Nondestructive Testing of Aging Aircraft

advertisement

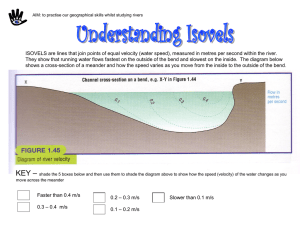

by Gary L. Burkhardt and lay L. Fisher, SeD A eam of Southwest Research Institute en gineers is developing more effective methods of detecting cracks in airplanes that can lead to deadly crashes - an increasingly urgent conce rn as the service life of aging aircraft is further ex tend ed . Several types of U.s. Air Force aircraft already have exceeded their designed 20- to 30-year "[etimes; the Air Force plans to extend some airframe service lifetimes up to 80 years. For example, the 1950s-vintage B-52 bomber and KC-135 tanker will operate until 2030 and 2040, respective ly. The nation's commercial aircraft fleet also is aging as airlines cu rb capita l equ ipment costs by extending the service lives of their Dr. Jay Fisher, left, is a program manager in SwRI's Applied Physics Division. Fisher is responsible for program development and project management for theoretical investigation and applied development of advanced electromagnetic nondestructive evaluation (NDE) techniques. Gary Burkhardt, right, is a staff scientist in the Applied Physics Division. His expertise includes the development of electromagnetic techniques and sensors for NDE of components and structures. Burkhardt holds five patents and has authored more than 60 publications in the NDE field. Fisher and Burkhardt previously developed inspection techniques for aircraft structures, and have evaluated reliability of other techniques. These evaluations fed them to understand shortcomings in present inspection technology and the need for improved sensors. 6 Technology Today . Fall 2001 aircraft. Aging can result i.n widespread fatigu e cracking of the aircraft's structure. Cracks emanating from fastener holes in the outer skin of the wing an d fuselage constitute a major safety issue. The in-air skin failure 13 years ago of an Aloha Airlines jet was the result of skin failure An "arrow" plot of eddy-current density illustrates current paths produced by the meander coil on an inspection surface with a long flaw. The arrows indicate current density according to the color bar scale at the top of the iffustration produced by cracks that formed from many small rivet holes. Aloha Airlines Flight 243 was en route to Honolulu on April 28, 1988, at 24,000 feet when a large section of the fuselage was ripped from the Boeing 737 airliner. Miraculously, the airplane landed safely, and the incident resulted in only one fatality. The National Transportation Safety Board accident report noted that a passenger boarding the airplane noticed a long crack in a row of rivets above the cabin door but did not tell the flight crew before takeoff. The eddy-current testing (ECT) method of nondestructive evaluation (NDE) can detect tiny cracks, which must be repaired before they become large enough to threaten the safety of an aircraft. The most common technique involves systematically moving a probe around each fastener. This process is time consuming because of the large number of fasteners involved. For example, the fuselage of a C-5 cargo plane has more than 500,000 fasteners. Although some new ECT technologies are in use, some are slow and difficult to set up and calibrate. One ECT technique can locate small cracks but cannot reliably detect cracks that connect two fastener holes. This shortcoming is of major concern because these connecting cracks can lead to the kind of catastrophic damage that caused the Aloha Airlines incident. SwRI's internal research and development program has funded work by engineers in the Institute's Applied Physics Division w ho proposed development of a more effective EeT method for detecting these dangerous cracks. Background Component Detected by Sensors Eer systems use alternating magnetic fields to induce electrical current flow into a test specimen. This is usually accomplished using single or multiple electromagnetic coils, with the coil axes perpendicular to the surface under inspection, or a sheet conductor that induces current flow over a large area. SwRI researchers believed that a meander coil system could detect cracks of all sizes consistently over a relatively large area at one time. A meander coil consists of a strip of conducting metal that repeatedly doubles back on itself, resulting in a series of parallel metallic pathways. An electrically activated meander coil generates eddy currents in the inspected part, and the magnetic fields from these currents I Sensors Coil The current flow (/) direction shown by the arrows alternates in opposite directions for each adjacent conductor line in the meander coil. The meander excitation coil generates eddy currents in the part under inspection, and flaws are detected using sensors arranged so as to be sensitive to magnetic fields (8) parallel to the inspection surface. Technology Today. Fall 2001 7 A laboratory breadboard of a small-scale array probe is shown on an aircraft wing skin specimen containing fasteners. This