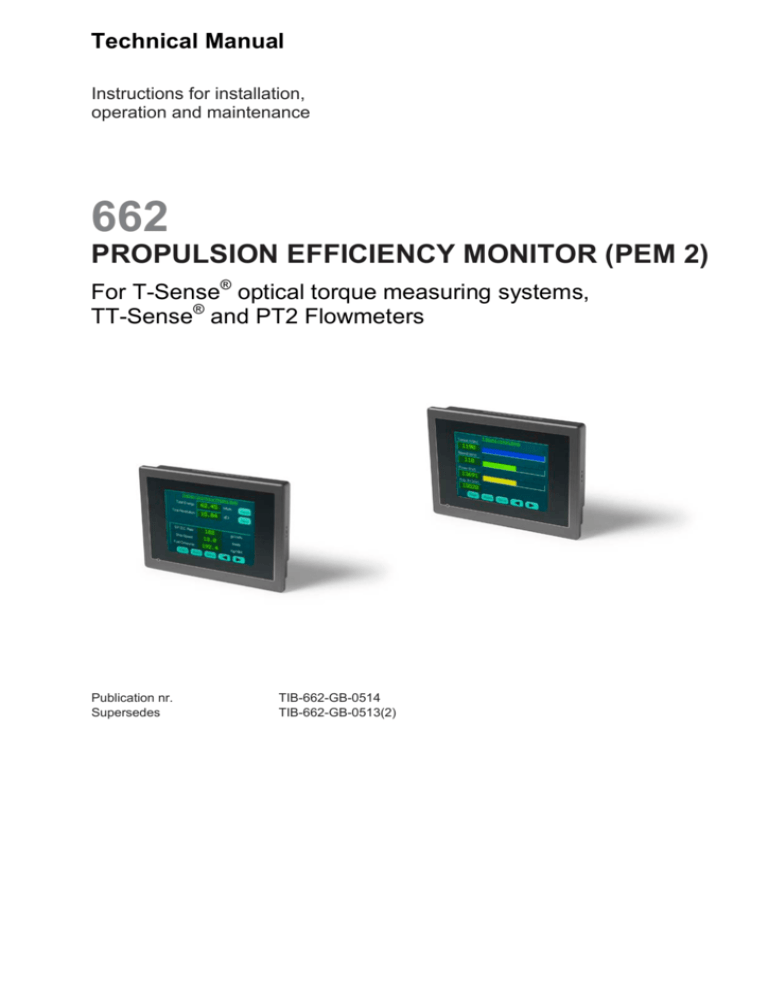

Technical Manual

Instructions for installation,

operation and maintenance

662

PROPULSION EFFICIENCY MONITOR (PEM 2)

For T-Sense® optical torque measuring systems,

TT-Sense® and PT2 Flowmeters

Publication nr.

Supersedes

TIB-662-GB-0514

TIB-662-GB-0513(2)

TABLE OF CONTENTS

1. PREFACE ....................................................................................... 3

1.1 General ........................................................................................................ 3

1.2 Symbols ....................................................................................................... 3

1.3 Copyright ..................................................................................................... 3

2. SYSTEM DESCRIPTION................................................................ 4

2.1 PEM 2 Efficiency Monitor ............................................................................. 4

2.2 System security............................................................................................ 4

3. TECHNICAL SPECIFICATIONS..................................................... 5

4. SAFETY INSTRUCTIONS .............................................................. 7

5. UNPACKING .................................................................................. 7

6. INSTALLATION AND FIRST USE .................................................. 8

6.1

6.2

6.3

6.4

6.5

6.6

To record nameplate data ............................................................................ 8

Installation diagrams .................................................................................... 9

Installation of the PEM 2 touch screen....................................................... 11

Installation of the signal processing unit (optional) .................................... 15

External connection diagram signal processing units (SPU) ...................... 16

Cable specifications ................................................................................... 17

7. OPERATING PRINCIPLES .......................................................... 18

7.1 General ...................................................................................................... 18

7.2 Displayed parameter and engineering units ............................................... 18

7.3 Explanation of the parameters ................................................................... 19

7.3.1

Torque .............................................................................................. 19

7.3.2

Shaft speed ....................................................................................... 19

7.3.3

Thrust (option)................................................................................... 19

7.3.4

Shaft generator (option) .................................................................... 19

7.3.5

Fuel oil flow consumption (option)..................................................... 19

7.3.6

Fuel oil temperature (option) ............................................................. 19

7.3.7

Ship speed via GPS (option) ............................................................. 19

7.3.8

Ship speed via pulse signal (option) ................................................. 19

7.4 Operating instructions ................................................................................ 20

7.4.1

Operating menus .............................................................................. 20

7.5 How to operate the touch screen ............................................................... 20

7.6 Method of calculations ............................................................................... 36

8. MAINTENANCE ............................................................................ 38

9. REPAIR ........................................................................................ 38

10.

TAKE OUT OF SERVICE ......................................................... 38

11.

REMOVAL AND STORAGE OF EQUIPMENT ......................... 38

12.

MALFUNCTION AND SEND FOR REPAIR ............................. 38

13.

ENVIRONMENT ....................................................................... 38

14.

DISPOSAL ................................................................................ 38

15.

TROUBLE SHOOTING ............................................................. 39

16.

EMC CLASSIFICATIONS OF THE PEM 2 ............................... 39

16.1

Certificates .............................................................................................. 39

17.

DRAWINGS .............................................................................. 40

18.

ABBREVIATIONS ..................................................................... 50

19.

SPARE PARTS......................................................................... 50

20.

WARRANTY CONDITIONS ...................................................... 51

2

1. PREFACE

1.1 GENERAL

The PEM 2 Efficiency Monitor is a microprocessor based instrument for use with the T-Sense® Optical

Torque Sensor and TT-Sense® Thrust & Torque sensor. The PEM 2 monitors and calculates several

parameters within narrow limits.

The T-Sense® torque sensor is the measuring instrument providing torque, speed and power as input

for the PEM 2 . The TT-Sense® additionally provides thrust measurements as input for the PEM 2.

This completely unique and compact total solution can be used for simple to very complicated

configurations.

The basis is a touch screen display able to fulfil standard calculations. This display can be extended

with a robust Signal Processing Unit for more complex calculations including a large number of extra

inputs.

To ensure safe and correct installation and operation, read this manual completely

before installing the equipment and starting operations.

For any additional information contact:

VAF Instruments B.V.

Vierlinghstraat 24, 3316 EL Dordrecht

P.O. Box 40, NL-3300 AA Dordrecht

The Netherlands

Tel.

Fax

E-mail:

Internet:

+31 78 618 3100

+31 78 617 7068

sales@vaf.nl

www.vaf.nl

Or your local authorized VAF dealer.

