Document

advertisement

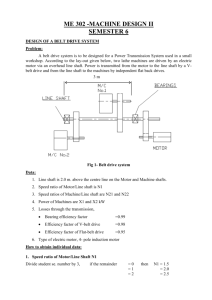

A shaft is a rotating member, usually of circular cross section, used to transmit power or motion. It provides the axis of rotation, or oscillation, of elements such as gears, pulleys, flywheels, cranks, sprockets, and the like and controls the geometry of their motion. An axle is a non-rotating member that carries no torque and is used to support rotating wheels, pulleys, and the like. A spindle is a short rotating shaft. It is not necessary to evaluate the stresses in a shaft at every point; a few potentially critical locations will suffice. Critical locations will usually be on the outer surface, at axial locations where the bending moment is large, where the torque is present, and where stress concentrations exist. A free body diagram of the shaft will allow the torque at any section to be determined. The bending moments on a shaft can be determined by shear and bending moment diagrams. Axial stresses on shafts due to the axial components will almost always be negligibly. Shaft Design for Stress due to Static loads A. Solid Shaft with single load • Where the shaft is subjected to axial force axial 4F d 2 • Where the shaft is subjected to pure bending moment bending 32 M d 3 • Where the shaft is subjected to pure torsional moment 16 T d 3 B. Solid Shaft with combined loads When the shaft is subjected to combination of axial, bending and torsional loads, the principles stresses and principle shear stresses are obtained by constructing Mohr’s circle as shown in below figure. x axial bending x x 1 zx2 2 2 2 x max zx2 2 2 1 max zx x When the shaft is subjected to combination of bending and torsional moments (σaxial = 0) which is the common case, the principle stresses will be x bending bending 1 2 bending zx2 2 2 bending zx2 max 2 2 I. Maximum shear stress theory of static failure (MSS) bending 16 M 16T 2 zx max 3 3 d d 2 2 max 16 3 d 2 2 M 2 T2 According to maximum shear stress theory, and using a permissible value τMax of max Sy Sy 2 F .S 16 2 F .S d 3 M 2 T2 32 F .S d S yt M T 2 1 3 2 II. Distortion energy theory of static failure (DE) 1 2 2 2 x y y z z x 3 xy2 yz2 zx2 2 For plane stress ( z yz zx 0 ) and y 0 x2 3 xy2 2 32 M 16T 3 3 3 d d 2 32 3 M 2 43 T 2 d According to Von-Mises theory, and using a permissible value σ′ of Sy F .S Sy 32 2 2 3 M T 4 F .S d 3 32 F .S d S yt 3 2 M T 4 1 3 2 • It is important to observe that these relations are only valid when the stresses are truly invariable. ASME Code for Shaft Design The ASME code defines a permissible shear stress which is the smaller of the two following values: p 0.3S yt or p 0.8 Sut The code states that these stresses should be reduced by 25% if stress concentration possible due to shoulder fillet or a keyway is present. Making τp equal τmax, lead to 16 p 3 d M 2 T2 In the code, the bending moment M and the torsional moment T are multiple by combined shock and fatigue factors Cm and Ct respectively, depending on the condition of particular application. 16 p 3 d Cm M 2 CtT 2 When p 0.3S yt 16.96 d S yt Cm M 2 CtT 2 1 3 When p 0.8 Sut 6.36 d Sut Cm M 2 CtT 2 1 3 • Recommended values of Cm and Ct are listed in Table (1) Table (1). Values of Cm and Ct for different loading type Type of Loading Cm Ct Load applied gradually 1 1 Load applied suddenly 1.5 – 2 1.5 – 2 Load applied gradually 1.5 1 Steady load 1.5 1 Load applied suddenly, minor shocks 1.5 – 2 1 – 1.5 Load applied suddenly, heavy shocks 2–3 1.5 – 3 Stationary shaft Rotating shaft Table (2). Typical sizes of solid shaft that are available in the market Diameter Increments Up to 25 mm 0.5 mm 25 to 50 mm 1.0 mm 50 to 100 mm 2.0 mm 100 to 200 mm 5.0 mm Example: the layout of a transmission shaft carrying two pulleys B and C supported by bearings A and D is shown in the figure below. Power is supplied to the shaft by means of vertical belt on the pulley B, which is then transmitted to the pulley C carrying a horizontal belt. The maximum tension in the belt on the pulley B is 2.5kN. The angle of warp for both the pulleys is 180̊ and the coefficient of friction is 0.24. The shaft is made of plain carbon steel 30C8 Syt = 400 N/mm2 and the factor of safety is 3. Determine the shaft diameter. 