Office of Applied Research - College of the North Atlantic

IDEAS

INNOVATION

IMPACT

Office of Applied Research

Chair’s Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

College of the North Atlantic . . . . . . . . . . . . . . . . . . . . . 2

Office of Applied Research . . . . . . . . . . . . . . . . . . . . . . . 3

Research Facilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applied Entomology Laboratory . . . . . . . . . . . . . . . . . . . . . 4

Centre for Agrifood Development . . . . . . . . . . . . . . . . . . . . 6

Geospatial Research Facility . . . . . . . . . . . . . . . . . . . . . . . . 8

Innovative Product Development Centre. . . . . . . . . . . . . . 10

Manufacturing Technology Centre. . . . . . . . . . . . . . . . . . . .12

Materials and Nanotechnology Research Lab . . . . . . . . . . .14

Ocean Technology and Wave Energy Centre . . . . . . . . . . . .16

Petroleum Specialty Centre . . . . . . . . . . . . . . . . . . . . . . . . .18

Researcher Showcase . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mohammad Iqbal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Gurinder K. Ahluwalia . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Aaruun V. M. Arunachalam . . . . . . . . . . . . . . . . . . . . . . . . 22

Michael Graham . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Barry J. Hicks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Jonathan Joy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

S. Karunanithy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Sanat Mandal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wade Parsons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Glenn Payne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Randal J. Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adrian Ricketts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Ranjan Kumar Patro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Gary Thompson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Rick Wheeler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Shannon White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Industry Outreach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Demand Innovation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Jim Maunder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dynamic Air Shelters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Humber Valley Potato . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pathway to Commercialization . . . . . . . . . . . . . . . . . . . 44

Sample Industry Projects . . . . . . . . . . . . . . . . . . . . . . . 46

Contact Us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

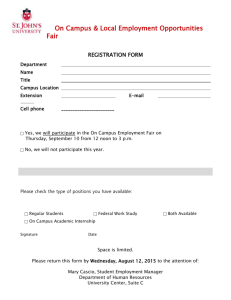

Chair’s message

The College of the North Atlantic, and its Office of Applied Research, is ranked among the best in its class in Canada. Our Office of Applied

Research serves as one of the college’s main points of contact for industry, government, and community groups interested in research collaborations and outreach activities.

As chair of this office, I am proud that we offer a research environment that is both intimate and expansive, one in which faculty are engaged in innovative ideas that, in some cases, are locally focused, while others have global reach and many are interdisciplinary in nature.

Our office takes great pride in the fact that we offer broad support to our faculty researchers as well as to our communities, businesses and industries in fostering a culture of innovation, creativity and prosperity.

Our research facilities and this publication will highlight some of these achievements.

Ideas, Innovation, Impact showcases diversity of ideas envisioned and interpreted by our researchers; profiles our unique capabilities, infrastructure and the innovative outcomes. As well, there is a glimpse of the impact these ideas have produced on our communities, businesses and industries.

We invite you to explore the pages of Ideas, Innovation, Impact. Feel free to contact one of our talented team to discuss how we may be able to assist you or visit us on line at www.cna.nl.ca/oar.

M. Iqbal

College of the North atlaNtiC

College of the North Atlantic – who are we?

We are Newfoundland and Labrador’s public college. We offer over 100 full-time programs and more than 300 part-time courses in Academics,

Applied Arts, Business Studies, Health Sciences,

Engineering Technology, Industrial Trades, Information

Technology, and Tourism and Natural Resources. We’re found in 17 locations throughout the province, and one in the Middle East State of Qatar. But our reach extends even further with the help of more than

200 courses offered through our Distributed Learning

Service and the many students and clients we serve through our International Business Development office and Contract Training and Continuing Education department.

But we are much more than what those numbers show. We have the lowest tuition fees of any post-secondary institution in Atlantic Canada, and offer a world-class, nationally accredited range of programming that meets the highest demands of industry. Thanks to our growing online course catalogue, and our system of credit transfer with other post-secondary institutions, students can continue their education at home and abroad.

Internationally, we are engaged in precedent-setting partnerships. Here at home, we are active in research and innovation activities that lead to the application of new knowledge to sustainable economic activity, alone or with one of the other college or university network members of Springboard Atlantic.

Our vision is one of lifelong learners who are educated and highly skilled, able to meet the demands of the labour market while contributing to the social, economic, and cultural well being of their communities.

How are we doing? Well, the provincial Department of

Education’s CareerSearch survey findings show that a higher percentage of CNA’s graduates find high-paying jobs specific to their field of study than those from other post-secondary options. That sounds like success to us.

2

offiCe of applied researCh

College of the North Atlantic began in the early 1960s as a network of District Vocational Schools scattered around the Province of Newfoundland and Labrador.

Over the course of about 30 years, new centres opened, were merged, renamed, consolidated … and finally, in

1997, came together as the province-wide institution we know today as College of the North Atlantic (CNA).

The name (and structure) stuck - but we didn’t stop changing and growing. Another significant milestone occurred in 1999, when the Board of Governors expanded the college’s mandate of providing postsecondary instruction and training, to include applied research and innovation. The college was no longer just about teaching – it was also about encouraging and leading research. This expanded mandate gave rise, in

2004, to the Office of Applied Research (OAR).

Through the OAR, the college generates new knowledge, manages research grants, deals with intellectual property, and helps transfer new technology to the community and industry. We are supported in these activities by public and private partners, individuals and groups, technology industries, regional universities, colleges, research laboratories, and national programs such as NRC-IRAP, Industry Canada,

CFI, NSERC, and ACOA.

We foster a spirit of creativity among faculty, students and staff, and engage in meaningful applied research and innovation. ‘Applied Research’ is research aimed at producing results that can be applied to real-world situations. Therefore an important, additional goal of the OAR is to transfer the benefits of the new knowledge, products and services to the community. This is achieved through activities such as market research, product development, incubation of technologies, patenting, and licensing.

College researchers are working in many different and diverse areas. They’re in agriculture, helping companies develop new food products. Others are using 3D printers to create complex scale models for companies designing new consumer products. There is work being done in Information Technology, Digital

Animation, Offshore Oil (Petroleum) Technology,

Advanced Manufacturing, Renewable Energy, and

Geomatics.

One of the newest areas of research for the college is the relatively strange and new field of nanotechnology, where work takes place at the atomic and molecular scale. You might say this is not your father’s vocational school. And with the leadership and innovation of the OAR, tomorrow’s college will be different again, as new research strengths are discovered, and new opportunities are found to apply state-of-theart technologies for the economic prosperity of our province.

3

Research Facilities

applied eNtomology lab

Does the flap of a butterfly’s wings in Brazil set off a tornado in Texas?

No, we’re not actually working on that, but it’s not that we couldn’t.

College of the North Atlantic’s Applied Entomology Laboratory in Carbonear does in fact study the impact of insect activity on humans. But we keep things a little closer to home; how bees help our beloved blueberries, for example.

Entomology is the study of insects, and it’s a very valuable science when we start looking at how the little critters affect our plants. Dr. Barry

Hicks is an entomologist at the Applied Entomology Laboratory, and bees represent just one area of his research. Bees and their pollination activities are clearly beneficial to many of our native plant species of course, but there are also insects that threaten our plants. Notorious examples include the spruce budworm and the hemlock looper, two destructive species that have wreaked havoc on our forests in the past.

Is there a safe, natural way to control such pests? That’s exactly the focus of Dr. Hicks’s research into a fungus called Beauveria bassiana. It grows naturally in soils worldwide, and – conveniently – kills various insect species, including the budworm and the looper. The research hopes to identify a sufficiently fatal strain of the fungus, and then figure out how to cultivate lots of it and prepare the spores for aerial spraying.

