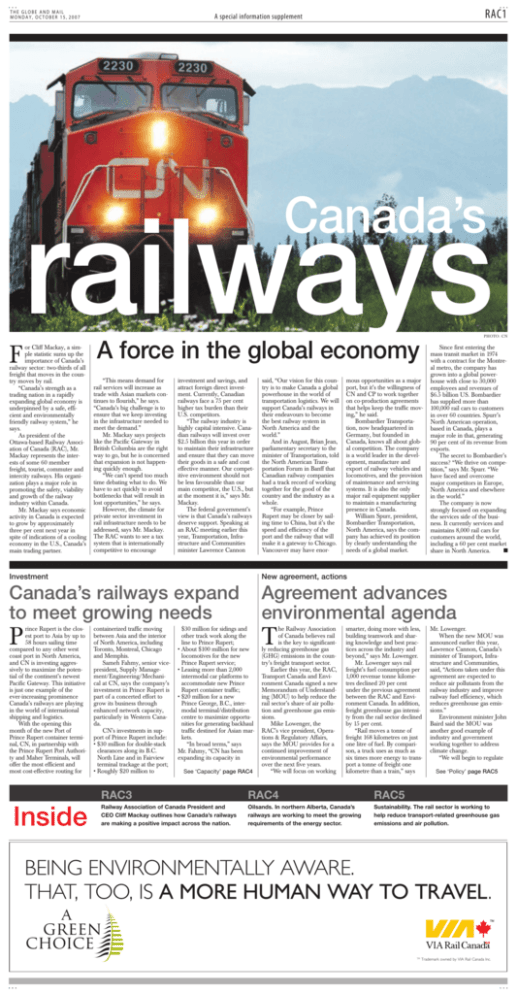

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

RAC1

A special information supplement

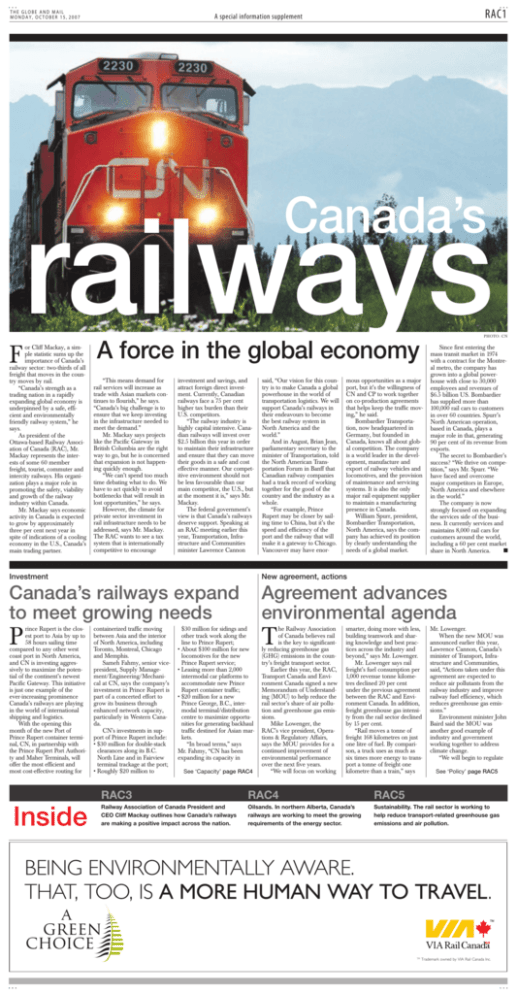

Canada’s

railways

PHOTO: CN

or Cliff Mackay, a simple statistic sums up the

importance of Canada’s

railway sector: two-thirds of all

freight that moves in the country moves by rail.

“Canada’s strength as a

trading nation in a rapidly

expanding global economy is

underpinned by a safe, efficient and environmentally

friendly railway system,” he

says.

As president of the

Ottawa-based Railway Association of Canada (RAC), Mr.

Mackay represents the interests of some 60 member

freight, tourist, commuter and

intercity railways. His organization plays a major role in

promoting the safety, viability

and growth of the railway

industry within Canada.

Mr. Mackay says economic

activity in Canada is expected

to grow by approximately

three per cent next year in

spite of indications of a cooling

economy in the U.S., Canada’s

main trading partner.

F

A force in the global economy

“This means demand for

rail services will increase as

trade with Asian markets continues to flourish,” he says.

“Canada’s big challenge is to

ensure that we keep investing

in the infrastructure needed to

meet the demand.”

Mr. Mackay says projects

like the Pacific Gateway in

British Columbia are the right

way to go, but he is concerned

that expansion is not happening quickly enough.

“We can’t spend too much

time debating what to do. We

have to act quickly to avoid

bottlenecks that will result in

lost opportunities,” he says.

However, the climate for

private sector investment in

rail infrastructure needs to be

addressed, says Mr. Mackay.

The RAC wants to see a tax

system that is internationally

competitive to encourage

investment and savings, and

attract foreign direct investment. Currently, Canadian

railways face a 75 per cent

higher tax burden than their

U.S. competitors.

“The railway industry is

highly capital intensive. Canadian railways will invest over

$2.5 billion this year in order

to maintain their infrastructure

and ensure that they can move

their goods in a safe and cost

effective manner. Our competitive environment should not

be less favourable than our

main competitor, the U.S., but

at the moment it is,” says Mr.

Mackay.

