Catalytic conversion of glucose in dimethylsulfoxide/water binary

Chemical Engineering Journal 254 (2014) 333–339

Contents lists available at ScienceDirect

Chemical Engineering Journal

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / c e j

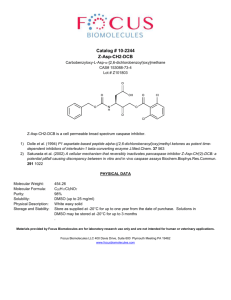

Catalytic conversion of glucose in dimethylsulfoxide/water binary mix with chromium trichloride: Role of water on the product distribution

Songyan Jia

, Zhanwei Xu

, Z.Conrad Zhang

⇑

a

Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Dalian 116023, China b

State Key Laboratory of Catalysis, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Dalian 116023, China g r a p h i c a l a b s t r a c t h i g h l i g h t s

Tuning water content in DMSO leads to desirable product distribution from glucose.

Pure DMSO solvent causes undesired dehydration of glucose and low HMF yield.

The available water in DMSO effectively suppressed undesired dehydration of glucose.

DMSO/H

2

O with v of stabilizing HMF.

w

6

0.3 is capable a r t i c l e i n f o

Article history:

Received 10 March 2014

Received in revised form 25 May 2014

Accepted 28 May 2014

Available online 4 June 2014

Keywords:

Glucose conversion

5-Hydroxymethylfurfural

DMSO/H

2

O mixed solvent

Water content

Product distribution a b s t r a c t

The production of 5-Hydroxymethylfurfural (HMF) from hexoses is a stoichiometric dehydration process.

Water content in a solvent is expected to play an important role in HMF formation by affecting the equilibrium and the reaction kinetics. In this work, the impact of water content on the catalytic conversion of glucose was investigated in detail in different dimethylsulfoxide (DMSO)/H

2

O mixtures ( v w

= 0–1) with chromium trichloride hexahydrate (CrCl

3

6H

2

O) as the catalyst at 110–130 ° C. Water content in the binary mix was found to dominantly affect the product distribution. Anhydrous DMSO system is favored for HMF formation from glucose but caused a number of side reactions, especially the undesired dehydration of glucose into cellobiose. Adding an appropriate amount of water in DMSO ( v w

= 0.17–0.50) was found to significantly suppress the undesired dehydration side reactions while preserving high HMF yield over the CrCl

3

6H

2

O catalyst, therefore remarkably improving the total selectivity of HMF and fructose from glucose conversion. While CrCl

3

6H

2

O was essential in isomerizing glucose into fructose, hydrochloric acid (HCl) from CrCl

3

6H

2

O hydrolysis in DMSO/H

2

O mixed system catalyzed the dehydration of in situ formed fructose to HMF. Although effective water removal was pronounced toward improving HMF yield from hexose dehydration in previous work, the results of this work indicate that a controlled amount of water in the non-aqueous system is favorable to drive the thermodynamic equilibrium for high HMF yield and desired product selectivity, providing reference information on designing a one-pot process for HMF synthesis from cellulosic materials.

Ó 2014 Elsevier B.V. All rights reserved.

⇑

Corresponding author at: Dalian National Laboratory for Clean Energy, Dalian Institute of Chemical Physics, Chinese Academy of Sciences, Dalian 116023, China.

Fax: +86 411 84379462.

E-mail address: zczhang@yahoo.com

(Z. Zhang).

http://dx.doi.org/10.1016/j.cej.2014.05.121

1385-8947/ Ó 2014 Elsevier B.V. All rights reserved.

334

1. Introduction

Biomass, the most abundant and available renewable carbon source on the earth, has attracted a great deal of attention in view of the diminishing fossil fuels

[1] . Biomass consists primarily of

lignocellulose, which includes polysaccharides (cellulose and hemicellulose) and lignin

. Compared with the complex and recalcitrant lignin, the polysaccharides have relatively regular structures with monosaccharide units and can be hydrolyzed into various sugars

[2,3] . Thus, the development of biomass biorefinery

is critically dependent on catalytic carbohydrate conversions with high selectivity.

5-Hydroxymethylfurfural (HMF) has recently been regarded as one important precursor for the production of biofuels and biobased compounds

[4] . Dehydration of hexoses into HMF has

emerged as a promising path toward sustainable development

. For the above purpose, fructose is a good starting material, which can be smoothly converted into HMF in varieties of reaction media, such as water/organic solvent biphasic system

dimethylsulfoxide (DMSO)

[6] , dimethylacetamide (DMA)-lithium

chloride (LiCl)

, with many different catalysts, including mineral acid

, organic acid

, solid acid

, and functionalized ionic liquid

. However, fructose is of limited abundance in nature and typically at a higher cost than glucose

.

Glucose is the most abundant monosaccharide in nature and, as the main monomer, can be produced from the hydrolysis of starch and cellulose

[14] . However, the obstacle of effectively converting

glucose into HMF has slowed the development of HMF based biorefinery. Zhang and co-workers first reported that chromium chloride (CrCl

2 or CrCl

3

) catalyzed the efficient production of HMF from glucose in ionic liquids by enabling the isomerization of glucose into fructose

. Since then, ionic liquids have been mostly employed as the reaction media for the HMF production from glucose based feedstocks with chromium chloride

ionic liquids, other solvents, such as DMA and DMSO, have been employed for glucose conversion as well, and it was found that chromium chloride was also effective in those systems for the isomerization of glucose into fructose

[7,21,22] . The versatility of

chromium chloride catalyst in different solvents offers more options toward the development of alternative reaction systems for saccharide conversions.