Their addresses can be found on www.vaf.nl

1.2 SYMBOLS

The following symbols are used to call attention to specific types of information.

A warning to use caution! In some instances, personal injury or damage to the instrument

or control system may result if these instructions are not followed properly.

An explanation or information of interest.

1.3 COPYRIGHT

This Technical Manual is copyrighted with all rights reserved.

While every precaution has been taken in the preparation of this manual, no responsibility for errors or

omissions is assumed. Neither is any liability assumed for damages resulting from the use of the

information contained herein. Specifications can be changed without notice.

3

2. SYSTEM DESCRIPTION

2.1 PEM 2 EFFICIENCY MONITOR

The basic version consists of a touch screen able to calculate several output data. Functions, which

can be performed with this PEM 2 Efficiency Monitor are:

Measurement and display of torque, shaft speed and power.

Calculation of average shaft power, shaft speed and torque during the last 1, 4 and 24 hours.

Calculation of total energy and total revolutions including reset.

Displaying of parameters.

The PEM 2 Efficiency Monitor is available with additional Signal Processing Unit.

This version is able to calculate above mentioned output data and in addition the Signal Processing

Unit can manage a maximum of 8 flow meter inputs together with PT100 temperature input related to

a maximum of 4 engines. Furthermore a speed log signal or GPS (NMEA) signal can be added as

input to the system. The Signal Processing Unit converts all these input signals to one RS485

Modbus signal for easy and accurate digital data transfer.

Functions, which can be performed with this PEM 2 Efficiency Monitor are:

Measurement and display of torque, shaft speed and power.

Calculation of average shaft power, shaft speed and torque during the last 1, 4 and 24 hours.

Calculation of total energy and total revolutions including reset.

Calculation of fuel consumption in kg per nautical mile, fuel consumption in kg per hour, fuel

consumption in kg per kWh (SFOC), average fuel consumption per nautical mile, fuel temperature

compensation and calculation of total fuel mass including reset.

Calculation of thrust, thrust power quotient, when a TT-Sense® Thrust & Torque sensor is installed.

Displaying of parameters.

The PEM 2 touch screen can be installed in a control cabinet or control panel.

The Signal Processing Unit can be installed in the vicinity of the flow meter(s) and/or booster unit or in

the engine control room.

Remark:

Optional 4-20 mA analogue output can be integrated in the stator control box near the T-Sense®

torque sensor. Please read paragraph 6.2 in TIB-661 for detailed information.

2.2 SYSTEM SECURITY

Besides checking the status of the torque measurement system and/or flowmeters the PEM2

Efficiency Monitor also checks itself continuously for program and configuration data integrity, normal

program flow and power supply conditions. When the system is equipped with optional Signal

Processing Unit the alarm messages will be logged.

4

3. TECHNICAL SPECIFICATIONS

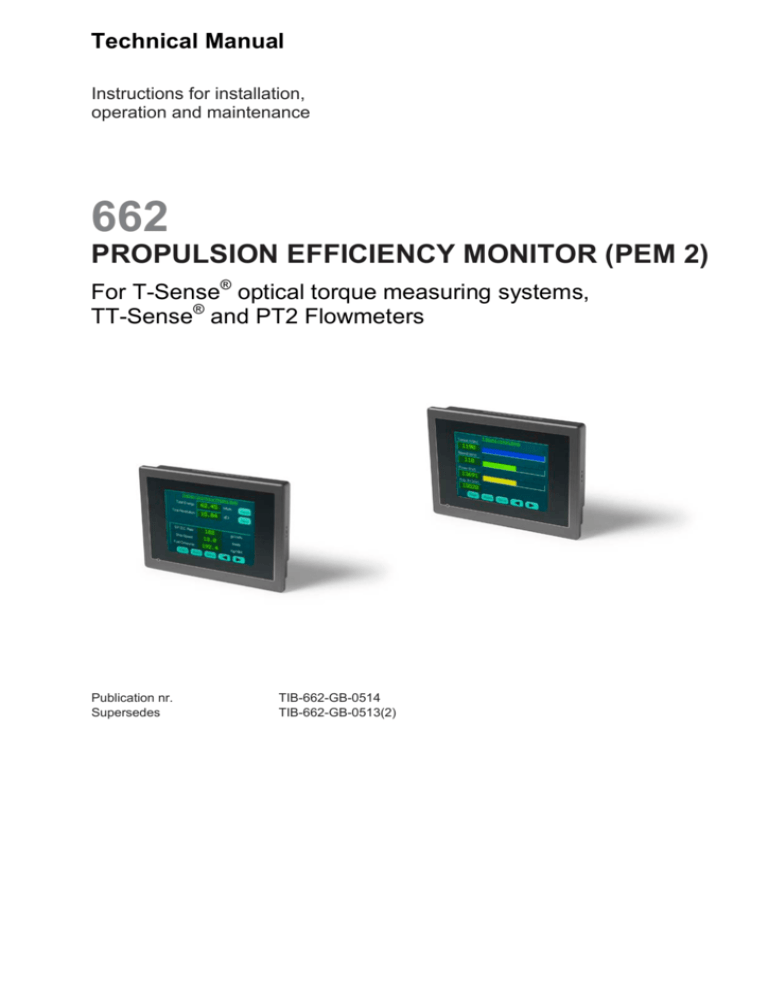

PEM 2 Touch Screen

Supply voltage

Dimensions

Cut out

Cut out depth

24 V DC ± 10%

188 x 143 x 46 mm (w x h x d)

174.5 x 132.5 mm (w x h)

40 mm

Front panel thickness

Connections

Temperature range

Display

Protection class

Power consumption

6 mm

screw terminals and RS485 connection on back panel

0 - 55 deg. C

Color TFT-Touch screen 5.6” (320x234 dots) with (optional)

adjustable LED backlight

IP 65 at front facia

10 W

Processor (CPU)

ARM926EJ-S 32bits, 200 MHz, 32 MB SDRAM

Net weight

0.8 kg

Signal Processing Unit

Supply voltage

Dimensions

CPU

Digital input

115 / 230 VAC ± 10%

600 x 300 x 155 mm (w x h x d)

Intel IXP 420, 533 MHz with 128 MB RAM

1x RS 485 Modbus connection, used for shaft speed, torque and

power input from T-Sense® torque sensor.

Analog input

1x option, used for shaft generator input (rate of propulsion power

absorbed by generator), range 4-20mA, passive signal from generator

Max. 8. flow meter pulse inputs for a flow measurement configuration

consisting of maximally 4 engines.

1x pulse input for (Doppler) speed log.

Hall sensor input as from VAF Instruments PT2 flowmeters.

NAMUR pulses (option)

Pulse counter input

Pulse counter inputs suitable

for

PT-100 input

NMEA input

Digital output

External alarms

Net weight

Protection class

Max. 8, used for fuel temperature compensation at flowmeters.

