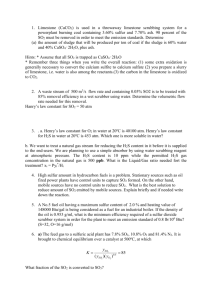

Helpful Calculations

advertisement

BENCH TRIALS AND CELLAR ADDITIONS COMMON RATES OF USE AND HELPFUL CALCULATIONS ENGLISH TO METRIC AND BACK oz = ounce lb = pound G = gallon g = gram kg = kilogram mL = milliliter L = liter hL = hectoliter 1 oz (fl) = 30 ml 1 ml = 1 cc = 0.035 fl.oz 1 oz (wt) = 28.35 g 1 g (100 mg) = 0.035 oz 1 quart = 0.95 L 1 L = 1000 ml = 1.06 qt 1 lb (16 oz) = 454 g 1 kg (1000 g) = 2.204 lb 1 G = 3 qt = 3785 mL 1 hL = 100 L = 26.4 G 1 ton = 907 kg 1 tonne = 1000 kg = 2204 lb UNITS 1 lb / 1000 G = 0.45 g/G = 0.00012 g/ml = 0.1 g / 100 ml = 100 ppm = 0.75 g/750 ml = 10 g/hL 1 ppm = 1 / 1,000,0000 = 10 = 1 mg/L = 0.0001 g/100 mL = 0.1 g/hL -6 0.12 g/L = 120 ppm COMMON ADDITION FORMULAS ACID (addition) +0.1 g/100 mL = 3.8 g tartaric in 1 G wine = 8.3 lb tartaric / 1000 G = 7.4 lb malic / 1000 G = 7.1 lb citric / 1000 G CARBONATE (reduces acid) -0.1 g/100 mL COPPER (treats sulfides/mercaptans) +0.1 ppm = 2.5 g/G calcium carbonate = 5.5 lb/1000 G = 3.8 g/G potassium carbonate = 8.3 lb/1000 G = 0.15 mL of 1% CuSO4.5H2O solution / G of wine = 0.1 mL of 0.05% CuSO4.5H2O in 120 mL (4 oz) wine ASCORBIC ACID (treats disulfides) +10 ppm = 0.1 mL of 1% solution in 100 mL wine = 3.78 mL/G ANY MATERIAL +1% = 1g/100 mL = 7.50 g/750 mL = 37.85 g/G +1 lb/1000 G = 0.45 g/G = 0.012 g/100 mL = 0.09 g/750 mL = 37.85 g ascorbic acid crystals in 1000 G wine SO2 (addition) +100 ppm = 76 g Kmeta/G = 7.6 mL of 5% SO2 = 6.3 mL of 6% SO2 = 45.4 g/Kmeta/60 G = 757 g Kmeta/1000 G Normality: normality (1) x volume (1) = normality(2) x normality(2) OR - amount to add = normality wanted x total volume wanted normality of stock solution Percentage: % additions : % (1) x volume (1) = % (2) x volume (2) OR - volume to add = % wanted x total volume wanted % solution to be added Parts per million ppm = grams (or mL) added x 1,000,000 + wine volume in mL (multiply Gallons by 3785 for ML) amount to add in grams (or mL) = wine volume in mL + 1,000,000 x ppm wanted (Adjust for strength of material added. For Pot. metabisulfite, the strength of the actual food grade material averages 50%) Chart and calculations courtesy of Lisa Van de Water Call our knowledgable sales staff for technical assistance Orders: 800.585.5562 | bsgwine.com 55 AMOUNTS (mL) TO ADD TO SAMPLE BOTTLES TO EQUAL CELLAR DOSES (in