ISSN 2319-8885

Vol.03,Issue.10

May-2014,

Pages:2128-2132

www.semargroup.org,

www.ijsetr.com

Universal Timer using Microcontroller for Home Appliances Software

Implementation

SU MON HTET1, ZAW MYO TUN2

1

Dept of Electronic Engineering, Mandalay Technological University, Mandalay, Myanmar, Email: sansan7487@gmail.com.

Dept of Electronic Engineering, Mandalay Technological University, Mandalay, Myanmar, Email: zawmyotun.mtu@ gmail.com.

2

Abstract: This paper deals with the design, development and implementation of microcontroller based universal On-Off timer

for home appliances. This system is developed for the users to control the operation of any home appliances. The system is

divided into two parts; software implementation and hardware implementation. This paper mainly concerns with software

implementation of the system. Man has no time to wait for a particular appliance to on for a particular period in modern world.

Under this control, the appliance can be on and off. It mainly consists of a keypad, microcontroller unit, relay driver circuits and

LCD display. The user can set any of the time given in the timer switch using keypad. The settings are stored in the

microcontroller and the details are displayed in the LCD display. The appliance is controlled to run for the particular period by

the timer switch. The timer switch automatically makes the appliance off if the particular period is over. This system is

efficient, reliable and user friendly.

Keywords: Timer, Microcontroller, Keypad, LCD, Relay Driver.

I. INTRODUCTION

With advancement of technology things are becoming

simpler and easier for us. Timer is an important function for

the sequence processing or precise producer of modern

control systems. The objective of this paper is to investigate a

cost effective solution that will provide controlling of home

appliances time efficiently. The PIC microcontrollers are

popular and in high demand throughout the world because it

is widely available, it has low cost, it is a large user base

device and it can work as an extensive collection of

application notes. This system aims to program and design

the required timing sequence for the automatic control

system. The maximum time the user can set is limited to 18

hours due to program memory. In this system, four sections

will be considered. These are power supply unit, input

switches for setting selection, PIC 16F877A microcontroller

unit and relay driver circuit. Power supply circuit is designed

to generate the require power for entire circuit. The keypad is

used for timer setting input.

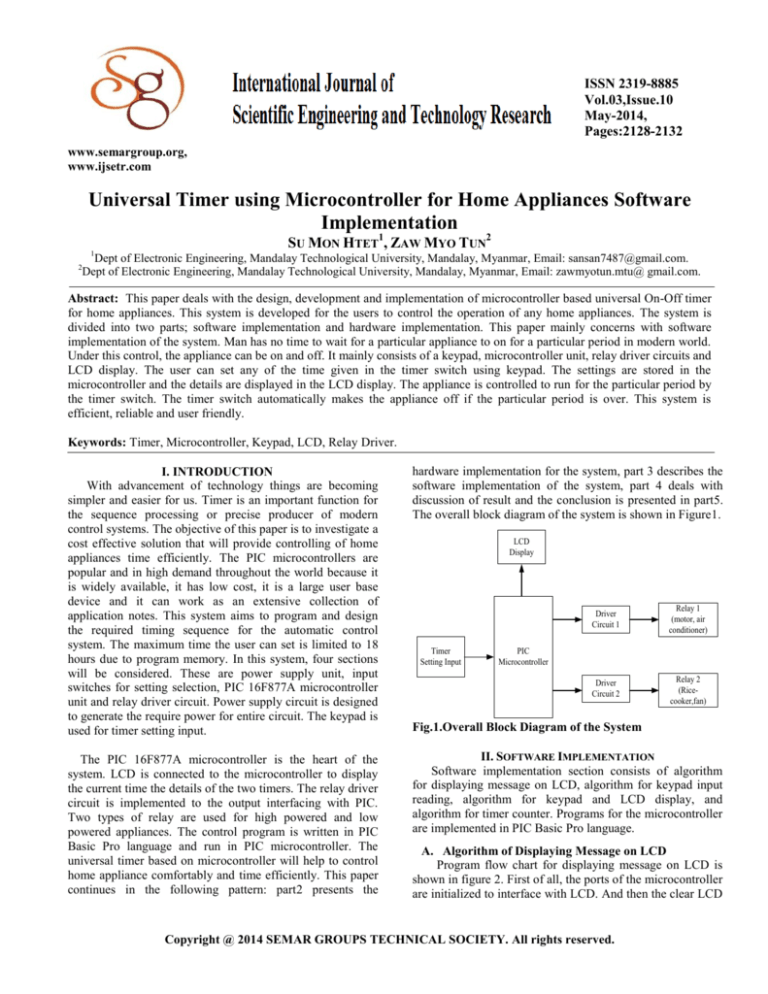

hardware implementation for the system, part 3 describes the

software implementation of the system, part 4 deals with

discussion of result and the conclusion is presented in part5.