NMEA 0183 input signal from GPS or Speedlog (option).

RS422, Talker ID “GP”, Baudrate 4800. The PEM 2 system will read

out the $GPVTG sentence (“speed over ground”)

1x RS 485 Modbus connection, used for torque, speed, power and

additional data transfer to the touch screen display or AMS (Alarm &

Monitoring System).

Galvanic separated alarms can be included (optional)

Approx. 10 kg

IP65 for box and IP54 for ventilation grill

5

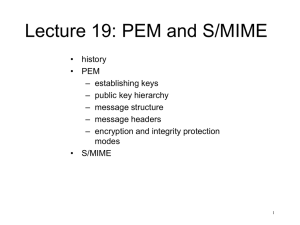

Figure 1. Signal Processing Unit and PEM 2 touch screen

4. SAFETY INSTRUCTIONS

There are no special safety instructions for the PEM 2 Equipment.

5. UNPACKING

Let the equipment acclimatize inside the closed box for at least one hour at the location where the PEM

2 will be installed.

When the equipment is taken out of the box, please leave the special protection supplied with the

equipment as long as possible in place to avoid any damage.

The special protection should be stored for the unlikely event the equipment has to be sent for repair.

Dispose of the packing material should be done according to the laws of the country where the

equipment is installed, or according to the rules that are applicable on the vessel.

Be careful when unpacking the PEM 2. The content is fragile.

Do not press on the PEM 2’s touch screen.

Be careful not to damage any of the connectors, control modules or wiring.

7

6. INSTALLATION AND FIRST USE

The PEM 2 will be delivered with the software and correct data settings installed. First connect all the

inputs and outputs to the PEM 2 components. The 110-230 volt and 24 volt wires should be connected

at last.

Note: There is no ON/OFF switch on the PEM2. When the power supply is switched on the PEM 2 will

turn on.

Check if the inputs show any errors. If that is the case the connection(s) or connected equipment(s)

should be checked and corrected.

6.1 TO RECORD NAMEPLATE DATA

This information is required when contact the supplier for any reason.

Date of delivery:

Serial number:

Hull number:

Type:

Software version:

Xx xxxxxxx xxxx

xxxxxxxxx

xxx

T-Sense® optical torque sensor

V0.xx

8

6.2 INSTALLATION DIAGRAMS

The PEM 2 touch screen and optional Signal Processing Unit can be connected to the

T-Sense® stator control box as shown in figure 2a, b, c and d.

When a TT-Sense® Thrust & Torque sensor is installed it can be connected in the same way as above

mentioned T-Sense® equipment.

Figure 2a T-Sense® torque sensor connected to one PEM 2 touch screen

Figure 2b Example of T-Sense® torque sensor connected to two PEM 2 touch screens

9

Figure 2c Example of T-Sense® torque sensor with Signal Processing Unit and PEM 2 touch screen

Figure 2d Example of T-Sense® torque sensor with Signal Processing Unit and two PEM 2 touch

screens

10

6.3 INSTALLATION OF THE PEM 2 TOUCH SCREEN

1. Install the PEM 2 touch screen in a control cabinet or control panel in the ECR or on the bridge,

where it will be free as possible from moisture, large fluctuations of temperature and particularly of

vibration shock. Also influences such as large magnetic fields caused by transformers, relays or

electromagnets must be avoided.

2. All cable connections should be made using cables as specified in paragraph 6.6.

3. Connect the RS485 Modbus cable and 24 VDC power supply to the PEM 2 touch screen in

accordance with figure 3 and 4 if the display is directly connected to the stator control box.

Important notes:

In case the PEM 2 touch screen is connected to the stator control box via a Signal

Processing Unit it is recommended to first of all go through paragraph 6.4 and the

external connection diagram in paragraph 6.5.

1

24 VDC power supply connector

2

COM 2 5 Pin terminal for data input via RS485 Modbus cable

6

COM 1 9 Pin female for data output/transfer to additional PEM 2 touch screen

Figure 3 Power supply and communication ports at backside of PEM 2 touch screen

11

Figure 4 Power supply and RS485 Modbus cable connection to PEM 2 touch screen

4. Ensure that the Modbus cable is properly shielded and grounded as close as possible to the stator

control box. The Modbus cable shield cannot be connected to the touch screen.

5. Check for correct DC supply power and integrity of external wiring connections. Turn on power and

observe several readings, like torque, shaft speed, power etc. If not, check wiring and verify whether

the inputs are in agreement with actual value.

Important notes:

Never connect cable shields at both ends to ground, but at one end only, to avoid

earth loops.

To avoid interference on the signal cables, such cables must be installed as far as

possible from electric power cables used for power supply and stator.

Ensure that the ambient temperature at the PEM 2 never exceeds 55°C (131°F).

12

6. Only applicable if an additional (second) touch screen is connected to the T-Sense® system.

Additional touch screens are connected to the system as described in figure 5.

Plug in a DB9 male connector into the COM 1 output port at the aft side of touch screen 1 and

connect COM 1 to the 5 pin terminal COM 2 at touch screen 2 as described in figure 5.

The cable connecting the two touch screens is a Modbus RS485 cable as specified in paragraph

6.6.

Check for correct DC supply power and integrity of external wiring connections. Turn on power and

observe several readings, like torque, shaft speed, power etc. If not, check wiring and verify whether

the inputs are in agreement with actual value.

RS485

MODbus

Figure 5 Connection of a 2nd touch screen to COM 1 output port of touch screen 1

13

7. Only applicable if RS485 output signal is required from the touch screen to an external system like

an AMS or external Efficiency Monitoring system.

Additional systems are connected to the COM 1 output port as described in item 6 and figure 5.

From the COM1, DB9 connector on the backside of the touch screen you can communicate through

Modbus with the PEM2 touch screen and read out the registers. The pin out of the connector is:

1 to B (DATA +), 6 to A (DATA -) and 5 to GND.

The settings to communicate with the touch screen are:

- Serial interface:

RS485

- Communication protocol:

Modbus RTU

- Baud rate:

115200

- Data bits:

8

- Stop bits:

1

- Parity:

None

- Function code:

3 (Holding Registers)

All the by VAF Instruments presented register addresses are described in a file called “TSense®_Modbus_tags”. In this file the applicable register address and corresponding units of the

read-out values can be found. Please contact VAF in case you like to receive this file or if you like to

have more information about the Modbus tags.

Be aware that the Modbus read-out values are presented as two 16 bits integers, which have to be

converted to a 32-bits float. A 32 bits IEEE 754 floating point number is a mathematical formula that

allows any real number with decimal points to be represented by 32 bits with an accuracy of seven

digits. For more info please check the IEEE 754 standard for binary floating point arithmetic.

