instruction manual f1-18

advertisement

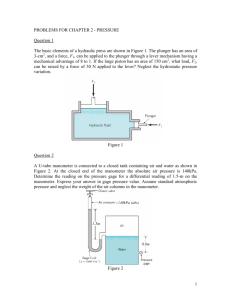

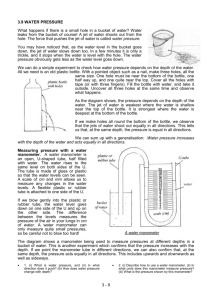

INSTRUCTION MANUAL F1-18 ENERGY LOSSES IN PIPES F1-18 ISSUE 3 SEPTEMBER 2001 ARMFIELD LIMITED OPERATING INSTRUCTIONS AND EXPERIMENTS F1-18 SAFETY IN THE USE OF EQUIPMENT SUPPLIED BY ARMFIELD 1 INTRODUCTION 2 DESCRIPTION 3 COMMISSIONING 4 ROUTINE MAINTENANCE 6 NOMENCLATURE 7 EXPERIMENTAL PROCEDURE 9 F1-18 Energy Losses In Pipes SAFETY IN THE USE OF EQUIPMENT SUPPLIED BY ARMFIELD Before proceeding to operate the equipment described in this text we wish to alert you to potential hazards so that they may be avoided. Although designed for safe operation, any laboratory equipment may involve processes or procedures which are potentially hazardous. The major potential hazards associated with this particular equipment are listed below. • INJURY THROUGH MISUSE • INJURY FROM ELECTRIC SHOCK • DAMAGE TO CLOTHING • RISK OF INFECTION DUE TO LACK OF CLEANLINESS • POISONING FROM TOXIC MATERIALS (EG. MERCURY) Accidents can be avoided provided that equipment is regularly maintained and staff and students are made aware of potential hazards list of general safety rules is included in the F1 Product Manual to assist staff and students in this regard. The list is not intended to be fully comprehensive but for guidance only. Please refer to the notes in the F1 Product Manual regarding the Control of Substances Hazardous to Health Regulations, The F1-10 Service Bench operates from a mains voltage electrical supply. The equipment is designed and manufactured in accordance with appropriate regulations relating to the use of electricity. Similarly, it is assumed that regulations applying to the operation of electrical equipment are observed by the end user. However, to give increased operator protection, Armfield Ltd have incorporated a Residual Current Device (RCD, alternatively called an Earth Leakage Circuit Breaker or ELCB) as an integral part of the service bench. If through misuse or accident the equipment becomes electrically dangerous, an RCD will switch off the electrical supply and reduce the severity of any electric shock received by an operator to a level which, under normal circumstances, will not cause injury to that person. Check that the RCD is operating correctly by pressing the TEST button. The circuit breaker MUST trip when the button is pressed. Failure to trip means that the operator is not protected and the equipment must be checked and repaired by a competent electrician before it is used. 1 F1-18 Energy Losses In Pipes INTRODUCTION Fluid mechanics has developed as an analytical discipline from the application of the classical laws of statics, dynamics and thermodynamics, to situations in which fluids can be treated as continuous media. The particular laws involved are those of the conservation of mass, energy and momentum and, in each application, these laws may be simplified in an attempt to describe quantitatively the behaviour of the fluid. The hydraulics bench service module, F1-10, provides the necessary facilities to support a comprehensive range of hydraulic models each of which is designed to demonstrate a particular aspect of hydraulic theory. The specific hydraulic model that we are concerned with for this experiment is the Pipe Friction Test Rig, F1-18. This consists of a test pipe which may be fed water at high or low flow rates. Two manometers, a water over mercury manometer and a pressurised water manometer can then be used to measure the head losses in the pipe. A full description of the apparatus is given later in these texts. 2 F1-18 Energy Losses In Pipes DESCRIPTION Inlet Pipe to Constant Head Tank Inlet Pipe to Test Section Air Bleed Screws Pressure Tapping (H.P.) Test Section (I/D 3mm Air Pump Water Over Mercury Manometer with Scale Pressurised Water Manometer with Scale Pipe Clips Constant Head Tank Air Inlet/Outlet Valve Pressure Tapping (L.P.) Flexible Outlet Pipe from Head Tank Overflow Flow Control Valve Adjustable Feet The accessory is designed to be positioned on the side channels of the hydraulics bench top channel. There are two methods of supplying water to the test pipe. For higher flow rates the inlet pipe is connected directly to the bench supply. For lower flow rates, the inlet pipe is connected to the outlet at the base of the constant head tank and the inlet to the tank is connected to the bench supply. The test section of pipe is mounted vertically on the rig and is instrumented using two manometers. A water over mercury manometer is used to measure large pressure differentials and a pressurised water manometer is used to measure small pressure differentials. When not in use a manometer may be isolated using Hoffman clips. Flow through the test section is regulated using a flow control valve. In use this valve should face the volumetric tank. A short length of flexible piping attached to the valve will prevent splashing. 