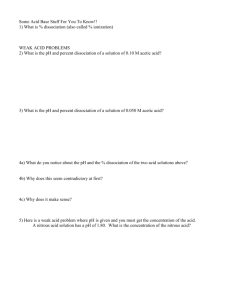

Fuel Air Cycles

advertisement

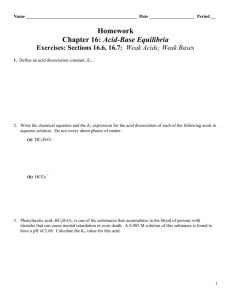

Lecture-8 Prepared under QIP-CD Cell Project Internal Combustion Engines Ujjwal K Saha, Ph.D. Department of Mechanical Engineering Indian Institute of Technology Guwahati 1 Background Air standard cycles had simplified approximations, and therefore, performance estimate of the engine is greater than the actual performance. With a compression ratio of 7:1, the actual indicated thermal efficiency of an SI engine is of the order of 30 %, while the ideal (or air-standard) efficiency is about 55 %. This divergence is due to partly due to noninstantaneous burning, incomplete combustion, valve operation etc. However, the main reason lies with the over-simplification of using values of properties of the working fluid. 2 Background-Contd. Ideal Case: Working fluid is air Air is a perfect gas Has constant specific heats Actual Case: Working fluid is air + fuel + residual gas Specific heats increases with increase in temperature Combustion products are subjected to dissociation at high temperature 3 Fuel-Air Cycle Considerations – Actual composition of the cylinder gas (fuel + air + water vapor in air + residual gas) – F/A ratio change during operation, and hence changes in amount of CO2, water vapor etc. – Specific heat changes with temperature (except for mono-atomic gas), and hence, ratio of specific heats (k) also changes. – Changes in no. of molecules in cylinder with the change in pressure and temperature. 4 Fuel-Air Cycles - Assumptions There is no chemical change in either fuel or air prior to combustion. There is no heat transfer between the gases and cylinder walls in any process (adiabatic). Compression and expansion processes are frictionless. The velocities are negligibly small. 5 Remark # The air-standard analysis allows how the efficiency is improved by raising the compression ratio of air. # It does not give any idea on the effect of F/A ratio on thermal efficiency. Fuel – Air Cycles Allows study of F/A ratio on thermal efficiency. Allows study of pmax and Tmax as F/A ratio is varied. This helps in structural design of the engine. Gives a good estimate of the power expected from an actual engine. 6 Variable Specific Heats: # Except mono-atomic gases, all other gases show an increase in specific heats at high temperature. This increase does not obey any law. 7 # Over the temperature range in general use for gases in heat engines (300 K – 1500 K), the specific heat curve is nearly a straight line, and can be expressed as Cp = a1 + k1T Cv = b1 + k1T R = Cp - Cv = a1-b1 # Above 1500 K, specific heats increase more rapidly, and may be expressed in the form Cp = a1 + k1T + k2T2 Cv = b1 + k1T + k2T2 8 Physical Explanation Cp = 1.005 kJ/kgK at 300 K Cp = 1.343 kJ/kgK at 2000 K Cv= 0.718 kJ/kgK at 300 K Cv = 1.055 kJ/kgK at 2000 K Increase of specific heat is that as temperature is raised, larger and larger fractions of heat input go to produce the motion of atoms within the molecules. 9 Explanation As temperature is an indication of motion of molecules as a whole, therefore, the energy that goes into the motion of atoms does not contribute to temperature rise. This is the reason, why more heat is required to raise the temperature of unit mass by one degree (This heat, by definition, is the specific heat). As Cp-Cv =Constant, and k (=Cp/Cv) decreases with increase of temperature. Therefore, variation of specific heats leads the FINAL temperature and pressure to lower values (as compared to constant specific heats). 10 1-2-3-4 : with constant specific heats 1-2´-3´-4´´ : with constant specific heat from point 3´ 1-2´-3´-4´ : with variable specific heats 2´ is lower than 2 : due to variable specific heats 3´ is lower than 3 : temperature rise due to a given heat release ↓ as Cp ↑, and also as 2´ is lower than 2. 3´ to 4´´ : resulting adiabatic expansion. 3´ to 4´ : correct expansion (Specific heat ↓ as Temperature ↓ during expansion). 