force Office of Scientific Research NASA Ames Research Center Old Dominion University Veridian Engineering NASA Langley Research Center Boeing Phantom Works National Institute for Aviation Research Boeing (St. Louis) Sverdrup Technology, Inc. (AEDC) Lockheed Martin Aiolos Engineering Corp. Micro Craft, Inc. Northrop Grumman Sverdrup Technology, Inc. (AEDC) NCR/IAR arnettsa@sverdrup.com earnest.a.arrington@grc.nasa.gov tom.beutner@afosr.af.mil aboone@mail.arc.nasa.gov britcher@aero.odu.edu garrell@calspan.com j.b.hallissy@larc.nasa.gov dennis.w.hergert@boeing.com bjohnson@wsuhub.uc.twsu.edu mark.e.kammeyer@boeing.com millsml@hap.arnold.af.mil mark.l.perry@lmco.com mark@aiolos.com dsanford@microcraft.com scherle@mail.northgrum.com steinle.frank@hap.arnold.af.mil jim.thain@nrc.ca Thrust Stand Working Group Daniel Cresci, chair The Thrust Stand Working Group has been inactive as of late, but steps are being taken to start things moving again. The group could always use additional participation in tackling this common issue. Please contact Chair Daniel Cresci at 516–737–6100, ext. 109, or at dcresci@gasl-usa.com for additional information. 6 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Working Group News Test Processes Working Group Mark R. Melanson, chair The Test Processes Working Group was formed in late 1992 to address concerns from wind tunnel model manufacturers that the industry was not bringing model manufacturing companies onboard early in test development. Various representatives sought out the AIAA as a forum to discuss and develop effective partnering methods between users and producers of wind tunnel test articles. After 2 years of discussion, the group focused on providing recommended practices for wind tunnel testing as a whole. While the original concept for the working group had merit, separating the design and fabrication of test articles from the whole process of wind tunnel test development was not practical, and a broader goal was defined. A two-part document was envisioned: the first part aimed at aircraft (or other aeronautic) program managers to set overall test program direction, and the second aimed at those charged with the actual execution of tests. The twopart document was begun in early 1995. Throughout each document, key activities and lessons learned would be described to help produce successful test programs and projects. Both parts of the document are complete and in final edit with a projected final review and publication in mid-2001. All participants of the working group have enjoyed the interaction necessary to achieve this goal and have invested tremendous skill and ability into the final consensus document. At the time of this publication, members of the working group include Thomas Aiken E. Allen Arrington Chris Athaide Jean Bianco Julie Carlile Drew Hope Ray Knowis Daniel E. Marren Laura McGill Mark R. Melanson Lew Scherer Rob Sheehan Dr. Frank W. Steinle, Jr. William A. Straka Steven Westmore NASA Ames Research Center Dynacs Engineering, NASA Glenn Research Center Tri Models Inc. NASA Glenn Research Center Air Force Research Laboratory NASA Langley Research Center Micro Craft, Inc. (retired) White Oak (AEDC) Raytheon Lockheed Martin (chair) Northrop Grumman Northrop Grumman Sverdrup Technology, Inc. (AEDC) Penn State Applied Research Laboratory Boeing Phantom Works GTTC Newsletter GTTC Newsletter GTTC Newsletter taiken@mail.arc.nasa.gov earnest.a.arrington@grc.nasa.gov cathaide@trimodels.com jean.bianco@grc.nasa.gov julie.carlile@ple.af.mil d.j.hope@larc.nasa.gov rknowis@microcraft.com dan.marren@arnold.af.mil ljmcgill@west.raytheon.com mark.r.melanson@lmco.com scherle@mail.northgrum.com sheehro@mail.northgrum.com frank.steinle@arnold.af.mil was@wt.arl.psu.edu steven.westmore@PSS.Boeing.com www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 7 Vol 4 No 1 January 2001 GTTC Student Contest 2001 AIAA Ground Test Technical Committee Student Engineering Contest First Place: $1000 plus up to $1000 travel to the AIAA Ground Test Conference Second Place: $500 Important Deadlines: 16 March 2001 Abstracts Due 4 May 2001 Final Reports Due The AIAA Ground Testing Technical Committee, working in conjunction with the AIAA Student Programs Office and numerous aerospace companies, is pleased to offer an aerospace engineering contest to graduate and undergraduate students in aerospace, aeronautical, and related engineering academic programs. The purpose of this contest is to provide an opportunity for interested engineering students to broaden their learning and understanding of the role of ground testing in their aerospace discipline. The winners will be invited to attend and participate in an AIAA professional conference. The contest is open to all junior and senior undergraduate and all graduate students in an engineering program accredited by the Accreditation Board for Engineering and Technology (ABET) or an equivalent engineering program offered by a degree-granting institution recognized by the AIAA. Participants must have continuous enrollment in their program of study throughout the contest period, August 2000 through May 2001. Teams of one to six qualified students can submit a project. Projects can be an extramural project, part of a design or special projects course, or part or all of a graduate thesis. It is