And speaking of nasty insects, we all love to brag about the mosquitoes here in Newfoundland and Labrador. They’re big, and they’re annoying; that much we know for sure. But do they carry disease, as they do in some other parts of the world? In fact, we don’t know for certain, but the

Entomology Lab hopes to determine what kinds and quantities – if any – of potential disease carrying mosquitoes actually share our home.

In keeping with the Office of Applied Research’s mandate to pass along benefits of research to our communities, the lab readily shares its information and expertise. Dr. Hicks has worked with the provincial

Department of Natural Resources, and occasionally is a guest of CBC’s

Radio Noon call-in show, answering questions on entomology.

And you might say this one is hot off the press ... Dr. Hicks has been working to determine the distribution of a recent immigrant to the province - the invasive ant, Myrmica rubra, or European Fire Ant.

For information on how the college can help you with your problem or opportunity, wherever you are in Newfoundland and Labrador, contact:

Applied Entomology Lab

Carbonear Campus

Tel: 709.596.6139

55

CeNtre for

agrifood developmeNt

It may surprise you that in a province affectionately known as ‘The Rock’, the agriculture industry provides over 6,000 jobs, and is worth over $500 million! But there’s still room for growth, and that’s what College of the

North Atlantic’s Centre for Agrifood Development is all about. Our goal is to help the industry grow, diversify, and achieve long-term sustainability in the province.

To do that, we are working on many fronts through various partnerships with industry. We provide workshops and training in areas such as production, processing, food safety awareness, sanitation, HACCP awareness (HACCP is a food production safety system), and the National

Food Safety Training Program. Training can range in duration from oneday courses to full multi-week programs, and can happen on site or off.

We can deal with the commercial side too, providing market analysis for your new products, and assistance with pilot projects. Wish everyone could try your mom’s delicious partridgeberry jam? We do too, and we can scale up the recipe to large-volume production.

Our applied research focuses on the application of new technologies and transfer of knowledge to the agrifoods sector. We tackle research and development, develop products and production processes, and even assist with things like nutritional and ingredient labelling, and shelf-life analysis.

If fish is more your thing, not to worry – we’ve got you covered through our partnership with the Marine Institute’s Centre for Aquaculture

Development, thereby meeting the needs of the aquaculture as well as the agrifoods sector.

6

The centre is guided by an Agrifoods Advisory Board which meets quarterly, and includes representatives from the following private and public participants:

• Department of Natural Resources

• Agriculture/Agrifood Canada

• Marine Institute’s Centre for Aquaculture and Seafood Development

• Atlantic Canada Opportunities Agency

• Rural Secretariat

• Department of Innovation, Trade and Rural Development

• National Research Council

• CNA’s Office of Applied Research

• Canadian Manufacturers and Exporters

• CNA’s Contract Training & Continuing Education department

Here are some of the clients we’ve helped so far:

• Belbin’s Grocery

• The Dark Tickle Company

• Decadent Delights

• Glenview’s Finest

• ICSpa Products

• Salmon Cove Future Development Association

Please visit our website to learn more, or contact us directly.

www.cna.nl.ca/agrifood

Centre for Agrifood Development

Carbonear Campus

Tel: 709.596.8957

7

geospatial researCh faCility

Facilitating Geospatial Solutions

As the old adage goes, a picture is worth a thousand words. At the

Geospatial Research Facility (GRF) in Corner Book, we produce much more than just pictures; novel, computer-generated, interactive 3-D maps using data stored in traditional Geographic Information Systems (GIS) and digital mapping databases. One key feature of the research underway at the GRF is exploring innovative ways to create maps and mathematical representations of real-world features such as topography, streets, vegetation, and buildings that come alive – at least in a virtual world. The applications for these emerging technologies in 3-D visualization research have potential across such diverse markets as: resource management, land use planning, tourism, education, community development and emergency management.

Focusing on applied research, the GRF has positioned itself in a leadership role by utilizing emerging geospatial technologies to assist in developing and transferring practical solutions to a variety of public and private partners. Corner Brook Pulp and Paper Limited recognized the value of geospatial solutions when they partnered with our facility to investigate the use of GPS-based navigation systems for the company’s harvesting operations. A combination of geospatial and information technologies was developed that ultimately gives the papermaker a near real-time view, via the Internet, of forest harvesting operations being carried out across its timber limits in the province.

8

Through our mature technical infrastructure and highly skilled research team, we are uniquely positioned to aid in any stage of project development involving GIS, GPS, or remote sensing technologies.

Established relations with national technology leaders such as ESRI

Canada, PCI Geomatics, Remsoft, Cansel and others, combined with our linkages with fellow researchers to academia and governmental research labs, provide a strong basis to support research and innovation needs throughout Newfoundland and Labrador.

The possible applications of geospatial technology are endless. Have an idea you want to turn into an innovative product or service involving geospatial technologies? Please contact us.

Geospatial Research Facility

Corner Brook Campus

Tel: 709.637.8584

9

iNNovative developmeNt

A sad chapter in Newfoundland and Labrador’s history is memorialized near the French village of Beaumont-Hamel, where most of the Newfoundland

Regiment perished on the first day of the Battle of the Somme. The memorial includes three large bronze plaques listing the names of the nearly 800 fallen. Today, many Newfoundlanders and Labradorians make the pilgrimage to this memorial site, but for those who can’t, there is a place closer to home where they can view a faithful replica of the

Beaumont-Hamel site and monument.

Appropriately, present-day Newfoundland and Labrador skill and know-how played a role in making this possible. A 3D laser scanner owned by the Office of Applied Research was used on-site at Beaumont-Hamel to scan the emblems that top the plaques. The scanned data was used to create a three-dimensional computer model, which in turn was sent to a ‘3D printer’, which created plastic moulds of the emblems for casting.

Thanks in part to this work, Newfoundlanders, Labradorians and others who wish to honour the memory of these heroes can now visit the

Beaumont-Hamel memorial replica – complete with precisely replicated plaques – at Bowring Park in St. John’s, Newfoundland and Labrador.

Not all the projects at the Innovative Product Development Centre

(IPDC) are quite as dramatic as this of course, but they are no less innovative or valuable. Using CAD design, 3D laser scanning, 3D printing in ABS plastics, rapid prototyping, and injection moulding for prototype production, we help companies with research and design tasks, production of prototypes, and early stage production of prototype injection moulds.

10

And while it may sound very technical, it’s not just for techies. We’ve helped a number of artists bring their creative ideas to fruition. Take furniture designer Christina Hilborne of Splintered Minx Inc., for example, who needed a scale model of a line of innovative plastic illuminated furniture she envisioned. After getting help from the centre in securing funding, Christina says, “I spent several hours with Randal (Power), discussing various designs, the pros and cons of different shapes and sizes, and of different plastic moulding methods. His input was invaluable, and, as a scientist, he was very patient with my artistic caprice! Together we came up with five different designs, which Randal created digitally using the program SolidWorks, and which he then printed out, in one-fifth scale, on the department’s 3D printer. Seeing things in three dimensions, even if they are scaled down in size, is incredibly helpful, compared to on a computer screen.”

Our work on other projects has helped create prototypes of parts destined for inclusion in all types of products, from coffee makers, to chocolate moulds, to mechanical prototypes. In fact, we’ve produced nearly 300 different parts for outside clients!

Our projects are limited only by your ingenuity. Please contact us if have a project in mind, or would like further information.

Innovative Product Development Centre

Prince Philip Drive Campus

Tel: 709.758.7487

11

maNufaCturiNg teChNology CeNtre

So, you’ve a great idea for a product, but you don’t have an injection moulding machine lying around to create that prototype? Well, you’re in luck, because we have one here, at the Manufacturing Technology Centre!