In previous works, it was reported that DMSO could improve the HMF yield from fructose by suppressing side reactions

Shimizu et al. reported that the in situ formed water from fructose dehydration lowered the HMF yield in DMSO system over Amberlyst-15

, so that effective water removal was pronounced toward the enhanced production of HMF

water formation is inevitable in a dehydration reaction, information on whether and how water content in non-aqueous media affects HMF production from hexoses, especially glucose, is an important subject of research and the existing literature remains lacking in such information. Recently, a few studies focused on the effect of water content in HMF chemistry by employing

DMSO/water (H

2

O) binary mix. Tsilomelekis et al. studied the origin of HMF stability in DMSO/deuterium oxide (D

2

O), and proposed that HMF solvation by DMSO reduced its susceptibility to nucleophilic attack, therefore minimizing undesirable hydrolysis of

HMF and humin formation

[25] . HMF solvation by DMSO remained

preferential at v

D2O

< 0.4

[25] , indicating that an appropriate

amount of water in such a system does not lower the stability of

HMF. Kimura et al. studied the non-catalytic conversion of cellobiose in DMSO/water at high temperature (170 ° C), in which higher

HMF yield ( 70%) was obtained after 23–26 h in the DMSO/water mixtures with v w

= 0.2–0.3 than that in pure DMSO (HMF yield of

45%) or water (HMF yield of 40%)

. In our previous study, it

S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339 was shown that isomerization of glucose into fructose catalyzed by

CrCl

3

6H

2

O followed a general curve in water independent of reaction variables, while adding a controlled amount of DMSO as co-solvent significantly changed the reaction behavior

example, when a DMSO/water mixture (v/v, 8/2) was used as the solvent, the obtained HMF yield (11.0%) was comparable to that

(12.4%) in pure DMSO at 110 ° C after 4 h

demonstrate that an appropriate amount of water may be tolerated and even more beneficial for HMF synthesis in DMSO.

It is noted that the DMSO/water mixture solvent has been well studied. For instance, several characteristic parameters of the mixture, such as melting point, density and viscosity, deviate from the ideal solution as a function of the molar fraction of water ( v w

)

[28,29] . As reported, water appears tetrahedrally hydrogen

bonded, linking each water molecule to four water molecule neighbors in tetrahedral geometry

[30] . In DMSO/water binary mixtures

with higher water content ( v w

> 0.5), the local tetrahedral structure of water is still preserved

v w

P 0.7

[33] , implying that the mixtures have water-like properties. How-

ever, in the DMSO-rich aqueous system ( v w

< 0.5), DMSO molecules retain the same molecular arrangement as in the pure state

[34] . Therefore, the DMSO/water binary mix may offer unique

properties for biomass conversion research.

In this work, we investigated the catalytic conversion of glucose with chromium trichloride catalyst in varied DMSO/water binary solvents. The objective was to explore how water content of the mixed solvents may affect the catalytic conversion of glucose.

Achieving such an understanding may also help reconcile the large difference between very high glucose conversion and relatively low HMF yield in some previous literatures

.

2. Experimental

2.1. Materials

D -Glucose (99%), D -fructose (99%), 1,6-anhydrob D -glucose

(AGP, 99%) and

D

-cellobiose (98%) were purchased from Alfa Aesar.

Chromium trichloride hexahydrate (CrCl

3

6H

2

O, 96%) was purchased from Sigma–Aldrich. 5-Hydroxymethylfurfural (HMF, 98%) and levulinic acid (LA, 99%) were purchased from Aladdin. Glycerol

(99%) and dimethylsulfoxide (DMSO, 99%) were purchased from

Sinopharm (China). Hydrochloric acid (HCl, 36–38 wt%) was provided by a local supplier. All the chemicals were used as received.

Deionized water (DI H

2

O) with a resistivity of 18.2 M X -cm was produced by a Milli-Q Integral 5 system.

2.2. Typical reaction procedure

Glucose (50 mg) or fructose (50 mg), CrCl

3

6H

2

O (3.7 mg,

5 mol% with respect to glucose or fructose) and total 1 mL of solvent were added into each reaction vial with a magnetic stir bar for reaction. The reaction vial was sealed and it was used as an autoclave. The reaction is conducted at autogenic pressure. It should be specified that some solvents may be composed of both

DMSO and DI H

2

O, and the 1 mL was defined as the sum volume of DMSO and H

2

O. Eight DMSO/H

2

O solutions with volume ratios

( l L/ l L) of 1000/0, 950/50, 900/100, 800/200, 600/400, 400/600,

200/800 and 0/1000 were employed. Based on that the relative densities of DMSO and H

2

O are 1.1 g/mL and 1.0 g/mL, and the molecular weights of DMSO and H

2

O are 78.13 g/mol and

18.02 g/mol, respectively, the molar fraction of H

2

O ( v w

) in the above DMSO/H

2

O solutions was calculated to be 0, 0.17, 0.30,

0.50, 0.72, 0.86, 0.94 and 1, respectively. The feedstocks have good solubilities in either water or DMSO. For example, the solubility of glucose in water and DMSO is 909 mg/mL and 540 mg/mL,

HPLC analysis was performed on an Agilent 1260 series with a refractive index detector and a PL Hi-Plex H column

(300 7.7 mm, 8 l m). The mobile phase was 0.005 M H

2

SO

4 aqueous solution at a flow rate of 0.6 mL/min and the volume for each injection was 10 l L. The column and detector temperatures were

65 ° C and 50 ° C, respectively. Authentic chemical compounds were used to identify the retention times. Glycerol was added as the internal standard for the quantitative calculations. The pH values were measured by Core Module 3 (CM3) System (Freeslate).

