The Rise of Supermarkets and Private Standards in Developing

The Rise of Supermarkets and Private Standards in Developing

Countries: Illustrations from the Produce Sector and Hypothesized

Implications for Trade

Thomas Reardon (Michigan State University, USA), C. Peter Timmer (University of California at San Diego, USA) and Julio A. Berdegue (International Farming

Systems Research Network, Chile)

Contributed paper presented at the

International Conference

Agricultural policy reform and the WTO: where are we heading?

Capri (Italy), June 23-26, 2003

The Rise of Supermarkets and Private Standards in Developing Countries: Illustrations from the Produce Sector and Hypothesized Implications for Trade

Thomas Reardon

Michigan State University , reardon@msu.edu

C. Peter Timmer

University of California at San Diego

Julio A. Berdegue

International Farming Systems Research Network (RIMISP, Chile)

June 2003

Paper for presentation at the International Conference, “Agricultural Policy Reform and the

WTO: where are we heading?” Capri, June 23-26, 2003

The Rise of Supermarkets and Private Standards in Developing Countries: Illustrations from the Produce Sector and Hypothesized Implications for Trade

1. Introduction

In the past decade, there has been a spectacular rise of supermarkets

1

in the two developing regions that are growing most rapidly -- Latin America and East/Southeast Asia. These two regions are home to four billion consumers among which roughly one billion middle class consumers, and the fastest growth in food markets on the planet. Fruits and vegetables (F&V) are a key component of this growth due to Bennett’s Law. By taking over the food retail sector, supermarkets have started a transformation of the F&V system right upstream to the farmers. Supermarkets in those regions have become major buyers of F&V from those regions -- in most cases dwarfing the exports of F&V from those regions to the rest of the world.

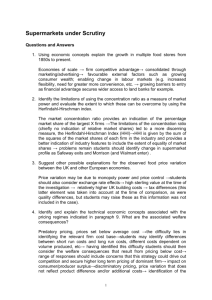

This paper proceeds as follows. First, we discuss the patterns in and reasons for the rapid rise of supermarkets in the regions. Second, we analyze the evolution of supermarket procurement systems, in terms of their organization and institutions including standards.

Third, we discuss the emerging effects of those change on F&V markets and trade, and hypothesize the ways in which converging patterns in organization and institutions in food industry over the regions studied (Asia and Latin America) and developed regions may affect trade patterns in the future, and discuss emerging public policy issues from these trends.

1

We use the term “supermarkets” for simplicity to indicate large self-service stores, in chains or independent; we specify a subset of that group, such as supermarkets or hypermarkets, where needed. Generally

(very, because the definitions differ over countries although there is rough similarity) these stores are classed as either ‘supermarkets’ (roughly 350 to 4000m

2

and/or with 3-4 or more cash registers, with the precise definition varying somewhat over countries), or the larger ‘hypermarkets’. Other large formats include warehouse-formats and membership clubs. Supermarkets tend to have a higher share of food in total sales than do the hypermarkets or clubs.

2

It should be noted that the data and trends discussed in this paper are based on preliminary evidence and emerging examples drawn from an amalgam of industry surveys, some government statistics, and many direct interviews by the author and collaborators.

There is in general a dearth of “official statistics” on these new phenomena, both for how they affect domestic markets in those regions and international trade.

2. The Spectacular Rise of Supermarkets in Latin America and East/Southeast Asia

This section draws on Reardon and Berdegue (2002) and Reardon and Timmer (2002); those papers synthesize recent evidence concerning the growth of supermarket sector in Latin

America and East/Southeast Asia, respectively.

Patterns in and Determinants of the Spread of Supermarkets in the Regions

Latin America is the leader among the developing regions in the growth of the supermarket sector. While there existed a small number of supermarkets in most countries of the region in the 1980s and before, they tended to be financed by domestic capital, to be in major cities, and in rich neighborhoods. That is, they were a niche retail market serving at most 10-20% of national food retail on average around 1990.

By 2000, supermarkets had risen to occupy 50-60% of national food retail on (countrypopulation-weighted) average. Compare this to an average of around 75% for the U.S. or

France. Latin American had thus made in a single decade the same development of supermarkets that the U.S. had experienced in five decades! The leading six countries had averages in the range 45-75%, with highest share to lowest shares running over Brazil,

Argentina, Chile, Costa Rica, Mexico, and Colombia. Those six countries have 85% of the income and 75% of the population of Latin America. The smaller/poorer countries also have experienced rapid growth of their supermarket sectors, but starting from a lower base and

3

somewhat later than the leading six countries. For example, Guatemala’s supermarkets had

15% of national food retail in 1994 – and today have 35%!

The development of the supermarket sector in East/Southeast Asia is amazingly similar to that of Latin America in its broad lines, but two elements differ: the East/Southeast Asian supermarket sector is on average some 5-7 years behind that of Latin America’s – but store growth is if anything, faster. The average food retail share (urban plus rural) over several

Southeast Asian countries -- Indonesia, Malaysia, and Thailand -- is 33%, hence similar most of Latin America in the mid 1990s, and over several East Asian countries – Republic of

Korea, Taiwan, and Philippines -- is on average 63% (hence similar to that of the average in most of Latin America today. The share of Chinese urban food markets of supermarkets is already 48% in 2001 (up from 30% in 1999). Given that the urban share of the population of

China is one-third, a very rough approximation of the total national food retail share of supermarkets is around 20% -- approximately where Brazil or Argentina were in the early

1990s, but the rate of store growth is three times faster in China today than it was in those countries.

The extremely rapid growth of the supermarket sector was driven by similar forces in both regions, and has and is taking broadly similar paths.

A first set of determinants of the growth of supermarkets included socioeconomic factors

-- rapid urbanization, income growth, and improvements in domestic infrastructure over the

1980s and 1990s. This was accompanied by women entering the away-from-home workforce and thus experiencing an increase in their opportunity cost of time. There was a rapid growth in ownerships of cars, access to buses and cheap collective taxis, and many more refrigerators in homes. These factors were similar to those that drove the much slower but as extensive growth of supermarkets in the U.S. over the past six decades.

4

Moreover, a key determinant was the deluge of foreign direct investment (FDI) that was induced by the liberalization of FDI undertaken in most countries in the two regions in the

1990s (China in 1992, Brazil, Mexico, Argentina in 1994, Indonesia in 1998, for example).

Overall FDI was 9 billion dollars per year in each region – by 2000 that figure had growth to roughly 90 billion (UNCTAD, 2001); growth of FDI in the food industry mirrored that overall growth.

Moreover, three trends characterize the development of the supermarket sectors in these regions.