We also have a vacuum former, a coordinate measuring machine, a wire electrical discharge machine, computer numerical-controlled machining centers and lathes, and a CO2 Laser. All this, and a full-time technician to help you work it all. This means you can quickly create complex geometric models of product concepts, and THAT means you get your product to market faster and cheaper.

In 1996 the Manufacturing Technology Centre came into being, with the clear goal of fostering the growth of the manufacturing sector in

Newfoundland & Labrador. Since then, we’ve worked diligently toward that goal by helping companies with research, prototyping, custom training, consultation — anything and everything related to manufacturing. In fact, we’re proud to report that since then, more than 50 such projects have passed through our facility.

12

The benefits to our clients have run the gamut from simple, helpful advice, to prototypes, to patent assistance, and so many areas in between.

We’ve helped some companies you’ve probably heard of, like ACAN, Lotek

Wireless, Provincial Airlines, Weathershore Windows, Precision Industries, and many more. Newfoundland and Labrador companies, products, and expertise. Anyone need help ... get in touch with us.

Manufacturing Technology Centre

Prince Philip Drive Campus

Tel: 709.758.7111

13

materials & NaNoteChNology

It might be located in “The Big Land”, but research at the Materials and

Nanotechnology Research Lab (MNRL) in Labrador deals with some incredibly small stuff. How small, you ask? Well, we’re talking nanometers.

The period at the end of this sentence measures about 100 million nanometers across. And guys, your beard grew by several nanometers while you read that sentence.

Nanotechnology involves working with materials – modifying them, shaping them, creating with them – at the nanometer level. It is science and engineering at the scale of atoms and molecules.

Nanotechnology is an emerging field, but already it boasts a vast array of both potential and working applications. This is because particles at such a small scale exhibit very unusual properties, which have been harnessed to produce such things as stain repellent khakis, golf club heads that are lighter yet stronger, and sunscreens that spread more easily, cover better, and are transparent on the skin.

In the Materials and Nanotechnology Research Lab, Dr. Gurinder K.

Ahluwalia pursues research in various areas of nanotechnology such as

Materials Characterization, Amorphous Semiconductors, Surfactants and

Polymers, Self Assemblies, Nano-photo-mechanical Systems and Nonlinear Optics. Resulting applications in electronic and optoelectronic devices will yield improvements in optical data storage technologies, allowing us to store even more information on our DVDs and memory sticks, and access it even faster.

In other areas, Dr. Ahluwalia’s work on synthesizing gold nano-particles

(under ambient conditions in aqueous phases by using surfactants as soft templates) has been published in peer-reviewed journals. She has achieved the assembly of nanowires: tiny structures that can then be used as building blocks for further applications in advancing technology.

Her work even has potential in battling cancer, with recent achievements in the biomineralization (creation) of the element Selenium with a protein called bovine serum albumin (BSA).

Clearly, nanotechnology holds tremendous promise, and in fact is already delivering on that promise. We’re confident there will be more big (or small) things coming from the Materials and Nanotechnology

Research Lab in the future.

For information about what we do or how we can help you please contact us.

Materials and Nanotechnology Research Lab

Labrador West Campus

Tel: 709.944.6478

oCeaN teCh & Wave eNergy

Back in 2001, down on Newfoundland’s Burin Peninsula, a Grade 9 student named Sarah needed an idea for a school science fair project. Her mom suggested she look at wave power: a rather fortuitous choice, when you consider that the Canadian Hydraulic Centre reports that the south coast of the Burin Peninsula has the highest “near shore wave energy density in eastern North America”. It was also fortuitous that Sarah’s dad, Mike

Graham, Ph.D., works at the Burin Campus of College of the North Atlantic.

Thus was sown the seed for the Ocean Technology and Wave Energy

Centre, located in Lord’s Cove on the Burin Peninsula, one of several research centres of the college.

The southeast coast of the Burin Peninsula is home to the ‘perfect storm’ of conditions for this research: a unique combination of geography

(significant waves, winds, and tidal currents) and technological capability

(metal fabrication, welding QA/failure analysis, electronics, control systems, biologists, chemists, and more) at the CNA campus in Burin.

Inspired by Sarah’s school project, the centre’s first project began in

2003 with the aim of designing and deploying a wave-powered piston pump to provide low-pressure seawater to shore-based facilities, such as shore-based aquaculture. Impressive as it is though, the pump is primarily a means to an end.

16

The farming of aquatic species is complex, and for many reasons, it works better if you can ‘farm’ many species (polyculture), instead of just one (monoculture). A relatively cheap supply of fresh seawater is crucial in this process: thus the importance of the pump.

A longer-term goal then, is to establish a prototype - the first in

Canada - for modelling commercial-scale polyculture, which would have significant potential for fish harvesters, processors and buyers, and aquaculturists.

Meanwhile, significant work has been done at Lord’s Cove: building and wharf renovations, and installation of piping, data acquisition equipment and telecommunications equipment, for example. This infrastructure, and the expertise and technology found at the college’s Burin Campus, are available to interested parties.

Ocean Technology and Wave Energy Centre

Burin Campus

Tel: 709.891.5601

17

petroleum speCialty CeNtre

In 1497, explorer John Cabot reported to the King of England that “the sea is full of fish, which are not only taken with a net, but also with a basket, a stone being fastened to it in order to keep it in the water.” Fivehundred years later, Newfoundland and Labrador’s prosperity remains closely bound to the sea. But now it’s more about oil than fish, and the technology required is not as simple as a stone and basket.

An array of sophisticated techniques, tools, skills, and equipment is required to coax that oil from miles beneath the sea floor. College of the North Atlantic plays a major role in ensuring many of those skills are available here in the province, through its Petroleum Specialty Centre at the Seal Cove Campus, where it maintains state-of-the-art equipment related to petroleum production, well control, fluid hydraulics and industrial instrumentation.

While this equipment and expertise is essential to delivering introductory and advanced training to students enrolled in the college’s

Petroleum Technology courses, it is also used to develop and deliver custom courses for industrial clients in the oil and gas sectors.

Offshore oil drilling is expensive and dangerous work, making on the job training a great challenge. One response to that challenge is to take advantage of simulations wherever possible. To this end, a key facility

18

at the centre is a fully operational drilling rig, with associated support.

Other resources include both Well Control and Process Loop simulators, a Reservoir Analysis Laboratory and Modelling Software, a Production

Process Facility, and an Instrumentation and Controls System.

The centre’s capabilities go beyond training. For example, the college is partnered with the University of Cape Breton and the University of

New Brunswick in a project called “Petroleum Applications of Wireless

Systems” (PAWS), aimed at developing a fully automated wireless control system for oil and gas installations. The facilities allow petroleum companies to test new equipment and procedures; again, in the safety of a controlled environment. There is also a strong opportunity for applied research in network-based remote control of petroleum productionrelated instrumentation.

Please contact us to discuss potential research and development projects, training opportunities, or other activities related to the offshore petroleum industry.

Petroleum Specialty Centre

Seal Cove Campus

Tel: 709.744.1041

19

Researcher Showcase

researCh

As department chair for the Office of Applied Research (OAR) at College of the North Atlantic, Dr. Mohammad Iqbal leads a team committed to fostering collaboration between the college and other educational institutions, government agency partners, and industry stakeholders to accelerate innovation for economic and social development.

With over 33 years of experience as a post-secondary educator, researcher and academic manager, Dr. Iqbal understands the crossroads of research and commercialization that is so central to the OAR’s mandate.

