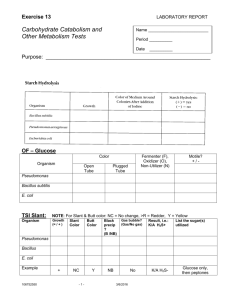

α-Amylolysis of barley starch

advertisement