600 200 200 All dimension by mm A D 500 φ1 B 250 φ2 C R1 Solution: R2 P1 2500 e P2 0.24 1176.673 N P3 P2 e TB ( P1 P2 )( D1 / 2 ) ( 2500 1176.673 )( 500 / 2 ) TB 330831 .75 N .mm P4 P1 P2 TB TC ( P3 P4 )( D2 / 2 ) ( P3 P4 )125 330831 .75 N .mm ( P3 P4 ) 2646 .654 N ........( 1 ) P3 e 2 .125................( 2 ) P4 Substituting Eq. (1) into Eq. (2), we get P3= 4999.235 N and P4= 2352.581 N • Bending and torsional moments P3+P4=7351.816 N 200 600 200 P1+P2=3676.673 N 200 C B 5881.453 1470.363 1176290.6 600 200 C B 735.335 2941.338 588267.6 294072.6 147067 Horizontal plane (XZ plane) Vertical plane (XY plane) M B 294118 2 588232 2 657675.804 N .mm M C 1176472 2 147058 2 1185448.556 N .mm 1185448.556 330831.75 657675.804 B C B Torsional moment diagram C Resultant bending moment diagram This shaft will be designed based on the stress at point C at which the bending moment is the maximum. 32 F .S d S yt 3 2 M Tc 4 1 3 2 c 32 * 3 3 2 2 ( 1185448.556 ) ( 330831.75 ) 4 ( 400 ) 45.3416 mm from table ( 2 ) d 46 mm 1 3 Shaft Design on Rigidity Basis The transverse shear V at a section of a beam in flexure imposes a shearing deflection, which is superposed on the bending deflection. Usually such shearing deflection is less than 1 percent of the transverse bending deflection, and it is seldom evaluated. However, when the shaft length-to-diameter ratio is less than 10, the shear component of transverse deflection merits attention. A transmission shaft is said to be rigid on the basis of torsional rigidity, if it does not twist too much under the action of an external torque. The angle of twist or the angular deflection θ (in radians) for right-circular cylindrical solid shafts in torsion is given in is given by: Tl JG Where, G: Modulus of rigidity d4 J: Polar moment of inertia ( J ) 32 By degree (θ̊), 180 Tl ( ) JG 584Tl Gd 4 For a stepped shaft with individual cylinder length li and torque Ti , the angular deflection can be estimated from Ti li i J i Gi For a constant torque throughout homogeneous material, li T G Ji By degree (θ̊), 584T G li d4 i The permissible angle of twist for machine tool applications is 0.25̊ per meter length. Example (2): the layout of a shaft carrying two pulleys 1 and 2, and supported on two bearings A and B is shown in figure below. The shaft transmits 7.5kw power at 360rpm from the pulley 1 to the pulley 2. The diameter of pulleys 1 and 2 are 250mm and 500mm respectively. The masses of pulleys 1 and 2 are 10kg and 30kg respectively. The belt tensions act vertically downward and the ratio of belt tensions on the tight side to slack side for each pulley is 2.5:1. The shaft is made of plain carbon steel 40C8 (Sy=380N/mm2) and the factor of safety is 3. Estimate suitable diameter of shaft. If the permissible angle of twist is 0.5̊ per meter length, calculate the shaft diameter on the basis of torsional rigidity. Assume G=79300N/mm2. 250 500 A 250 B 1 2 Example (3): A line Shaft supporting two pulleys A and B is shown in figure below. Power is supplied to the shaft by means of vertical belt on the pulley A, which is then transmitted to the pulley B carrying a horizontal belt. The ratio of the belt tension on tight and loose sides is 3:1. The limiting value of tension in the belt is 2.7kN. The shaft is made of plain steel 40C8 ( Sut=650N/mm2 and Sy=380N/mm2). The pulleys are keyed to the shaft. Determine the diameter of the shaft according to the ASME code if, load applied gradually. 450 250 φ 450 A 250 450 φ B H.W. Check the designed shaft according to angular deflection. Example (4): The layout of an intermediate shaft of a gear box supporting two spur gears B and C is shown in the figure below. The shaft is mounted on two bearings A and D. The pitch circle diameters of gears B and C are 900 and 600mm respectively. The material of shaft is steel FeE 580 (Sut=770 and Sy=580N/mm2). The factor Cm and Ct of ASME code are 1.5 and 2 respectively. Determine the diameter of the shaft using the ASME code. Assume that the gears are connected to the shaft by means of keys. FBr F 4421N 900 FBr 1609 N FBt t B 900 900 FCt 6631.5 N FCr 2413.67 N φB =900 & φC =600mm A D FCr B C FCt