Throughout his career, Dr. Iqbal has been involved with interdisciplinary teaching and research in chemical engineering, environmental sciences, quality assurance, science policy and innovation planning. This collaborative approach delivers mutual benefits for industry and the research and academic communities.

Having completed a Ph.D. and a post-doctoral fellowship at the

University of Saskatchewan, Dr. Iqbal has conducted research and taught at a number of post-secondary institutions across Canada, including the University of Saskatchewan, the Saskatchewan Institute of Applied

Sciences and Technology (SIAST), and St. Peter’s College.

Under Dr. Iqbal’s direction, the OAR promotes an innovation culture, bringing together the various nodes of research and development activity that exist across the college’s 17 provincial campuses. These initiatives ensure that the OAR continues to successfully foster the collaborative and mutually beneficial links between research, development, and commercialization.

Mohammad Iqbal

Ph.D.

Office of Applied Research and Innovation

Prince Philip Drive Campus

Research Interests:

• Environmental Sciences

• Chemistry

• Chemical Engineering

• Material Science

• Quality Assurance,

• Science Policy

• Science Management

20

big ChaNges-small materials

Gurinder K. Ahluwalia

Ph.D.

School of Academics & Applied Arts

(Physics)

Labrador West Campus

Research interests:

• Materials characterization

• Nanotechnology

• Amorphous Semiconductors

• Surfactants and Polymers

• Self Assemblies

• Nano-photo-mechanical systems

• Non-linear optics

As Physics Instructor at the college’s Labrador West Campus, Dr. Gurinder

K. Ahluwalia oversees all aspects of student supervision and research for projects on Materials and Nanotechnology.

A graduate of the University of New Delhi, Dr. Ahluwalia took up her position at the college’s Labrador West Campus in 2007. With a Ph.D. in

Physics and over 19 years of research and teaching experience, Dr. Ahluwalia established the Materials and Nanotechnology Research Laboratory at the college. She is skilled in sophisticated technologies for nano-structuring of new materials and is experienced in the use of high tech instrumentation including: synchrotron beam line, thin film technologies, differential scanning calorimetry, UV-VIS-NIR spectroscopy, atomic force spectroscopy, dielectric measurements, dark and photoconductivity measurements, and cell designing for conductivity and dielectric measurements.

An experienced professional with a research background in international and intercultural environments, Dr. Ahluwalia has contributed to several international conferences and has served on organizing committees of world-class events across Asia, Europe and North America. The winner of several international awards, she is a recipient of the prestigious visiting

JSPS fellowship from Japan. Her recent presentations include the plenary talk at the International Conference on Amorphous and Nanostructured

Chalcogenides-ANC-4 at University of Constanta, Romania.

A major emphasis of Dr. Ahluwalia’s research work has been the synthesis and optimization of novel materials for electronic and optoelectronic devices. Her work has been highlighted in over 45 research papers and several peer-reviewed journals, earning her a reputation as a leading scientist in the area of material sciences.

a titaNiC ChalleNge

A mathematics and physics instructor at the college’s Burin Campus,

Dr. Aaruun Arunachalam is researching computational models to better predict the effects of forces on engineered structures, particularly as it relates to ice and its effects on structures located at sea. The research will enable offshore operators to build structures better designed to withstand ice-induced forces, making offshore activities safer and more predictable.

Understanding the limits of an engineering design in withstanding the forces of sheet ice and other ice-induced forces is the first step in the design of any engineering process. Depending on the intensity, type, and distribution of forces, and the characteristics of the engineered structures, the behavior of the structures will be different.

The ability to estimate the intensity, type, nature and distribution of these forces on structures like ships and offshore oil platforms will greatly improve safety and predictive risk management. Available experimental data is being used to apply the concept of dimensional analysis and similarity theory to developing the most realistic computational models for ice-induced forces on structures interacting with sheet ice.

Dr. Arunachalam’s research on computational models and designs for ice-induced forces on offshore structures will pave the way for further improvements in understanding the physics of the ice-structure interaction problem.

Aaruun V. M. Arunachalam

B.Eng., M.Tech., Ph.D.

School of Academic and Applied Arts

(Physics and Mathematics)

Burin Campus

Research Interests:

• Ice-Induced Forces on Offshore

Structures

22

ridiNg the Wave

Michael Graham

Ph.D., CET

Campus Administrator

Burin Campus

Research Interests:

• Alternative Energy

• Ocean Engineering

• Meteorology

• Aquaculture

As one of the Campus Administrators at Burin Campus, Dr. Michael Graham sees community involvement as key to promoting practical applied research.

Dr. Graham provides operational and academic leadership for the campus, and is responsible for the development and management of internal and external teams and partnerships.

A biophysicist, agricultural meteorologist, and Certified Engineering

Technologist, Dr. Graham brings this team approach to his research interests and his additional role as a researcher and educator in biology and engineering technology. Dr. Graham is the key driver behind a project to investigate wavepowered pumping of seawater: the Wave-Powered Pumping of Seawater

for On-Shore Use and Electrical Generation Project in Lord’s Cove, near the campus on the Burin Peninsula.

The interdisciplinary research project is prototype development and testing of a wave-powered pump that will use water flow to supply a flushing stream for shore-based operations. Many onshore or platform-based activities, such as aquaculture and fish processing, use high flows of seawater driven by electrical pumps at considerable cost.

Dr. Graham is researching how best to harness the power of wave action to bring seawater to shore for these operations. Set up of an onshore aquaculture farm optimizing feed and waste in the water flow for a number of species is another key aspect of the project. Minor modifications to this design can allow the pump to generate electricity from wave action. Power can also be made from the flow of returning water to the ocean.

The collaborative approach of this project has allowed the incorporation of skills and contributions from various stakeholders, both from within the college and externally, and continues to form the basis of Dr. Graham’s continued research into the possibilities of wave-powered energy.

23

No flies oN us

As a biology instructor, Dr. Barry Hicks is always seeking ways to bring science to life for his students. There is no better way to learn than by doing and with this in mind, Dr. Hicks set out to establish a facility where his students could do just that.

Founded by Dr. Hicks at the college’s Carbonear Campus, the Applied

Entomology Laboratory is a hive of activity. It’s here where he and his team investigate applied approaches to the impacts of insect activity on humans.

In the shadow of ever-increasing global concerns regarding pesticide use, Dr. Hicks is also researching production of an insect pathogenic fungus. It might sound like weird science, but the results will mean less chemical dependence for agricultural production, and reducing chemicals in the food chain is good news for the planet – and everyone on it!

Dr. Hicks studied Forest Entomology at the University of Edinburgh,

Scotland, where he received his Ph.D. in 2001. His forestry research includes developing fungal biological control agents to combat forest defoliators, and examining the characteristics of potential diseasecarrying mosquitoes in Newfoundland and Labrador.

When not immersed in the laboratory or inspiring students in the classroom, Dr. Hicks can be found partnering with government agencies to educate the public on the importance of healthy pollination, biological control and environmental studies.

What inspires him about his research and the field of Entomology?

“I’m inspired mainly by the pursuit of knowledge. I really enjoy discovering things that no one else has done.”

Barry J. Hicks

B.Sc. (Hons.) M.Sc. Ph.D.

School of Academics & Applied Arts

(Biology)

Carbonear Campus

Research Interests:

• Insect Ecology

• Biological Control

• Entomopathogens

• NL Insect Biodiversity

• Native Bees and Pollination

24

big fish stories

Jonathan Joy

B.Sc. (Hons.), M.Sc.