The federal government’s

view is that Canada’s railways

deserve support. Speaking at

an RAC meeting earlier this

year, Transportation, Infrastructure and Communities

minister Lawrence Cannon

said, “Our vision for this country is to make Canada a global

powerhouse in the world of

transportation logistics. We will

support Canada’s railways in

their endeavours to become

the best railway system in

North America and the

world.”

And in August, Brian Jean,

parliamentary secretary to the

minister of Transportation, told

the North American Transportation Forum in Banff that

Canadian railway companies

had a track record of working

together for the good of the

country and the industry as a

whole.

“For example, Prince

Rupert may be closer by sailing time to China, but it’s the

speed and efficiency of the

port and the railway that will

make it a gateway to Chicago.

Vancouver may have enor-

mous opportunities as a major

port, but it’s the willingness of

CN and CP to work together

on co-production agreements

that helps keep the traffic moving,” he said.

Bombardier Transportation, now headquartered in

Germany, but founded in

Canada, knows all about global competition. The company

is a world leader in the development, manufacture and

export of railway vehicles and

locomotives, and the provision

of maintenance and servicing

systems. It is also the only

major rail equipment supplier

to maintain a manufacturing

presence in Canada.

William Spurr, president,

Bombardier Transportation,

North America, says the company has achieved its position

by clearly understanding the

needs of a global market.

Since first entering the

mass transit market in 1974

with a contract for the Montreal metro, the company has

grown into a global powerhouse with close to 30,000

employees and revenues of

$6.5 billion US. Bombardier

has supplied more than

100,000 rail cars to customers

in over 60 countries. Spurr’s

North American operation,

based in Canada, plays a

major role in that, generating

90 per cent of its revenue from

exports.

The secret to Bombardier’s

success? “We thrive on competition,” says Mr. Spurr. “We

have faced and overcome

major competitors in Europe,

North America and elsewhere

in the world.”

The company is now

strongly focused on expanding

the services side of the business. It currently services and

maintains 8,000 rail cars for

customers around the world,

including a 60 per cent market

share in North America.

Investment

New agreement, actions

Canada’s railways expand

to meet growing needs

Agreement advances

environmental agenda

rince Rupert is the closest port to Asia by up to

58 hours sailing time

compared to any other west

coast port in North America,

and CN is investing aggressively to maximize the potential of the continent’s newest

Pacific Gateway. This initiative

is just one example of the

ever-increasing prominence

Canada’s railways are playing

in the world of international

shipping and logistics.

With the opening this

month of the new Port of

Prince Rupert container terminal, CN, in partnership with

the Prince Rupert Port Authority and Maher Terminals, will

offer the most efficient and

most cost-effective routing for

he Railway Association

of Canada believes rail

is the key to significantly reducing greenhouse gas

(GHG) emissions in the country’s freight transport sector.

Earlier this year, the RAC,

Transport Canada and Environment Canada signed a new

Memorandum of Understanding (MOU) to help reduce the

rail sector’s share of air pollution and greenhouse gas emissions.

Mike Lowenger, the

RAC’s vice president, Operations & Regulatory Affairs,

says the MOU provides for a

continued improvement of

environmental performance

over the next five years.

“We will focus on working

P

Inside

containerized traffic moving

between Asia and the interior

of North America, including

Toronto, Montreal, Chicago

and Memphis.

Sameh Fahmy, senior vicepresident, Supply Management/Engineering/Mechanical at CN, says the company’s

investment in Prince Rupert is

part of a concerted effort to

grow its business through

enhanced network capacity,

particularly in Western Canada.

CN’s investments in support of Prince Rupert include:

• $30 million for double-stack

clearances along its B.C.

North Line and in Fairview

terminal trackage at the port;

• Roughly $20 million to

$30 million for sidings and

other track work along the

line to Prince Rupert;

• About $100 million for new

locomotives for the new

Prince Rupert service;

• Leasing more than 2,000

intermodal car platforms to

accommodate new Prince

Rupert container traffic;

• $20 million for a new

Prince George, B.C., intermodal terminal/distribution

centre to maximize opportunities for generating backhaul

traffic destined for Asian markets.

“In broad terms,” says

Mr. Fahmy, “CN has been

expanding its capacity in

See ‘Capacity’ page RAC4

T

smarter, doing more with less,

building teamwork and sharing knowledge and best practices across the industry and

beyond,” says Mr. Lowenger.

Mr. Lowenger says rail

freight’s fuel consumption per

1,000 revenue tonne kilometres declined 20 per cent

under the previous agreement

between the RAC and Environment Canada. In addition,

freight greenhouse gas intensity from the rail sector declined

by 15 per cent.

“Rail moves a tonne of

freight 168 kilometres on just

one litre of fuel. By comparison, a truck uses as much as

six times more energy to transport a tonne of freight one

kilometre than a train,” says

Mr. Lowenger.

When the new MOU was

announced earlier this year,

Lawrence Cannon, Canada’s

minister of Transport, Infrastructure and Communities,

said, “Actions taken under this

agreement are expected to

reduce air pollutants from the

railway industry and improve

railway fuel efficiency, which

reduces greenhouse gas emissions.”

Environment minister John

Baird said the MOU was

another good example of

industry and government

working together to address

climate change.

“We will begin to regulate

See ‘Policy’ page RAC5

RAC3

RAC4

RAC5

Railway Association of Canada President and

CEO Cliff Mackay outlines how Canada’s railways

are making a positive impact across the nation.

Oilsands. In northern Alberta, Canada’s

railways are working to meet the growing

requirements of the energy sector.

Sustainability. The rail sector is working to

help reduce transport-related greenhouse gas

emissions and air pollution.

BeIng enVIRonMenTAlly AWARe.

