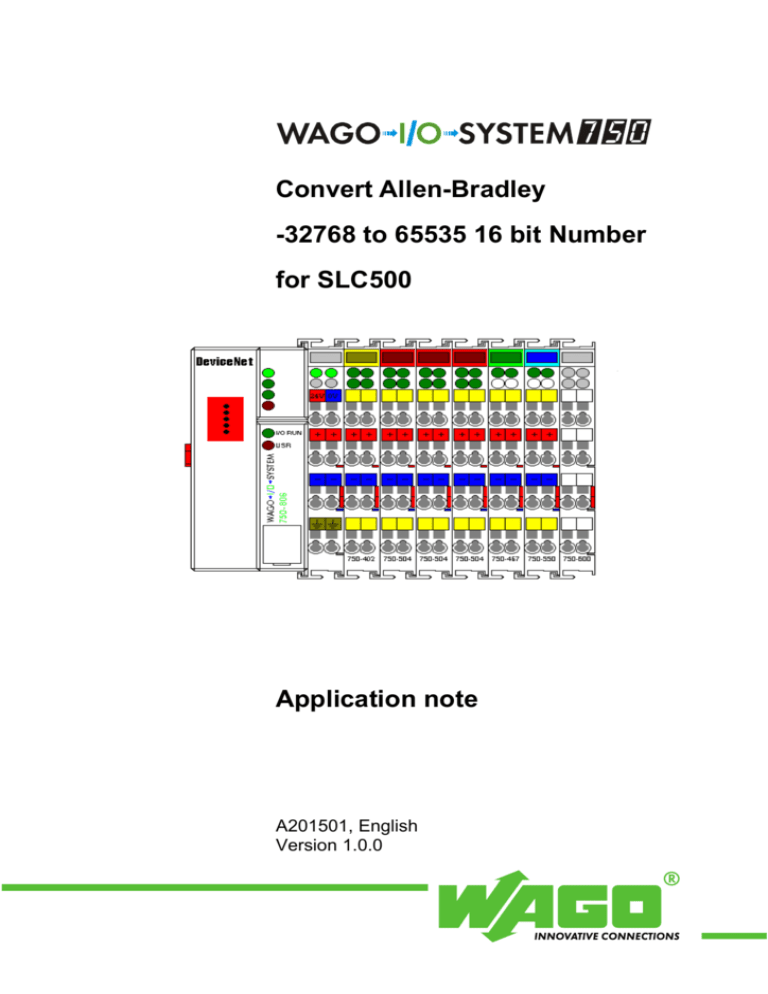

Convert Allen-Bradley

-32768 to 65535 16 bit Number

for SLC500

Application note

A201501, English

Version 1.0.0

2 • General

Copyright ã 2002 by WAGO Kontakttechnik GmbH

All rights reserved.

WAGO Kontakttechnik GmbH

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax:

+49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web:

http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax:

+49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time.

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

Application note

A201501

Table of Contents

•3

TABLE OF CONTENTS

1 Important comments.................................................................................. 4

1.1 Legal principles............................................................................................ 4

1.1.1

Copyright .......................................................................................... 4

1.1.2

Personnel qualification ..................................................................... 4

1.1.3

Intended use ...................................................................................... 4

1.2 Range of validity.......................................................................................... 5

2

Description.................................................................................................. 6

3 Reference Material..................................................................................... 7

3.1 DeviceNet Configuration ............................................................................. 7

3.2 SLC500 PLC Logic.................................................................................... 17

3.3 Overview.................................................................................................... 18

Application note

A201501

4•

Important comments

1

Important comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanation is

carefully read and adhered to.

1.1 Legal principles

1.1.1

Copyright

This manual is copyrighted, together with all figures and illustrations contained therein. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and photo-technical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH. Non-observance will entail the right of claims

for damages.

1.1.2

Personnel qualification

The use of the product detailed in this manual is exclusively geared to specialists having qualifications in PLC programming, electrical specialists or

persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH declines all liability resulting from

improper action and damage to WAGO products and third party products due

to non-observance of the information contained in this manual.

1.1.3

Intended use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only admitted within the framework of the possibilities documented in the manuals. All

other changes to the hardware and/or software and the non-conforming use of

the components entail the exclusion of liability on part of WAGO Kontakttechnik GmbH.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH.

Application note

A201501

Important comments

•5

1.2 Range of validity

This application note is based on the stated hardware and software of the specific manufacturer as well as the correspondent documentation. This application note is therefore only valid for the described installation.

New hardware and software versions may need to be handled differently.

Please note the detailed description in the specific manuals.

Application note

A201501

6•

Description

2

Description

There are 2 parts to this solution. First part is configuring the Devicenet side

correctly and the second part is configuring the SLC500 logic. This will make

the 750-631 Encoder module Data useable for the full range of 0-65535.

Software used for this App Note:

RSNetworx for Devicenet configruation

RSLogicx for SLC500 programming

For other details about WAGO I/O please refer to the WAGO Users Manuals.