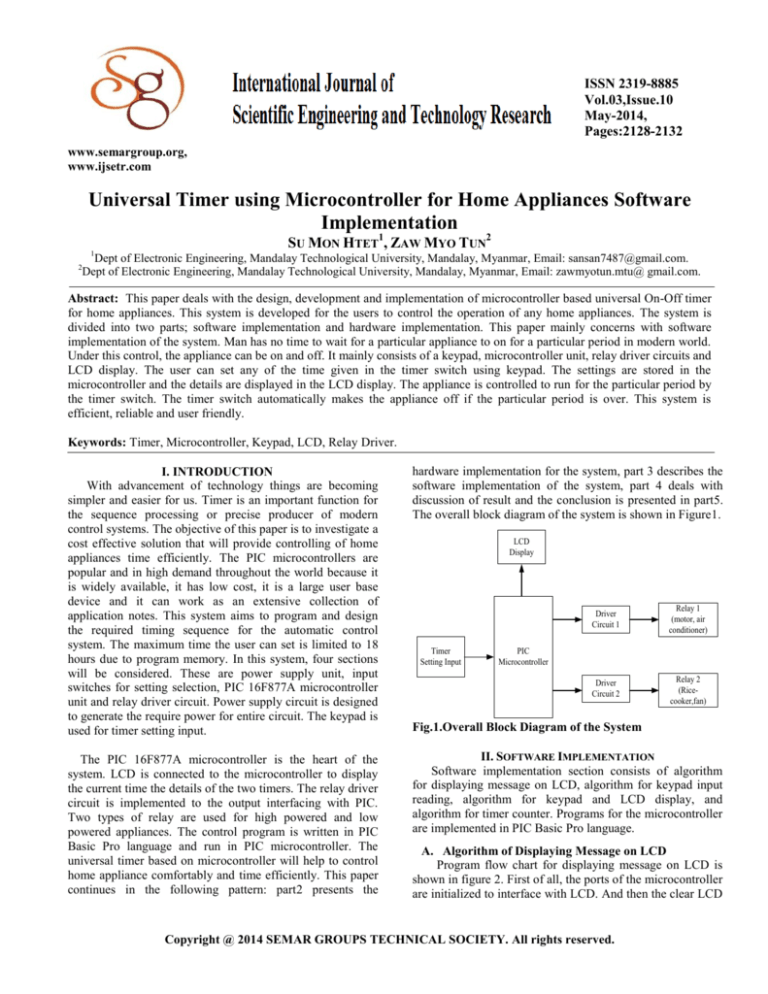

The overall block diagram of the system is shown in Figure1.

The PIC 16F877A microcontroller is the heart of the

system. LCD is connected to the microcontroller to display

the current time the details of the two timers. The relay driver

circuit is implemented to the output interfacing with PIC.

Two types of relay are used for high powered and low

powered appliances. The control program is written in PIC

Basic Pro language and run in PIC microcontroller. The

universal timer based on microcontroller will help to control

home appliance comfortably and time efficiently. This paper

continues in the following pattern: part2 presents the

II. SOFTWARE IMPLEMENTATION

Software implementation section consists of algorithm

for displaying message on LCD, algorithm for keypad input

reading, algorithm for keypad and LCD display, and

algorithm for timer counter. Programs for the microcontroller

are implemented in PIC Basic Pro language.

LCD

Display

Timer

Setting Input

Driver

Circuit 1

Relay 1

(motor, air

conditioner)

Driver

Circuit 2

Relay 2

(Ricecooker,fan)

PIC

Microcontroller

Fig.1.Overall Block Diagram of the System

A. Algorithm of Displaying Message on LCD

Program flow chart for displaying message on LCD is

shown in figure 2. First of all, the ports of the microcontroller

are initialized to interface with LCD. And then the clear LCD

Copyright @ 2014 SEMAR GROUPS TECHNICAL SOCIETY. All rights reserved.