3. Results and discussion

S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339 respectively, around room temperature

tose has higher solubility than other sugars as well as other sugar alcohols in water

, and it also has a good solubility in DMSO

[38] . Moreover, HMF is also soluble in water and many polar

organic solvents

. Therefore, it is believed that the used feedstocks and produced HMF completely dissolved in the above reaction systems. The reactions were operated on a heating and stirring module (TS-18821, Thermo Scientific) with the stirring rate at

500 rpm for a specified time at the reaction temperature. After the reaction was quenched in ice water bath, 1 mL of DI H

2

O and the internal standard were added into the reaction mixture. Then, a small amount of the sample mixture was taken out and further diluted by DI H

2

O for 15 times and analyzed by high performance liquid chromatography (HPLC).

2.3. Analyses

The production of HMF from hexoses is a stoichiometric dehydration process in a solvent. The effect of water content on the catalytic conversion of glucose was studied in DMSO/H

2

O mixtures with CrCl

3

6H

2

O. The initial investigations were carried out in various DMSO/H

2

O ratios at 110 ° C.

As illustrated in

Fig. 1 a, after the experiments were run for 2 h,

the glucose conversion for all the systems reached a similar level of

23%. However, the product distribution showed different patterns. In anhydrous DMSO, the HMF yield (9.6%) was the highest among all the systems with only a little fructose (3%) detected.

As reported, CrCl

3

6H

2

O is a good catalyst for isomerizing glucose into fructose

. Anhydrous DMSO is a strong dehydration medium, which facilitates HMF formation from the in situ formed fructose. As a general trend, with increasing v w from 0 to

1, HMF yield was decreased along with increased fructose yield, indicating that water addition suppressed the dehydration of

335 fructose into HMF. It is noted that, however, in the system with v w

= 0.17, the HMF yield (6.4%) remained close to that in anhydrous DMSO, while fructose yield was much increased (11.2%).

The total yield of HMF and fructose was much higher than that in anhydrous DMSO. With v w

> 0.50, HMF production was essentially quenched, and fructose was the primary product as a result of the isomerization of glucose over CrCl

3

6H

2

O, which is consistant with previous work

. Cellobiose, 1,6-anhydrob -

D

glucopyranose/glucofuranose (AGP/AGF) and levulinic acid (LA) were also detected. Cellobiose, AGP and AGF are the products by undesired intermolecular or intramolecular dehydration of glucose. LA is a downstream product due to the hydrolytic cracking of HMF, with formic acid (FA) as a concomitant product

However, the LA yields in the above systems were generally lower than 2% and no FA was detected by HPLC, so they were not discussed herein. The total yield of cellobiose, AGF and AGP is hereafter called by-product yield. Notably, quantities of by-products

(9.1%) were produced in anhydrous DMSO, where cellobiose was the main component with a yield of 7.5%. With increasing v w

, the yield of by-product dropped substantially to a very low level, which can be attributed to the increased water concentration that suppressed the dehydration of fructose into HMF as well as the undesired dehydration of glucose into by-products.

Given in

Fig. 1 b, when the reaction time was extended to 3 h,

the glucose conversion in anhydrous DMSO was much improved by 12%, while the other aqueous systems gave an average of

5% increase, indicating that water addition did retard the glucose conversion. The product distribution was comparable to that obtained at 2 h. The formation of by-products was significantly enhanced in anhydrous DMSO, especially cellobiose, of which the yield increased from 7.5% to 12.4%. However, the by-product yields just slightly increased in other water containing systems (

b), which further demonstrates that water addition could drive the thermodynamic equilibrium to circumvent undesired dehydration of glucose. The HMF production remained at a very low level with v w

> 0.50, possibly because the DMSO/H

2

O mixed solvents displayed water-like properties

, and the potential of DMSO for the dehydration of in situ formed fructose was much inhibited under these conditions. Remarkably, with v w

= 0.17, the HMF yield

(13.5%) was higher than that (11.3%) in anhydrous DMSO system, evidently demonstrating that an appropriate amount of water could be tolerated and beneficial for a non-aqueous system in producing HMF from glucose. With v w

= 0.30 and 0.50, the HMF yields were 8.7% and 7.5%, respectively, both close to that in anhydrous

DMSO. The above results imply that higher water content up to

Fig. 1.

Catalytic conversion of glucose in different DMSO/H

2

O mixtures at 110 ° C. (a) 2 h; (b) 3 h. Conditions: 50 mg of glucose with CrCl

3

6H

2

O (5 mol% with respect to glucose) was added into 1 mL of DMSO/H

2

O solvent and heated at 110 ° C for different times.