ThAT, Too, Is a more human

way to travel.

VIA

TM

Tradmark wd b VIA Rai Caada Ic.

RAC2

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

A special information supplement

ADVERTORIAL

GO Transit improves efficiency and air quality in the GTA

O Transit is in the midst of a major expansion program, which will improve rail and

road travel in the Greater Toronto Area

(GTA) and will reduce harmful greenhouse gas

emissions.

One of the most successful transit systems

in Canada, GO has grown from a single rail line

that carried 2.5 million passengers in 1967 into

a comprehensive train and bus network that

today carries over 49 million passengers per

year.

GO was established by the Province of

Ontario to help deal with highway traffic congestion. Road traffic is still a serious problem in

the GTA; however, for the past 40 years, GO

has offered commuters an attractive alternative to driving to work. Without GO Transit,

eight more expressway lanes would be

required to transport GTA-dwellers into downtown Toronto.

Taking cars off the roads reduces emissions that are harmful to air quality. One 10-car

GO Train carries about the same number of

people as 1,400 air-polluting cars, and one bus

can replace about 50 cars.

On a typical weekday in September 2007,

GO operated 181 train trips and 1,804 bus

trips, carrying about 195,000 passengers per

day an average of 33.5 kilometres each.

Expansion projects will help to accommodate

demand for more service, allowing GO to

carry 50 per cent more customers over the

next 10 years.

GO Transit’s expansion plan represents a

total investment of a billion dollars by the

Government of Canada, the Province of

Ontario, and the GTA municipalities. Projects

fall into two main categories: renewal of facilities, tracks and signals in the Union Station

area; and construction of tracks and bridges on

rail corridors.

passes, so that GO Trains no longer have to

stop and wait for freight trains to pass, and

building third tracks along busy stretches of

CN lines. Adding a third track will allow for

more GO Trains and will improve on-time performance.

Another important and much-anticipated

rail improvement project is the extension of

GO Train service to Barrie. This is expected to

happen in the next few months.

G

RENEWING UNION STATION

The Union Station renewal program involves a

number of projects in this 1920s facility and

MORE TRAINS AND BUSES

GO Transit is also in the process of considerably expanding its fleet to accommodate the

growing number of commuters switching to

GO.

GO has purchased 27 new locomotives

that are more powerful, more fuel-efficient,

more reliable and more environmentally

friendly than those in its current fleet. The new

locomotives can pull 12-car trains, two more

than the current maximum of 10 cars per train,

allowing GO Trains to carry 300 more passengers each – a 20 per cent increase.

GO has also ordered 12 double-decker

buses. These buses seat 78 passengers each,

23 more per bus than current vehicles. The

new buses will be used on GO’s busy Highway

407 service.

GO Transit helps keep Toronto on the move, carrying about 195,000 passengers daily. Already operating one of Canada’s

most successful transit systems, GO is now undergoing a major one-billion-dollar expansion to help Toronto address traffic

congestion, growing commuter needs and reduce emissions of greenhouse gases and other forms of air pollution.

the tracks surrounding it.

The shed, or roof, over the train platforms

at Union Station is badly deteriorating and will

be rebuilt. GO is also continuing to add more

stairs from street level to the train platforms for

the over 150,000 GO passengers who use

Union Station each day.

The track and signal system in the Union

Station rail corridor is being modernized to

more easily handle the high volume of trains

that use the downtown Toronto hub each day.

A new storage facility for GO Trains, the Don

Yard, has been built east of Union Station to

improve efficiency and reduce train congestion.

IMPROVING RAIL INFRASTRUCTURE

Work across GO’s rail network includes separating GO tracks from intersecting freight

tracks with rail-to-rail underpasses or over-

LESS CONGESTION AND CLEANER AIR: A

BRIGHT FUTURE WITH GO

Getting people out of their cars and onto GO

Trains and GO Buses frees up space on highways for those who need to drive. It also

improves air quality by reducing the number

of cars on the road: fewer traffic jams mean

fewer harmful car emissions. GO Transit’s

expansion is vital to the success of the GTA as

Ontario’s economic engine and as an attractive place to live and work.

For more information about GO Transit, visit

gotransit.com.

In just one hour on a typical weekday morning, GO Trains carry the same

number of people into downtown Toronto as eight congested expressways.

416 869 3200 1 888 GET ON GO (438 6646) TTY 1 800 387 3652 gotransit.com

Pour plus de renseignements, veuillez composer les numéros ci-dessus.

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

RAC3

A special information supplement

Opinion

Strengthening Canada’s backbone

By Cliff Mackay

President and CEO

Railway Association of Canada

n addition to the role that

railways play in supporting Canada’s economy,

railways are key to helping

Canada and its communities

resolve issues concerning traffic congestion, pollution and

public transportation needs.

Freight, intercity and tourism

services are other ways railways serve the public.

Unlike Europe, where passenger traffic accounts for 90

per cent of rail revenue

because population density is

greater and distances shorter,

freight rail traffic in North

America accounts for 90 per

cent of their business.

In Canada, railways move

two-thirds of surface freight by

I

volume and 65 million passengers, yet they generate only

three per cent of greenhouse

gas emissions. This has happened by design, not by accident.

The rail industry has outperformed the Canadian economy with regard to greenhouse gases in the last 10

years. Greenhouse gas emissions grew for the economy as

a whole at about 35 per cent,

and only eight per cent for the

railway industry over the past

10 years.