First, the supermarket sector is increasingly and overwhelmingly multinationalized

(foreign-owned). In Latin America, for example, global multinationals constitute roughly 70-

80% of the top 5 firms/chains in the countries. The tidal wave of FDI in retail was mainly due to the global retail multinationals – Wal-mart, Carrefour, Ahold, as well as smaller global chains such as Casino, Metro, Makro, and regional multinationals such as Dairy Farm

International (Hong Kong).

Second, there is rapid consolidation of the sector, mirroring what is occurring in the developed regions. For example, in Latin America the top 5 chains per country have 65% of the supermarket sector (versus 40% in the US and 72% in France). The results are striking: 3 of each 10 pesos of food expenditure by Mexican consumers are made in Wal-mart – with a similar situation for Ahold in Costa Rica, and Carrefour in Argentina. The consolidation takes place mainly via foreign acquisition of local chains. This is done via large amounts of

FDI: for example, in the first 8 months of 2002, 5 global retailers (British Tesco, French

Carrefour and Casino, Dutch Ahold and Makro, and Belgian Food Lion) spent 6 billion bhat, or $120 million in Thailand (Jitpleechep, 2002). Wal-mart spent $660 million over the past year in Mexico to build new stores.

5

Third, the above trends show that supermarkets are no longer in a small niche in capital cities serving the only rich or even the middle class – they have spread well beyond the middle class in order to penetrate deeply into the food markets of the poor. They have also spread from big cities to intermediate towns, and in some countries, already to small towns in rural areas. About 40% of Chile’s smaller towns now have supermarkets. And supermarkets are now spreading fast beyond the top-60 cities of China along the coastal area and are now moving to smaller cities and to the poorer and more remote northwest and southwest and interior.

Supermarkets have cut costs over the past decade, allowing them to compete with – and beat – wetmarkets (fresh markets for produce in central plazas or streets) and mom and pop stores (small shops run by a family). (1) Supermarket chains opened other formats, such as hypermarkets with low prices and large volume and diverse product lines. (2) Supermarket chains have started franchise operations to spread more quickly in poor areas. (3) They also made huge strides to increase distribution efficiency via making logistical improvements to increase procurement efficiency, both in the dry goods (including processed F&V) for which large-format stores have natural advantage due to economies of scale, but also in perishables

(discussed below).

Focus on the Size of the “supermarket-market” in F&V

The share of supermarkets in the F&V retail sector in these regions tends to be lower than their share in overall food retail. A very rough rule of thumb that one finds in general in Latin

America is that the supermarkets’ share of the F&V retail sector is about one-half to twothirds of their share in overall food retail. For example, supermarkets have 50% of the F&V market in Brazil but 75% of overall food retail; in Argentina the shares are approximately 30 and 60%.

6

The reason for this lagged penetration of the F&V market is that small shops and wetmarkets – such as feria libres in Chile or warungs in Indonesia – have maintained a fresh and convenient daily shopping option for urban residents. Whereas many other culturally traditional retail forms such as bread, meat, and fish shops have been driven into bankruptcy and those retail sectors absorbed into supermarkets, often in a format imitating the original/traditional. However, in general fresh F&V sales have been less easily taken over by supermarkets.

This is not to say that supermarkets do not eventually take over the F&V market. For example, in Brazil in the 1980s fresh F&V used to be sold nearly exclusively outside supermarkets -- but 50% of fresh F&V sales are through supermarkets. Food traditions do change, as the rise of supermarkets itself attests. The point is merely that fresh F&V retail is less quickly absorbed into the supermarket sector than are other rubrics.

Supermarkets in these regions tend to win increasing share of the fresh F&V market by dint of: (1) supermarkets’ reducing costs and gradually increasing quality (via the imposition of private standards, discussed below) and via improving logistical interfaces with suppliers bringing more freshness to the product, thus competing with a key initial advantage of the wetmarkets; (2) supermarkets’ offering a range of other products and services (such as air conditioning, cleanliness, banking facilities, food courts, and non-food products) that make buying produce at the same time convenient and cost-effective when one figures the more general set of transaction costs involved in shopping; (3) supermarkets even mimicking the sales styles and appearance of wetmarkets to reduce the “cultural friction” of buying fresh

F&V in supermarkets. In Chile we observed supermarkets’ selling F&V in big wooden bins, with personalized attention to the shopper, as one would see in a feria libre. In China, live fish are sold in tanks in supermarkets, just as in the wet markets – the consumer sees she can get hyper-fresh product in either; (5) municipal governments’ regulating wetmarkets due to

7

hygiene and congestion considerations, but most of all because they do not pay many taxes

(they operate in the informal sector) while supermarkets are easy targets for taxation. This has been a major factor in pressures on wetmarkets in China (Moustakerski and Brabant,

2001).

The wetmarkets are fighting back however. In Chile and Malaysia, for example, there are recently emerging movements among the organizations of wetmarkets to upgrade facilities and procurement – even with a certain amount of mimicry of supermarkets in the latter’s hygiene practices and in collective hence large-volume procurement of produce from farmers.

By inducing similar commercial behavior in the rest of the retail sector, that makes supermarkets’ impacts on the retail sector and on procurement systems spread well beyond their direct impacts.

Moreover, typically fresh F&V are about 8-12% of total sales of the supermarkets and so are important category, and are a big “customer draw” into the stores. Rising incomes combined with Bennett’s Law implies that the importance of this category to supermarkets will grow even further in these regions. Moreover, just as in supermarkets in developed countries, one observes the importance to store managers of year-round availability of highquality, diverse, fresh F&V in the produce section, and diverse value-added products such as dried fruits and juices, with certain year-round items, such as stone fruit, available in the higher-income area stores.

Finally, the conventional image in those regions is that there are two produce markets: (1) the “local market” with relatively low standards, quite fragmented, non-tradeable, traditional; and (2) the “export market” with high standards.

But there is a third market that has been outside of most if not all policy discussion, and that is the produce market for supermarkets inside the two regions – the “supermarketmarket”. Despite the lagged development of the portion of the retail market for F&V

8

dominated by the supermarkets, the absolute size of the supermarket-market for F&V is huge inside the two regions. In Latin America, the supermarket-market for F&V is roughly onethird of all F&V consumed in Latin America: roughly 2.5 times more F&V are sold by supermarkets in Latin America to local consumers than are exported to the rest of the world!

(Reardon and Berdegue, 2002). In Central America alone, the supermarket-market for fresh

F&V is roughly $300 million; compare that with total produce exports of $500 million, outside of Costa Rica. In rough approximations, we estimate that supermarkets in Mexico sell

$3 billon of fresh produce (a very conservative estimate), versus $4.8 billion in exports; in

Brazil, they sell $15 billion of produce (versus 1.5 billion of exports), Argentina, 4 billion

(versus 1 billion), and Colombia, 800 million (versus 600 million of exports).