14

6.4 INSTALLATION OF THE SIGNAL PROCESSING UNIT (OPTIONAL)

Only applicable if flowmeters or speed log/GPS/NMEA signals are incorporated in the PEM 2

Efficiency Monitoring System.

1. Always install the SPU with cable glands facing downwards. Do not take electronics out of the

cabinet.

2. Install the Signal Processing Unit in the engine room, engine control room or near to the HFO

booster units, but as much as possible free from moisture, large fluctuations of temperature and

particularly of vibration shock. Also influences such as large magnetic fields must be avoided.

Ambient temperature should under all circumstances be lower than 55°C (131°F). External

dimensions drawings of the Signal Processing Unit can be found in chapter 17.

3. Connect the RS485 Modbus output from the stator control box to the Signal Processing Unit in

accordance with the external connection diagram in paragraph 6.5.

4. Connect the signal outputs from flowmeters, speed log and/or shaft generator to the Signal

Processing Unit in accordance with the external connection diagram in paragraph 6.5. Cable shields

of flow meter cables should always be connected to the Signal Processing Unit only.

5. Connect the RS485 Modbus output from the Signal Processing Unit to the PEM 2 touch screen in

accordance with the external connection diagram in paragraph 6.5 and figure 3 and 4 in paragraph

6.3. Cable shield of the cable to the PEM 2 touch screen to be connected to the Signal Processing

Unit.

6. Ensure that all relevant signal cables are properly connected and grounded.

7. In order to have a proper data synchronisation from the Signal Processing Unit to the touch

screen(s), first connect the 115/230 VAC power supply to the SPU than subsequently connect the

24 VDC power supply to the first PEM 2 touch screen and press RUN and connect the 24 VDC

power supply to the second touch screen (if available) and press RUN.

Check if the output data is available on the touch screen(s). If any applicable output data is not

available on the touch screen a pop-up alarm screen describing the failure(s) will show up.

Important notes:

Never connect cable shields at both ends to ground, but at one end only, to avoid

earth loops.

To avoid interference on the signal cables, such cables must be installed as far as

possible from electric power cables used for power supply and stator.

Ensure that the ambient temperature at the Signal Processing Unit never exceeds

55°C (131°F).

15

6.5 EXTERNAL CONNECTION DIAGRAM SIGNAL PROCESSING UNITS (SPU)

The table Project Specific Flow Meter Data provides you with detailed information regarding flowmeter

configuration and wiring of terminal numbers 10 until 57. This table belongs to technical manual TIB662 in case flow meters are incorporated in the PEM 2 system.

= terminated at cable gland

POWER SUPPLY

B A

Figure 6. External connection diagram PEM 2 Signal Processing Unit

16

6.6 CABLE SPECIFICATIONS

Specification for the input, output and power supply cables connected to the Signal Processing Unit

and PEM 2 touch screen(s).

Power supply PEM 2 touch screen

24 V DC

cable 2x0,75 mm²

Power supply Signal Processing Unit

115/230 VAC, single phase

cable 3x1,5 mm²

screened

Output signal control box

Modbus, RS485 from

Control box to touch screen

cable 2x 2x0,75 mm²

twisted pair, screened

PEM2 touch screen to additional PEM2 touch screen

Modbus, RS485 from

touch screen to touch screen

cable 2x 2x0,50 mm²

twisted pair, screened

Input signals Signal Processing Unit

Modbus, RS485 from T-Sense

control box

cable 2x 2x0,75 mm²

twisted pair, screened

Flowmeter type PT2

(+ PT100)

2x 3x0,75 mm² individually screened, twisted pair or

4x 2 x0,75 mm² individually screened, twisted pair

Speedlog

2x0,75 mm²

shielded

GPS (NMEA 0183)

T+/T- are input to R+/R- of

PEM 2

2x0,75 mm²

Shielded

Shaft generator power

(optional)

cable 1x 2x0,75 mm²

twisted pair, screened

Table 1. Specification of input and output cables at Signal Processing Unit and touch screen

17

7. OPERATING PRINCIPLES

7.1 GENERAL

A zero setting procedure is always necessary in order to obtain a correct measurement and reading.

For more detailed information see paragraph 6.3 in TIB-661 of the T-Sense® torque sensor.

The PEM 2 Efficiency Monitor is easy to operate and provides the operator with a wide selection of

detailed process data. A number of conditional messages will inform you about error/fault conditions.

Setups determining functionality are subdivided in two levels and access is only possible via a right-ofaccess code. All setups and computations are stored in a battery backup RAM. The PEM 2 system is

self-checking as for correct functioning of its memories, program run and existence of supply voltage.

7.2 DISPLAYED PARAMETER AND ENGINEERING UNITS

The following parameters are available:

Torque

Shaft speed

Shaft power

Total energy

Total mass

Time-base

(kNm)

(rpm)

(kW)

(kWh, MWh, GWh)

(kg)

(seconds)

Option:

Shaft generator power (to calculate total power)

Fuel flowmeters (max. 8x)

K-factors flowmeters

Fuel temperature sensors (8x)

Ship speed via GPS or

Ship speed via pulse signal

Ship speed (input)

Fuel consumption

Specific gravity

Gravity change

Ref. temperature

Specific Fuel Oil Consumption (SFOC)

Propeller thrust

Thrust power quotient

(kW or MW)

(l/min)

(pulses/litre)

(°C)

(knots)

(knots)

(pulses/mile)

(kg/h or kg/NM)

(kg/l)

(%/°C)

(°C)

(g/kWh)

(kN)

(kN/MW)

18

7.3 EXPLANATION OF THE PARAMETERS

7.3.1 Torque

The torque signal, measured in the rotor part, is sent wireless via the stator antenna into the electronics

in the control box. In this control box the signal is converted to a RS485 Modbus signal, which signal is

connected to the PEM 2 touch screen or PEM 2 Signal Processing Unit.

The sensor configuration is set as follows:

Zero torque adjustment will be done during commissioning of the T-Sense® rotor and control

box.

Full scale adjustment of the bar graph range is programmed at VAF location.

7.3.2 Shaft speed

The shaft speed is measured via a gravity sensor in the T-Sense® rotor part connected wireless to the

stator electronics. The shaft speed output is connected to the PEM 2 via RS485 Modbus. Full scale

adjustment of the shaft speed and power bar graph range is programmed at VAF location.

7.3.3 Thrust (option)

In case a TT-Sense® is installed, which additionally measures the axial displacement due to propeller

thrust, the thrust values are converted to a RS485 Modbus signal in the same way as the torque and

shaft speed outputs.

7.3.4 Shaft generator (option)

The shaft generator output signal should be a current signal of 4-20mA. The input range is

programmed at VAF location. With the shaft generator value the total power of the engine can be

calculated. (Total power = Shaft power + shaft generator power).