School of Tourism and Natural Resources

(Natural Resources)

Bonavista Campus

Research Interests:

• Renewable energy

• Marine ecology

• Seabirds, whales, squid

Jon Joy’s classroom includes the ocean, the coastline, the forest, the firing range and the biology lab. As an instructor for the Natural Resources

Technician program at the college’s Bonavista Campus, Joy’s students take courses in everything from fish and wildlife biology to safe firearms certification and wilderness survival. The students often go on to pursue careers as technicians and enforcement officers for various natural resource management agencies within government and the private sector.

Recognizing a need for such a program, Joy was the driving force in striking an advisory committee to define the program and the curriculum in 1992, and the program was formally launched in January of 1993. The curriculum reflects the wide scope of natural resources management, and provides students with skills in all areas of monitoring and managing terrestrial, freshwater, and marine resources.

A Masters graduate of Aberdeen University, Joy’s research interests range from renewable energy and marine ecology, to tourism and natural resources. Joy is often engaged by both government and private industry partners to conduct wildlife or natural resource research on their behalf. He has conducted avian surveys for Environment Canada, and has completed several avian surveys for proposed wind farms around the province.

One area of specific interest to Joy is the study of cephalopod (squid and octopus) remains from the stomachs of marine vertebrates including: sperm whales, northern bottlenose whales, dolphins, porpoise and various fish species. This research enables scientists to better understand the diets of marine mammals and their impact on the marine ecosystem.

Joy also manages the inshore squid-sampling program for

Newfoundland and Labrador, on behalf of the Canadian government’s

Department of Fisheries and Oceans.

25

all Natural iNNovatioN

For Dr. S. Karunanithy, the secrets to good human health might be found in the smallest food forms nature has to offer. A chemistry instructor at the college’s Carbonear Campus, Dr. Karunanithy’s work focuses on the extraction and analysis of antioxidants and other compounds from natural products. The human benefit derived from these compounds is a major area of research and interest.

A graduate of the University of British Columbia’s Ph.D. program in chemistry, Dr. Karunanithy’s latest project is to extract antioxidants and other phytochemicals from berries and fruits, and to develop natural products using the compounds in these extracts.

In this on-going project, phytochemicals, which are naturally occurring chemical compounds derived from plants, are extracted from blueberries, cranberries, pomegranates and sea buckthorn. The ingredients in these extracts are then analyzed for nutritional values and human health applications, for future incorporation into nutraceutical health products.

Dr. Karunanithy’s future work will focus on the value addition of agrifoods using these research results.

S. Karunanithy

Ph.D.

School of Academics & Applied Arts

(Chemistry)

Carbonear Campus

Research Interests:

• Antioxidants

• Nutraceuticals

• Phytochemicals

26

fightiNg the better fight

Sanat Mandal

B.Sc. (Hons.), M.Sc., Ph.D.

School of Academics & Applied Arts

(Chemistry)

Clarenville Campus

Research Interests:

• Rational Drug Design

• Bio-mimetic electrocatalytic conversion of minerals to metals

• Development of drug delivery technology for control release of drug to the target cells

• Development of light-weight recharge battery of polymer origin

• Conversion of light energy to electrical energy by developing and using photo/electro chromic materials

Dr. Sanat Mandal’s goal is to find smarter weapons for the battle against life-threatening cancers and other diseases and he’s found one in bioinformatics, the application of statistics and computer science to the field of molecular biology. A Ph.D. graduate of the University of Calcutta in

Chemistry, Dr. Mandal is a chemistry instructor at the college’s Clarenville

Campus.

His main research interests are in developing potent tumour-selective drugs for breast, lung, and blood cancers. Drugs that are developed applying this approach are expected to be less toxic and be able to overcome drug resistance. Applying this approach, Dr. Mandal has been able to develop several target-specific molecules, resulting in treatments that are more effective and less harmful for the patient.

Dr. Mandal uses state-of-the-art techniques in his drug design and development research activities. He combines his multi-disciplinary skills in his approach to drug development, targeting drug docking profiles and interaction evaluations, identifying the marker (target) genes using bioinformatics tools, and molecular biological validation techniques.

The success of targeted drug therapies for human pharmacology is an exciting prospect for those at the frontlines of medical research, and these concepts are brought to life for Dr. Mandal’s students, linking the study of bioinformatics to progress in the real-world battle against cancer.

27

all the Water Without the Wet

Since 1980, Dr. Wade Parsons has been teaching engineering technology students how to apply mathematics and physics to real-world problems like oil spills and wave energy analysis, and through his own research, he is advancing the college’s program curriculum. A PhD graduate in Applied Mathematics from Memorial

University, Wade is excited by the prospects of research and education combining to further the goals of industry.

With a significant background in consulting and an extensive publication record in the areas of ocean wave simulation and energy measurement, Dr. Parsons’ research is focused on improving processes for ocean technology applications.

Responding to the needs of industry and researchers alike, Dr. Parsons has also developed a new signal processing algorithm for use in accurately estimating ocean wave energy. Dr. Parsons has also developed a mathematical hydraulics simulation model for use in the measurement and control of the interface between oil and water, an application of critical importance to the chemical and petroleum industries in the prevention and management of oil spills.

By using applied mathematics for numerical analysis, wave modeling and signal processing, Wade delivers innovative applications for research partners, public sector stakeholders and private industry. “My work in water-wave mechanics, which strives to model the ocean environment, has particular application to industries working in an ocean environment“, says Wade. “I’ve always enjoyed mathematics and I love to solve difficult real-world problems”. This desire to solve real-world problems brings applied mathematics to life in Dr. Parsons’ classroom.

The intersection of research, industry and academics at the core of Dr. Parsons’ work is what OAR is all about; students see the real-world application of applied mathematics to tangible problems, industry gains knowledge applicable to the commercial applications at the core of their businesses, and the comprehensive research body of knowledge continues to grow.

28

Wade Parsons

B.Sc., M.Sc., Ph.D.

School of Engineering Technology

(Mathematics)

Ridge Road Campus

Research Interests:

• The application of mathematical methods to challenging engineering problems

• Simulation of Water Waves

• New Signal Processing Technique

• Mathematical Hydraulics Simulation

it’s all iN the truNk

Glenn Payne

B.Sc.F. (Hons.) , MCPM

Research Coordinator

Geospatial Research Facility

Corner Brook Campus

Research Interests:

• Sustainable Forest Management

• Geographic Information Systems (GIS)

• Geo-data visualization

• Remote Sensing

• Forest Biometrics

As the Research Coordinator for the Geospatial Research Facility (GRF) at the college’s Corner Brook Campus, Glenn Payne performs a dual role as both a researcher and project manager. His research interests focus on the development and application of practical, geospatial-enabled solutions in sustainable resource planning and management.

Through projects focused on predictive forest development modeling, visual forest planning tools, and pre-harvest and operational forest planning and digital mapping technologies, Payne is assisting government and private industry stakeholders in adopting new technologies aimed at improving competitiveness, through increased productivity and streamlined processes. Glenn’s projects focus on using geospatial technologies to strengthen core business functions, and for best practices within organizations. His research is driven by the practical needs of collaborators, and the opportunity to improve, develop and transfer technology solutions.

Glenn’s research projects include the creation of technology solutions to help make digital mapping data, usually found inside GIS databases, more accessible and engaging through the use of 3-D visual modeling. This research replaces the technical and scientific information that is already available to analysts with visual data products such as video, images, and interactive maps. These visual products allow non-technical stakeholders to better understand, and participate in, resource planning, environmental assessment and decision-making processes. Another use of this research includes the creation of novel educational simulation products to educate future forest and environmental management practitioners.

29

makiNg it real

As lead of the Innovative Product Development Centre for the Office of

Applied Research at the college’s Prince Philip Drive Campus in St. John’s,

Randal Power is facilitating the unit’s acquisition and implementation of new pieces of engineering and manufacturing equipment focusing on the area of applied research.