2

Preliminary results show similar figures in E/SE Asia. For example, China’s supermarkets buy and sell roughly $2 billion of F&V (while China exports $3.3 billion). In

Indonesia, supermarkets sell roughly $500 million of F&V to Indonesian consumers – versus country exports of $286 million in 2001. As the rate of growth of supermarkets (circa 10-20% in E/SE Asia) exceeds the rate of growth of most of the countries’ exports of F&V, one expects the local “supermarket-market” to exceed exports over the next decade.

3. F&V Procurement Systems of Supermarkets in Latin America and E/SE Asia

Objectives and Context of Supermarkets’ F&V Procurement in the Regions

F&V procurement officers in supermarket chains decide what, where, when, and how to buy the huge amounts of F&V noted above. Whether in the U.S., Europe, Nicaragua, Chile, or

China, they are under several common “pressures” by supermarket managers, given the extremely intense competition and low average margins of supermarkets. In general the

2

The supermarket produce sales data are rough approximations based on our calculations of total supermarket food sales, times the roughly typical share of produce in supermarket food sales in representative countries

(10%, in Chile and Mexico). The export data are 2001 figures from FAOSTAT.

9

procurement officers are under orders to the equivalent of “beat Wal-mart (or whoever is the cost leader in the area) and beat the Wet-markets”. That translates into: (a) cut costs of products and transactions to keep prices as low as possible for consumers; (b) raise quality

(diversity, year-round availability, flavor/appearance) and safety; (c) raise convenience/valueadded (fresh cuts, etc.). The weighting of the objectives differs by the consumer segment that the chain or sub-chain (specific format or market segment) is serving.

The context in which supermarkets’ sourcing of F&V takes place in these two regions in general (with wide variance over countries) includes the following relative to the North

American or European context: (a) poor institutional and public physical infrastructure; (b) inadequate private infrastructure, such as packing houses, cold chains, shipping equipment among suppliers and distributors, lacking the assets specific to efficient interface between suppliers and the logistical platforms of supermarkets; (c) risk and uncertainty both in output and in responsiveness to incentives, due to various market failures (idiosyncratic, hence specific to specific supplier groups, and also general to given regions – such as inadequate credit, third-party certification, information, and input markets) – that constrain supplier response to incentives

3

. These impediments pose especially severe problems in the face of rapid growth of demand and of supermarket chains, hence of the latter’s need to expand procurement volumes quickly. Boselie (2002a) notes the implications of these problems in

Thailand with respect to vegetable supply to Ahold stores:

“ For perishable products roughly 250 suppliers were delivering goods directly at the backdoor of the supermarkets at least three times a week. Incidents of out-of-stock were common and shrinkage in the store was high. The lead times between the farms and the supermarket shelve was up to 60 hours and due to the lack of pre-cooling and cooled transportation the post-harvest losses were high. It was impossible to trace products back

3

For example, there are obstacles to the import of vegetable seed into Nicaragua; HORTIFRUTI informed us that this is a severe constraint on their vegetable suppliers (personal communication, director of HORTIFRUTI

Nicaragua, November 2002).

10

to the farm; there was no insight into farming practices and post-harvest practices. There were no clear uniform product specifications that could be communicated throughout the supply chain.” (Boselie 2002a, page 5)

The operational objectives of procurement officers derived from the general goals noted plus the above context, drives a series of organization and institutional (in the new institutional economics sense of these terms) changes in produce procurement in chains in the two regions. These changes are discussed in the next two sections.

Organizational and Technological Changes in Retail’s F&V Procurement Systems

There are several key organizational and technological trends in the F&V procurement systems of supermarkets in the two regions.

Tendency Toward Centralization of Procurement

As the number of stores in a given supermarket chain grows, there is a tendency to shift from a per-store procurement system, to a distribution center (DC) serving several stores in a given zone or district, to a DC serving the stores in a country, to a DC serving stores in a given region (several countries). This is accompanied by fewer procurement offices for produce that decide on produce purchase, and increasing use of centralized depots. This implies increasing levels of centralization of procurement, of procurement decisions and of the physical distribution processes. The centralization increases efficiency of procurement by reducing coordination costs and other transaction costs related to product standardization – although it increases transport costs by extra movement of products.

Illustrations for the procurement centralization abound – in the U.S (such as the formation in fall 2002 of the Perishables Procurement Office of Ahold near Boston), as well as Latin America and E/SE Asia. Part of the reason for this is that these economic choices

11

face chains wherever they are. The other reason is that the same chains tend to be present in the various regions, and tend to follow similar procurement and growth strategies in the different regions. The shift from one stage to the next is usually a function of attaining threshold levels of through-put. For example, Mainville (2002) cites Brazilian work (de

Souza et al., not dated) showing that the minimum through-put is 2000 tons of produce per month to move from per-store procurement to the use of a DC.

The top three retailers have made or are making such a shift toward more centralized procurement in all regions in which they operate. This practice is followed by Wal-Mart in most of its operating areas. Carrefour has been moving quickly to centralize its procurement system, first as it did in France over the past several years, and then in other countries, such as in Brazil, where in 2001 Carrefour established a DC in São Paulo serving three Brazilian states (with 50 million consumers), serving 50 hypermarkets (equivalent to about 500 supermarkets) in the Southeast Region. The trade press reports that Carrefour is also building a national DC in China in 2003. Ahold centralized its procurement system in Chile and

Thailand over 2001/2002

4

, and in Central America as is planned over the coming 1-2 years via Hortifruti (discussed below).

Regional chains are also centralizing procurement. China Resources Enterprises (CRE) of

Hong Kong, with Vanguard stores in southern China, is tenth in retail in China, and has 17 large stores now in the provinces of Shenzhen and Guandong, and has announced it will spend $680 million in investment in China over the next five years. In anticipation of that growth, they are this year moving from store-by-store procurement system to a centralized system by province for southern China -- finishing two large DCs in 2002 in the two provinces. The DC in Shenzhen is 65,000 square meters; it will be able to handle 40 department stores and 400 superstores/discount stores. CRE notes that the efficiency gains

4 The “World Fresh Production and Distribution Centre” on the periphery of Bangkok, serving all the Tops (Ahold) stores in Thailand (Boselie, 2002a).

12

due to centralized distribution and improved logistical interfaces will become more apparent when they reach $2 billion of sales (up from their 0.4 billion now), and they are projecting an increase in profits of 40% by implementing the procurement centralization plan (China

Resources Enterprise, 2002).