3 F1-18 Energy Losses In Pipes COMMISSIONING The apparatus is supplied fully assembled and ready for connection to the F1-10 Hydraulics Bench. The mercury manometer fitted to the column must be primed with mercury before the apparatus can be used. The apparatus can be prepared for use as follows:Before filling the apparatus with water remove the flexible connection from the tapping at the base of each manometer tube and place a drop of wetting agent into the tube. Replace each flexible tube and ensure that the clip is secured. Locate the apparatus over the moulded channel in the top of the bench. Connect the flexible inlet tube from the top of the test pipe to the outlet fitting in the bed of the moulded channel. Place the free end of the flexible tube from the overflow on the top reservoir (tube exits from the side of the supporting column near the base) through the overflow in the side of the volumetric tank (water overflowing from the constant head arrangement should return directly to the sump and not into the volumetric tank). Open the discharge flow control valve at the bottom of the test pipe. Close the bench flow control valve, start the service pump then open the bench flow control valve slightly. Allow water to flow through the test pipe until all air is dispelled. Close off the flexible connections to the mercury manometer (fitted with knurled screws at the top) using the tubing clips supplied and allow water to flow through the water manometer until all air bubbles have dispersed. Open the connections to the mercury manometer and close off the flexible connections to the water manometer. Open the knurled screw at the top of each manometer tube briefly to allow the tube to fill with water. When the apparatus is fully primed close the discharge flow control valve at the bottom of the test pipe then close the bench flow control valve and switch off the service pump. Remove the knurled screws from the top of each tube on the mercury manometer then carefully pour approximately 0.4 kg of clean mercury (not supplied) into one of the tubes using a small funnel (not supplied) until the level of the mercury coincides with 250 mm on the manometer scale. Water will be displaced as the mercury enters ensuring that no air is trapped in the manometer tube. When the mercury is at the correct level replace the two knurled screws and tighten them. Place the flexible tube attached to the exit from the test pipe in the clip on the side of the support column. Position the end of the flexible tube so that water exiting the tube can be collected using a measuring cylinder. For accurate results at low flowrate, the position of the flexible tube should not be moved while taking readings. 4 F1-18 Energy Losses In Pipes Note: Low flowrates through the test pipe can be generated using the head tank at the top of the support column. The flexible inlet tube on the test pipe is connected to the tapping at the base of the head tank and the inlet tube to the head tank is connected to the outlet fitting in the bed of the moulded channel. The flow of water to the head tank should be adjusted using the bench flow control valve so that water just flows from the overflow. If the bench flow control valve is opened too far then water will spill from the top of the head tank. Note: When using the mercury manometer to measure head loss in excess of the range on the water manometer it will be necessary to close the flexible tubing to the water manometer using the tubing clips supplied. The F1-18 Energy Loss In Pipes apparatus is ready for use. 5 F1-18 Energy Losses In Pipes ROUTINE MAINTENANCE Little maintenance is required but it is important to drain all water from the constant head tank and all pipework when not in use. It is not necessary to drain the mercury from the mercury manometer or the water trapped above the mercury columns. The apparatus should be stored where protected from damage. 