Minimum Equipment List Policy and Procedures Manual

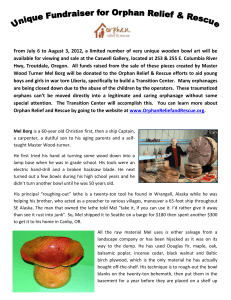

advertisement