Logistics Improvements Accompanying Procurement Consolidation

To defray some of the added transport costs that arise with centralization, supermarket chains have adopted (and required that suppliers adopt) best-practice logistical technology. This has taken various forms.

First, chains have also required their suppliers to adopt practices and make physical investments that allow the most frictionless logistical interface possible with the chain’s warehouse(s). In Argentina, the requirement of use of best-practices in logistics by suppliers even figures in the private sector “Code of Good Commercial Practices” signed by supermarket chains and suppliers in 2001 in Argentina (Brom, 2002). In Thailand, Ahold instituted a supply improvement program for vegetable suppliers in 2001, specifying postharvest and production practices that would improve supply to and efficiency of operation of their Thailand F&V distribution center mentioned above (Boselie, 2002a).

Second, retail chains in the two regions increasingly (at varying rates over countries) outsource logistics and wholesale distribution function, entering joint ventures (JVs) with logistics firms and wholesale distribution firms. Examples from the two regions include the following. (1) To establish the Carrefour DC in Brazil, Carrefour entered a JV with Cotia

Trading (a major Brazilian wholesaler distributor) and Penske Logistics (a US global multinational firm). (2) Wu-mart (China) announced in March 2002 (CIES, 2002a) that it will build a large DC in 2003 to be operated in JV with Tibbett and Britten Logistics (a UK global multinational firm). (3) Ahold-Thailand has partnered with TNT Logistics (part of the TPG

Group of the Netherlands) for the establishment of its DC for F&V in Thailand (Boselie,

13

2002a). These examples are mirrored in the U.S. and Europe, such as several Ahold chains

(Stop and Shop, Tops, and Giant) in the north and central coast of the U.S. outsourcing wholesale distribution for dry goods with C&S Wholesale Grocers Inc. (Vermont).

Third, supermarket chains are moving toward new intermediaries, striving as much as possible, to “side-step” the traditional wholesale system and/or transform parts of it to their needs. In general, they tend to work with specialize wholesalers dedicated to – and capable of meeting – supermarket chain needs. These specialized wholesalers cut transaction and search costs, enforce private standards and contracts on behalf of the supermarkets, and lead to convergence in terms of actors and standards between the export and the domestic supermarkets market. Efforts by chains to reduce reliance on traditional wholesale markets are documented in Gutman (2002) and Ghezan (2002) for Argentina, and in Farina and

Machado (2001) and Mainville (2002) for Brazil, in particular for the Sao Paulo wholesale market that declined 20% over the 1990s even while the city of Sao Paulo grew quickly.

Various leading agroexport and agroindustrial firms in these regions have or are establishing new divisions in their companies to cater specifically to the supermarket-market in their countries – as in Schwentesius and Gomez (2002) for Mexico. Not all the specialized wholesalers are physically outside the traditional wholesale markets. Mainville (2002) notes for Brazil that a number of wholesalers operating in the traditional wholesale market have set up specialized large-scale operations for the supermarkets, and that grower/packers have done the same with needed investments to interface with the logistics systems of the specialized wholesalers and/or the DCs; these arrangements tend to be under contract between the retailer and the wholesaler or the grower/packer. Our field observations show that supermarkets naturally tend toward relationships with export and agroindustrial firms because they can assure the quality (private standards) the supermarkets want, the volumes, are used to

14

consistency and on-time delivery, and in any case the “seconds” (in quality) from the export are sold to the supermarket market.

Moreover, there is emerging evidence that in both regions, when supermarket chains source imported F&V, they tend to do so mainly via specialized importers. For example, hypermarkets in China tend to work with specialized importers/wholesalers of fruit, and the latter in turn, for example in Guandong, sell nearly half of their imported fruit (apples, oranges, and grapes from the U.S., durians from Thailand, kiwi from New Zealand) to hypermarket and supermarket chains (Produce Marketing Association, 2002).

An interesting example is that of Hortifruti in Central America. Hortifruti is the “buying arm” of most (with a tendency toward all) of the regional supermarket chain “Central

American Retail Holding Company,” (composed of 253 stores with sales of 1.3 billion dollars per year), an Ahold chain representing a fusion in 1999 with La Fragua (based in

Guatemala) and then CSU supermarkets in Costa Rica in 2001. Hortifruti has begun to be

(starting with certain products such as beans) to be the chain’s specialized wholesaler for the whole region for the chain (personal communication with Armando Gonzales of Hortifruti,

Nicaragua, November 2002). That procurement includes contracting with farmers (small and medium) and then labeling the product with the private label “Hortifruti” and sending it to the stores. The Hortifruti warehouse in Nicaragua has a variety of vegetables from Costa Rica

(competitive with those of Nicaragua due to quality and consistency), onions from California and Canada, apples from Michigan, Oregon, Washington, and Chile, garlic from China.

About 40% of the F&V in the Nicaraguan CARHCO stores is at present imported, mainly from other countries in the region, especially Costa Rica, via Hortifruti.

5

Nevertheless, smaller and more regional/local chains tend to continue to rely on traditional wholesale markets (which is in fact opposite to the trend in the U.S. where

5

Similar in North America: Melissas or Friedas in the US, Oppenheimer in Canada

15

regional chains rely increasingly on outsourcing procurement at the wholesale distribution level), or to form buying associations among themselves, as they have done in Brazil (see

Mainville, 2002) or Malaysia, for example.

Fourth, as supermarkets are driven to reduce transaction costs and seek “one stop shopping” from suppliers and wholesalers, there is a concomitant change in the organization of the upstream segments of the supply chain, among suppliers. While this section focuses on what retailers are doing, this upstream change is noted because it is so closely integrated with retailer strategies. The consolidation of the supermarket sector, combined with the goal of supermarkets to have year-round supplies of various fresh F&V, has induced a recent wave

(we think slated to increase) of horizontal joint ventures and other types of strategic alliances between produce firms in the northern and southern hemispheres. Where a supplier in either hemisphere was constrained in meeting the requirements of volume and year-round availability of large chains, by partnering with a supplier in the other hemisphere both requirements are met. A recent and successful example of this is that of Global Berry Farms

(GBF), formed in 2000 as a 50/50 JV owned by Michigan Blueberry Growers Marketing

(MBG) and Hortifrut (Chile). GBF markets all the fresh fruit for MBG worldwide and

Hortifrut ’ s fresh fruit in the North-American market. Formed in 1936 and with sales exceeding $63 million in 2000, MBG is the single largest marketer of fresh and processed cultivated blueberries in North America, representing over 550 producers in Michigan,

Indiana, Georgia and Florida. Hortifrut is a leading bush berry grower in Chile, Mexico and

Spain. The pair added in August 2002 to the JV the strawberry supplier, Naturipe, of

California. Thanks to the combined resources of its founding partners, GBF can offer almost year-round delivery of the complete berry category (blueberries, blackberries, raspberries and strawberries). This JV now offers “one stop shopping” to retailers in the Americas and increasingly in Europe (Neven and Reardon, 2002).