essential that the work reported be primarily the work of the student (team) and that the contributions of others outside the team be clearly indicated. To enter, submit an abstract, 500 words or less, detailing the Problem Description, Project Relevance, Research Approach, and Potential Outcome. Include a cover letter containing the level for each student (junior, senior, M.S. or Ph.D.), mailing address, telephone number and facsimile number, signature of each student (team) member, and signature of the faculty advisor of the project. Also include a signed statement by the AIAA faculty advisor stating that the project meets the requirements set forth herein. A team of engineers and scientists from industry, government, and academia will evaluate the abstracts and final reports. Final project submission details will be mailed upon receipt of the abstract. Mail abstracts to Bonnie L. Johnson, Director of Aerodynamic Labs Wichita State University/National Institute for Aviation Research 1845 North Fairmount Wichita, KS 67260–0093 Voice: 316–978–3569, facsimile: 316–978–3521 E-mail: bjohnson@twsu.edu 8 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Congressional Visits Day 2000 GTTC Members Participate in Congressional Visits Day 2000 Several Ground Test Technical Committee members had the opportunity to participate in the 2000 “Congressional Visits Day” or CVD event, which was the largest to date. Tom Beutner and Mark Melanson represented the technical committee and were among approximately 200 participants. The message conveyed to Congress was that the Federal Government must make a long-term commitment to aerospace research and development (R&D). Aeronautics and astronautics R&D has made major contributions to America’s prosperity and the quality of life of the general public. In addition, an attempt was made to define the appropriate role of the Federal Government in supporting aerospace R&D. The program began with an orientation that included briefings on the CVD 2000 message, “The Do’s and Don’ts on Capitol Hill,” and was followed by a welcoming reception at the Washington Court Hotel, which allowed participants and AIAA staff the opportunity to discuss the next day’s activities. AIAA members Carol Cash (aeronautics), Phil Hattis (astronautics), and Cecil Black (defense) presented FY 2001 budget overviews. Other key speakers throughout the two days included Congressman David Weldon (R-FL), who talked about aerospace, Congressman Herb Bateman (R-VA), who spoke about aeronautics, and former CIA Director Jim Woolsey, who discussed defense issues. For the Congressional visits, AIAA staff established teams and meeting schedules in advance to maximize coverage and match AIAA representatives with Congressional Representatives or Senators from their own district or state, when possible. The teams fanned out to the Capitol to talk with key members of Congress and their staffs about the AIAA message, and to leave behind short writeups on the message provided by AIAA. Several teams also had the opportunity to attend hearings on key aerospace or research issues. Congressional Visits Day 2000 concluded with a Congressional Reception in the Rayburn House Office Building on Capitol Hill that allowed AIAA participants, Members of Congress, and Hill staffers to network with one another. Most participants were favorably impressed by the 2-day event. As a first-time participant, Mark Melanson commented, “I expected the level of knowledge about the message to be low, but I was amazed at just how tuned-in the members of Congress and their staffs are to this issue. The other thing that impressed me was that most of the staff are very young—not many are over 30.” Tom Beutner added, “AIAA did a great job of scheduling meetings and putting this event together. The invited speakers were outstanding, and I was surprised by how well informed the staffers were in our meetings.” AIAA will conduct a similar event in the spring of 2001 and AIAA members who are able to participate should strongly consider attending. Attendance at the CVD is an excellent way to communicate an important message, and learn a great deal in the process. GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 9 Vol 4 No 1 January 2001 GTTC Ground Testing News Multimillion-Dollar Construction Project Completed in the NASA Glenn Icing Research Tunnel Contributed by Susan Kevdzija Over the last year, the NASA Glenn Research Center’s Icing Research Tunnel (IRT) has undergone a major $5.2million rehabilitation project as part of the Construction of Facilities program. The scope of the project included redesign and replacement of the 55-year-old heat exchanger, addition of fan outlet guide vanes for flow across the tunnel cross section reduced to ±1 °F. Flow angularity and turbulence intensity in the test section and settling chamber also improved. The achievable velocity in the test section during icing tests has increased due to less pressure drop across the heat exchanger and less frost buildup. Calibration tests were completed in July 2000, and the IRT’s first research test program was successfully completed in early August. With the extensive facility modifications, the IRT is now well positioned to support both NASA icing research programs and private industry customers well into the future. Hypersonic Tes