336 S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339 v w

= 0.50 is also not significantly inhibitive for HMF production, because DMSO molecules still retain similar feature as its pure state at v w

< 0.5 according to the well studied properties of the

DMSO/H

2

O binary mixture

To explore whether DMSO with higher water content was also effective for HMF production from glucose, we next investigated the effect of reaction temperature. As illustrated in

a, when the reactions were run at 120 ° C for 1 h, the glucose conversion for all the systems were around 26%. In anhydrous DMSO, the

HMF yield was 12%. With increasing v w

, the HMF yield decreased from 9.7% ( v w

= 0.17) to 1.2% ( v w

= 1), while the fructose yield increased accordingly. It was again found that much higher yield

(9%) of by-product was observed in anhydrous DMSO. Since isomerization of glucose as well as the rate limiting step in the dehydration of fructose are endothermic

ing that similar glucose conversions and HMF yields were obtained in varied DMSO/H

2

O systems at 120 ° C within short time (1 h) and at 110 ° C for 2 h (Figs.

a and

2 a). Dehydration of glucose into HMF

is considered to undergo a two-step tandem reaction, including isomerization of glucose into fructose and dehydration of fructose into HMF

. HMF and fructose are the desired products. As seen in

a, due to the large formation of by-products, the selectivity of desired product (56.2%) was low in anhydrous DMSO, while the corresponding selectivities in other aqueous systems stood at the level of 80%, mainly because water did suppress the undesired dehydration from glucose.

As shown in

Fig. 2 b and c, when the reaction time was extended

to 2 h and 3 h, glucose conversions were significantly improved in anhydrous DMSO than in other water containing systems. HMF was more effectively produced in DMSO/H

2

O systems with v w in

= 0.17–0.50. For 2 h reaction at 120 ° C, the HMF yield (19.4%) v w

= 0.17 system was higher than that (15.3%) in anhydrous

DMSO. The v w

= 0.30 and 0.50 systems gave HMF yields of 14% and 12.7%, respectively. Remarkably, for 3 h reaction, the HMF yields in v w

= 0.17, 0.30 and 0.50 systems were 21.5%, 20.1% and

17.6%, respectively, all of which were higher than that (16.6%) in anhydrous DMSO. However, the selectivity of desired product decreased with prolonging reaction time. After 3 h at 120 ° C, the selectivity of desired product dropped to only 33.8% in anhydrous

DMSO. Due to much increased formation of by-products, the selectivity of desired product decreased to 60.4% in v w

= 0.17 system, while the selectivity of desired product still remained at the level of 70% with v w

= 0.30–1 under these conditions. The difference between glucose conversions and total product yields as shown in

represents unaccounted by-products. However, as illustrated in Figs. S1 and S2 , no obvious other products could be detected by HPLC analysis except the known compounds. The difference could be ascribed to the formation of polymeric byproducts or humins

[45] . Mass balance is an important indicator

for a reaction, and further study is essential for reducing mass loss by circumventing undesired side reactions and humin formation.

When the reaction temperature was elevated to 130 ° C, HMF production was further improved. As illustrated in

d, after

3 h, the HMF yields in DMSO/H

2

O with v w

= 0.17, 0.30 and 0.50

reached up to 35%, 33.5% and 31.6%, respectively, which were much higher than that (24.5%) in anhydrous DMSO. Although a

Fig. 2.

Effect of temperature on the catalytic conversion of glucose in different DMSO/H

2

O mixtures. (a) 120 ° C, 1 h; (b) 120 ° C, 2 h; (c) 120 ° C, 3 h; (d) 130 ° C, 3 h. Conditions:

50 mg of glucose with CrCl

3

6H

2

O (5 mol% with respect to glucose) was added into 1 mL of DMSO/H

2

O solvent and heated at 120 ° C or 130 ° C for different times.

S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339 little more by-products (22.5%) were produced in anhydrous DMSO after 3 h at 130 ° C, the cellobiose yield (9.2%) was lower than that

(13.4%) after 3 h at 120 ° C, possibly because more cellobiose underwent deep polymerization into cellotriose, cellotetrose and even oligomers. The above results further demonstrate that an appropriate aqueous DMSO system is more beneficial for the

HMF production under specified conditions.

The blank tests for glucose conversion were also studied in different DMSO/H

2

O systems. As seen in Table S1 , when the reactions were run at 120 ° C for 2 h, negligible glucose conversions were observed. However, the glucose conversion reached about 10.8% with cellobiose (9.1%) as the primary product in anhydrous DMSO at 130 ° C for 2 h. The results indicate that pure DMSO system is capable of causing the undesired direct dehydration of glucose even in the absence of a catalyst. However, the available water in

DMSO could effectively suppress the side reactions, which explains why lower yields of by-products were formed in aqueous systems.

As reported in the literature, fructose is generally considered as the intermediate for the conversion of glucose into HMF

.

We also studied how water content affected the conversion of fructose into HMF in varied DMSO/H

2

O systems with CrCl

3

6H

2

O.

Fig. S3 presents the results for blank tests of fructose conversion in different DMSO/H

2

O mixtures. It was found that fructose underwent effective dehydration into HMF in anhydrous DMSO even without a catalyst, which is consistent with the existing literature

. At 120 ° C for 1 h, fructose conversion was 86% with HMF yield of 56.4%, and at 130 ° C for 1 h, fructose was almost completely converted with HMF yield of 67.2%. However, the dehydration of fructose into HMF stopped when only a little water (i.e.

v w

= 0.17) was added, indicating that the available water in the system was detrimental to the conversion of fructose in the absence of a catalyst.

When CrCl

3

6H

2

O (5 mol% with respect to fructose) was added, the dehydration of fructose was recovered at different levels in different DMSO/H

2

O systems. As illustrated in

, moderate to high yield of HMF could be achieved in v w

= 0.17–0.50 systems.