“My projects range from research and development initiatives for new products to the design and fabrication of prototypes for industry and college clients,” says Power. Generally, these projects have the potential for real-world implementation with a novel or technical challenge in need of a solution.”

Power, a graduate of Memorial’s School of Engineering, leads the centre team on innovative manufacturing projects, working closely with clients to understand their requirements and challenges for the required finished products. To date, over 300 products have been produced for private clients using the centre’s 3D printing technology, and internally the unit has worked on numerous projects for college researchers and students.

Major projects undertaken by Power and the centre include: the reproduction of the emblems and trim work of the Beaumont Hamel plaques in Bowring Park, the production of tooling and parts for Demand Innovations’ coffee makers, a technology to improve the Nomex clothes dryer, UV-based sterilizing technologies, a new type of underwater thruster technology, and a new type of solar air heating technology for industrial and home use.

Under Power’s supervision, the Innovative Product Development Centre’s mandate of applying engineering technologies to applied research is providing companies with an innovative and cost-effective path to commercialization, while supplying the research community with the equipment needed to develop new prototypes for industry.

30

Randal J. Power

M.Eng.

Office of Applied Research

Research Engineer

Prince Philip Drive Campus

Research Interests:

• Manufacturing

• Product Development

• Ocean Technologies

oN top o’ the World

Adrian Ricketts

Research Assistant – GIS

Geospatial Research Facility

Corner Brook Campus

Research Interests:

• Cartographic Design

• GIS Automation

• GIS Data Development

• Web-Based GIS

• Field-Based Research

As a GIS (Geographic Information Systems) Research Assistant and Cartographer at the college’s Geospatial Research Facility (GRF), Adrian Ricketts is responsible for cartographic design and GIS data development at the Corner Brook campus.

A graduate of the college’s Forest Resources Technician program, Ricketts’ advanced training at the Centre of Geographic Sciences allows him to contribute to the development of practical GIS products and services in the natural resource sector. This combination of training in cartographic standards in digital mapping, drafting and design, and in sustainable forest management practices means

Ricketts’ research project contributions are technically diverse and innovative.

His project activities combine both fields of study to improve methods for data collection and geospatial analysis.

Adrian has been involved in various sectors of geospatial research, ranging from GIS deployment strategies to a web-enabled geo-database design. The geodatabase enables users to access and print various types of map products for disciplines such as the Eastern Boreal Forest Tree Model Library, an initiative which saw Ricketts’ and the GRF team create source data containing nearly 160 unique tree and shrub measurements for 3D model development in environmental applications.

Projects like the Canvec Web Mapping Database and Tree Model Library are advanced by the implementation of RIA (Rich Internet Applications) using GeoWeb

2.0 software. This type of web interface development provides users with standard web browser access to GIS functionalities, without the requirements of costly GIS software and expertise.

These innovative projects provide stakeholders with access to advanced technologies, increasing the community knowledge base, improving resource management processes for industry and resource management authorities alike.

31

bubbliNg With kNoWledge

At CNA’s Happy Valley-Goose Bay Campus, Dr. Ranjan Patro divides his time between researching the impacts of bubble properties across a broad range of industries, and mentoring students. Through his own efforts, Dr.

Patro is furthering the college’s research portfolio, enhancing the CAS-

Transfer Program curriculum, and ensuring students are supported and mentored while undertaking their course of study and research.

Dr. Patro completed his Masters of Science in Physics and Oceanography at Berhampur University in India. He went on to study the hydrodynamics of large bubbles at the National University of Ireland, Galway, where he received his Ph.D. Before joining CNA, Dr. Patro also conducted research work at Memorial University and the University of California.

Bubbles are found wherever gas and liquids interact, and are critical to many processes of interest to engineers and scientists. Several inherent properties of the bubble are fundamental in understanding processes for industries as diverse as mining, aquaculture, beverage production, chemical manufacturing and even naval warfare. Dr. Patro’s research on bubble properties has far-reaching benefits for applications in chemical engineering, biology and medicine, automotive engineering, biotechnology and food processing, and wastewater technologies

Having mentored students at the campus from as far away as Qatar,

Dr. Patro is enthusiastic about his research and his students. An engaged mentor, researcher and educator, Dr. Patro is constantly seeking ways to further the college experience for his students.

What drives him?

“I love challenges. I started bubble research in 1996 and the field is still growing. The potential for research and discovery is very exciting for my students, and for me.”

32

Ranjan Kumar Patro

B.Sc. (Hons.), B.Ed, M.Sc, Ph.D.

School of Academics & Applied Arts

(Physics)

Happy Valley-Goose Bay Campus

Research interests:

• Hydrodynamics of bubbles

• Bubble-mediated gas exchange

• Flotation cell: Bubble-mediated particle transport

• Visualization

• Image processing

the roCk of the roCk

Gary Thompson

P Geo, B.Sc., M.Sc. Ph.D.

School of Academics & Applied Arts

(Chemistry/Earth Sciences)

Burin Campus

Research Interests:

• Geochemical Mineral Exploration

An instructor of chemistry and earth sciences at the college’s Burin

Campus since 2003, Dr. Gary Thompson brings 18 years of international experience in the geosciences to the classroom. A registered professional geoscientist, Dr. Thompson’s research activities are of particular interest for mining and natural resources exploration, shaping discovery and extraction strategies for operators.

Dr. Thompson’s research focuses on geochemical techniques used in research for mineral exploration. In 2009, Dr. Thompson was awarded an Industrial Research and Innovation Fund grant of $97,000 to explore methods for the discovery and extraction of ore below bedrock. Most, if not all, exposed ore has already been discovered in Newfoundland and

Labrador. Any remaining economic deposits are hidden below the surface of exposed bedrock, making geophysical and geochemical methods for mineral exploration increasingly important.

Dr. Thompson’s more recent research has focused on trace element mineral chemistry and application methods for finding buried uranium deposits and orthomagmatic nickel sulfide deposits. Over the summer of

2009, with support of Aurora Energy Inc. and Memorial University, a study was initiated to examine biogeochemical exploration techniques in the

Central Mineral Belt, Labrador.

In addition to his research in geochemical exploration, Dr. Thompson is working with Dr. Barry Hicks, college researcher at the Carbonear Campus, to examine the possible role of heavy metals as a contributing cause of autism. A pilot study examining the variation of heavy metals in the teeth of autistic and normally developing children is underway in an effort to identify any possible correlation between the presence of heavy metals and the disorder.

33

all teCh is good teCh

In 14 years of designing and administering GIS (Geographic Information

Systems) and the ESRI Platforms, Rick Wheeler has witnessed the evolution of geospatial research methods. As GPS (Global Positioning System) navigation and GIS data models have evolved, so too have the information systems which manage and analyze the resulting data.

As a Data and Systems Specialist at the college’s Geospatial Research

Facility (GRF), located at its Corner Brook Campus, Wheeler is trained in a wide variety of server-based technologies for geospatial applications. He is responsible for geo-database design implementation and management, and works with industry and government partners on the design, configuration, training and testing of field-based data collectors, GPS systems and GIS server management.

A frequent collaborator with public and private forestry stakeholders,

Wheeler is often involved in the design and implementation of information systems for various projects. Recent projects include the Forestry Data

Model Project, in conjunction with the Department of Natural Resources, to develop a data model for storing and managing forestry data. The resulting data model will be implemented as a new customized forestry geo-database for the province.

GPS-based systems are also changing the practices of forest harvesters.