SU MON HTET, ZAW MYO TUN

screen command is sent to LCD and home cursor is set. After

Endif

that, the desired message can be displayed on LCD. Source

If (row2 == 0) Then

code for displaying message on LCD is as follows;

' key 5 is down

lcdout $FE, 1

Endif

RPT:

If (row3 == 0) Then

lcdout $FE, 2

' key 8 is down

lcdout "Hello World! "

Endif

pause 1000

If (row4 == 0) Then

lcdout $FE, $C0

' key 0 is down

lcdout "I am Su Mon Htet."

Endif

goto RPT

' Check column 3

end

High col1 : High col2 : Low col3

If (row1 == 0) Then

start

' key 3 is down

Endif

Initialize Inputs,

If (row2 == 0) Then

Output Ports

' key 6 is down

Endif

If (row3 == 0) Then

Clear LCD screen

' key 9 is down

Endif

If (row4 == 0) Then

Set home cursor

' key # is down

Endif

goto loop

Display Message

start

End

Fig.2. Displaying Message on LCD.

B. Algorithm for Keypad Input Reading

Program flow chart for keypad input reading is shown in

figure 3. First of all, the inputs and outputs ports are

initialized. And then LCD screen is cleared and display

message to press the key. The input pins of the

microcontroller are checked until the key is pressed. When

any key is pressed, microcontroller checks which key is

pressed and displays the pressed key on LCD. The following

shows the keypad polling loop in basic pro language.

loop:

' Check column 1

Low col1 : High col2 : High col3

If (row1 == 0) Then

high PORTD.0 ' key 1 is down

Endif

If (row2 == 0) Then

HIGH PORTD.1' key 4 is down

Endif

If (row3 == 0) Then

' key 7 is down

Endif

If (row4 == 0) Then

' key . is down

Endif

' Check column 2

High col1 : Low col2 : High col3

If (row1 == 0) Then

' key 2 is down

Initialize Inputs,

Output Ports

Clear LCD screen

Display Message

“Press Any Key

Key Press?

No

Yes

Check which

key is pressed

Display pressed

key on LCD

End

Fig.3. Flowchart for Keypad Input Reading.

C. Algorithm for Timer Counter Display

Timer counting is the essential part of the microcontroller

based home appliance system since the user can set the on/off

timing for home appliances in smart home system. The user

needs to set the timing using keypad. The microcontroller

stores the key pressed numbers and calculates the count for

timer. After that, the timer is counted down and when the

setting time is reached, the PIC sends the command to the

output pin to show the setting time is completed. In this

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.10, May-2014, Pages: 2128-2132

Universal Timer using Microcontroller for Home Appliances Software Implementation

research, LED is connected to the output pin to describe the

III. RESULTS

result. The program is implemented to turn on and off the

In this system, the user has firstly set the desired hours,

LED three times when the setting time is completed to see

minutes and seconds for two timers. After that, the

the result quite clear.

microcontroller starts comparing and counting the times.

Figure 6 shows the condition when timer 1 ON time is

reached. The output signal is described with a LAMP. Figure

start

Check which

6 shows the condition when timer 2 ON time is reached. The

key is pressed

output signal is described with a LAMP.

Initialize Inputs,

Output Ports

Clear LCD screen

Display Message

“Press Any Key

Calculate count

for timer

Decrease count

Turn on/off

LED 3 times

Display on LCD

No

Key Press?

Yes

End

No

No

Count = 0 ?

Yes

Fig.4. Flowchart for Timer Counter Display.

D. Overall System Flow and Algorithm for Timer Setting

There are six subroutines included in the program. They

are subroutines for key test from keypad, for second count,

for key number calculation, for time calculation, for asking

the timer setting, and for calculating the interval of timer on

conditions. First of all,. “ON” time or “OFF” time of timer 1

and timer 2 will be asked. Then the microcontroller will

calculate the duration time for timer 1 and timer 2 and then

the output signal will be set when the setting time is

completed. The system flow procedure is shown in figure 5.

Fig.6. Simulation Result for timer 2 is ON.

.