However, HMF production remained at a low level when v w was higher than 0.50, which is consistent with the low HMF yields from glucose at v w

> 0.50 as shown in

a. CrCl

3

6H

2

O could be hydrolyzed into Cr species and HCl in an aqueous solution. In previous works, Cr species was proposed as the catalyst for the isomerization of glucose

, while HCl worked for the conversion of fructose

[40] . Therefore, the different levels of HMF

yield in

could be attributed to the pH value in available water. We then checked the above hypothesis by employing two

337

DMSO/H

2

O solutions with v w

= 0.30 and 0.50. The v w

= 0.30 system contained 3.7 mg of CrCl

3

6H

2

O and 100 l L of water, while the v w

= 0.50 system contained 3.7 mg of CrCl

3

6H

2

O and 200 of water. On the assumption that HCl was formed by CrCl

3

6H l L

2

O hydrolysis in available water, the pH values of the two CrCl

3 solutions with concentrations of 3.7 mg/100

6H

2

O l L and 3.7 mg/200 l L were 2.08 and 2.34, respectively, at room temperature. However, the conversion of fructose was conducted at 120 ° C for 1 h, high temperature would accelerate the hydrolysis of CrCl

3 leading to a low pH value

. After the above CrCl

3

6H

2

6H

2

O,

O solutions were heated at 120 ° C for 1 h, the corresponding pH values dropped to 1.09 and 1.42, respectively. Then two solutions with pH of 1.09 and 1.42 were prepared by diluting concentrated HCl solution, and used for fructose conversion. As shown in

fructose conversions and HMF yields in DMSO/H

2

O with

(900 l L DMSO/100 l L H

2

O, pH(H

2

O) = 1.09) and v w

= 0.30

v w

= 0.50 (800 l L

DMSO/200 l L H

2

O, pH(H

2

O) = 1.42) were comparable to those with CrCl

3

6H

2

O as catalyst, indicating that the conversion of fructose in aqueous DMSO system is correlated with the pH value in available water.

As shown in

Fig. 3 , glucose was also detected in the reaction.

According to previous literature, the isomerization between glucose and fructose is reversible

. Most recent work also indicates that CrCl

3

6H

2

O catalyzed the conversion of aldoses (i.e. glucose, xylose) and established a reversible path between aldose and ketose (i.e. fructose, xylulose)

. Therefore, the formation of glucose from fructose is expected. As shown in Fig. S4 , when the reaction time was extended or the temperature was elevated, the

HMF yields in DMSO/H

2

O systems with v w

= 0.30 or 0.50 were further improved, either superior or very close to that in anhydrous

DMSO, which is consistent with the results that HMF production from glucose was superior or close to that in anhydrous DMSO

(

b–d). The results indicate that the negative effect of water on the dehydration of fructose into HMF could be overcome by adding a catalyst under specified conditions.

We finally tested the stability of HMF in different DMSO/H

2

O mixtures. As seen in

Table 1 , HMF was essentially stable in

DMSO/H

2

O with v w

6

0.50 at 120 ° C in the absence of a catalyst, of which the recovery was higher than 95%. However, when the v w was further increased, HMF recovery slightly decreased. Tsilomelekis et al. recently studied the origin of HMF stability in

DMSO/D

2

O mixtures

. It was found that DMSO could bind to both the hydroxyl and carbonyl groups of HMF more strongly than water. When HMF was solvated by DMSO, the LUMO energy of

HMF was higher, which indicates that solvation by DMSO reduces

Fig. 3.

Catalytic conversion of fructose in different DMSO/H

2

O mixtures at 120 ° C for 1 h. Conditions: 50 mg of fructose and CrCl

3

6H

2

O (5 mol% with respect to fructose) were added into 1 mL of DMSO/H

2

O solvent and heated at 120 ° C for 1 h.

Fig. 4.

Comparison on the dehydration of fructose into HMF in DMSO/H

2

O with v w

= 0.30 and 0.50 in the presence of CrCl

3

6H

2

O and HCl at 120 ° C for 1 h.

338 S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339

Table 1

Stability of HMF in different DMSO/H

2

O systems.

v w

0 0.17

0.30

0.50

0.72

1

HMF recovery (%) without catalyst 96.3

96.1

96.9

96.8

92.9

92.2

HMF recovery

(%) with catalyst 97.3

96.0

95.3

89.2

89.1

86.6

Reaction conditions: 17 mg of HMF and 1 mL of solvent were added into each reaction vial and heated at 120 ° C for 2 h.

a

3.7 mg of CrCl

3

6H

2

O (10 mol% with respect to HMF) was added.

its susceptibility to nucleophilic attack, therefore minimizing undesirable hydrolysis of HMF and humin formation

HMF/DMSO/D

2

O ternary mixtures, DMSO preferentially solvated the carbonyl group of HMF if v

D2O was less than 0.4

, which may explain why HMF was more stable at v w

= 0–0.50 without a catalyst in this work. Since HMF was produced from glucose or fructose under catalytic reaction conditions, the stability of HMF was also examined in the presence of CrCl

3 stable at v w

6

6H

2

O. HMF was still

0.30, while its recovery showed remarkable decrease than those without catalyst at v w

P 0.50, possibly because the solvation of DMSO was disrupted to some extent, and the catalyst, especially the formed HCl, caused the degradation of HMF. In previous study, it is also reported that in DMSO/H

2

O binary mixtures, the local tetrahedral structure of water is still preserved in the presence of DMSO molecules at higher water content

( v w

> 0.5)

. However, in the DMSO-rich system ( v w

< 0.5),

DMSO molecules retain the same molecular arrangement as in the pure state

[34] , which offers a perspective basis for the stability

of HMF. In brief, DMSO is a solvent capable of stabilizing HMF and the stabilization persists in the presence of an appropriate amount of water.

