Group Annual Report - BSH Bosch und Siemens Hausgeräte GmbH

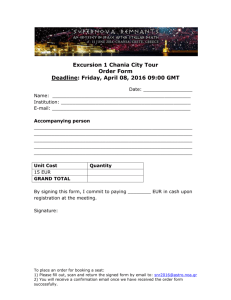

advertisement