SAADA MOHAMMED - Kwame Nkrumah University of Science

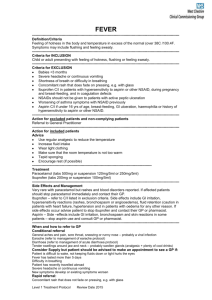

advertisement