t Facility at NASA Glenn Research Center’s Plum Brook Station Contributed by Mark Woike conditioning downstream of the 25-foot diameter fan, and redesign and replacement of the “C” and “D” corner turning vanes. The purpose of the rehabilitation was to replace old portions of the infrastructure and to improve the aerodynamic flow quality in the tunnel. After the construction phase was completed, the IRT facility engineers and technician staff successfully completed the integrated systems testing. Next, a full calibration of the IRT’s aerothermodynamics and icing cloud characteristics was completed. Results of these calibrations indicate that the temperature uniformity of the tunnel has improved significantly, with variation The Hypersonic Tunnel Facility (HTF) at NASA Glenn Research Center’s Plum Brook Station is a freejet wind tunnel that simulates Mach 5, 6, and 7 true enthalpy flight conditions by controlling t emperature, altitude, and air composition. The overall facility operating envelope spans from 68,000 to 120,000 ft in altitude, 70 to 1200 psia stagnation pressure, and 2200 to 4200 °R stagnation temperature. The high stagnation temperatures that are required for true enthalpy conditions are produced by flowing clean nitrogen gas through a 3.5-MW electric induction heater. This heated nitrogen gas is then mixed with clean oxygen to yield the true air composition of the simulated environment. The facility has three discrete nozzles 42 in. in exit diameter that are used to set the Mach number conditions. The HTF can accommodate test articles up to 10 ft in length. Plans are in place to expand this capability to 14 ft. The test article is mounted on a thrust stand that can accommodate up to 8,500 lb of thrust. Liquid hydrocarbon and gaseous hydrogen propellant systems 10 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Ground Testing News support air-breathing propulsion testing. The HTF is currently the only large-scale nonvitiated (clean air) hypersonic wind tunnel in the United States. The facility’s size and run duration allow for full systems testing of flight-rated structures and engines. Recently, the HTF underwent an extensive rehabilitation. A series of integrated systems tests were successfully completed in January of 2000, validating the operational capability of the restored facility. The HTF is being prepared for a facility calibration program to validate its calibration and document the flow-field conditions in the facility. This testing is scheduled for January and February 2001. A2I2 GASL Group Receives NASA Recognition Contributed by Daniel Cresci The NASA Glenn Research Center recently recognized the success of the GTX Project (formerly known as Trailblazer). Members of GASL’s GTX Rig 4 team received letters of commendation from Mr. Richard A. Blech, Chief Manager), Michael Celentano (leader for Rig 4 design and fabrication), Dan Cresci (leader for installation and testing), Nicholas Tiliakos, Jason Tyll, Patricia Florence, John Dallaire, Richard Brass, Robert Herold, Carl Sauter, and Kenneth Truhon. The team designed, fabricated, assembled, and instrumented the rig; installed and tested it in GASL’s Leg IV facility; and helped interpret the data in close coordination with NASA Glenn’s test team led by Scott R. Thomas and John D. Saunders. The close teamwork between NASA and GASL personnel was acknowledged as a major contributing factor in the success of the program. The GTX Rig 4 Test Project is scheduled to continue this summer, and design and construction of additional GTX test rigs for use at the NASA Glenn Research Center and GASL are currently underway. Boeing to Improve Transonic Wind Tunnel, Sell Two Others Contributed by Dennis W. Hergert Boeing has embarked on a major upgrade to their transonic wind tunnel facility. The central goal of these upgrades is to reduce the risk of facility downtime caused by mechanical and structural failures, and to reduce operating costs and test cycle times while improving data quality and productivity. Boeing’s Wind Tunnel Modernization Initiative is being conducted in three phases. In 1996, during the first phase, the drive system was upgraded with a 55,000-hp motor and an LCI drive system. In addition, the fan structure was upgraded to replace highly stressed parts with redesigned components. The electrical and control systems were also improved to reduce the manpower needed to run the facility. Michael Celentano and Dr. Nicholas Tiliakos with the GTX Test Rig. of the Engine Systems Technology Branch, and Donald J. Campbell, Center Director. GTX Rig 4 team members include Anthony Castrogiovanni (GASL GTX Project GTTC Newsletter GTTC Newsletter GTTC Newsletter Currently, during the second phase, the tunnel circuit is being upgraded. The tunnel shell from just downstream of the fan to the entrance of the test section is being replaced with a steel shell. This will reshape the tunnel aerodynamic lines to reduce power losses and allow installation of the new tunnel components. A heat www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 11 Vol 4 No 1 January 2001 GTTC Ground Testing News Wind Tunnel Modernization Initiative Boeing Transonic Wind Tunnel Planned Improvements New drive system and fan upgrades 1996 New drive system Fan and fan structure upgrades Fan nacelle upgrade 1999 