Canada’s railways achieved

this impressive performance in

spite of the fact that freight

traffic increased 25 per cent,

intercity passenger traffic

increased 11 per cent, and

commuter traffic a whopping

42 per cent since 1990.

At the same time, NOx

emissions averaged below the

115 kilotonnes cap set by the

previous voluntary government-industry agreement. The

railway industry also reduced

its greenhouse gas emissions

intensity rate by 15 per cent in

the same period. A new agreement to continue the industry’s

efforts was signed in mid-2007

with Hon. Lawrence Cannon,

minister of Transport, Infrastructure and Communities,

and Hon. John Baird, minister

of the Environment.

“By 2010, we expect that

from the 1990 levels, (rail’s)

fuel efficiency will be 44 per

cent better under this new

MOU,” said Minister Cannon,

adding that the new agreement

will also result in immediate

reductions in air pollutants and

greenhouse gas emissions from

railways. “I have great hopes

for rail as an important contributor to green transportation.”

Canada’s railways are committed to being a key part of

meeting our environmental

goals. At the same time, they

are working to improve our

communities. The Federation

of Canadian Municipalities

(FCM) and the RAC signed a

new Memorandum of Understanding this year to continue

and expand their activities

designed to resolve problems

between the communities and

the railways.

During the life of their pre-

vious agreement, FCM and

RAC established a website at

www.proximityissues.ca with a

wide range of information and

contacts.

The partnership also established several Community

Advisory Panels, published the

first comprehensive Proximity

Guidelines and Best Management Practices resource dealing with noise management

and municipal planning, and

developed and tested a formal

dispute settlement process.

The new agreement is

designed in part to deal with

amendments to the federal

Canada Transportation Act,

which confirmed that regulating railway noise is a federal

responsibility. The agreement

will build on previous work to

improve municipal planning,

develop new techniques for

mitigating noise and vibrations, and further enhance

public safety around railway

operations.

The Canadian Association

of Municipal Administrators

(CAMA), representing city

managers and administrators,

has also joined the initiative’s

Freight rail traffic accounts for 90 per cent of North American

rail business. In tandem with rail’s growing contribution to the

Canadian economy, Canada’s railways are committed to

advancing an array of environmental sustainability practices.

PHOTO: SUPPLIED

steering committee.

Finally, Canada’s railways

are working with government

and communities to deal with

critical infrastructure needs.

Major expansion of the Pacific

Gateway in Vancouver, Prince

Rupert and inland is underway to cope with a doubling

of traffic moving between Asia

and North America. Similar

initiatives for international

traffic moving between eastern

Canada and the U.S. are

underway.

In addition to the obvious

economic benefits that will

flow from the investment,

major improvements in community safety and a reduction

in congestion are expected.

Canada’s railways have

been an important part of our

history. We are committed to

playing an equally important

role in Canada’s future!

Rail delivers added value to the country’s economy

• Canada’s railways collectively operate one of the largest

railway systems in the world and are fully integrated with

the U.S. railway system.

• Rail is an enabler of economic activity within Canada

and its international markets.

• Canada’s freight railways handle more than 65 per cent

of surface traffic; more than 4.3 million carloads of

freight and containers annually.

• Passenger railways move over 60.6 million commuters to

and from work each year, and more than 4.3 million

people use intercity rail service to move about the

country – 85 per cent to and from communities in

Ontario and Quebec.

• Overall, Canada’s railways directly employ 34,500

people and contribute approximately $10 billion to the

Canadian economy.

• The railway industry is highly capital intensive.

Canadian railways are currently investing approximately

$2.5 billion on an annual basis in order to

maintain their infrastructure and ensure that they

can move their goods in a safe and cost-effective

manner.

• The federal government plays a significant role in

establishing the operating environment for railways.

As such, it must provide regulatory and legislative

certainty with respect to the railways’ operating

environment, environmental obligations and safety

requirements, to allow the rail industry to make the

necessary capital investments to increase the capacity

and operational efficiency of their operations.

This report was produced by RandallAnthony Communications Inc. (www.randallanthony.com) in conjunction with the advertising department of The Globe and Mail. It did not involve The Globe’s reporting or editing staff. Richard Deacon, National Business Development Manager, rdeacon@globeandmail.com.

Your way. All ways.

Your gateway

to North America.

Welcome to CN’s unparalleled network. Your way

of getting single line service from coast to coast

to coast. The smart way to get consistent, reliable

shipment delivery. And the best way to access more

markets than ever before. For more information

call 1-888-MOVIN-CN.

www.cn.ca

BOMBARDIER

NORTH AMERICA’S RAILROAD

CN

RAC4

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

A special information supplement

Gaining efficiencies

New technologies address challenges

F

aced with one of the

world’s most challenging physical environments and vast distances,

keeping trains running on

time has never been easy for

Canada’s rail sector. Through

the development and implementation of new technologies and practices, however,

Canada’s railways are not

only meeting historic challenges, they are setting a new

pace in logistics efficiencies.

The challenges posed by

engineering-related delays, for

example, led CN to develop

its Precision Engineering program. The mobile computer

system at the heart of its Precision Engineering initiative will

help CN manage engineering

processes more efficiently,

reduce engineering-related

delays to trains, and allow

engineering officers to quickly

access documentation in the

field.

Sameh Fahmy, CN’s senior

vice-president, supply management/engineering/mechanical,

says the staged deployment

will begin this month in CN

operating regions across North

America. The program’s full

deployment is expected by the

first quarter of 2008.