16

Fifth, in its incipience in the two regions is the use of B2B internet exchange systems

6

for supermarket chains to source produce and interface with suppliers.

On the one hand, the use of EDI (electronic data exchange) is becoming increasingly common between major chains and their major suppliers in the regions, and is mainly for dry goods at present. For example, Wal-mart China screens suppliers in part on the criterion of their capacity to interface via EDI ( www.Wal-martChina.com

, 2003). The EDI system of

Wal-mart has been and is an industry leader, allowing Wal-mart to send out orders by internet, verify that the supplier received the order, schedule delivery, and provide the supplier data on sales so the supplier can help manage inventory (via its Vendor Managed

Inventory (VMI)); other retailers have followed these innovations.

On the other hand, chains globally, as well as in operations in East/Southeast Asia and

Latin America, are beginning to reduce coordination costs and outsource logistics operations via internet B2B exchanges cum e-procurement and logistics services. There is little publicaccess information to present on the specifics of the use of these services for F&V procurement by supermarkets, but there is emerging evidence that there is already some use in the two regions.

Globally, there are several main “general” internet B2B exchanges into which large retail chains made large investments during the “internet boom” of the late 1990s early 2000s. Each is anchored in several large retailers. Global retailers (apart from Wal-mart which uses only its own system) and (at least incipiently) key regional retailers in Asia and Latin America are drawing, or at least starting to drawn, on these exchanges. WorldWide Retail Exchange

(www.WWRE.com) is the largest internet-based B2B exchange for retailers and their suppliers, with annual transactions of $9 billion. The WWRE currently has 62 members including Ahold and Tesco as key “anchors”. WWRE has a number of Asian and Latin

6

We benefited here from comments from Jean-Marie Codron and Loren Stoddard on this theme.

17

American retailers participating: (a) Dairy Farm International (Hong Kong; $3.7 billion sales,

2160 units (diverse formats) in Southeast Asia, China, and now India), joined WWRE in

2000; (b) Lotte Group (South Korea, retailer); (c) Makro-Asia (Netherlands); (d) Comerci

(number 2 retailer in Mexico, JV with Costco). GlobalNetXChange.com is another important internet exchange with a number of major retailers using it, including Kroger and Carrefour

(the latter with operations in Asia and Latin America). These services are mainly used to reduce transaction costs of identification of suppliers to initiate transactions, not to manage transactions.

Each general exchange has a perishables exchange component, strengthened by a JV with an exchange specializing in perishables. There is a tendency for general exchanges to enter

JVs with specialized perishables and specialized regional-suppliers exchanges:

(a) WWRE entered a JV in April 2001 with Agribuys, and Ahold (member of WWRE) entered a JV (for perishables e-procurement) in April 2002, with Agribuys. Agribuys is an internet B2B exchange founded in 2001, with headquarters in the US and an office in Japan.

Agribuys.com specializes in fresh-produce supply chain and transaction management, including orders, deliveries, auctions, and inventories. This incipient e-service allows retailers to outsource produce transactions, distribution, and inventories much as chains outsource physical procurement logistics through wholesale distributors as discussed above. Services such as Agribuys may grow in importance, however, because such transactions management outsourcing is particularly useful for perishables because day-to-day relationship management of perishables transactions is costly to retailers and they look constantly for ways to cut these costs. Supplier identification and transaction initiation is less costly for perishables, as the latter are a more personal-contacts business with a well-known set of longterm suppliers, compared to non-perishables.

18

(b) GlobalNetXChange.com established a JV with www.tradingproduce.com

in October

2001. www.tradingproduce.com

, competitor of www.agribuys.com, emphasizes US and

Latin American F&V suppliers.

(c) WWRE entered a JV with www.globalsources.com

, an internet B2B network featuring a large number (140,000) of Asian suppliers (including of F&V) and 369,000 buyers in 230 countries and territories, including the giant Tesco (UK) now active in Asia, buyers who make 3.3 million inquiries annually ( www.GlobalSources.com

, 2002a).

The upshot of the above five trends in retail (and concomitant supplier) organization and technology change is that economies of scale plus reduction in coordination costs, offset only partially by increased transport costs, have allowed supermarket chains to drive down costs to the point where they can compete with local wetmarkets and mom and pop stores.

Here is an illustration from Hong Kong:

“Hong Kong supermarket chain Wellcome is to open 10 new stores and expand 30 existing outlets next year, reports the South China Morning Post. The retailer, which is owned by Dairy Farm International… The enlargement … is designed to increase its fresh food offer. The plan was criticised by wet market operators, who fear a further threat to their business. A price war between Wellcome and main rival ParknShop this year saw fresh food prices at supermarkets fall well below those at traditional markets. ”

(CIES, 2002b)

Institutional Change – to Cut Coordination Costs and Raise Quality

The Rapid Rise of Private Standards

19

There has been a rapid rise of the imposition of private food quality and safety standards by supermarket chains and large-scale food manufactures in the two regions. Several factors induce the rise of private standards, in particular in non-commodity markets, such as F&V, meat/fish, dairy, and differentiated and/or value-added grain products. Private standards are used: (a) as strategic tools in markets by these “downstream” firms, for instance to differentiate products from their competitors, and to create and protect market niches; (b) as instruments of coordination of supply chains by standardizing product requirements over suppliers (over zones and countries) and narrowing the product and delivery specifications to increase efficiency and lower transaction costs and meet (as minima) the public standards in all the markets in which the retail chain operates; (c) as substitutes for missing or inadequate public standards (that is, inadequate in level, type, or enforcement), common in both regions

(for the MERCOSUR example, see Reardon and Farina, 2002); (d) as competitive arms against the informal sector by claiming superior food safety attributes.

The private standards cover detailed quality specifications as well as food safety requirements – normally well beyond public food safety regulations. Occasionally, private standards are applied even for phytosanitary attributes of the product, if the latter can affect the quality or safety of the final product, and if public standards are missing or inadequate.

That is because the latter are often inadequate or missing or exist but are not harmonized across the countries from which the retail chain – whether Carrefour or Ahold or Wal-mart or

Dairy Farm International -- source. Flores (2002) notes that the government of Guatemala enacted a food safety law in 2001 but lacks the administrative means to implement the law and so the law is “on the books only” and Ahold’s local chain implements its own private safety and quality standards.