Tunnel air qualities control: new heat exchanger, cooling towers, and dehumidification system 1999 PD ONLY Not shown: Systems automation and improved Mach control Balance calibration machine PD ONLY Plenum flow conditioning Pitch strut modification Major elements 2002 Drive/Fan Circuit Balance Test section Other PD ONLY Test section walls upgrade New main balance New bellmouth and flow conditioners 1999 exchanger will replace the current air exchanger to improve control over the tunnel air temperature and temperature uniformity and to enable cooler operations. A cooling tower system and a dehumidification system are being installed to dissipate the heat and reduce the moisture content of the tunnel airstream. The tunnel circuit is being extended to accommodate additional settling distance and provide room for the improved turbulence reduction system. The current bellmouth and flow conditioners, located in front of the test section, will be replaced with a more gradual bellmouth and a long cell honeycomb for turbulence reduction. In addition, the aft fan nacelle is being redesigned to reduce power losses and unsteady flow coming from the aft fan nacelle and diffuser area. An integrated control system is being installed to automate the control of the new equipment being added to the facility. An acoustic enclosure is also being added to the new steel portion of the circuit to reduce the ambient noise levels. New fan blades will be designed, built, and installed as part of the second-phase upgrade. Aero Systems Engineering, a division of Celsius Aviation Services, is responsible for the new design, new equipment, integrated control systems, and system-level integration. Boeing’s Facility Asset Management Organization, through their subcontractors Harris Group and BAUGH Construction, is responsible for demolition and construction of the new portion of the tunnel. 12 GTTC Newsletter Tunnel air qualities control: air exchanger eliminated www.lions.odu.edu/~dlandman/gttchome.html Circuit extension (new circuit-fan nacelle to bellmouth) 1999 Overall project management is being provided by the Phantom Works Enterprise Laboratories of The Boeing Company. In the third phase, the facility’s external balance, which is located under the test section, will be replaced to avoid component failures and facility downtime and to improve balance measurement accuracy. This upgrade is targeted for 2002. As a part of Boeing’s Wind Tunnel Strategy plan, both the Boeing Supersonic Wind Tunnel (BSWT) and the Boeing Research Aerodynamic Icing Tunnel (BRAIT) are being offered for sale. The BSWT is an intermittent blowdown facility with a 4- by 4-ft supersonic test section capable of testing models from Mach 1.2 to 4.0 and a 4by 4-ft transonic test section that covers the Mach range from 0.3 to 1.3. The BRAIT is a closed-circuit low-speed atmospheric facility capable of testing models from 0 to 250 knots over a temperature range of –45 to 100 °F. More information on both of these tunnels can be found on the Wind Tunnel Connection web site (http:// www.worthey.net/windtunnels/). Boeing’s Dual Aerospike Engines Ready for Test Contributed by Neil Bosmajian Boeing’s dual Aerospike engines are ready to begin testing at NASA’s Stennis Space Center in Mississippi. The GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Ground Testing News Aerospike will power the X– 33, a subscale technology demonstrator that is being developed as part of NASA’s Reusable Launch Vehicle program. The goal is to greatly reduce the cost of transporting payloads into low-Earth orbit. The dual-engine test series follows the highly successful single-engine hot-fire testing that was performed earlier this year. Holloman High Speed Test Track Contributed by David Minto The Holloman High Speed Test Track (HHSTT) has been continuing the Hypersonic Upgrade Program, which will provide the capability to deliver payloads to targets with an impact velocity of around 10,000 ft/sec. Fabrication of the first prototype Hypersonic Upgrade sled has been completed, and the first test of the design was conducted in October. The highly instrumented sled provided the data to verify predicted drags and vehicle and payload loads. A new 200,000-lb-thrust rocket motor (the Super Roadrunner) is being developed for the program, and three prototype motors were poured in September. Two of the motors were static tested in November. In December, the third motor was used to propel a Hypersonic Upgrade sled to 5600 ft/sec in a single stage. The first- and second-stage pusher sleds that are needed to reach higher velocities are being fabricated. Additionally, the Test Track recently completed testing to evaluate the lethality of the Navy’s Standard Missile– 2 Block IVA, the effectiveness of the Army’s Suite of Integrated Infrared Countermeasures System, the accuracy of the Translated Global Positioning System (GPS) Ranging System, and the ef fectiveness of improvements to the Air Force’s ACES II ejection seat. Beech Memorial Wind Tunnel adds Aeroprobe Contributed by Bonnie L. Johnson The Walter H. Beech 7x10 Memorial Wind Tunnel has recently added an Aeroprobe seven-hole probe (Aeroprobe Corp.) to our inventory of f low measurement equipment. A new probe traversing system was also constructed to sweep out the area of interest behind the wind tunnel