Fig.5. Overall System Flow for the Home Automation

System.

Fig.7.Simulation Result for timer 1 is ON.

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.10, May-2014, Pages: 2128-2132

SU MON HTET, ZAW MYO TUN

IV. DEVELOPING HEX CODE AND DOWNLOADING HEX

CODE INTO MICROCONTROLLER

Developing Hex Code and Downloading hex code into

microcontroller. To develop the PIC and LCD interfacing

circuit, the program is written in Microcode Studio Plus

window and compiled. If compiling process succeeds, the

Microcode Studio creates hex code for microcontroller.

Figure8 shows software development window with

Microcode Studio and hex code created for microcontroller.

Fig. 10. Importing Hex file to the Microcontroller

Fig.8. Software Development Window with Microcode

Studio and Hex Code Created for Microcontroller.

The hex code is created by compiling the program in

Microcode studio Plus software. This code is burnt in

microcontroller using PIC kit 2 programmers and interfacing

software. Figures 2 and 3 shows the blank check of the

microcontroller, the importing hex file into microcontroller

and burning the hex file to the microcontroller using PIC kit

2 programmer and interfacing software.

V. SUMMARY

The hardware design and software implementation of the

timer system is described. The desired programming software

is used in PIC Basic Pro. The system can count the two

timers at the same time and switch on and off for the

particular period. The PIC 16F877A microcontroller is the

heart of the system. The twelve-key matrix keypad, 4×20

LCD and two types of relay driver are used. The user can use

this system time efficiently and comfortably.

VI. CONCLUSION

The main motivation of this system is to develop and

implement a simple and inexpensive universal timer for

home appliances.The maximum time is limited to 18

hours.The Proteus simulation software and PIC Basic Pro

programming language are used. How to implement the PIC

program is described with flowchart. Proteus test for the

system is described. A flexible and easy way for controlling

home appliance is created.

VII. REFERENCES

[1]Microchip, PICMicro Mid-Range MCU Family Reference

Manual, DS33023A, Microchip Technology Inc, 1997.

[2] Design and Development of Activation and Controlling

of Home Automation System VIA SMS through

Microcontroller, Ch. Naga Koti Kumar*, Y.V. Raghu

Babu**,A. Gamya***, P.Jainath****, M. Vijay*****(MarApr 2012,pp.1349-1352).

[3] Microcontroller based IR Remote Control Signal Decoder

for Home Application, Nhivekar G.S and Mudholker

R.R,2011.

[4] Microcontroller Based Home Automation System With

Security, Inderpreet Kaur (Asstt. Prof.), IJACSA,Vol. 1,No.6,

December 2010.

[5] Home appliances Controlling Using Windows Phone 7,

Chesti Altaff Hussain, K. Vijaya Lakshmi, International

Journal of Advanced Research in Electrical, Electronics and

Instrumentation Engineering,Vol 2,Issue 2, February 2013.

Fig.9. PIC kit2 Programmer checking whether the device

is blank or not.

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.10, May-2014, Pages: 2128-2132

Universal Timer using Microcontroller for Home Appliances Software Implementation

[6] “DC Motorised Treadmill For Home” http://treadmill.

jkexer.com/en/2 1789 60763/product/Motorized Treadmills

id342279.html.

[7] Herman, Stephen L. Electric Motor Control. (http://

books.google.com/books?id=Yxy8WRWfIy0C&pg=PA12

&dq=dc+electric+motor+protection&hl=en&ei=xwC8TrefF

OHq0gHW4czfCQ&sa=X&oi=book_result&ct=result&resnu

m=9&ved=0CHAQ6AEwCA#v=onepage&q=dc%20electric

%20motor%20protection&f=false) 9th ed. Delmar, Cengage

Learning, 2009. Page 12.

[8] Malcolm Barnes. Practical variable speed drives and

power electronics. (http://books.google.com/books?id=LxW

9F9WCixcC&pg=PA151&dq=dc+motor+insulation +failures

&hl=en&ei=UCrATsnlK-j30gG_s7i3BA&sa=X&oi= book _

result&ct=result&resnum=3&ved=0CD4Q6AEwAjgK#v=on

e page &q&f=false) Elsevier, Newnes, 2003. Page 151.

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.10, May-2014, Pages: 2128-2132