Moreover, there is a tendency for global multinational retailers to strive for convergence between the private standards of the chain applied in developed countries and in

20

developing regions. This is exemplified at a global level by the Global Food Safety Initiative of CIES (see www.ciesnet.com

), the global association of the top 250 retailers and roughly the same number of their major suppliers. Another example is the EUREPGAP standard for food safety and phytosanitary practices applied at farm and post-harvest levels to fresh produce and meat, imposed by major European retailers. This is being applied by Pick N Pay stores in South Africa (Weatherspoon and Reardon 2003). Convergence of standards and practices is not driven only by retailers – but also by consumers and NGOs. Several months ago GreenPeace picketed Carrefour stores – in Thailand – to have the same GMO labeling that Carrefour does in its stores in Europe. the interest of the chain, there are other forces pushing the firms to have convergence.

The rise of private standards favors the use of specialized wholesalers (discussed above) rather than traditional intermediaries to supply supermarkets in these two regions. The specialized wholesalers work closely with the supermarkets to identify suppliers who can meet the standards and in many cases monitor the meeting of the standards. The latter is sometimes, but not yet often, done via the use of contracts (see below). Moreover, especially in the fruit sector, private standards favor the use of agro-exporters as intermediaries for procurement of fruit, as the agro-exporters often use the domestic supermarket-market as a

“market for seconds” that do not pass the quality standards – but do pass the safety standards

– of the export market, as observed in Chile or Nicaragua.

There is little publicly accessible data on supermarkets’ use of private standards in the two regions. Thus, the following should be taken as an indicative taxonomy used to classify existing arrangements that we have observed in the two regions, and to use as a structure for further research. Note that below “standards” relate to quality and safety unless otherwise specified.

21

a) Supermarkets’ private standards without third-party certification.

This appears to be a common current type of private standard system in the two regions at present. Examples include the following. Carrefour applies the Carrefour Quality Assurance certification, specifying stringent quality and safety private standards – specific to Carrefour, and applicable to 200 products and the its 35,000 suppliers whether it is to stores in Mexico,

Thailand, France, or Brazil. These are applicable to vegetable suppliers in Sao Paulo state

(see Mainville 2002), to tomato suppliers to Carrefour stores in Guadalajara, or to meat suppliers to Mato Grosso. Hortifruti (formerly linked to the Costa Rican chain CSU, and now linked to the Ahold regional chain CARHCO, as discussed above), applies private standards for lemons (and other F&V), which include quality plus rules related to acceptable use of pesticides. (Personal communication by the director of Hortifruti Nicaragua, Armando

Gonzalez, November 2002). b) Private standards with third-party certification . This subset of private standards occurs where (based on preliminary observations) the product is sold both in the local supermarket-market as well as in an export market that requires that the exporter obtain certification; an example is organic coffee sold by Paiz supermarkets in Guatemala and also exported, certified by MAYACERT ( www.mayacert.com

) c) Hybrid mixes of public and private standards (and implementation systems).

This appears to be increasingly common, for example where there is a system of certification for export products that can relatively easily be extended to non-tradeables that enter a chain’s local procurement system. For example, suppliers of certain vegetables in Guatemala have recently begun to be subjected to the requirement of certification (if they want to sell to the

Ahold chain) by the PIPAA Certification system (for food safety and phytosanitary attributes), administered jointly by the Ministry of Agriculture, the Association of

Agrochemicals, and the Non-Traditional Exporters Association (www.AGEXPRONT.org),

22

using a benchmark of FDA (U.S.) safety standards (Flores, 2002). Another example is a combination of private quality standards plus public safety standards, seen in Thailand where

Ahold’s quality standards, the Ministry of Health’s safety standards, and certification by SGS are combined for vegetables (Boselie, 2002a), or seen in Tianjin, China, where vegetable exporters (who also sell to local supermarket chains) use certification of local authorities for application of anti-pollution laws to vegetable production (Boselie, 2002b).

The hybrid private-public standards system also appears to be common for processed

F&V products. One observes labels on processed F&V products in supermarkets in Latin

America that note the application of HACCP for example, and application of public laws for safety of processed food products, often noting the regulation number. However, we have found few studies (academic or trade press) on this issue. An exception is Del Grossi and

Graziano (2002) analyzing the promotion of the implantation of private quality standards

(demanded by supermarkets) and the creation of state-level health standards for processed

F&V products sold to supermarkets by small enterprises in Parana, Brazil, part of a project called “Fabricas do Agricultor” started by the state government and the World Bank in 2001 to help small food processing firms sell to supermarkets.

The gradual rise of contracts

Retailers institute contracts with suppliers to guarantee, with low risk and transaction costs, they will have the volume and quality of product delivered to them when they want it, as well as to provide incentives to the suppliers to stay with the buyer and over time make investments in assets (such as learning, equipment, and so on) specific to the transaction and the product specifications. This “formality” is relatively new in one of the most personalized, informal markets in the food sector, as most produce suppliers in the US or the two regions

23

under study usually work with a verbal informal contract renewed on continued good performance.

There is emerging evidence that supermarkets in the two regions are making increased use of contracts, but the use appears to be still quite limited. They are particularly limited with smaller farmers, such as Lourenzani et al. (2002) show for tomato growers who sell to supermarkets in Sao Paulo, or Boselie (2002a) shows for lowland (near Bangkok) growers of vegetables for Ahold. This appears to be because supermarkets can “easily”, from a cost/benefit perspective, get the F&V they need through specialized wholesalers, direct but informal relationships with growers, and even traditional wholesale markets – wherein they announce the volumes they need, the price, and the private standards that need to be met.

Indeed they appear to be in a “buyers’ market” most of the time as suppliers vie for this market with prices with modest to moderate premiums over the traditional wholesale market, with steady demand.

There are several situations in which supermarket contracts with suppliers are emerging. a) For a portion of their supply of important produce items, where they want to “lock in” the best suppliers and communicate their private standards through contracts. An example is given in Schwentesius and Gomez (2002) for citrus in Mexico. Supermarket chains there have a trifurcated procurement system: (a) for roughly half to two-thirds of their oranges, they contract with large-scale suppliers, meeting both the supplier and buyer needs for low risk, low costs, net benefit; (b) for from a third to a half of their oranges, they accept deliveries by medium-sized growers directly to their distribution centers, but do not write formal contracts with these suppliers, and instead rely on a short-term verbal agreement and an implicit understanding that the supplier is welcome if he can meet the private standards and the logistics-interface requirements; there is of course some rejection of product, but the

24

rate is relatively low; (c) for a tenth to a fifth of their oranges, supermarket procurement agents just send trucks to the wholesale (spot) markets and pick the best and cheapest, supplied mainly by smaller growers. b) Supermarket chains’ “buying arms” such as Hortifruti in Central America, sets up lists (that are de facto informal contracts in that the growers are selected, given input credit, and informed of requirements, and can be delisted if they do not comply or pay back the credit) with a number of farmers (500 in the case of Costa Rica, 100 in Nicaragua, 100 in

Honduras). The growers in the outgrower-scheme are informed of the volume and price, delivery date, and the private standards of quality and safety of the product. Hortifruti has collection centers in the growing areas and from there delivers the product to the stores in the chain. The contract includes farm input credit and technical assistance. This arrangement is similar to most agroindustrial contracts in the region.

