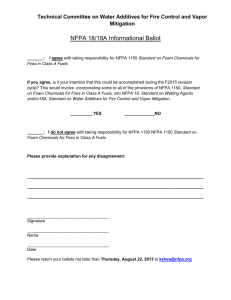

National Fire Protection Association Report

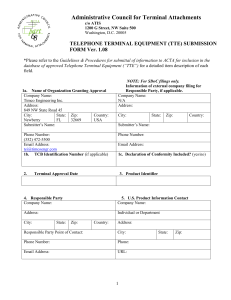

advertisement