Wheeler recently collaborated with Corner Brook Pulp and Paper Limited

(CBPPL) on a research project to investigate the use of GPS-based navigation systems for forest harvesting operations. Using GIS and GPS information to monitor and plan field operations using near real-time data, Wheeler and

CBPPL team members deployed a customized ArcPad application to provide a real-time virtual view of a harvester’s GPS location, and the area to be harvested, allowing for better planning for harvesting operations.

34

Rick Wheeler

B.Sc.

GeoSpatial Research Facility

Data and Systems Specialist

Corner Brook Campus

Research Interests:

• Global Positioning Systems (GPS)

• Geographic Information Systems (GIS)

• GeoDatabase Management

playiNg the map

Shannon White

B.Sc.

GeoSpatial Research Facility

Forest Modeling Analyst

Corner Brook Campus

Research Interests:

• Ecosystem Modeling

• 3D Visualization

• .Net software

• Development

• GIS Analysis

At the college’s Geospatial Research Facility (GRF) located at the Corner

Brook Campus, Geospatial Analyst Shannon White is researching and developing innovative modeling applications for solving complex spatial problems, using GIS (Geographic Information Systems) and statistical analysis methods.

At the GRF, White’s primary responsibilities include ecosystem, habitat, forest productivity, and wood supply modeling and research. He focuses on 3D visualization of these modeling systems, leveraging the power of modern gaming technologies to display traditional GIS mapping data. He has also developed and deployed mobile navigation systems for harvest equipment, and created a mapping website for these applications.

White holds a Bachelor of Science in Forestry and Environmental

Management from the University of New Brunswick, and prior to joining the college, held various positions within several private and public sector organizations as a GIS programmer, GIS analyst, and GIS manager.

Many of the innovative software programs and techniques that White and the GRF team have developed in the course of their research have been adopted by the GRF’s partners and other interested parties who use them in their own workflow processes and research.

The work done at the GRF is invaluable to the progress of forestry management, and the facility is a regional leader in innovative natural resources management practices.

35

Industry Outreach

demaNd iNNovatioN

Demand Innovation Inc., Deep Bight, NL

Bernard Cook is constantly thinking about innovation; how to make a product better, how to solve a common problem in a new way. His company, Demand Innovation Inc., is the creator of the Survival Perk coffee maker. The portable coffee maker employs pressure fusion technology to make freshly brewed coffee, making the filter an essential component in the assembly of the product.

Cook wanted to improve the design of the filter for the Survival Perk, and through the Canadian Manufacturing and Exporters Association (CME), he learned of the college’s Office of Applied Research’s (OAR) capabilities in engineering and prototyping. He approached the OAR with his idea and requirements, and working with Mohammad Iqbal, Randal Power, and representatives from the National Research Council, launched the project in November 2009.

“Partnering with the college made available to Demand Innovation Inc. a team of researchers able to work together in refining innovative ideas.

The further development of design by researchers and dedicated students led to the success of the project. Prototyping 3D computerized fabricating equipment made it possible to create components for trial testing. This one piece of equipment is essential to the development of innovative, new products. The availability of this equipment saves valuable time that

“Innovation is the ability to see change as an opportunity - not a threat”

Steve Jobs

36

Benard Cook

Demand Innovation www.demandinnovation.net

would be lost if prototyping had to be done outside of the province,” says

Cook.

The results of the project speak for themselves: by June 2010 the new filter clip design developed in partnership with the OAR had become standard on all Survival Perks. When asked about the college’s mandate and commitment to programs leading to the application of new knowledge to sustainable economic activity, Cook is quick to point out the value of academic and private collaboration.

“The OAR’s model of academic and private partnership for commercial innovation is really an innovation in itself. My company’s partnership with the OAR has provided experience for students. This experience not only encompasses first-hand insight on innovative, new ideas, but also everything from A-Z on taking an idea and developing the idea into the final prototype, from design, development, manufacturing, and logistics considerations,” he says.

“The development and introduction of the new filter clip has made the

Survival Perk more attractive and easier to use. The customer’s satisfaction has increased due to the further design development. This has impacted the product with increased sales due to improved value and better product performance.”

37

Jim mauNder

Jim Maunder, Artist, St. John’s, NL

As an accomplished artist, educator and sculptor, Jim Maunder’s entire career has been based on creativity and innovation. Since graduating in

1994 from the Ontario College of Art and Design’s interdisciplinary studies,

Maunder has exhibited his works to the world in mediums ranging from watercolour and acrylic to bronze, steel and glass.

While he practices art in all mediums, Maunder is best known for his large-scale sculptures carved from industrial materials. His sculptures can be seen in various locations around the province of Newfoundland and Labrador, and often invoke the spirit of the tenacity that shapes the province.

When the City of Mount Pearl issued a request for proposals for a new public sculpture in 2009, Maunder was looking for a way to quickly produce a 3D scaled model of his proposed design. Having learned of the capabilities of the college’s Office of Applied Research (OAR) through the government of

Newfoundland and Labrador’s “Made Right Here” promotional campaign, he decided to approach the OAR to assist in the creation of a scale model of his proposed sculpture.

“Somewhere, something incredible is waiting to be known.”

Carl Sagan

38

Jim Maunder www.jimmaunder.ca

Working with Randal Power of the college’s Innovative Productive

Development Centre, and Jason Legge from the Manufacturing Technology

Centre, Maunder produced a 1/6 scale model of the proposed sculpture made from bronze and fabricated steel. The model won positive reviews and placed second in the competition; more importantly, Maunder discovered a whole new way to approach scale model design and fabrication: “This method opens up several time-saving and accuracy possibilities, not just for model making, but for presentations and for large-scale productions,” he says.

When asked about partnering with OAR again in the future, Maunder is clear in his assessment of the project:

“I was very pleased with the level of openness to ideas, and the patience and professionalism shown; Randal and Jason both went above and beyond the call of duty. The willingness of the college and the OAR to work with me on this allowed me to make a complicated model in a relatively short time. The 3D printing proved to be a quick and effective way to solve a problem when time and money is short, and the visual effect is quite convincing.”

39

dyNamiC air shelters

Dynamic Air Shelters Ltd. Grand Bank, NL

Dynamic Air Shelters is changing the landscape, literally, for rapid response teams, industrial work sites and promotional events. With 14 years invested in the development of their inflatable air shelters, the company is a leader in the temporary shelter market. Dynamic’s clients range from Gulf Coast oil refineries to professional sports teams, with requirements that include blast resistance and custom dimensions.

The company’s growth and industry-leading performance largely depends on the accurate installation of their shelters by their technicians and agents around the world. When company president Harold Warner decided to pursue establishing a certification program for the installation of Dynamic

Air Shelters, he approached College of the North Atlantic to help develop a curriculum for certifying their Blast Resistant Shelter Installers and Service

Technicians.

“We approached the college’s Office of Applied Research and they were eager to get involved and take on the project. We met on several occasions with Innovation Officer Kay Graham, and college instructors

James Manning and Brendan Mullett, at the Burin Campus. They needed to understand the problem we needed to solve, and we needed to understand the college’s process for curriculum development.”

“There’s a way to do it better — find it.”

Thomas Edison

40

www.dynamicairshelters.com

To demonstrate their course requirements, Dynamic set up a 46 x 66 foot shelter at the Burin Campus. The result is a standard certification program for the company’s installation and service technicians, which delivers higher customer confidence in the safety and quality of the air shelters.

“Certifying our installers gives credibility with customers,” says Warner.

“Most of our customers are petro-chemical refinery operators - they need assurance that our people are competent to perform installations on their worksites - certification gives confidence.”

Regarding Dynamic’s overall experience, Warner is enthusiastic about working with the OAR team in the future. “All of our expectations were met; we now have a documented certification process to follow and our clients have increased confidence in our shelters.