7.3.5 Fuel oil flow consumption (option)

For this option 1 up to 8 flow meters for a maximum of 4 engines, each with a pulse transmitter, are

required as input to the PEM 2 Signal Processing Unit. The K-factor of each flow meter is programmed

at VAF location or can be set via the settings menu for VAF authorised representatives at the PEM 2

touch screen.

7.3.6 Fuel oil temperature (option)

Temperature sensors PT-100, one in each flowmeter line, are needed when a flow consumption return

system is programmed. The PT-100 sensors are connected to the PEM 2 Signal Processing Unit. The

PT-100 range is programmed in the PEM 2 no settings are needed. For accurate calculation of fuel

consumption, it is strongly recommended to connect PT100’s.

7.3.7 Ship speed via GPS (option)

The GPS signal is connected to the RS422 or RS485 port of the PEM 2 Signal Processing Unit. The

ship speed information is hidden in the NMEA-0183 protocol. The PEM 2 will detect the ship speed and

the value will be displayed in knots. No adjustments are possible.

7.3.8 Ship speed via pulse signal (option)

In this case the ship speed will be measured with a (Doppler) speed log and the pulse output signal is

transmitted to the PEM 2 Signal Processing Unit. The ship speed range is programmed at VAF location

or can be set via the settings menu for VAF authorised representatives at the PEM 2 touch screen

(default: 200 pulses/nautical mile).

19

7.4 OPERATING INSTRUCTIONS

7.4.1 Operating menus

The PEM 2 touch screen has the following operating menus:

7.4.1.1 The user mode

For daily use: In this mode all relevant system menus are displayed. With the

next screen can be displayed (scroll function).

and the

keys the

7.4.1.2 The settings mode (settings menu) for users

Only displayed after choosing the ‘settings menu’ key and entering your password (1234). The

following data can be set in this menu: the range settings of the Torque, Speed Power and Thrust bar

graphs at the PEM 2 touch screen and date and time settings. When fuel flowmeters are connected to

the PEM 2 system, specific gravity, gravity change, reference temperature and internal alarm levels can

be set in the same menu. All other adjustments are only allowed in cooperation with VAF authorized

representatives. The PEM 2 system will be discontinued from his operational functions, when the

settings mode is selected.

7.4.1.3 The settings mode (settings menu) for VAF authorised representatives

This mode is used to set the customized parameters. Only VAF authorized personnel can enter this

mode. It determines the functionality (what is on the screen, what are the in- and outputs, etc.).

These settings are programmed in our factory, on the basis of the process requirements specified by

the customer. Process control will be interrupted when the PEM 2 is in this mode.

WARNING:

WRONG SETTINGS MAY RESULT IN SYSTEM FAILURE. VAF INSTRUMENTS B.V. WILL

NOT ASSUME RESPONSIBILITY FOR OPERATIONS CARRIED OUT BY

UNAUTHORIZED PERSONS.

7.5 HOW TO OPERATE THE TOUCH SCREEN

The PEM 2 touch screen screens are designed in such a way that they are easy to operate and self

explaining. By pressing the grey keys at the touch screen the next menu is selected or specific values

can be changed.

Browsing through the menus by using the

and the

screen will help you to find the information you are looking for.

keys at the bottom of the touch

The Main and Setup keys at the bottom of the touch screen will give you direct access to

respectively the Main Menu and the Settings Menu.

In the Settings Menu you will be able to change specific values via a numeric keypad.

This keypad will be displayed after pressing the values in the grey sections at the touch screen.

The value will change when a new value is set and the Ent key is pressed. If you do not want to

change the value, pressing the Esc key will close the numeric keypad and the touch screen will

return to the previous menu. (See Figure 7 below)

20

Figure 7. Numeric keypad

In the following tables at page 21 - 31 several examples of PEM2 screens are shown and a description

of the main PEM 2 functions is added.

On page 22 - 25 the PEM 2 screens for a PEM 2 without Signal Processing Unit are described.

On page 26 - 35 the PEM 2 screens for a PEM 2 including optional Signal Processing Unit are

described.

21

PEM 2 touch screen

1) Main menu

By pushing the touch screen buttons Main and Setup at the bottom of the screen you will be able to

select the main screen or the settings menu.

The

and the

keys at the bottom will help you to browse quickly from screen to screen.

When the backlight is switched off by pressing the key it will automatically be activated again when

you are touching the screen.

2) T-Sense® monitoring

T-Sense®

TT-Sense® optional screen

This is the main screen submitting information about the actual torque, propeller speed and power at

the propeller. The bar graphs are specially designed to have a clear overview of the situation.

The Avg. 1hr power indicator in the left bottom corner makes it easy to compare the actual propulsion

power and average power during the last hour the vessel was sailing. Comparing these two values

helps the crew to efficiently detect changes in power absorption of the propulsion system.

In case a TT-Sense® Thrust & Torque sensor is applied an extra thrust monitoring screen is added to

the PEM 2 system. This screen will show you total Thrust and Power values and the average

Thrust/Power quotient during the last 1, 4 and 24 hours.

22

3) Propulsion data

The upper part of this screen is showing average propulsion data over the last 1, 4 and 24 hours.

When the propeller shaft is rotating the PEM 2 is continuously recalculating these average values.

In case the propeller shaft is not rotating the average values stay as they are.

Total energy consumed by the propeller and the total number of revolutions made by the shaft are

available at the lower part of the screen.

The Total Energy value jumps from kW to MW to GW (min. 0,000 kW and max. 9999 GW).

The Total revolutions value jumps from E3 to E6 to E9 (respectively 1000, 1x106 and 1x109

revolutions)

These total values can be set to zero anytime by pushing the Reset buttons.

After resetting Total energy and Total revolutions the previous displayed values are lost.

4) Info screen

This screen is displaying all essential data in case you to have to contact VAF Instruments regarding

your T-Sense® torque measuring system.

23

5) Settings menu

This Settings Menu is accessible by entering the 4-digit password 1234 in the Login screen. This

screen is your entrance to adjustment of the bar graph ranges and date and time setting.

Bar graph range settings:

In order to have a clear overview of the actual Torque, shaft Speed and Power it is possible to change

the displayed bar graph range in the Settings Menu.

Push the grey sections on the screen and change the Min. or Max. value via the Numeric Keypad,

which pops up.

Inverse Torque:

When the touch screen is showing a negative torque value, when sailing ahead you are able to

convert this negative value to positive by pushing the Torque Standard/Torque Inverse key once.

Pushing the Torque Inverse key once again will return the original value again.

24

Date and time settings:

Push the grey touch screen sections on the screen and change the values of date and time via the

Numeric Keypad.

Push Set to save the date and time in the PEM 2 system.

