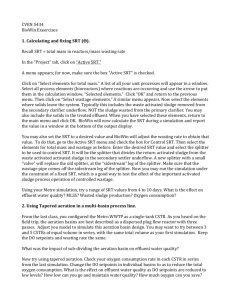

Relationship between Oxidation Reduction Potential (ORP) and

advertisement