models. The probe traversing mechanism is shown in the photograph below. The vertical arm determines the length of the radius of the probe boom. The horizontal arm determines the angle swept by the probe boom. We can cover the test section from 18 in. below the ceiling of the test section to 18 in. above the test section’s floor. The horizontal distance varies depending on the distance from the ceiling: 20 in. at the top of the boom travel area and 80 in. at the bottom of the boom travel area. The illustration shows results taken in horizontal and vertical increments of 0.5 in. behind a sailboard skeg at an angle of 4° and a dynamic pressure of 20 lb/ft2. We can take data from 18 in. aft of the model to 42 in. aft of the model. The plot was created using Tecplot 8.0. GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 13 Vol 4 No 1 January 2001 GTTC Ground Testing News Cryogenics Testbed at Kennedy Space Center Contributed by Eric Ernst With its one-of-a-kind test facilities, advanced test equipment and systems, and the multifaceted expertise of its workforce, Kennedy Space Center (KSC) is an ideal environment for product development and testing. As a further enhancement, the Center has developed the Cryogenics Testbed, which is jointly managed by NASA and Dynacs Engineering Co., NASA KSC’s engineering development contractor. The testbed is the result of collaboration among industry, aerospace, and research partners. It will provide cryogenic engineering development and testing services to government, academic, and commercial organizations. Elements of the Cryogenics Testbed • Cryogenics Test Laboratory—This facility includes three state-of-the-art laboratories, a high bay, and a class–100 clean room. • Launch Equipment Test Facility (LETF)—The LETF is home to a modern machine and fabrication shop to support advanced prototype development, as well as large-scale testing apparatus for space launch systems. • Material Science Laboratory (MSL)—The MSL located at KSC provides complete materials characterization, material development, and failure analysis capabilities. In addition to testing of systems and components, the Cryogenics Testbed supports the design and fabrication of one-of-a-kind test apparatus. The testbed can supply liquid nitrogen, oxygen, hydrogen, air, and helium, and gaseous nitrogen and helium to 6000 psig. Specialized facilities include pneumatic test circuits and environmental simulation chambers. • Low-temperature material evaluation and testing • High-vacuum pumping and measurements • Cryogenic systems engineering consultation • Sensor and instrumentation development • Large-scale system qualification • Conceptual design and prototype construction • Machine and fabrication services Core lines of work include low-temperature applications and development of thermal insulation systems, cryogenic components, and propellant processing systems. Current programs underway at the testbed include the following: • Development and testing of advanced thermal insulation systems • Cryogenic ground support equipment flow testing and analysis • Advanced launch system umbilical development and testing, automated umbilical systems development • Launch pad hydrogen entrapment testing • Research and development on long-term storage of cryogens technology for application to Lunar and Mars missions • Low-cost, high-efficiency pipeline studies for longdistance transfer of cryogens • Commercial cryogenic component testing Potential customers exist in a wide range of scientific disciplines and industries. The Cryogenics Testbed is available for project consultation. No matter what size the project or testing need, the testbed can provide a unique service on a fixed-price basis to both government and industry. F–22 Engine Completes Qualification Test Milestone for Initial Service Release Contributed by Thomas Fetterhoff Testbed Services • Flow testing • Leak detection, measurement, and testing • Insulation system testing using cryostat, tank, or pipeline test fixtures • Component development, testing, and evaluation • Thermal insulation systems testing 14 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html The Pratt & Whitney F119 engine for the Air Force’s new Lockheed Martin F–22 Raptor air dominance fighter has successfully met a major Initial Service Release test milestone. The Defense Acquisition Board criterion for Initial Service Release of the Raptor’s engine was to complete half of GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Ground Testing News 4,330 total accumulated cycle (TAC) tests by December 2000. A TAC is a measure that takes the jet engine from one power setting to another and then back to the original setting. The Air Force and Pratt & Whitney team at the Air Force’s Arnold Engineering Development Center (AEDC) at Arnold Air Force Base in Tennessee had completed 2,168 TAC’s on October 31. Executive Independent Review Team (EIRT). The EIRT is headed by Dr. Bill Heiser, a former AEDC chief scientist. Albro said that after the engine has been inspected, it will be reassembled and go back to SL–2 for additional RAM sea-level tests. Then it will go to ASTF for altitude tests to complete the required 4,330 TAC’s before May 31, 2000. The first part of the test began at Pratt & Whitney’s Florida test facilities in April, where 750 