6) Alarm screen

In case the PEM 2 touch screen detects that output data is missing the system will generate a pop-up

screen showing the alarm message Communication Fail. Make sure that the cable connections are

OK and read instruction manual TIB-661 Chapter 15 - Trouble Shooting.

25

PEM 2 touch screen Signal Processing Unit included

1) Main menu

By pushing the touch screen buttons Main and Setup at the bottom of the screen you will be able to

select the main screen or the settings menu.

The

and the

keys at the bottom of the screen will help you to browse quickly from screen to

screen.

When the backlight is switched off by pressing the key it will automatically be activated again when

you are touching the screen.

2) T-Sense® monitoring

Single screw vessel

Twin screw vessel

This is the main screen submitting information about the actual torque, propeller speed and power at

the propeller. The bar graphs are specially designed to have immediate overview of the situation.

The Avg. 1hr power indicator in the left bottom corner makes it easy to compare the actual propulsion

power and average power during the last hour the vessel was sailing. Comparing these two values

helps the crew to efficiently detect changes in power absorption of the propulsion system.

26

TT-Sense® optional screen

In case a TT-Sense® Thrust & Torque sensor is applied an extra thrust monitoring screen is added to

the PEM 2 system. This screen will show you total propeller Thrust and shaft Power values and the

average Thrust/Power quotient during the last 1, 4 and 24 hours [MW = Megawatt]. Please keep in

mind that ship speed through water (STW) and propeller power and thrust are related to each other.

3) Propulsion data

Single screw

Twin screw

Above screen is showing average propulsion data over the last 1, 4 and 24 hours. When the propeller

shaft is rotating the PEM 2 is continuously recalculating these average values.

In case the propeller shaft is not rotating the average values stay as they are.

27

4) Energy overview

Total Energy and Total Revolutions are the total energy consumed by the propeller and the total

number of revolutions made by the propeller shaft.

The Total Energy value jumps from kW to MW to GW (min. 0,000 kW and max. 9999 GW).

The Total revolutions value jumps from E3 to E6 to E9 (respectively 1000, 1x106 and 1x109

revolutions) These total values can be set to zero anytime by pushing the Reset buttons.

S.F.O.C. rate indicates the Specific Fuel Oil Consumption in gramms of fuel per kilowatt per hour of

the propulsion engine(s).

In case a speedlog (Doppler log) is involved in the system this screen will show the ship speed of the

vessel through the water. In case a GPS system is used as input for ship speed this screen will show

the ship speed over ground. In case GPS speed is used local currents on the vessels route are not

taken into account in the fuel consumption calculation.

Fuel consumption in kg per Nautical Mile is fuel consumption of the propulsion engine(s) divided by

the ship speed value from the speed log or GPS system.

After resetting Total energy or Total revolutions values the previous displayed values are lost.

5) Fuel flows

This screen only occurs when fuel flow meters are involved in the PEM 2 system.

28

The flow in liters per minute indicates what the amount of fuel is, measured by the supply or return

flowmeter in the fuel system. This amount is not yet compensated for gravity change due to

temperature deviations of the fuel. Flow values will be converted to a reference temperature of 15.6°C

if temperature sensors are incorporated in the fuel system.

The difference between the Supply flow and Return flow values represents the fuel consumption per

engine.

6) Actual fuel consumption

Rate in kilogram per hour indicates the fuel consumed by the propulsion engines, diesel generator

drives or other type of consumers, which have flowmeters incorporated in their fuel system.

Specific name of the consumers can be set by VAF authorized personnel in the settings menu.

7) Total fuel consumption

Total mass in kilo gram indicates the total fuel consumed by the propulsion engines, diesel generator

drives or other type of consumers, which have flow meters incorporated in their fuel system.

Specific name of the consumers can be set by VAF authorized personnel in the settings menu.

The mass values in the left column are cumulative and fixed. The values in the right column are

resettable. The values jump from 99999 to 10000 E1 (10000x101 = 100000 [kg]).

Be aware that by pushing the Reset button the values in the right column will be set to zero and

29

the previous displayed values will be lost.

8) Info screen

This screen is displaying all essential data in case you to have to contact VAF Instruments regarding

your T-Sense® torque measuring system.

9) Settings menu

The Settings Mode for Users is accessible by entering the 4-digit password 1234 in the Login screen.

This screen is your entrance to adjustment of the bar graph ranges and date and time setting.

The Settings Mode for VAF representatives is only accessible in cooperation with your contact at the

VAF Service Department. In this mode the input data for fuel flows (pulses/liter, specific gravity etc.)

and the input of the speed log or GPS system can be adapted.

WARNING:

WRONG SETTINGS MAY RESULT IN SYSTEM FAILURE. VAF INSTRUMENTS B.V.

WILL NOT ASSUME RESPONSIBILITY FOR OPERATIONS CARRIED OUT BY

UNAUTHORIZED PERSONS.

30

10) Bar graph range settings and Torque Inverse (User settings)

In order to have a clear overview of the actual Torque, shaft Speed and Power it is possible to change

the displayed bar graph range in the Settings Menu. Push the grey sections on the screen and

change the Min. or Max. value via the Numeric Keypad, which pops up.

Inverse torque:

When the touch screen is showing a negative torque value, when sailing ahead you are able to

convert this negative value to positive by pushing the Torque Standard/Torque Inverse key once.

Pushing the Torque Inverse key will return the original value again.

11) Date and time settings (User settings)

Push the grey touch screen sections on the screen and change the values of date and time via the

Numeric Keypad.

Push Set to save the date and time in the PEM 2 system.

31

12) PEM2 System Alarm Settings (User settings)

Above screen is available for adjusting specific PEM 2 system alarms concerning torque, flow rate

and temperature of the fuel in the engines fuel system.

13) Gravity Settings (user settings)

Above screen is used for adjustment of the specific values of the fuel consumed by the engines.

In this screen the following parameters are set: specific gravity (default 0.997 kg/l), reference

temperature (Default 15.6 °C) and gravity change (default 0.070%/°C).

32

Settings mode for VAF authorised representatives.

(Only applicable if a Signal Processing Unit is in the Scope of Supply)

14) Settings speed log or GPS for Ship Speed

In above screen authorized personnel can choose for GPS(NMEA 0183) or Doppler speed log input in

case ship speed is used as input for the PEM 2 system.

Adjustment of the number of pulses per nautical mile in case a Doppler speed log is incorporated can

be done via the Numeric Keypad.

33

15) Fuel flows settings and configuration of engines and flow meters

Settings like k-factor of the flowmeters, high set point of flow temperature, net flow cut-off values etc.

are set via these screens. This mode is available for VAF authorised personnel only.

34

Alarm screens and alarm logging

(Only applicable if a Signal Processing Unit is in the Scope of Supply)

16) Alarm screens

Key starts blinking when an alarm is detected.