“The first phase will be

Railways across Canada are rolling out a spate of new technologies and processes to help

improve efficiencies. At CN, shifts to Precision Engineering and SmartYard practices are among

the railway’s efforts to enhance productivity. PHOTO: CN

track inspection and will combine all information about a

section of track – rail flaws,

track geometry, visual inspections – in a single database

that will be invoked by GPS,

while the supervisor is inspecting that section of track. It will

also ensure closure of any

repair tickets,” says Mr.

Fahmy.

CN expects the program to

deliver numerous benefits

including a significant

improvement in labour efficiency and reduced supervisor

reliance on office-based computer systems. In the field, the

system is designed to enable

better monitoring of rail lines

and improved tracking of

maintenance and repair activities, not to mention enhanced

material and machine productivity and tighter control of

engineering-related capital

spending.

CN’s introduction of its

SmartYard practice is another

example of the railway’s efforts

to improve service and productivity through technology.

Mack Barker, CN’s assistant vice-president, network

optimization, says SmartYard

is not just technology. “It’s

about orchestrated process

management,” he says. “Everyone shares the same plan,

which is visible through SmartYard. Management of the

process is the key. Good people armed with timely information have made SmartYard

a success.”

Implemented in 2005 as a

pilot project at MacMillan

Yard – CN’s largest freight car

classification yard north of

Toronto – SmartYard is a computer information system that

takes input from various CN

systems, combines the data,

and models the optimal

sequence for cars in a yard’s

inventory. Further, the system

continually adjusts to the constantly changing variables and

conditions of a busy rail network.

“SmartYard produced a

six-hour reduction in the average time a train is in MacMillan Yard, and produced a 300

per cent improvement in a

train’s dwell time in the receiving track,” says Mr. Barker.

When it comes to such

productivity enhancements,

railways such as CN don’t

always work in isolation. As a

major supplier to Canada’s

railways, Acklands-Grainger

knows the challenges facing its

rail customers and has developed processes to enhance its

customers’ operating efficiencies through integrated supplychain management systems.

Through a network of five

regional warehouses and 155

branches throughout Canada,

the Richmond Hill, Ontariobased company provides its

customers with access to more

than 100,000 items.

Acklands-Grainger president Court Carruthers says

some customers consider the

company’s inventory as simply

an extension of their own instock supplies.

“We are never very far

from a customer, which means

we are ready and able to

quickly slot into their supply

chains to serve both planned

and unplanned purchasing

needs. It’s like having their

own supplies on hand, but

without having to manage a

large inventory,” says Mr.

Carruthers.

tion Centre that handles other

steel goods, and the Edmonton

Bissell CargoFlo, which handles methanol and similar

products.

There should be growth

opportunities for many of the

commodities produced at these

upgraders, including sulphur,

petroleum coke, asphaltenes

and LPGs. “Although shipments will not move for a few

years, planning is already in

progress, and CN is playing an

increasingly important advisory role on the logistics, engineering and marketing fronts

for these upgrader projects,” he

said.

Fred Green, CP president

and CEO, says extending the

track network is a strategically

important initiative. The

expansion “will provide rail

access to new markets for the

industries that have made, or

will make, the decision to

invest in the Industrial Heartland. Our objective will be to

build in tandem with the oilsands upgraders and related

businesses to create a new network of rail access and

strengthen the industry’s supply chain competitiveness in

world markets.”

CP is investing $15 million

in new infrastructure to

increase fluidity and distribution and logistics capacity, Mr.

Green said. The railway will

begin with expanded transload

capabilities for in-bound construction materials, including

dimensional shipments

required by the upgraders.

Railways help oilsands projects advance

he national railways are

adding tracks and

transload and distribution centres in northern Alberta

to meet the growing requirements of the booming energy

sector.

Improved transportation

infrastructure including rail

service to new industrial sites

T

and additional freight handling

centres were identified as priorities by the Alberta Heartland

Industrial Association in a

report released earlier this year

on the region’s economic

growth challenges.

Association chairman Roy

Lopushinsky says crude oil is

delivered from the oilsands by

pipeline to the Heartland area

north of Edmonton for upgrading. Rail is important to shipping many of the byproducts

created during processing and

delivering supplies to the companies.

CP is waiting for regulatory

approval to build 16 miles of

tracks to connect existing and

future heavy oil upgraders in

the Heartland area. The lines

would link with the railway’s

North American network.

Meanwhile, CN is investing

about $30 million in the Fort

Saskatchewan Oil and Gas Distribution Centre, said

spokesman Mark Hallman. It

“is designed to meet the transportation, storage and distribution needs arising from the

burgeoning demand for steel

and construction materials

from the oilsands and energyrelated industry and for petrochemical byproducts generated

by these sectors.”

The new facility will complement CN’s Oil and Gas Services Centre, which handles

primarily pipe and long products; the Edmonton Distribu-

Rail expanding to meet growing needs

From page RAC1 ‘Capacity’

RAC

engines of change

The Railway Association of Canada

www.railcan.ca

Western Canada consistently

in recent years to accommodate longer, more efficient

freight trains and increased

traffic.”

Mark Hallman, director,

Communications, Media &

Eastern Region at CN, says the

company is also continuing to

expand its routing protocol

effort to improve service to

customers.

Routing protocols, which

are part of co-production

arrangements with other railway companies, serve to

reduce rail-freight costs industry-wide by placing traffic on

the most efficient routing –

regardless of ownership without undermining competitive

options. The result is a structured plan to direct rail traffic

flows through the most efficient interchange locations in

order to improve both transit

times and asset utilization –

thereby making the most efficient use of capacity.

