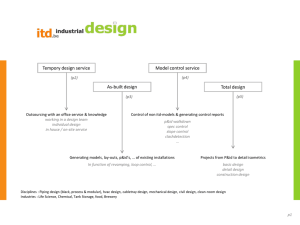

3d and 4d modeling for design and construction coordination

advertisement