6 F1-18 Energy Losses In Pipes NOMENCLATURE Column Heading Units Nom. Type Description Length of Test Pipe m L Given Length of pipe test section. The test pipe length is measured in mm. Convert to metres for the calculation. Diameter of Test Pipe m d Given Diameter of pipe test section The test pipe diameter is measured in mm. Convert to metres for the calculation. . Volume Collected m3 V Measured Volume of water collected in a known time. The volume is measured in ml. Convert to cubic metres for the calculation. (divide reading by 1,000,000) Time to Collect s t Measured Time taken to collect the known volume of water, V. Temp of Water °C Measured The temperature of the water collected. Kinematic Viscosity m2/s ν Measured See Table Manometer m h1 Measured Head at inlet to test section of the pipe. The head is measured in mm. Convert to metres for the calculation. Manometer m h2 Measured Head at outlet to test section of the pipe. The head is measured in mm. Convert to metres for the calculation. Head Loss m h1 - h2 Calculated Head loss over the test section of the pipe. Flow Rate m3/s Qt Calculated Velocity m/s v Calculated 7 Qt = Volume Collected v = t Time to Collect Fluid velocity through the pipe Flow Rate v= Area of Pipe F1-18 Energy Losses In Pipes 2gd Lv 2 Friction Factor f Calculated f = ∆h Reynolds Number ln f Re Calculated vd ν Natural log of friction factor, f, to show relationship between f and Re Calculated Re = ln Re Calculated Natural log of Reynolds Number, Re, to show relationship between f and Re ln h Calculated Natural log of head loss, h, to show relationship between h and v ln v Calculated Natural log of velocity, v, to show relationship between h and v 8 F1-18 Energy Losses In Pipes EXPERIMENTAL PROCEDURE Objective To investigate the head loss due to friction in the flow of water through a pipe and to determine the associated friction factor. Both variables are to be determined over a range of flow rates and their characteristics identified for both laminar and turbulent flows. Method By measurement of the pressure difference between two fixed points in a long (length = many diameters) straight tube of circular cross-section for steady flows. The range of flow rates will cover both laminar and turbulent flow regimes. Equipment In order to complete the demonstration we need a number of pieces of equipment. • • • • • • The F1-10 Hydraulics Bench which allows us to measure flow by timed volume collection. The F1-18 Pipe Friction Apparatus. A stopwatch to allow us to determine the flow rate of water (not supplied). A thermometer (not supplied). A spirit level for setting up the equipment A measuring cylinder for measuring very low flow rates (supplied with hydraulics bench) Technical Data The following dimensions from the equipment are used in the appropriate calculations. If required these values may be checked as part of the experimental procedure and replaced with your own measurements. Length of test pipe Diameter of test pipe L = 0.500 d = 0.003 m m Theory A basic momentum analysis of fully developed flow in a straight tube of uniform crosssection shows that the pressure difference (p 1 − p 2 ) between two points in the tube is due to the effects of viscosity (fluid friction). The head-loss ∆h is directly proportional to the pressure difference (loss) and is given by ∆h = (p 1 − p 2 ) ρg and the friction factor, f, is related to the head-loss by the equation ∆h = fLv 2 2gd 9 F1-18 Energy Losses In Pipes where d is the pipe diameter and, in this experiment, ∆h is measured directly by a manometer which connects to two pressure tappings a distance L apart; v is the mean velocity given in terms of the volume flow rate Qt by v= 4Q t πd 2 The theoretical result for laminar flow is f= 64 Re where Re = Reynolds number and is given by Re = vd ν and ν is the kinematic viscosity. For turbulent flow in a smooth pipe, a well known curve fit to experimental data is given by f = 0.316 Re −0.25 Procedure - Equipment Set Up Mount the test rig on the hydraulic bench and, with a spirit level, adjust the feet to ensure that base plate is horizontal and, hence, the manometers are vertical. Check with a demonstrator that the mercury (Hg) manometer is correctly filled; this should not be attempted by students because Hg is a hazardous substance. Attach a Hoffman clamp to each of the two manometer connecting tubes and close them off. Setting-up for high flow rates The test rig