“Customers can now reach

key markets in Canada, the

U.S. – and beyond – more efficiently thanks to increased traffic velocity, reduced number

of handlings, shortened routes,

and the use of less congested

gateways,” says Mr. Hallman.

For Canadian Pacific, the

recently announced Alberta

Heartland Strategy and the

acquisition of the DM&E railroad signal the company’s willingness to extend the reach of

the railway as a value creation

strategy, says president and

CEO, Fred Green.

“CP’s performance track

record demonstrates that we

are transforming this railway

With the opening this month of the new Port of Prince Rupert

container terminal, CN, in partnership with the Prince Rupert

Port Authority and Maher Terminals, will offer the most efficient

and most cost-effective routing for containerized traffic moving

between Asia and central North America. PHOTO: SUPPLIED

into a highly efficient business.

Our focus on execution excellence has now positioned us to

pursue both operating efficiency and growth opportunities as

ways to create value for our

shareholders and customers,”

he says.

The Heartland Strategy

includes a proposal to construct rail lines to serve

planned and existing bitumen

upgraders northeast of Edmonton. The company has

arranged for 26 kilometres of

right of way that provide the

ability to develop direct rail

service to industries locating

on either side of the North

Saskatchewan River. The

“project description,” the first

step in the regulatory process,

has been filed with the Canadian Transportation Agency.

The DM&E acquisition,

which is subject to review and

approval from the U.S. Surface

Transportation Board, will

expand CP’s current network

by approximately 4,000 kilometres and increase its access

to U.S. Midwest markets

including agri-products, coal

and ethanol.

The DM&E is the largest

regional railroad in the U.S.

and the only Class II railroad

that connects and interchanges

traffic with all seven Class I

railroads.

CP is also in the process of

acquiring the necessary land

and seeking regulatory

approvals for a new intermodal complex near Montreal. The Les Cèdres Intermodal Complex will be built

on 300 hectares of land located in the municipality of Les

Cèdres (Vaudreuil-Soulanges

RCM), mainly on the former

site of Soulanges Industries,

an industrial site recently

acquired by CP.

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

RAC5

A special information supplement

Environment

Rail sector rolls out sustainability practices

A

s public priorities

increasingly focus on

the environment,

Canada’s railway sector is

proving its mettle as a means

of helping reduce transportrelated greenhouse gas (GHG)

emissions and air pollution.

William Spurr, president,

Bombardier Transportation,

North America, says global

concern about climate change

is good news for the rail sector,

particularly in the context of

urban transportation.

“Modern cities cannot be

environmentally sustainable

and provide a good quality of

life unless they can offer a

clean and efficient public transit system, which is what we

specialize in,” he says.

While VIA Rail Canada

has been including explicit

environmental goals in its

strategic business planning

since 2003, executives at the

Crown corporation say VIA is

constantly striving to do even

better.

Established in 1977, VIA

provides coast-to-coast passen-

VIA Rail’s sustainability practices extend throughout its operations including its policy of “green procurement,” which emphasizes

VIA’s use of environmentally responsible products. PHOTO: SUPPLIED

ger service, operating up to

492 trains weekly on 12,500

kilometres of track that connect over 450 Canadian communities and carrying more

than four million passengers

annually.

Despite VIA’s significant

passenger load, chief operating

officer John Marginson says

that since 1990, VIA has cut

its fuel consumption by 25 per

cent per passenger-kilometre,

and greenhouse gas emissions

by 13 per cent.

“Significant reductions

were achieved by modernizing

VIA’s transcontinental equipment in the 1990s, and

through the purchase of 21

new cleaner-running locomotives in 2001,” says Mr. Marginson.

Plans for rebuilding VIA’s

older locomotives would

reduce fuel consumption by

another five million litres per

year – and eliminate another

15 million tonnes of GHG

emissions annually.

“We have worked hard to

manage our entire fleet more

efficiently and increase productivity. So while fuel consumption is down significantly,

VIA has actually increased

passenger miles per train –

quite literally, doing more with

less,” says Mr. Marginson.

Mark Hallman, director,

Communications, Media &

Eastern Region at CN, says his

company is in the process of

acquiring 130 new fuel-efficient, high-horsepower locomotives for delivery this year

and in 2008.

“The new locomotives will

help us improve the efficiency

and reliability of our fleet,

reduce fuel consumption significantly and lower exhaust

emissions,” says Mr. Hallman.

“Rail is the environmentally

friendly mode, and our new

locomotives will further

enhance our environmental

performance.”

CN’s new units are about

15 per cent more fuel-efficient

than the locomotives they will

replace, and will comply fully

with the latest regulatory

requirements for reduced locomotive emissions. The orders

will allow CN to retire 145

older locomotives.

“All the locomotives we

have purchased since 2005

comply with U.S. Environmental Protection Agency limits, resulting in approximately

40 per cent less nitrogen oxide

emissions compared to unregulated locomotives,” says Mr.

Hallman.

Beyond VIA’s infrastructure investments and

improved operating procedures, the company has also

implemented sustainability

practices that include its

“Green Procurement” handbook, which emphasizes the

use of environmentally responsible products in all business

activities. For example, recycled paper is used for onboard

products such as napkins and

toilet paper, and for printed

materials such as train schedules.

The corporation has also

been particularly successful in

reducing the environmental

impact of train maintenance

operations. VIA maintenance

centres in Montreal, Winnipeg,

Mission (B.C.) and Vancouver

have achieved ISO14001 certification, a testament to their

sound environmental practices. Over the past two years,

maintenance teams have

reduced the use of chemicals

for processes such as water

treatment and train cleaning

by almost 50 per cent.