“We also plan to use the Service Technician certification to develop a re-certification program and that will be a revenue generator for our company. We would most definitely partner with OAR again in the future.”

41

humber valley potato

Humber Valley Potato Co., Deer Lake, NL

When Michael Campbell, president of Humber Valley Potato Company, decided to develop a new agrifoods product, the college’s Office of

Applied Research (OAR) delivered just the right combination of facilities, expertise and innovative personnel to help bring his Fresh Fry™ to life.

Working with Sharon McLennon, Industry Liaison and Centre for Agrifood

Development team members Leona Raymond and Cindy Morrissey in Carbonear, Humber Valley Potato was able to develop a Modified

Atmospheric Packaging (MAP) process, extending the shelf life of their fresh French Fry product by four weeks in comparison to similar products already in the market.

The MAP packaging process developed in partnership with the OAR is being implemented as a core process at the company’s new production facilities in Deer Lake, Newfoundland and Labrador. Regarding the success of the partnership with the OAR, the company is quick to point to the innovative and collaborative spirit that drives OAR staff.

“We have a great working relationship! The college staff took a high interest in our project, showing enthusiasm and helping to enhance our process for creating our new product, the Fresh Fry. Lab scheduling, flexibility, and professionalism were outstanding,” says Campbell.

“The profit of great ideas comes when you turn them into reality.”

Tom Hopkins

42

Michael Campbell

Humber Valley Potato Company

“I believe the most unique capability of the Centre for Agrifood

Development is the ability of the staff to give personal attention to each project, and to also demonstrate genuine interest in what we were trying to achieve. They were very accommodating to supply needed equipment, and understood our requirements for product development.”

The success of the project has Humber Valley Potato thinking beyond potatoes to packaging other fresh, extended shelf life vegetable products in the future.

In the meantime, Humber Valley is hard at work bringing their new production facility online and readying for their new product launch.

Partnering with the college has enabled the company to accelerate their development goals.

“The process of developing MAP packaging for our product validated our product’s potential, and defined our shelf life capabilities,” says Campbell.

Would Humber Valley recommend partnering with the college?

“We started our second project with the OAR team in February 2011.”

43

Pathway to Commercialization

Office of Applied Research: 5 year Summary

.

.

130+ Industries served since 2005

.

.

Over.50

Researchers Involved

.

.

12 Campuses Involved

.

.

over.$270,000 IRAP grants received

.

.

$10+.Million

Other grants received

.

.

10+ work term students employed

.

.

$9.5.Million

Current & Completed Projects

Idea/

Concept

Screening

R&D/

Discovery

Applied R&D

IP

Proof of

Concept

Product or

Process

Innovation/

Knowledge

Feasibility

& Prototype

Product

Development

Market

Testing

Demonstration/Incubation

Licensing

Startup/Serial

Entrepreneur

Production

Accelerators

Marketing

& Sales

Expansion

Entrepreneurs, Existing SMEs, Springboard Members, Angels & VCs, Government Support Agencies, Incubators

44

The services and activities of the college’s Office of

Applied Research (OAR) extend all along the Innovation

Continuum. OAR is committed to promoting the ideas and innovation of industry and college researchers and to transferring the benefits of innovation to industry and the community for positive economic and social impact .

Idea/

Concept

Screening

R&D/

Discovery

Applied R&D

IP

Proof of

Concept

Product or

Process

Innovation/

Knowledge

Feasibility

& Prototype

Product

Development

Market

Testing

Demonstration/Incubation

Licensing

Startup/Serial

Entrepreneur

Production

Accelerators

Marketing

& Sales

Expansion

Entrepreneurs, Existing SMEs, Springboard Members, Angels & VCs, Government Support Agencies, Incubators

45

Sample Industry Projects*

Industry.Partner

ACAN Windows Ltd./

Ted Kwon

Canadian Manufacturers &

Exporters /

David Haire

Demand Innovation Inc./

Bernard Cook

Demand Innovation Inc. /

Bernard Cook

Dockside Appetizers/

Henry Cowan

Exact Machining/

John Moores

Project.Title

Development of an Injection

Moulding Process

Lean Manufacturing

Consortium & Getting The

Right Things Done Workshop

Description

The Manufacturing Technology Centre assisted ACAN

Windows Ltd. in manufacturing a finished end cap product using the injection mould technology currently existing at the MTC.

The college provided assistance to Canadian

Manufacturers & Exporters (CME) to conduct a Lean

Diagnostic on five Central NL companies and determine opportunities for improvement. The Fluent Consortium is built around employing cooperation between member companies to build better practices and increase company capacity. The college assisted CME with bringing in the speaker for this workshop who provided training that is not readily available in this province.

Fabrication of Product Parts by Demand Innovation Inc.

(Project 1)

Development of a filter screen and accessories for coffee maker “Survival Perk”.

Research and Design Initiative for Demand Innovation Inc.

(Project 2)

Demand Innovation Inc. will be modifying and/or developing the next generation of the pressure infusion coffee maker the “Survival Perk”, which will be named

“The Squeeze”. Like the “Survival Perk”, “The Squeeze” will fall under the patent pending application of pressure infusion beverage device.

Development of a Fish Pate

Mould

Exact Machining Efficiency

Review

The Manufacturing Technology Centre (MTC) worked with Dockside Appetizers to assist in researching and developing a fish pate mould and packaging process.

Exact Machining is a company located in the rural area of Flower’s Cove specializing in manufacturing high quality plastic components for local manufacturing and snowmobile industries. The college assisted this company in research and implement innovative ways to increase productivity.

Foley and Janes Ltd./

Paul Foley

Development of a Production

Process for the PF Medical

Roller

The Manufacturing Technology Centre (MTC) worked with Janes and Foley to assist in researching and developing a production process for the PF Medical

Roller.

46

Industry.Partner

GFI Composites Ltd./

Patrick Galway

Splintered Minx

Productions/

Christina Hilborne

Tip of the Iceberg Inc. /

Peter O’Neil

Project.Title

Development of a Fiberglass

Moulding Process

Innovation Product

Development by Splintered

Production

Iceberg Ice Cube Prototype

Development

Description

The Manufacturing Technology Centre (MTC) worked with GFI Composites in researching and developing a fibreglass manufacturing process to produce the back doors of the all terrain enclosure.

The college assisted this company for a value addition to Agrifood products and quality improvement.

Humber Valley Potato

Company Inc./

Michael Campbell

IFS Enterprises/

Mark Ingerman

Value Addition to Humber

Valley Potato Co. Products

Development of a Card

Washing Machine

Jim Maunder Sculptures

Newfoundland Chocolate

Company/

Brent Smith

Development of a Working

Scale Model of the Proposed

Mount Pearl Water Sculpture

Development of a Unique

Chocolate Moulding Process

The Manufacturing Technology Centre (MTC) at the college provided assistance to this company to help in researching and developing a prototype for a card operated washing machine.

The college provided assistance to Jim Maunder, a local art proprietor, to create a water sculpture for the City of

Mount Pearl.

Newfoundland Chocolate Company is a local manufacturer producing the finest Belgium chocolates.

The college MTC assisted in research methods for moulding chocolate, including material, melting temperatures and mould design.

The college provided assistance to Splintered Minx

Productions for the development of a new CoolMoon plastic furniture with LED lighting.

The college assisted Tip of the Iceberg Inc. in developing an improved design for the ice cube structure which will be developed as a first component in the company’s planned creation of a manufacturing unit. The OAR’s role is to manufacture a prototype pattern which is modular in nature to facilitate the creation of iceberg shaped ice cubes on an industrial scale.

*A sample of industry projects from 2008-2010.

47

Contact Us