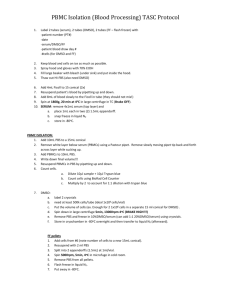

In the end, we use

to summarize the conversion of glucose in DMSO/H

2

O mixed solvents. Anhydrous DMSO with CrCl

3

6H

2

O significantly accelerated glucose conversion, leading to effective production of HMF. In the meantime, however, glucose is apt to undergo undesired dehydration to produce cellobiose, AGP and

AGF as well at high temperature, reducing the selectivity of desired product. In the literature, glucose was converted in DMSO at 120 or

140 ° C with about 100% conversion and 50% yield of HMF

but the large difference between glucose conversion and HMF yield was not explained. The results in this work imply that by-product such as cellobiose, AGP and AGF may account for bulk of the missing products. However, a number of other products remained unknown, possibly humins. Compared with anhydrous DMSO system, the key role of added water in DMSO was to suppress the undesired dehydration of glucose. Water addition also limited the dehydration of in situ formed fructose into HMF in DMSO without a catalyst. CrCl

3

6H

2

O catalyzed the isomerization of glucose. HCl from the hydrolysis of CrCl

3

6H

2

O was sufficient for the dehydration of fructose into HMF. In aqueous solution, HMF also is known to undergo hydrolysis to form LA and FA under acid catalyzed conditions

[5,23] . However, only a very low amount of LA

was detected in this work, which may be explained by the following reasons: (1) LA was effectively synthesized from carbohydrates at temperature up to 160–200 ° C in strongly acidic media

, while the employed conditions in this work were much milder; (2) at v w

< 0.5, the DMSO/H

2

O systems preserved the DMSO-like properties, which may suppress the side reactions as mentioned above

[5,25,51] ; (3) although the reaction media had water-like proper-

ties at v w

> 0.5, HMF formation was much inhibited, and the low

HMF concentration in the media would not effectively drive the equilibrium into LA.

4. Conclusions

Water content in DMSO/H

2

O binary mixture effectively affected the product distribution in the catalytic conversion of glucose.

Anhydrous DMSO system was favored for the effective production of HMF from glucose but also gave rise to many side reactions, such as the undesired intermolecular and intramolecular dehydrations of glucose. The key role of added water in DMSO was to suppress undesired formation of cellobiose, AGP and APF so that to improve the selectivity of desired product. Employing a catalyst in an appropriate DMSO/H

2

O mixed solvent may overcome the limitation of water addition on the dehydration of fructose into HMF.

With v w

= 0.17–0.50, HMF yield reached up to 35% after 3 h at

130 ° C, which was much higher than that obtained in anhydrous

DMSO. Therefore, tuning the water content in DMSO is an effective approach to achieve high HMF yield. CrCl

3

6H

2

O catalyzed the isomerization of glucose into fructose. The conversion of fructose into HMF was achieved by HCl from the hydrolysis of CrCl

3

6H

2

O, and by a comparable acid concentration with the same pH value in available water of the DMSO/H

2

O mixture. HMF was stable in

DMSO/H

2

O with v w

6

0.30 with or without CrCl

3

6H

2

O in this work, implying that a certain amount of water was tolerated in

DMSO in terms of HMF stability. In short, although effective water removal is pronounced toward the enhanced production of HMF from hexose dehydration in previous work, a system with an appropriate amount of water is superior to an anhydrous system in producing HMF by effectively circumventing side reactions.

Fig. 5.

Schematic diagram on the conversion of glucose in DMSO/H

2

O binary mix system.

the online version, at

S. Jia et al. / Chemical Engineering Journal 254 (2014) 333–339

The results reported herein may provide reference information for the one-pot synthesis of HMF from cellulosic materials, because water is necessary for the hydrolysis of the polymer feedstocks.

Acknowledgements

This work was supported by the China Postdoctoral Science

Foundation (2013M530952, 2013M540236), National Natural

Science Foundation of China (21306186), and the Chinese Government ‘‘Thousand Talent’’ program funding.

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in

References http://dx.doi.org/10.1016/j.cej.2014.05.121

.

[1] P. Gallezot, Conversion of biomass to selected chemical products, Chem. Soc.

Rev. 41 (2012) 1538–1558 .

[2] J.A. Melero, J. Iglesias, A. Garcia, Biomass as renewable feedstock in standard refinery units. Feasibility, opportunities and challenges, Energy Environ. Sci. 5

(2012) 7393–7420 .

[3] P. Mäki-Arvela, B. Holmbom, T. Salmi, D.Y. Murzin, Recent progress in synthesis of fine and specialty chemicals from wood and other biomass by heterogeneous catalytic processes, Catal. Rev. 49 (2007) 197–340 .

[4] R.v. Putten, J.C.v.d. Waal, E.d. Jong, C.B. Rasrendra, H.J. Heeres, J.G.d. Vries,

Hydroxymethylfurfural a versatile platform chemical made from renewable resources, Chem. Rev. 113 (2013) 1499–1597 .

[5] Y. Román-Leshkov, J.N. Chheda, J.A. Dumesic, Phase modifiers promote efficient production of hydroxymethylfurfural from fructose, Science 312

(2006) 1933–1937 .