In case the PEM 2 system including Signal Processing Unit detects an alarm the Alarm key starts

blinking and an Alarm Message will both pop up on the touch screen and will appear on the Alarm

Screen.

The Alarm Messages will disappear when you have solved the error. When the alarm condition has

been eliminated the alarm will no longer be active and the ‘system alarm’ key stops blinking. The

messages can be read using the ‘upper’ or ‘lower’ key.

The following alarms are detected:

Alarm

Flowmeter 1-8, pulse sensor fail

Flowmeter 1-8, temp sensor fail

Flowmeter 1-8, temp high

T-Sense® 1-2, communication fail

GPS/ship speed, communication fail

Shaft Gen. 1-2, sensor fail

Possible cause

Faulty sensor or connection/cable between SPU and meter

Faulty sensor or connection/cable between SPU and meter

Temperature set point override

Connection/cable between SPU and touch screen is broken

Connection/cable between SPU and sensor is broken

Connection/cable or 4-20 mA analogue output is faulty

35

7.6 METHOD OF CALCULATIONS

Shaft power reading

Shaft power is calculated from the measured torque and the revolutions of the shaft.

Shaft power:

P

M ∙n

9 .549

P = Shaft power [kW]

M = Torque [kNm]

n = rotations per minute [rpm]

Total energy is calculated from the integrating shaft power over time

E = ∑∆P·∆t

E = Total energy [kWh]

Fuel consumption including temperature compensation:

Fuel oil specific gravity at 15.6 degr. Celsius is set as a fixed parameter in the PEM 2.

The specific gravity of the fuel oil, which is heated to a temperature t, is found as follows:

Specific gravity:

t = Specific gravity heated to a temperature t [kg/l]

15.6 = Specific gravity at reference temperature [kg/l]

gc = gravity change [%/°C]

Fuel oil consumption:

Fuel volume flow is measured by our VAF Series PT2 flowmeter, giving a fixed number of pulses per

litre to the PEM. Volume flow calculation is as follows:

v

p

K _ factor

Where K-factor = pulses per litre from flowmeter

p = number of pulses

v = volume [litre]

Total volume flow:

V v

V = Total volume [litre]

Volume flow rate

Q

v

t

Q = Flow rate [l/sec]

t = time interval [sec]

36

Qtc Q ∙ 15.6/ t

Qtc = Temperature compensated flow rate [l/sec]

t = Specific gravity heated to a temperature t

15.6 = Specific gravity at reference temperature [kg/l]

m ∙ Vtc

m = Mass [kg]

= Density [kg/l]

Vtc = Temperature compensated volume

M m

M = Total Mass [kg]

g

m

t

g = Mass flow rate [kg/sec]

t = time interval [sec]

Specific Fuel Oil Consumption rate (S.F.O.C. Rate):

SFOC

g ∙ 1000

P

SFOC = Specific Fuel Oil Consumption rate [g/kWh]

g = mass flow rate to M/E [kg/h]

P = Shaft power [kW]

Ship efficiency:

FOC

g

v

Ship efficiency → FOC = Fuel Oil Consumption [kg/Nautical Mile]

g = mass flow rate to M/E [kg/h]

v = ship speed [knots]

Thrust quotient:

T

Thrust quotient

P . 1000

T = Thrust [kN]

P = Shaft power [kW]

This quotient indicates the amount of thrust generated per MW propulsion power. The thrust

quotient is an indicator of propeller efficiency. Be aware that propeller thrust and ship speed

influence each other.

37

8. MAINTENANCE

No special maintenance is needed for the PEM 2 equipment.

The touch screen can be cleaned with a dry and clean cloth.

Do not use any cleaning product or chemical on the screen.

When removing a PEM 2 system precautions must be taken to prevent personal

injuries and damage to the touch screen and Signal Processing Unit.

9. REPAIR

Nothing on the PEM 2 system can be repaired on site.

10. TAKE OUT OF SERVICE

Switch off the 24 Volts and/or 115/230 Volts power supply.

11. REMOVAL AND STORAGE OF EQUIPMENT

Switch off the 24 Volts and 115/230 Volts power supply.

Make sure that all wires that are connected to the PEM 2 are labelled correctly so that re-installation of

the PEM 2 can be done without any errors.

Disconnect all the input and output wires.

Store the PEM 2 in a box in a cool and dry place, so that the PEM 2 cannot be damaged.

12. MALFUNCTION AND SEND FOR REPAIR

If the PEM 2 stops working completely contact VAF Instruments for instructions.

In the event the PEM 2 has to be sent back for repair, you can send it directly to:

VAF Instruments B.V.

Vierlinghstraat 24

NL-3316 EL Dordrecht

The Netherlands

13. ENVIRONMENT

The PEM 2 equipment has no negative influence on the environment during normal operation.

14. DISPOSAL

The PEM 2 equipment is made out of metal and electronics. It should be disposed according to local

laws of the country.

38

15. TROUBLE SHOOTING

If the PEM 2 does malfunction, power the PEM 2 down, check all wiring and power the PEM 2 back up

again. This will restart the program.

No torque signal

The connection between the PEM 2 and the stator control box is broken.

Check wires for damage.

Check the connections in the stator control box or in the PEM 2 Signal Processing Unit

if applicable.

No signal from shaft generator

The connection between the PEM 2 Signal Processing Unit and the shaft generator sensor is broken.

Check the wires for damage

Check the connections to the terminal strip of the PEM 2 Signal Processing Unit

(see chapter 17 Drawings)

Temperature sensor failure

The connection between the PEM 2 Signal Processing Unit and the temperature sensor is broken.

Check the wires for damage

Check all connections inside the temperature sensor.

Check the connections to the terminal strip of the PEM 2 Signal Processing Unit

(see chapter 17 Drawings)

Flowmeter alarms can occur when:

Flowmeter 1 (supply) < Flow meter 2 (return)

Flowmeter 1 (supply) >> 0 and Flow meter 2 (return) = 0

Check the wires for damage.

Check all the connections at the flow meter side.

Check the settings of the flowmeters and relevant parameters and adjust them

accordingly in cooperation with a VAF service engineer.

Temperature supply or return is too high

Adjust the maximum level(s) accordingly.

16. EMC CLASSIFICATIONS OF THE PEM 2

PEM 2 Efficiency Monitor is tested in accordance with:

General Vibration Strain, IEC publication 60068-2-6.

Also complies with EMC and ESD tests according to EN61000.

16.1 CERTIFICATES

For a torque measuring system no classification certificates are required.

39

17. DRAWINGS

40

41

42

43

44

45

46

47

B A

48

49

18. ABBREVIATIONS

PEM 2

Propulsion Efficiency Monitor 2

SPU

Signal Processing Unit

CPU

Central Processing Unit

TFT

Thin Film Transistor - Liquid Crystal Display

PT100

Temperature sensor type PT100

PT2

Type of flowmeter with Hall sensor and PT100 output

RS485

Serial interface for long distance data communication

19. SPARE PARTS

A recommended spare part list is not applicable.