New technology showcase

General Electric has developed a 4,400-horsepower

hybrid locomotive that meets

strict air emission reduction

guidelines and is capable of

recycling thermal energy generated during the braking of

the locomotive. This system

will reduce fuel consumption

and greenhouse gas emissions

by 10 per cent. The energy dissipated in braking a heavy

locomotive would power 160

households annually.

Railpower Technologies of

Montreal plans to produce

more than 200 hybrid switcher

units a year with a range of

1,400 and 2,700 horsepower

for use in branch-line operations and away from freight

yards. Railpower’s products,

built from recycled locomotives, exceed U.S. Environmental Protection Agency airquality regulations. The innovative switchers stop idling

when not in use and use only

their batteries to boost engine

power.

Bombardier Transportation

of Montreal has developed a

commuter train that can use its

braking system to generate

electricity for the train’s batteries. The system saves 30 per

PROUD SUPPORTERS OF THE

CANADIAN RAILWAY INDUSTRY

Railpower Technologies’ hybrid-powered switcher units exemplify innovation seen across the rail sector. PHOTO: SUPPLIED

cent of the energy that would

be used to power a conventional transit train and reduces

power demand by 50 per cent.

Relying on fewer power substations, the new train can travel over a kilometre on its battery power, reducing the need

for overhead power lines.

ZTR Control Systems have

developed an idling reduction

system for locomotives that

shuts them off when not in use.

This feature saves fuel and

reduces air emissions.

Portec Rail last year introduced

a system that deposits a thin

bead of lubricant on the rail

when a train passes. The lubricant reduces friction and

reduces noise, wear and energy

consumption.

Kelsan Technologies of Vancouver, a world leader in

wheel/rail friction control, has

developed unique friction

modifiers. The product is

applied by trackside and onboard units and hi-rail trucks to

reduce greenhouse gas emissions, improve fuel efficiency

and minimize rail squeal.

Acklands Grainger

Pollution reduction measures accelerate

From page RAC1 ‘Policy’

emissions from the rail industry in 2011, but while regulations are being put in place,

this agreement provides a

framework for realizing reductions in both air pollutants and

greenhouse gas emissions,” he

said.

The MOU was another

step in a broader plan to

reduce air pollution from railway operations consistent with

the requirements of the worldleading standards of the U.S.

Environmental Protection

Agency (EPA). The agreement

will help Canada build

towards its goal of an absolute

150-megatonne GHG reduction by 2020.

Because CN, CP, VIA and GO Transit account for the

majority of locomotives and emissions, they are at the core of

the industry’s emission reduction and fleet renewal strategies.

According to the MOU, these companies will:

• Acquire only new, EPA-certified locomotives;

• Retire 130 medium-power units built between 1973 and

1999;

• Upgrade all high-horsepower locomotives to EPA standards,

and

• Upgrade to Tier O the remaining medium-power units,

beginning in 2010, to the EPA standards in effect at that

time.

For its part, the RAC will encourage all its members to make

every effort to reduce GHG emissions from rail operations. The

2010 emission targets for the industry are:

• Class 1 Freight

• Short Lines

• Intercity Psgr.

• Commuter

16.98 kg CO2 eq per 1,000 rtk

(revenue tonne-kilometres)

15.38 kg CO2 eq per 1,000 rtk

0.12 per CO2 eq per 1,000 passenger-km

1.46 kg CO2 eq per 1,000 passengers-30

MAKE US YOUR SINGLE SOURCE SUPPLIER. SAVE TIME AND MONEY.

HERE’S HOW:

Canada’s largest distributor of industrial and

safety supplies, serving Canadian industry

since 1889

155 branches and 5 distribution centres

coast to coast

Canada’s largest inventory supporting the

immediate requirements of the railway industry

Knowledgeable product and technical expertise

to help you in your product selection

Our own factory trained technicians to

service and repair your critical industrial

and safety equipment

A wide range of customized inventory

management and e-business solutions

INDUSTRIAL

FLEET

SAFETY

FASTENERS

® ™ The Acklands-Grainger logo is a trademark of W.W. Grainger Inc., used under license by Acklands-Grainger Inc. © Acklands-Grainger Inc. 2007. All rights reserved.

RAC6

THE GLOBE AND MAIL

MONDAY, OCTOBER 15, 2007

A special information supplement

Flexibility among advantages

Shortline railways fill important niche

S

hortline railways are

often credited with taking over tracks the major

railways no longer wanted to

operate and restoring them to

profitability. What Robert

Grindrod says shortlines don’t

get enough credit for is making it possible for their customers to remain open.

The president of the 745mile Montreal, Maine &

Atlantic (MM&A) Railroad

says that a major shipper of

particle board in Quebec’s

Eastern Townships undertook

an expensive rebuilding after its

operation was gutted by fire in

2006. “Without the service we

were providing, I don’t think

that would have happened.”

Marc Laliberte, president

of the Quebec Railway Corp.,

which operates shortlines in

New Brunswick, Quebec and

Ontario, also identifies customer service as key strength

of shortlines. “Shortlines are

important to the Canadian

transportation systems because

they provide an advantage to

shippers.”

The lower-cost structure of

shortline railways allows them

to keep light-density lines profitable, he says. “Thanks to

shortlines, shippers do not

depend only on highway

transport to move their product. Shortlines also react quickly to shippers’ needs and concerns, because they are more

flexible than larger railways,

and their main focus is on customer service.”