TAC’s were accomplished in 246 engine run hours. The test was then brought to AEDC in July. Initial altitude testing was conducted in the AEDC Aeropropulsion Systems Test Facility (ASTF). The ASTF is a unique facility that can duplicate flight conditions from ground level to 100,000 ft and airspeeds up to Mach 3.8. “This is a great achievement for the F–22 program and the Air Force,” said Col. Michael Heil, AEDC commander. “I am proud that AEDC is playing a role in delivering the nation’s next-generation air dominance fighter to the warfighters.” AEDC has been supporting development of the F–22 since 1989. The F119 engine has been in the center’s jet engine test facilities regularly since that time. After approximately 110 engine run hours in the ASTF, the engine was moved to SL–2, AEDC’s RAM sea-level test facility (one of four jet engine test cells built at the AEDC in the 1990’s to replace Navy test facilities that were located at Trenton, New Jersey). “SL–2 engine operations were supported seven days per week, three shifts per day after testing began in late September,” said AEDC Pratt & Whitney site manager Hugh Horrocks. “Sverdrup (AEDC test contractor), DOD military and civilian, and Pratt & Whitney project support personnel are commended for their contribution to this significant accomplishment,” Horrocks said. Jeffrey Albro, a Navy employee at Arnold and AEDC F119 program manager, said, “AEDC and Pratt & Whitney test teams have done a superlative job of supporting an ambitious test schedule to get to the required milestone. We tested six days a week, essentially around the clock, and took day seven for facility, engine, and people maintenance.” Albro said test objectives included performing base lining back-to-back calibrations from the ASTF test cell to SL–2 to document performance of the engine before the start of accelerated mission tests, and completing high-cycle fatigue and accelerated mission tests. Testing in SL–2 took approximately 333 hours of engine run time. According to Albro, now that the engine has completed its first goal, it will be removed from the test cell and disassembled for evaluation by Pratt & Whitney and an GTTC Newsletter GTTC Newsletter GTTC Newsletter “AEDC and Pratt & Whitney test teams have done a superlative job of supporting an ambitious test schedule to get to the required milestone. We tested six days a week, essentially around the clock, and took day seven for facility, engine, and people maintenance.” Aerodynamic and weapons carriage and release tests have also been accomplished in the center’s large and small transonic wind tunnels. Pratt & Whitney has maintained a field office at AEDC for more than 30 years. United Technologies Corp. (Pratt & Whitney’s parent corporation) and AEDC signed a 20year alliance contract in 1992. Pratt & Whitney engines tested in the last decade at AEDC include the F119 for the F–22, F119 derivatives for both the Boeing and Lockheed Martin candidates for the Joint Strike Fighter, and F100 engines, which power F–15 and F–16 aircraft. www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 15 Vol 4 No 1 January 2001 GTTC Ground Testing News Wright Flyer Model B Airfoil Testing Contributed by Drew Landman The Wright Experience, Old Dominion University (ODU), Wichita State University, and NASA Langley Research Center (LaRC) cosponsored two wind tunnel tests on a Wright model B airfoil geometry. The model B airfoil test, under the direction of ODU’s Dr. Drew Landman, was part of a program to evaluate the aerodynamic performance of early Wright aircraft. The model B was chosen as the first test article because it was the Wrights’ first production aircraft and has the most complete engineering specifications and documentation. With completion of the wind tunnel tests, Ken Hyde of the Wright Experience plans to fly the model B to improve his understanding of its handling qualities and gain familiarity with the controls. The overall test program, directed by ODU’s Dr. Robert Ash, will proceed by moving back in time to test first the 1905 Flyer and, finally, the 1903 Flyer. The Wright Experience was chosen by the Experimental Aircraft Association to build an exact, flightworthy reproduction of the 1903 craft for the National Park Service’s centennial celebration of the Wrights’ first flight at Kitty Hawk. Propeller tests and now airfoil tests have been completed. A full aircraft test is slated for the Langley Full-Scale Tunnel in summer 2001. The airfoil testing was done using two models, a full-scale fabric-covered replica and a one-third-scale solid-surface model with pressure orifices. Since the model B did not use rib stitching on the top surface, researchers had some doubts about the legitimacy of using a solid-surface model for all testing. The chord of the aircraft wing was 74 in., so testing at full-scale in available twodimensional airfoil facilities would have to be limited to low angles of attack to avoid excessive boundary corrections. The data for higher angles of attack were obtained using a smaller scale model; those data will be combined with the full-scale test data to provide the complete story. The full-scale testing program was completed in the Wichita State Walter H. Beech 7x10 Memorial Wind Tunnel in August 2000. Lift and pitching moment were obtained at the flight Reynold’s