50

20. WARRANTY CONDITIONS

1. Without prejudice to the restrictions stated hereinafter, the contractor guarantees both the

soundness of the product delivered by him and the quality of the material used and/or delivered for

it, insofar as this concerns faults in the product delivered which do not become apparent during

inspection or transfer test, which the principal shall demonstrate to have arisen within 12 months

from delivery in accordance with subarticle 1A exclusively or predominantly as a direct consequence

of unsoundness of the construction used by the contractor or as a consequence of faulty finishing or

the use of poor materials.

1A. The product shall be deemed to have been delivered when it is ready for inspection (if

inspection at the premises of the contractor has been agreed) and otherwise when it is ready for

shipment.

2. Articles 1 and 1a shall equally apply to faults which do not become apparent during inspection or

transfer test which are caused exclusively or predominantly by unsound assembly/installation by the

contractor. If assembly/installation is carried out by the contractor, the guarantee period intended in

article 1 shall last 12 months from the day on which assembly/installation is completed by the

contractor, with the understanding that in this case the guarantee period shall end not later than 18

months after delivery in accordance with the terms of subarticle 1A.

3. Defects covered by the guarantee intended under articles 1, 1a and 2 shall be remedied by the

contractor by repair or replacement of the faulty component either on or off the premises of the

contractor, or by shipment of a replacement component, this remaining at the discretion of the

contractor. Subarticle 3A shall equally apply if repair or replacement takes place at the site where

the product has been assembled/installed. All costs accruing above the single obligation described

in the first sentence, such as are not restricted to shipment costs, travelling and accommodation

costs or disassembly or assembly costs insofar as they are not covered by the agreement, shall be

paid by the principal.

3A.If repair or replacement takes place at the site where the product has been assembled/installed,

the principal shall ensure, at his own expense and risk, that:

a. the employees of the contractor shall be able to commence their work as soon as they have

arrived at the erection site and continue to do so during normal working hours, and moreover,

if the contractor deems it necessary, outside the normal working hours, with the proviso that

the contractor informs the principal of this in good time;

b. suitable accommodation and/or all facilities required in accordance with government

regulations, the agreement and common usage, shall be available for the employees of the

contractor;

c. the access roads to the erection site shall be suitable for the transport required;

d. the allocated site shall be suitable for storage and assembly;

e. the necessary lockable storage sites for materials, tools and other goods shall be available;

f. the necessary and usual auxiliary workmen, auxiliary machines, auxiliary tools, materials and

working materials (including process liquids, oils and greases, cleaning and other minor

materials, gas, water, electricity, steam, compressed air, heating, lighting, etc.) and the

measurement and testing equipment usual for in the business operations of the principal, shall

be available at the correct place and at the disposal of the contractor at the correct time and

without charge;

51

g. all necessary safety and precautionary measures shall have been taken and adhered to, and

all measures shall have been taken and adhered to necessary to observe the applicable

government regulations in the context of assembly/installation;

h. the products shipped shall be available at the correct site at the commencement of and during

assembly.

4. Defects not covered by the guarantee are those which occur partially or wholly as a result of:

A. non-observance of the operation and maintenance instructions or other than foreseeable normal

usage;

B. normal wear and tear;

C. assembly/installation by third parties, including the principal;

D. the application of any government regulation regarding the nature or quality of the material used;

E. materials or goods used in consultation with the principal;

F. materials or goods provided by the principal to the contractor for processing;

G. materials, goods, working methods and constructions insofar as are applied at the express

instruction of the principal, and materials or goods supplied by or on behalf of the principal;

H. components obtained from third parties by the contractor insofar as that party has given no

guarantee to the contractor.

5. If the principal fails to fulfil any obligation properly or on time ensuing from the agreement concluded

between the principal and the contractor or any agreement connected to it, the contractor shall not

be bound by any of these agreements to any guarantee regardless of how it is referred to. If, without

previous written approval from the contractor, the principal commences disassembly, repair or other

work on the product or allows it to be commenced, then every agreement with regard to guarantee

shall be void.

6. Claims regarding defects must be submitted in writing as quickly as possible and not later than 14

days after the discovery of such. All claims against the contractor regarding faults shall be void if this

term is exceeded. Claims pertaining to the guarantee must be submitted within one year of the valid

complaint on penalty of invalidity.

7. If the contractor replaces components/products under the terms of his guarantee obligations, the

replaced components/products shall become the property of the contractor.

8. Unless otherwise agreed, a guarantee on repair or overhaul work carried out by the contractor or

other services shall only be given on the correctness of the manner in which the commissioned work

is carried out, this for a period of 6 months. This guarantee only covers the single obligation of the

contractor to carry out the work concerned once again in the event of unsound work. In this case,

subarticle 3A shall apply equally.

9. No guarantee shall be given regarded the inspection conducted, advice given and similar matters.

10.Alleged failure to comply with his guarantee commitments on the part of the contractor shall not

absolve the principal from his obligations ensuing from any agreement concluded with the

contractor.

11.No guarantee shall be given on products which form a part of, or on work and services on, goods

older than 8 years.

52

Revision 0911:

Chapter 6.4: point 6 corrected.

Revision 0512:

Chapter 3: table SPU extended, picture SPU updated

Chapter 6.5: B A added to external connection diagram

Chapter 7.4: item 7 page 28, new picture and text added

Chapter 7.4; item 13 page 31, new picture

Revision 1112:

Chapter 1.1: added TT-Sense® Thrust & Torque sensor

Chapter 2.1: added Calculation of thrust, thrust power quotient

Chapter 3: table SPU extended

Chapter 6.2: TT-Sense® text added

Chapter 6.3: figure 4 and 5 updated and item 7 extended

Chapter 6.6: table 1 extended and updated

Chapter 7.3.3 Thrust option added

Chapter 7.5: TT-Sense® option and optional TT-Sense® screen added, pictures of screens updated

Chapter 7.6: Thrust quotient added

Chapter 17: Drawings 0815-2003, 0815-2004, 0815-2007/08 and 0815-2014

Revision 1112 (2):

Chapter 3: NMEA input -> Added Sentence $GPVTG

Chapter 6.6: Table 1 -> 115/230 VAC added

Chapter 7.5: Pictures Total fuel consumption updated and text added

Revision 0213:

Chapter 7.4.1.2 corrected

Revision 0513:

Chapter 17: drawing 0815-2013 added

Revision 0513(2):

Chapter 6.6 table 1 -> updated with touch screen info

Chapter 7.4 item 16 Alarm list updated

Revision 0514:

Chapter 6.4 Installation information added

53