11 Dissociation Loss Dissociation : disintegration of combustion products at high temperature. During dissociation, heat is absorbed, whereas during combustion heat is liberated. At 10000C, CO2 U CO + O2 + heat At 13000C, H2O U H2 + O2 + heat Presence of CO and O2 in the gases tends to prevent the dissociation of CO2 in rich mixture, which, by producing more CO suppresses the dissociation of CO2. That means, there there is no dissociation in the burnt gases of a lean mixture, because the temperature produced is too low for the phenomenon to occur. 12 Remarks Lean Mixture : No dissociation takes place due to low temperature. Maximum dissociation : Chemically correct mixture when the temperature is high. Rich Mixture : Dissociation is prevented by the available CO and O2. Further, heat transfer to cooling medium causes a reduction in maximum temperature and pressure. As temperature falls (during the expansion stroke) the separated constituents recombine and heat absorbed (during dissociation) gets released. But, it becomes too late to recover. 13 The curve shows the reduction in exhaust gas temperature due to dissociation with respect to air-fuel ratio. 14 Effect of dissociation on Power (SI Engine) Power Output is maximum at stoichiometric ratio where there is no dissociation. Shaded area represents loss of power due to dissociation. For Lean mixture : No dissociation. For Stoichiometric : Maximum dissociation. For Rich mixture : Effect declines due to incomplete combustion and also due to increased quantity of CO. 15 Effect of Operating Variables Compression Ratio: For a given φ, efficiency (fuelair cycle) increases with compression ratio (r) in a similar manner as that of air standard cycle. pmax increases with increasing r and liberation of chemical energy at high pressure gives more scope for expansion work. Thus, there is higher efficiency but to a certain value of compression ratio (r). 16 At the same compression ratio, efficiency (fuel-air) decreases with increasing φ. φ = Equivalence Ratio = Actual F A Ratio Stoicheometric F A Ratio φ < 1 implies a lean mixture. Tmax becomes lower due to excess air. This results in lower specific heats and higher values of k. Hence, efficiency increases with decreasing φ (gases expand to a larger temperature before exhaust). When φ > 1, efficiency (fuelair) decreases with increasing φ, because insufficient air leads to incomplete oxidation of fuel. 17 Effect of Equivalence Ratio on Temperature At a given r, maximum temperature is reached when the mixture is slightly rich (about 6 - 8 %). This is because, at φ=1, there is still some oxygen present at point 3 because of chemical equilibrium effects, and a rich mixture will cause more fuel to combine with oxygen at that point thereby raising the temperature T 3. However, at rich mixtures increased formation of CO counteracts this effect. 18 Effect of Equivalence Ratio on Pressure The pressure of a gas in a given space depends upon its temperature and the number of molecules. The curve of p3,therefore follows T3, but because of the increased no. of molecules, p3 starts decreasing when the mixture is about 18 to 20 % rich. 19 References Crouse WH, and Anglin DL, DL (1985), Automotive Engines, Tata McGraw Hill. 2. Eastop TD, and McConkey A, (1993), Applied Thermodynamics for Engg. Technologists, Addison Wisley. 3. Fergusan CR, and Kirkpatrick AT, (2001), Internal Combustion Engines, John Wiley & Sons. 4. Ganesan V, (2003), Internal Combustion Engines, Tata McGraw Hill. 5. Gill PW, Smith JH, and Ziurys EJ, (1959), Fundamentals of I. C. Engines, Oxford and IBH Pub Ltd. 6. Heisler H, (1999), Vehicle and Engine Technology, Arnold Publishers. 7. Heywood JB, (1989), Internal Combustion Engine Fundamentals, McGraw Hill. 8. Heywood JB, and Sher E, (1999), The Two-Stroke Cycle Engine, Taylor & Francis. 9. Joel R, (1996), Basic Engineering Thermodynamics, Addison-Wesley. 10. Mathur ML, and Sharma RP, (1994), A Course in Internal Combustion Engines, Dhanpat Rai & Sons, New Delhi. 11. Pulkrabek WW, (1997), Engineering Fundamentals of the I. C. Engine, Prentice Hall. 12. Rogers GFC, and Mayhew YR, YR (1992), Engineering Thermodynamics, Addison 1. Wisley. 13. Srinivasan S, (2001), Automotive Engines, Tata McGraw Hill. 14. Stone R, (1992), Internal Combustion Engines, The Macmillan Press Limited, London. 15. Taylor CF, (1985), The Internal-Combustion Engine in Theory and Practice, Vol.1 & 2, The MIT Press, Cambridge, Massachusetts. 20