number with a floor-to-ceiling balance system, and drag was evaluated using a wake rake. Flow visualization using tufts helped reveal stall patterns. Many thanks go out to Ms. Bonnie Johnson, Director of Aerodynamic Laboratories at the National Institute for Aviation Research, for her support of this project and help during the test. The one-third-scale testing was completed at the NASA LaRC Low-Turbulence Pressure Tunnel (LTPT) in October 2000. The lift and pitching moment data were obtained by integrating surface pressures, and drag was measured with a rake wake. All runs were made at the flight Reynold’s number, again using flow visualization with tufts to evaluate stall behavior. The Wright Flyer program is grateful to the many NASA LaRC employees who helped make this test possible, including Dr. Jerry Kegelman, Mr. Long Yip, Mr. Frank Quinto, Ms. Pam Phillips, and Ms. Ruth Martin. Mr. Juan Cruz and Mr. Brad Crawford were very helpful during the one-third-scale model design and construction process. At the time of this writing, Mr. Julian Alvarez, graduate assistant in the ODU Aerospace Engineering Department, is sorting through the reams of data acquired during the tests. Stay tuned for further reports on this exciting endeavor. 16 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter GTTC Newsletter GTTC Newsletter Vol 4 No 1 January 2001 GTTC Special Topics Formal Experiment Design in Wind Tunnel Testing Contributed by Dick DeLoach NASA Langley has been experimenting with a new approach to wind tunnel testing called the Modern Design of Experiments (MDOE). “Randomization,” a key MDOE concept, is discussed in a brief article for the lay reader available from the author at R.DeLoach@larc.nasa.gov. Condensed excerpts follow. Ronald Fisher and colleagues had formulated the basic rules of modern experimentation by 1935, the year he published his landmark book, “The Design of Experiments.” These rules, comprising a set of well-defined procedures to ensure objective inferences from empirical research, stress the importance of randomizing the order in which independent variables are set in an experiment. There are many reasons for disappointing wind tunnel test results, but one that we don’t often consider is our failure to follow Fisher’s randomization prescription in wind tunnel testing. Systematic variations in time can lead us to mischaracterize the influence of independent wind tunnel variables like angle of attack on response variables such as lift, drag, or pitching moment. Randomization defends against such effects. Suppose, for example, that while we are acquiring a polar, some very subtle, systematic change occurs in flow angularity. Suppose this causes earlier points in the polar to be biased as slightly low and later points to be biased as slightly high. (Such effects become important whenever they consume a significant fraction of the error budget, which can easily occur in high-precision wind tunnel testing.) This unknown, systematic variation will rotate and/ or distort conventional polars in which the alpha values are set sequentially in time. If we are unaware of the withinpolar flow angularity changes, then every nuance in the polar will be attributed exclusively to alpha effects, even though flow angularity effects are responsible for some of them. Complex structures in certain conventional pitch polars may be due to just such unknown systematic variations, confounding less exotic underlying alpha effects. When these systematic variations occur between polars, they can also cause displacements, or bias shifts from one polar to the next (in addition to using randomization, MDOE practitioners cope with these effects with another technique known as “blocking”). Systematic variation also causes measurement errors to be correlated and thus not independent of each other, as would be required for valid standard precision interval computations and other common variance estimates. Even relatively mild correlation can corrupt variance estimates by an order of magnitude or more, introducing substantial errors into estimates of “95-percent-confidence intervals” and other such quality metrics. Here’s how randomization works: It ensures that the systematic error at a given angle of attack is equally likely to be either positive or negative (relative to the mean systematic variation) depending entirely on whether that angle of attack was set early or late in the randomized polar. The error in the next angle-of-attack level will likewise have an equal chance to be positive or negative, depending on whether it was set early or late. So randomization converts unseen systematic error to an additional component of ordinary random error that is easy to detect and easy to correct, by replication and other means. Fisher randomized as if there were some systematic variation in any given experiment, even when he had no specific reason to suspect that there was. He did this to be sure of the correct cause-and-effect relationship between his dependent and independent variables. MDOE wind tunnel practitioners always randomize for precisely the same reason. Without randomization, it would be difficult to be sure of the correct relationship between response variables (e.g., forces and moments) and independent variables such as angle of