The Users Manuals can be downloaded from the web site www.wago.com

Application note

A201501

Reference Material

3

Reference Material

3.1 DeviceNet Configuration

Part 1: Configure Device Net using RS Networx

The 1747-SDN scanner has to be configured for the 750-631 module.

RX = 6 Bytes

TX = 6 Bytes

Output Register Map

D0 = Control Byte

D1 = Set Counter –Byte 1

D2 = Set Counter – Byte 0

D3 = Not Used – Need to add to configuration

D4 = Not Used – Need to add to configuration

D5 = Not Used – Need to add to configuration

Input Register Map

D0 = Status Byte

D1 = Counter Byte 1 (Most Significant Byte/ High Byte)

D2 = Counter Byte 0 (Least Significant Byte/LowByte)

D3 = Not Used –Need to add to configuration

D4 = Latch Value Byte 1

D5 = Latch value byte 0

Application note

A201501

•7

8•

Reference Material

The 1747-SDN can be configured using Discrete for single bit level and M

File for Memory register.

Fig. 1:

Scan List

Select Scan List

Configure the RX and TX

Configure RX = 6 Bytes

Configure TX = 6 Bytes

Application note

A201501

Reference Material

Fig. 2:

Input Configuration Discrete

Select Input and Click on Advanced

Application note

A201501

•9

10 •

Reference Material

Fig. 3:

Advanced Input Configuration Discrete

Message Select Polled

Memory Select Discrete

Word = 1

Bit Length = 8

Click on Apply Mapping

Click on close

This will make the Status byte of the module Discrete inputs.

The Discrete Map should look like the above Input Configuration discrete

Display.

Application note

A201501

Reference Material

Fig. 4:

Advanced Input Configuration M File

Message Select Polled

Memory Select M File

Word = 1

Bit Length = 40

Click on Apply Mapping

Click on close

Application note

A201501

• 11

12 •

Reference Material

Fig.5:

Input Configuration M File

Click on Memory and change window to M File

40 Bits are configured as displayed above Input Configuration M File.

This will place the encoder data into 1 16 bit memory register M1:1.0

Application note

A201501

Reference Material

Fig.6:

Output Configuration Discrete

Select Output and Click on Advanced

Application note

A201501

• 13

14 •

Reference Material

Fig. 7:

Advanced Output Configuration Discrete

Message Select Polled

Memory Select Discrete

Word = 1

Bit Length = 8

Click on Apply Mapping

Click on close

This will make the Control byte of the module Discrete outputs

The Discrete Map should look like the above Output Configuration discrete

Display.

Application note

A201501

Reference Material

Fig. 8:

Advanced Output Configuration M File

Message Select Polled

Memory Select M File

Word = 1

Bit Length = 40

Click on Apply Mapping

Click on close

Application note

A201501

• 15

16 •

Reference Material

Fig. 9:

Output Configuration M File

Click on Memory and change window to M File

40 Bits are configured as displayed above Output Configuration M File.

This will place the Set counter data into 1 16 bit memory register M0:1.0

Application note

A201501

Reference Material

3.2 SLC500 PLC Logic

Use the COP command to copy the data from the M File to the N7:0

Use the above Logic to convert the data to the full 16 Bit Number (65535)

Application note

A201501

• 17

18 •

Reference Material

3.3 Overview

Device Net:

SEE Top of Document for Register Byte format D0-D5 Input / Output.

The Status Byte and Control Byte are configured in the Devicenet

scanner to be placed into the Discrete I/O. This makes it east to

view the Status and Control byte.

The rest of the 40Bits are located into M1 and M0 files. This will locate Byte 1 and

Byte 0 into 1 word data register 16bits long so it makes programming easy on the

SLC500 side.

In this example I:1.0 is the status byte in the discrete inputs

M1:1.0 holds Byte1 & Byte0 which the Encoder position data Register

SLC500:

COP command is used to transfer the M1:1.0 data (Encoder Position) to N7:0.

Use the COP command because it does not affect the Math Flags. Do not use

the MOV command because it does affect the Math Flags.

MVM The MVM will mask the N7:0 Sign Flag and the result is placed into

N7:1

ADD This command will add the result of N7:1 to 32768.0 when the sign flag

is set to continue the full 16bit value from 32768 to 65535 with the result in

Register F8:0.

MOV When the sign flag is not set (0-32767) the value is moved from N7:1 to

Register F8:0

Register F8:0 is the data register that will contain the encoder data 0-65535

Application note

A201501

Reference Material

Application note

A201501

• 19

WAGO Kontakttechnik GmbH

Postfach 2880 • D-32385 Minden

Hansastraße 27 • D-32423 Minden

Phone:

05 71/8 87 – 0

Telefax: 05 71/8 87 – 1 69

E-Mail:

info@wago.com

WAGO Corporation USA

N120W19129 Freistadt Road

PO Box 1015

Germantown, Wi 53022

Phone: 1-262-255-6333

Fax: 1-262-255-3232

Internet:

http://www.wago.com

Call Toll Free: 1-800-DIN-RAIL

(346-7245)