SwRI-developed probe could dramatically cut the time required to inspect the many thousands of fasteners ' holes in aircraft. Modeling As a first step, the research team developed a three-dimensional electromagnetic model to optimize the meander coil design. The software model calculated the edd y-curren t distribution in the inspected material and the associated magnetic fiel d d istribution above its surface. The team used the resulting information to determine the orientation and loca tion of the receiver sensors and to design the meander coil. The modeling showed that a m eand er coil device would produce detectable flaw responses for short and long cracks. This d evice would thus be superior to certain conventional sensors that have d ifficulty detecting long cracks. are detected by giant magnetoresistive (GMR) sensors, solid-state devices that change resistance in response to a m agnetic field. These GMR sensors are arranged to sense the fields parallel to the inspection surface. Where no crack exists, there is no field component in this direction, and no direct coupling occurs between the main field and the sensor. If a crack does exist, a magnetic field is produced in this parallel direction. This parallel field is generated in the inspected component by eddy cu rrents, whose paths are d isturbed by the crack. The team built a prototype probe with a single GMR sensor based on promising modeling results. The m eand er coil was fabricated with conductors spaced close together on printed circuit board material. A GMR sensor was placed against th e meander coil with the sensor's active area positioned between two conductors. Engineers bonded these components to form a probe package and placed B InspectIon Surface The non-conducting boundary of the flaw causes the electrical currents to bend and flow parallel to the flaw. This perturbed current generates magnetic field (B) in a direction parallel to both the inspection surface and the unperturbed current lines. End View Current Lines 8 Technology Today. Fall 2001 D009432 II The bottom of the small-scale array probe shows the sensors positioned in holes cut between the meander coil traces. a bar magnet on the package to provide the magnetic bias field required by the GMR senso r. Engineers used the probe to systematically scan several aluminum test panels. The panels contained fastener holes with no cracks as well as fla wed holes with induced notches to simulate cracks. The flaws that connected fastener holes showed up well, as did those that were not connecting. The probe was also scanned over a plastic shim fastened to the panel's surface to simulate paint that frequently separates a sensor from the metal part under inspection. These separations can result in high electromagnetic noi se and reduced crack detection capability in conventional EeT devices, but the meander probe sustained almost no negative effect from this "lift-off" condition. Small-scale array probe The research team then prepared a probe with several GMR sensors to demonstrate the feasibility of an array probe and to gain experience with fabricating an array. Engineers employed the same coil configuration as with the singleprobe sensor, but they incorporated fom GMR sensors in die form (a bare device with no package). The team evaluated the array probe for sensitivity and spatial resolution. The probe was scanned over the same panel maanc;l4.IxI, 0 degree rotalioo " used in the sin gler-------- probe tests. The 20 probe readily 8.6-mmFlaw detected connecting and nonconnecting flaws, even th ough the resolution was reduced because the 1.2mm spacing between the array sensors is g reater 60 than the O.5-nun spacing between 20 3D 40 50 60 Index Increment (mm) scans used for the single sensor. In a Color images are generated from meander probe signals as the probe is test with an scanned over a test specimen. The top image shows signals from fastener un£lawed hole and holes with a connecting flaw (top signal) and no flaws (bottom signal). The holes with 3.2- and bottom image shows signals from fastener holes with short flaws . Also 1.6-mm flaws, the shown is an area where the probe was lifted off of the specimen surface probe detected the with very little response generated by the lift-off change. 3.2-mm flaw. To detect the 1.6-mm on-board electronics. Externally funded flaw clearly, the sensor spacing would need to be reduced to approximately development may lead to a chip contain0.75 mm. ing sensors and integrated electronics .•:. " Conclusions SwRI staff demonstrated the feasibility of meander probe technology. The Instih.tte is seeking external funding to develop the sensor probe further. Future development could involve an array w ith more elements and containing Technology Today . Fall 2001 Comments about this article? Con.tact Burkhardt at (210) 522-2705 or gb urkhardt@swri. org. Acknowledgement The authors would like to acknowledge Staff Technician David Jones for his contributions to experimental lab testing of the probe. 9