attack. GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 17 Vol 4 No 1 January 2001 GTTC Committee News USAFA’s Eagle Peak 2000 Summer Golf Scramble is a Huge Success! Six hardy souls braved the elements of the Rocky Mountains for the alternative Thursday afternoon activity. Jean Bianco, Dennis Hergert, Tom McLaughlin, Julie Morrow, Mark Perry and Mat Rueger drove down to the U.S. Air Force Academy to climb Eagle Peak, a 9,368foot mountain rising to the west of the cadet area. The monumentally steep trail followed Goat Camp Creek for a mile. In many places, the trail was so steep hands were required to scramble up the slope. At about 8,800 feet, the trail flattened out into a beautiful aspen grove and meadow full of Colorado columbine and Indian paintbrush. After the wildflower meadow, it was an even steeper climb over loose dirt and huge boulders another quarter of a mile to the top. Though it was a tough hike, all climbers summitted, including Mat “you go ahead, I’m going back” Rueger. Everyone was rewarded with breathtaking panoramic views of Pikes Peak, the Front Range Rockies, the entire Air Force Academy, and perhaps even Kansas. The first annual GTTC summer golf scramble was held at the lovely Englewood Municipal Golf Course located in beautiful Englewood, Colorado (don’t let the fact that the front nine holes are built on a garbage dump fool you!). There were four teams competing for fabulous prizes such as golf ball sleeves and a full year of bragging rights. Besides overall lowest score, there were two longest drive and three closest-to-the-pin awards. The two powerhouse long-drive winners were Dan Marren on hole 2 and Allen Arrington on hole 15. The golfers showing pinpoint accuracy on the par 3s were John Lafferty on holes 4 and 10 (of course, he was using Nancy Swinford’s clubs) and John Magill on hole 17. The lowest overall score was earned by the team of John Magill, Dave Minto, Mark Rennie, and Frank Steinle, an impressive 5 under par. Although the competition was stiff, a fun time was had by everyone. Congratulations to all who participated! And remember, without the losers, there wouldn’t be any winners! 18 GTTC Newsletter GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html Vol 4 No 1 January 2001 GTTC Calendar of Upcoming Events 2001 January 8 to 11 39th AIAA Aerospace Sciences Meeting and Exhibit; Reno, NV March 21 to 22 AIAA Congressional Visits Day March 16 Abstracts due for GTTC Student Engineering Contest April 1 Input due for AIAA GTTC Newsletter April 15 Nominations due to AIAA for Associate Fellow May Abstracts due for 40th AIAA Aerospace Sciences Meeting and Exhibit May 4 Final reports due for GTTC Student Engineering Contest July 8 to 11 37th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit; Salt Lake City, UT August 1 Input due for Aerospace America Highlight December issue October 1 Nominations due for AIAA Ground Testing Award November 1 Nominations due to AIAA for TC membership November 1 Input due for AIAA GTTC Newsletter December 1 Aerospace America Highlights Issue 2002 January 14 to 17 40th AIAA Aerospace Sciences Meeting and Exhibit; Reno, NV June 24 to 27 22nd AIAA Advanced Measurement Technology and Ground Testing Conference; St. Louis, Missouri GTTC Newsletter GTTC Newsletter GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter 19 Vol 4 No 1 January 2001 Request for GTTC Membership Information The purpose of the Ground Testing Technical Committee (GTTC) is to advance the state of the art and technologies associated with ground testing and ground testing facilities. The scope of the committee’s interests includes duplication and simulation of aerodynamic and aerospace flight environments for the testing of aerospace systems, subsystems, and components. The ground test facilities of interest include wind and shock tunnels, ballistic and high-speed test track ranges, space environment facilities, and aeropropulsion test facilities. The GTTC is composed of approximately 35 to 40 AIAA professionals from commercial, government, and academic sectors representing the technical spectrum for state-of-the-art ground testing of aerodynamic, propulsion, and space systems. The Committee continually seeks members from all parts of the ground testing community. The membership term on the GTTC is 4 years with approximately 25 percent of the membership rotating off each year. Prospective members should be willing to make a commitment to GTTC activities and attend the semiannual GTTC meetings. If you are interested in receiving further information concerning membership in the GTTC, please fill out the form below and mail to E. Allen Arrington Dynacs Engineering, MS 6–2 NASA Glenn Research Center Cleveland, OH 44135 216–433–8507 fax 216–433–8551 Name: Title: Company: Address: City: State: Zip: Phone: Country: E–mail: Professional responsibility: Professional membership: AIAA Years experience: SAE ASME ITEA Other Educational background (degree, discipline, year): Prior service on AIAA Technical Committees: Name: Prior experience organizing conferences, sessions, short courses: Area of interest: Aerodynamics Aeropropulsion Space systems Does your company currently support other AIAA Technical Committees? Other comments: M–0702 Nov 00 20 GTTC Newsletter www.lions.odu.edu/~dlandman/gttchome.html GTTC Newsletter GTTC Newsletter GTTC Newsletter