Sometimes these “buying arms” are regional wholesalers who set up contracts with local growers: Boselie (2002a) notes that Ahold/Thailand procures from lowland producers not under contract, and upland producers (far from Bangkok) via regional wholesalers who have strict contracts with F&V producers who operate under sharecropping arrangements, with the wholesalers the land owners. Sometimes the contracts are with the specialized wholesalers themselves, as Mainville (2002) notes for Brazil. c) Manufacturers of private label processed F&V products for supermarkets are typically under formal contract in these regions; the supermarket chain has a contract with an agroindustrial firm, such as IANSAFRUT in Chile, and IANSAFRUT in turn has contracts with vegetable growers (Milicevich et al. 1998). This is also the case of processed F&V done under the label SABEMAS for CSU in Costa Rica. As private label products as a share of total inventories is rising from a low base in Latin America, this sort of contract will ipso

25

facto increase. There is very little in the research literature or the trade press about these contracts, if anything. d) Several supermarket chains have “lead suppliers” programs, with benchmarks and annual (but usually not long-term) contracts, such as Ahold has in some countries, starting now in Costa Rica and Peru and Brazil. This joins a general movement by retail chains to have lists of preferred suppliers that meet their specifications and are reliable and consistent.

The selection of Lead Suppliers and establishment of contracts with them is often part of a general program by the retailer to improve efficiency and consistency in its F&V procurement system – and is linked to the establishment of private standards or private/public standards systems. For example, Ahold undertook a vegetable supply-chain improvement program in Thailand. Boselie (2002a) notes: “Improve quality and safety of perishable goods by developing preferred supplier relationships and introducing good agricultural practices and a certification scheme. Between fall 1998 and spring 2002 we have seen the emphasis of the development strategy change from chain optimisation (reducing post-harvest losses, reducing shrinkage, reduce handling costs) towards integral chain care (HACCP, good agricultural practices and certification).” e) Emerging are “collective contracts” between supermarket chains and suppliers, with notable involvement of associations of each. These contracts are quite new in the regions, with the first – the “Code of Good Commercial Practices” emerging in Argentina in

2001 (on the heels of a similar code in Spain in the same year). Costa Rican and Colombian retailers and suppliers are currently adopting a similar code, and it is under study in Brazil.

These codes emerged after private sector conflict, negotiations, and are private sectorimplemented – but usually with the looming regulatory presence of a government competition commission, such as occurred in Argentina (Brom, 2002). These codes are

“voluntary” versions of similar codes embedded in public regulations such as PACA in the

26

US. The codes focus on requiring transparent and fair contracts, reasonable payment periods, and investments by both parties to promote convergence of logistical interfaces to increase efficiency in the supply chains. In several countries, such as in Argentina in April 2002, the codes are being followed by the enactment of public regulations to force limits to the time that retailers take to pay suppliers, such as was enacted in the Prompt Payment Law in the US in 1993.

3. Implications for Trade and Policy

It is fair to say that the spectacular rise of supermarkets in Latin America and East/Southeast

Asia have deeply shaken up the fastest growing food markets in the world. Precisely what those changes are is as yet only describable at the level of working hypotheses, emerging evidence, case studies, and taxonomies of preliminary results. This paper aimed at assembling those initial observations into an initial analysis of those changes. This section lays out the key emerging implications of the changes for trade and policy.

First, there appears, with of course exceptions and ambiguities, to be a tendency toward global convergence in the organization and institutions of procurement systems of supermarkets. That convergence is occurring over the stores in global chains over regions, and between global chains and local chains within developing regions. That implies that it is reasonable to hypothesize that procurement systems of supermarkets will be a factor in “trade regulations harmonization” given that much of what can be considered “regulation” in the produce market is in fact private standards.

Many of the changes in organization and institutions of the produce sector in the two regions under study are similar to changes that have been occurring, say with a five-ten year lead, in the US and Europe. For example, Cook (2000) and Perosio et al. (2001) write of similar changes in produce procurement systems of supermarket chains in the U.S., such as

27

rapid consolidation/centralization in procurement and the emerging use of contracts. Similar tendencies are occurring in Europe: Codron et al. (2002) notes the rise of private safety standards for produce in French supermarkets; EUREPGAP ( www.eurepgap.org

) specifies private process standards for produce bought by most of the large European retail chains.

Moreover, as the geographic space of the procurement system of a given chain increases from zone to country to region to global, there exists the incentive and capacity to impose a standardization of private standards over suppliers in the various countries that are part of the procurement system. That is, to supply to the Central American Retail Holding Company operated by Ahold and two other regional chains in Central America, there is increasing convergence in the quality and eventually safety standards that will be necessary for a

Nicaraguan just like a Guatemalan or Costa Rican supplier to meet to supply to the regional procurement system. In the same way, Brazilian melon suppliers supplying to the Carrefour system have to meet a single standard for the whole Carrefour system.

Second, the organizational change discussed above (consolidation, restructuring of procurement systems, emergence of new players and relationships) together imply the defragmentation and consolidation of F&V markets that were traditionally quite fragmented and local. That implies that suppliers need to be able to supply larger volumes consistently over a year for centralized buying systems. That is inducing suppliers to form joint ventures to achieve volume and year-round supply. It is inducing and will induce increasing interest in supplying supermarket chains in those two regions both by local suppliers who can meet the requirements and by suppliers from other countries and regions who can now “hit a larger target”, a limited number of large chains and their specialized wholesalers, instead of attempt to sell in a fragmented market.

Third, institutional change in the retail procurement systems – the rapid development of systems of private standards or private and public hybrid standards systems used by

28

supermarket chains, and the emergence of the use of contracts – imply much more demanding quality and safety standards being imposed on suppliers as compared to the traditional market or even public standards. There is in fact a convergence (fast in some countries and subsectors, slower in others) of the “supermarket-market’s” standards and export standards. We gave an example above of Pick ‘n Pay supermarkets in South Africa adopting the EUREPGAP standard; CSU-Supermarkets and Hortifruti their produce buying arm in Costa Rica have expressed the plan to also adopt that standard. That, plus the shift to specialized wholesalers that are often also involved in the export markets, implies a gradual – or rapid, depending on the case – disappearance of the distinction, held dear in trade and markets literature in these regions, between demanding exports and lax, traditional local markets. The implication for suppliers is that it is going to be much harder (compared to traditional markets) to “make the grade”, satisfying the private standards for quality and safety. That implies the need for major investments at production and post-harvest levels by suppliers.