outlet tube must be held by a clamp to ensure that the outflow point is firmly fixed. This should be above the bench collection tank and should allow enough space for insertion of the measuring cylinder. Join the test rig inlet pipe to the hydraulic bench flow connector with the pump turned off. Close the bench gate-valve, open the test rig flow control valve fully and start the pump. Now open the gate valve progressively and run the system until all air is purged. Open the Hoffman clamps and purge any air from the two bleed points at the top of the Hg manometer. Setting up for low flow rates (using the header tank) 10 F1-18 Energy Losses In Pipes Attach a Hoffman clamp to each of the two manometer connecting tubes and close them off. With the system fully purged of air, close the bench valve, stop the pump, close the outflow valve and remove Hoffman clamps from the water manometer connections. Disconnect test section supply tube and hold high to keep it liquid filled. Connect bench supply tube to header tank inflow, run pump and open bench valve to allow flow. When outflow occurs from header tank snap connector, attach test section supply tube to it, ensuring no air entrapped. When outflow occurs from header tank overflow, fully open the outflow control valve. Slowly open air vents at top of water manometer and allow air to enter until manometer levels reach convenient height, then close air vent. If required, further control of levels can be achieved by use of hand-pump to raise manometer air pressure. Procedure - Taking a Set of Results Running high flow rate tests Apply a Hoffman clamp to each of the water manometer connection tubes (essential to prevent a flow path parallel to the test section). Close the test rig flow control valve and take a zero flow reading from the Hg manometer, (may not be zero because of contamination of Hg and/or tube wall). With the flow control valve fully open, measure the head loss hHg shown by the manometer. Determine the flow rate by timed collection and measure the temperature of the collected fluid. The Kinematic Viscosity of Water at Atmospheric Pressure can then be determined from the table provided in this manual. Repeat this procedure to give at least nine flow rates; the lowest to give hHg = 30mm Hg, approximately. Running low flow rate tests Repeat procedure given above but using water manometer throughout. With the flow control valve fully open, measure the head loss h shown by the manometer. Determine the flow rate by timed collection and measure the temperature of the collected fluid. The Kinematic Viscosity of Water at Atmospheric Pressure can then be determined from the table provided in this manual. Obtain data for at least eight flow rates, the lowest to give h = 30mm, approximately. Plot graphs of: 11 F1-18 Energy Losses In Pipes ln (friction factor) vs ln (Reynold’s no.) and ln (head loss) vs ln (velocity) Kinematic Viscosity of Water at Atmospheric Pressure Temperature (degrees C) 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Kinematic Viscosity ν 6 (10 x m2/s) 1.793 1.732 1.674 1.619 1.568 1.520 1.474 1.429 1.386 1.346 1.307 1.270 1.235 1.201 1.169 1.138 1.108 1.080 1.053 1.027 1.002 0.978 0.955 0.933 0.911 Temperature (degrees C) 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 45 50 55 60 65 70 75 80 85 Eg. At 20°C the kinematic viscosity of water is 1.002 x 10-6m2/s. 12 Kinematic Viscosity ν 6 (10 x m2/s) 0.893 0.873 0.854 0.836 0.818 0.802 0.785 0.769 0.753 0.738 0.724 0.711 0.697 0.684 0.671 0.658 0.602 0.554 0.511 0.476 0.443 0.413 0.386 0.363 0.342 F1-18 Energy Losses In Pipes Recording your Results Tabulate your results as follows: Test Pipe Length L (m) Test Pipe Diam. d (m) Volume V (m³) Time To Collect t (sec) Temp of Water (°C) Kin. Visc. Man. Man. Head Loss Flow Rate Vel. ν (m²/s) h1 (m) h2 (m) ∆h (m) Qt (m³/s) v (m/s) Friction Factor Reynolds Number In f f Re Application of Theory Identify the laminar and turbulent flow regimes. What is the critical Reynolds Number? Assuming a relationship of the form f = K Re n calculate these values from the graphs you have plotted and compare these with the accepted values shown in the theory section. What is the cumulative effect of experimental errors on the values of K and n? What is the dependence of head loss upon flow rate in the laminar and turbulent regions of flow? What is the significance of changes in temperature to the head loss? 13 In Re In h In V