[6] X. Tong, Y. Li, Efficient and selective dehydration of fructose to 5hydroxymethylfurfural catalyzed by Brønsted-acidic ionic liquids,

ChemSusChem 3 (2010) 350–355 .

[7] J.B. Binder, R.T. Raines, Simple chemical transformation of lignocellulosic biomass into furans for fuels and chemicals, J. Am. Chem. Soc. 131 (2009)

1979–1985 .

[8] A.H. Jadhav, A. Chinnappan, R.H. Patil, S.V. Kostjuk, H. Kim, Green chemical conversion of fructose into 5-hydroxymethylfurfural (HMF) using unsymmetrical dicationic ionic liquids under mild reaction condition, Chem.

Eng. J. 243 (2014) 92–98 .

[9] C. Sievers, I. Musin, T. Marzialetti, M.B.V. Olarte, P.K. Agrawal, C.W. Jones, Acidcatalyzed conversion of sugars and furfurals in an ionic-liquid phase,

ChemSusChem 2 (2009) 665–671 .

[10] N. Jiang, R. Huang, W. Qi, R. Su, Z. He, Effect of formic acid on conversion of fructose to 5-hydroxymethylfurfural in aqueous/butanol media, Bioenerg. Res.

5 (2012) 380–386 .

[11] Z. Zhang, B. Liu, Z. Zhao, Conversion of fructose into 5-HMF catalyzed by GeCl

4 in DMSO and [Bmim]Cl system at room temperature, Carbohydr. Polym. 88

(2012) 891–895 .

[12] V.V. Ordomsky, J.C. Schouten, J. Schaaf, T.A. Nijhuis, Foam supported sulfonated polystyrene as a new acidic material for catalytic reactions,

Chem. Eng. J. 207–208 (2012) 218–225 .

[13] Q.

Bao, K.

Qiao, D.

Tomida, C.

Yokoyama, Preparation of 5hydroymethylfurfural by dehydration of fructose in the presence of acidic ionic liquid, Catal. Commun. 9 (2008) 1383–1388 .

[14] A. Corma, S. Iborra, A. Velty, Chemical routes for the transformation of biomass into chemicals, Chem. Rev. 107 (2007) 2411–2502 .

[15] H. Zhao, J.E. Holladay, H. Brown, Z.C. Zhang, Metal chlorides in ionic liquid solvents convert sugars to 5-hydroxymethylfurfural, Science 316 (2007)

1597–1600 .

[16] C. Li, Z. Zhang, Z.K. Zhao, Direct conversion of glucose and cellulose to 5hydroxymethylfurfural in ionic liquid under microwave irradiation,

Tetrahedron Lett. 50 (2009) 5403–5405 .

[17] Y. Zhang, E.A. Pidko, E.J.M. Hensen, Molecular aspects of glucose dehydration by chromium chlorides in ionic liquids, Chem. Eur. J. 17 (2011) 5281–5288 .

[18] Y. Yi, M. Ha, J. Lee, C. Chung, New role of chromium fluoride: its catalytic action on the synthesis of hydroxymethylfurfural in ionic liquid using raw plant biomass and characterization of biomass hydrolysis, Chem. Eng. J. 180 (2012)

370–375 .

[19] Y. Su, H.M. Brown, X. Huang, X. Zhou, J.E. Amonette, Z.C. Zhang, Single-step conversion of cellulose to 5-hydroxymethylfurfural (HMF), a versatile platform chemical, Appl. Catal. A 361 (2009) 117–122 .

[20] J. Zhang, Y. Cao, H. Li, X. Ma, Kinetic studies on chromium-catalyzed conversion of glucose into 5-hydroxymethylfurfural in alkylimidazolium chloride ionic liquid, Chem. Eng. J. 237 (2014) 55–61 .

339

[21] Z. Yuan, C. Xu, S. Cheng, M. Leitch, Catalytic conversion of glucose to 5hydroxymethyl furfural using inexpensive co-catalysts and solvents,

Carbohydr. Res. 346 (2011) 2019–2023 .

[22] C.B. Rasrendra, J.N.M. Soetedjo, I.G.B.N. Makertihartha, S. Adisasmito, H.J.

Heeres, The catalytic conversion of

D

-glucose to 5-hydroxymethylfurfural in

DMSO using metal salts, Top. Catal. 55 (2012) 543–549 .

[23] B.F.M. Kuster, 5-Hydroxymethylfurfural (HMF). A review focussing on its manufacture, Starch/Stärke 42 (1990) 314–321 .

[24] K.

Shimizu, R.

Uozumi, A.

Satsuma, Enhanced production of hydroxymethylfurfural from fructose with solid acid catalysts by simple water removal methods, Catal. Commun. 10 (2009) 1849–1853 .

[25] G. Tsilomelekis, T.R. Josephson, V. Nikolakis, S. Caratzoulas, Origin of 5hydroxymethylfurfural stability in water/dimethyl sulfoxide mixtures,

ChemSusChem 7 (2014) 117–126 .

[26] H. Kimura, K. Yoshida, Y. Uosaki, M. Nakahara, Effect of water content on conversion of

D

-cellobiose into 5-hydroxymethyl-2-furaldehyde in a dimethyl sulfoxide-water mixture, J. Phys. Chem. A 117 (2013) 10987–10996 .

[27] S. Jia, K. Liu, Z. Xu, P. Yan, W. Xu, X. Liu, Z.C. Zhang, Reaction media dominated product selectivity in the isomerization of glucose by chromium trichloride: from aqueous to non-aqueous systems, Catal. Today (2014), http://dx.doi.org/

10.1016/j.cattod.2014.02.038

.