Cliff Mackay, president and

CEO of the Railway Association of Canada, says nearly a

quarter of the freight carried by

CN and CP either begins or

concludes its journey on a

shortline. There now are more

than 40 shortlines in Canada

operating on about 16,000 kilometres of track, much of it originally slated for abandonment.

Like many other shortlines,

the MM&A is reaching out to

customers that aren’t served

by a rail siding with transload

The Railway Association of Canada reports there are more than 40 shortline railways in Canada operating on about 16,000 kilometres of track, much of which was

formerly slated for abandonment. These independent railroads operate over relatively short distances, typically linking industries requiring rail freight, interchanging

revenue traffic with larger railroads and fulfilling niche tourism-sector needs. PHOTO: SUPPLIED

facilities, Mr. Grindrod says.

These warehouses, located in a

yard or siding, can be used to

store materials until customers

pick them up or load rail cars

for outbound shipments. “It

allows them to gain the longhaul economic advantage of

shipping by rail.”

David Church, director of

transportation and recycling

for the Forest Products Association of Canada, credits shortlines for tailored service for

paper, lumber and other products for the forestry sector.

“Service to individual mills by

shortlines is very good.” There

are concerns about the ability

of some shortlines to handle

fully loaded modern freight

cars and getting an adequate

supply of those cars from the

major railways, he cautioned.

The important role of

shortlines in keeping industries

viable has been recognized by

the federal and Quebec governments, which are investing

$55 million in projects to

restore track and structures,

add sidings to improve operations and enable them to carry

fully loaded modern freight

cars.

Mr. Mackay would like to

see a similar program in

Ontario, which has 13 shortline and regional railways.

“The shortlines inject an estimated $1.2 billion into the

province’s economy and play

a vibrant role in ensuring sustainable, green growth.”

Shortlines play an important role in reducing shipping

costs, alleviating highway congestion and lowering the

amount of greenhouse gas

emissions in Canada.

Mr. Grindrod says, “It

would be a much different

life for our customers without

us.”

Human resources

Harnessing talent increasingly

important to railways

ike other business sectors in Canada, railways

are putting increasing

emphasis on HR practices as

companies face the dual challenges of meeting rising

demands while replacing a

wave of long-time employees

now approaching retirement.

Cliff Mackay, president

and CEO of the Railway Association of Canada (RAC), sees

it as one of the big issues that

companies are addressing.

Broad action – both by

individual railways and

through industry initiatives –

has taken shape. Among its

organized efforts, industry is

working with technical schools

across the country to develop

new conductor-training curricula. The goal is to develop

skilled workers to fill the some

500 conductor jobs expected

annually over the next five

years.

“Across Canada, the number of conductor graduates has

grown sixfold since 2004,” says

Kent Flint, director of the

RAC’s Institute of Railway

Training and HR Planning.

“But the demand is – and will

be – so high in the coming

years that we would still like to

double the output of those students.”

Four schools across Canada are now offering the program: the British Columbia

Institute of Technology,

Edmonton’s Northern Alberta

Institute of Technology, the

Southern Alberta Institute of

Technology in Calgary, and

George Brown College in

Toronto.

Students learn to work as

members of a train crew and

manage tasks ranging from

switching and marshalling cars

to making or splitting up trains

in yards and moving cars

between yards, sidings or

tracks. Conductors are considered essential to efficient operations.

For its part, VIA Rail’s HR

initiatives includes its transformation of its HR management

function to strategically align

OUR TRAINS OF THOUGHT L

CREATE A POWERFUL

ENGINE OF GROWTH.

At Canadian Pacific, we have over 15,000 trains of thought pulling together every

day. This combined intelligence provides innovative solutions that keep industry

moving. And creates a powerful engine of growth for the Canadian economy.

CP

the talents of its employees

with the corporation’s goals.

The importance of a welltrained and happy workforce at

VIA is clear. With growth in

travel and tourism markets

having slowed in recent years,

VIA has made customer service the core of its business strategy.

“To ensure passenger rail

keeps thriving, and to grow

our revenues, we have to provide the best possible experience to every passenger who

boards our trains,” says VIA

president and CEO Paul Côté.

“That means understanding

how and why customers are

choosing VIA Rail, anticipating their needs, and delivering

a service, every day, that goes

beyond their expectations.”

Denis Pinsonneault, VIA’s

chief people officer, says the

talent of VIA’s 3,000 employees is the one competitive

advantage that no one else can

duplicate. “And all VIA’s

major objectives for the foreseeable future depend on harnessing that talent.”

Court Carruthers, president of Ackland Grainger,

whose business includes training programs for railway staff,

says attracting talent requires

more than just offering people

jobs. “It’s about providing an

environment in which people

want to work, and that

includes a safe environment.”

Mr. Carruthers says, “We

believe standardization of safety products is key to the development of an effective safety

culture. If an employee knows

that the product will be the

same and work in the same

way, regardless of where they

may be in the country, there is

a far better chance that product will be used properly and

safely.”

Steve Del Bosco, VIA’s

new chief customer officer,

says safety also helps promote

customer confidence as well as

customer-focused service.

“Our 98 per cent customer

satisfaction rating is one of the

highest in the industry. And 40

per cent of our customers say

that we not only meet, but

exceed their expectations – a

10 per cent increase over the

past five years.”

To help ensure it keeps its

roster full, VIA recently

launched e-Careers, an online

recruitment and career development service to help attract

new people and new ideas into

the corporation.

Students at George Brown College in Toronto are among those

gaining practical, hands-on experience working on local railways as part of new industry-supported conductor programs

taught at post-secondary schools across Canada. PHOTO: SUPPLIED