The most worrying implication of the above is the huge challenge this poses for small farms and firms trying to survive in the rapidly transforming food markets. To sell to those markets increasingly means for them to sell to a handful of large supermarket chains or their intermediaries. There is emerging evidence that many small suppliers cannot meet these requirements, and already 1000s are being excluded and going bankrupt, and as the

“secondary market” outside of the supermarket sector rapidly shrinks, the options for the small producers will shrink. That is frightening in regions where there are millions of rural poor who are looking to agricultural diversification and urban markets as an escape route from poverty. It is crucial and urgent that governments and donors adapt their policies and programs of assistance and training to small suppliers to meet the new requirements of the regions’ supermarkets. An example is the program launched in November 2002 by INDAP’s

29

(the Chilean rural development agency) new Quality Assurance Program assists groups of small farmers supplying berries to supermarket chains to increase the quality and safety of the berries supplied. The actors include the berry growers associations, INDAP, and FEPACH and ASACH, the supermarket associations. The latter are supplying 70% of the training funds of the project (Villalobos, 2002).

30

References

Boselie, D. 2002a. "Business case description: TOPS Supply Chain Project,

Thailand," Agrichain Competence Center , Den Bosch , KLICT International

Agri Supply Chain Development Program.

Boselie, D. 2002b. "Business case description: Tianjin Vegetable Supply Chain

Project," LEI: The Hague. Senter, Asia Facility project AF00/1/CH/17.

Brom, F. (2002) ‘Experiencia Argentina: Relación entre los proveedores y los supermercados,’ Speech at the 7 th

Biennial Congress of the Costa Rican Food Industry

Chamber of Commerce, Costa Rica, June.

China Resources Enterprise. 2002. “Retailing Strategies and Execution Plan, July 2002”, posted on website of China Resources Enterprise, Limited, Hong Kong.

CIES. 2001. “Wu-mart”, Food Business Forum – News of the Day, no paging.

CIES. 2002. “Wellcome pursues store development,” Food Business Forum - News of the

Day, September 2 (no paging).

Codron, J-M., J. Sterns, and X. Vernin. 2002. “Grande distribution et Agriculture raisonnee dans la filière fruits et legumes frais, » draft, INRA-Montpellier.

Cook, R. 2000. “The Fresh Fruit and Vegetable Value Chain Faces New Forces for Change,”

Paper presented at the AAEA Preconference Workshop on Policy Issues and the Changing

Structure of the Food System, Tampa, Florida, July.

Farina, EMMQ. 2002. “Supermarkets, Dairy and Horticulture in Brazil,” 441-58.

Development Policy Review, 20 (4), September: 317-34.

Flores, L. 2002. “Private standards for food safety and Supermarkets in Guatemala,” Working

Paper, Michigan State University.

Gautier, R. 2001. France Retail Food Sector Report, 2001. GAIN Report FR1082, USDA.

GlobalSources.com (2002) “Global Sources reports profitable third quarter and continued expansion in China” Press release Nov 21, 2002

Globalsources.com (2001) WorldWide Retail Exchange and Global Sources to develop Asian

Supplier Sourcing Program,” Press Release, November 25.

Jitpleechep, S. 2002. “Who is who,” Bangkok Post article posted August 28 in www.siamfuture.com

.

Lourenzani, A. E. B. S., S. M. d. A. Schiavi, da Silva, A. L., and H. M. de Souza Filho.

(2002). Avaliação da comercialização de produtos hortícolas as provenientes da agricultura familiar: Barreiras e oportunidades. Sociedade Brasileira de Economia e Sociologia Rural

(SOBER), Passo Fundo, Rio Grande do Sul, 29-31 July.

31

Mainville, Denise Y. (2002). Fresh Produce Markets in São Paulo: Recent Developments,

Trends and Implications for Market Structure. Sociedade Brasileira de Economia e

Sociologia Rural (SOBER), Passo Fundo, Rio Grande do Sul, 29-31 July.

Milicevic, X., J. Berdegue, and T. Reardon. 1998. “Impacts on rural farm and nonfarm incomes of contractual links between agroindustrial firms and farms: The case of tomatoes in

Chile,” proceedings of the Meetings of the Association of Farming Systems Research and

Extension (AFSRE), Nov 30-4 December, Pretoria, South Africa.

Moustakerski, P. and L. Brabant. (2001) “Peoples Republic of China: Retail Food Sector

Report 2001,” USDA Foreign Agricultural Service, Global Agricultural Information Network

Report CH1810, November .

Neven, D. and T. Reardon. 2002. “Modal Choice in International Alliances between

Producers of Horticultural Products,” Contributed Paper (selected) for the 12the Annual

IAMA Meetings, Chain Conference, June.

Perosio, D.J., E.W. McLaughlin, S. Cuellar, and K. Park. 2001. “ FreshTrack 2001 : Supply

Chain Management in the Produce Industry,” R.B. 2001-05, Cornell Food Industry

Management Program, September.

Produce Marketing Association. 2002. China: Produce Industry Market Research Study.

Final Report to USDA/FAS. 2001 Emerging Markets Program. December.

Reardon, T. and J.A. Berdegué. 2002. “The Rapid Rise of Supermarkets in Latin America:

Challenges and Opportunities for Development,” Development Policy Review, 20 (4),

September: 317-34.

Reardon, T. and E.M.M.Q. Farina. 2002. “The Rise of Private Food Quality and Safety

Standards: Illustrations from Brazil,” International Food and Agricultural Management

Review (4) : 413-421.

Schwentesius, R. and M. Gomez. 2002. “Supermarkets in Mexico: Impacts on Horticulture

Systems,” Development Policy Review, 20 (4), September: 487-502.

Reardon, T. and C.P. Timmer. 2003. “The Rapid Rise of Supermarkets in Asia: Challenges and Opportunities for Development,” Working Paper, Jointly Michigan State University and

University of California at San Diego.

Villalobos, P. 2002. “The new quality assurance program of INDAP for small producers in

Chile,” presentation at INDAP’s Quality Assurance Conference, November, Santiago. www.wal-martchina.com

. 2003. Information for Suppliers.

Weatherspoon, D.D and T. Reardon. 2003. “The Rise of Supermarkets in Africa: implications for agrifood systems and the rural poor,” Development Policy Review, May, 21(3).

32