[28] D.H. Rasmussen, A.P. MacKenzie, Phase diagram for the system waterdimethylsulphoxide, Nature 220 (1968) 1315–1317 .

[29] J.M.G. Cowie, P.M. Toporowski, Association in the binary liquid system dimethylsulphoxide-water, Can. J. Chem. 39 (1961) 2240–2243 .

[30] I. Brovchenko, A. Oleinikova, Interfacial and Confined Water, Elsevier, 2008 .

[31] E. Antoniou, Structure-property relationships in associating polymer solutions.

(Dissertation) State University of New York at Buffalo, 2008.

[32] S.E. McLain, A.K. Soper, A. Luzar, Investigations on the structure of dimethyl sulfoxide and acetone in aqueous solution, J. Chem. Phys. 127 (2007) 174515 .

[33] N. Zhang, W. Li, C. Chen, J. Zuo, Molecular dynamics simulation of aggregation in dimethyl sulfoxide-water binary mixture, Comput. Theor. Chem. 1017

(2013) 126–135 .

[34] Y. Koga, Y. Kasahara, K. Yoshino, K. Nishikawa, Mixing schemes for aqueous dimethyl sulfoxide: support by X-ray diffraction data, J. Solution Chem. 30

(2001) 885–893 .

[35] http://en.wikipedia.org/wiki/Glucose (checked on May 23th, 2014).

[36] http://www.gaylordchemical.com/uploads/images/pdfs/literature/

102B_english.pdf

(checked on May 23th, 2014).

[37] http://en.wikipedia.org/wiki/

Fructose#Fructose_solubility_and_crystallization (checked on May 23th,

2014).

[38] K. Tahvildari, S. Taghvaei, M. Nozari, The study of hydroxymethylfurfural as a basic reagent for liquid alkanes fuel manufacture from agricultural wastes, Int.

J. Chem. Environ. Eng. 2 (2011) 62–68 .

[39] http://ntp.niehs.nih.gov/ntp/htdocs/chem_background/exsumpdf/ hydroxymethyl.pdf

(checked on May 23th, 2014).

[40] V. Choudhary, S.H. Mushrif, C. Ho, A. Anderko, V. Nikolakis, N.S. Marinkovic, A.I.

Frenkel, S.I. Sandler, D.G. Vlachos, Insights into the interplay of Lewis and

Brønsted acid catalysts in glucose and fructose conversion to 5-

(hydroxymethyl)furfural and levulinic acid in aqueous media, J. Am. Chem.

Soc. 135 (2013) 3997–4006 .

[41] V. Choudhary, A.B. Pinar, R.F. Lobo, D.G. Vlachos, S.I. Sandler, Comparison of homogeneous and heterogeneous catalysts for glucose-to-fructose isomerization in aqueous media, ChemSusChem 6 (2013) 2369–2376 .

[42] Y.B. Tewari, Thermodynamics of industrially-important, enzyme-catalyzed reactions, Appl. Biochem. Biotechnol. 23 (1990) 187–203 .

[43] C. E. Wyman, Aqueous Pretreatment of Plant Biomass for Biological and

Chemical Conversion to Fuels and Chemicals (This edition first published

2013), John Wiley & Sons Ltd.

[44] R.S. Assary, P.C. Redfern, J.R. Hammond, J. Greeley, L.A. Curtiss, Computational studies of the thermochemistry for conversion of glucose to levulinic acid, J.

Phys. Chem. B 114 (2010) 9002–9009 .

[45] A.A.

Rosatella, S.P.

Simeonov, R.F.M.

Frade, C.A.M.

Afonso, 5-

Hydroxymethylfurfural (HMF) as a building block platform: Biological properties, synthesis and synthetic applications, Green Chem. 13 (2011)

754–793 .

[46] A.S. Amarasekara, L.D. Williams, C.C. Ebede, Mechanism of the dehydration of

D

-fructose to 5-hydroxymethylfurfural in dimethyl sulfoxide at 150 ° C: an

NMR study, Carbohydr. Res. 343 (2008) 3021–3024 .

[47] V. Choudhary, S.I. Sandler, D.G. Vlachos, Conversion of xylose to furfural using

Lewis and Brønsted acid catalysts in aqueous media, ACS Catal. 2 (2012) 2022–

2028 .

[48] B. Girisuta, K. Dussan, D. Haverty, J.J. Leahy, M.H.B. Hayes, A kinetic study of acid catalysed hydrolysis of sugar cane bagasse to levulinic acid, Chem. Eng. J.

217 (2013) 61–70 .

[49] L. Peng, L. Lin, J. Zhang, J. Zhuang, B. Zhang, Y. Gong, Catalytic conversion of cellulose to levulinic acid by metal chlorides, Molecules 15 (2010) 5258–5272 .

[50] R. Weingarten, Y.T. Kim, G.A. Tompsett, A. Fernández, K.S. Han, E.W. Hagaman,

W.C. Conner Jr., J.A. Dumesic, G.W. Huber, Conversion of glucose into levulinic acid with solid metal(IV) phosphate catalysts, J. Catal. 304 (2013) 123–134 .

[51] J.N. Chheda, J.A. Dumesic, An overview of dehydration, aldol-condensation and hydrogenation processes for production of liquid alkanes from biomassderived carbohydrates, Catal. Today 123 (2007) 59–70 .