lb/1000G) 100 mL sample bottle 250 mL sample bottle % Soln 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1.0 0.15 0.30 0.60 1.20 2.4 4.8 9.6 0.38 0.75 1.50 3.0 6.0 12.0 24.0 1.2 0.12 0.25 0.50 1.00 2.0 4.0 8.0 0.31 0.62 1.25 2.5 5.0 10.0 20.0 2.0 0.07 0.15 0.30 0.60 1.2 2.4 4.8 0.19 0.38 0.75 1.5 3.0 6.0 12.0 2.4 0.06 0.12 0.25 0.50 1.0 2.0 4.0 0.16 0.31 0.62 1.25 2.5 5.0 10.0 4.5 0.03 0.07 0.13 0.27 0.53 1.1 2.1 0.08 0.17 0.33 0.67 1.33 2.7 5.3 4.8 0.03 0.06 0.12 0.25 0.50 1.0 2.0 0.08 0.16 0.31 0.62 1.25 2.5 5.0 5.0 0.03 0.06 0.12 0.24 0.48 0.96 1.9 0.07 0.15 0.30 0.60 1.20 2.4 4.8 375 mL sample bottle 750 mL sample bottle % Soln 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1.0 0.56 1.12 2.25 4.50 9.0 18.0 36.0 1.12 2.25 4.5 9.0 18.0 36.0 72.0 1.2 0.47 0.94 1.87 3.75 7.5 15.0 30.0 0.94 1.87 3.75 7.5 15.0 30.0 60.0 2.0 0.28 0.56 1.12 2.25 4.5 9.0 18.0 0.56 1.12 2.25 4.5 9.0 18.0 36.0 2.4 0.23 0.47 0.94 1.87 3.8 7.5 15.0 0.47 0.94 1.87 3.8 7.5 15.0 30.0 4.5 0.12 0.25 0.50 1.00 2.0 4.0 8.0 0.25 0.50 1.00 2.0 4.0 8.0 16.0 4.8 0.12 0.23 0.47 0.94 1.9 3.8 7.5 0.23 0.47 0.94 1.9 3.8 7.5 15.0 5.0 0.11 0.22 0.45 0.90 1.8 3.6 7.2 0.22 0.45 0.90 1.8 3.6 7.2 14.4 1000 mL sample bottle 3785 mL sample ( 1 Gallon) % Soln 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1/8 lb 1/4 lb 1/2 lb 1 lb 2 lb 4 lb 8 lb 1.0 1.50 3.00 6.00 12.0 24.0 48.0 96 5.62 11.25 22.50 45.0 90.0 180 360 1.2 1.25 2.5 5.00 10.0 20.0 40.0 80 4.69 9.37 18.75 37.5 75.0 150 300 2.0 0.75 1.50 3.00 6.0 12.0 24.0 48 2.81 5.62 11.25 22.5 45.0 90 180 2.4 0.62 1.12 2.50 5.0 10.0 20.0 40 2.34 4.69 9.37 18.7 37.5 75 150 4.5 0.33 0.67 1.33 2.7 5.3 10.7 21 1.25 2.50 5.00 10.0 20.0 40 80 4.8 0.31 0.62 1.12 2.5 5.0 10.0 20 1.17 2.34 4.69 9.4 18.7 38 75 5.0 0.30 0.60 1.20 2.4 4.8 9.6 19 1.12 2.25 4.50 9.0 18.0 36 72 Chart courtesy of Lisa Van de Water 56 Orders: 800.585.5562 | bsgwine.com CALCULATING MOLECULAR SO2 DISTRIBUTION OF FREE SO2 AT VARIOUS pH’S pH %SO2 (molecular) %HSO3 %SO3 0.009 2.90 7.5 2.95 6.6 3.00 6.1 3.05 5.3 3.10 4.9 3.15 4.3 3.20 3.9 3.25 3.4 3.30 3.1 3.35 2.7 3.40 2.5 3.45 2.2 3.50 2.0 3.55 1.8 3.60 1.6 3.65 1.4 3.70 1.3 3.75 1.1 3.80 1.0 3.85 0.9 3.90 0.8 3.95 0.7 4.00 0.7 92.5 FREE SO2 NEEDED TO ACHIEVE MOLECULAR SO2 OF: 0.8 ppm 0.5 ppm 11 ppm free 7 ppm free 12 7 8 93.9 0.012 13 15 9 95.1 0.015 16 10 19 12 96.1 96.8 97.5 0.019 0.024 0.030 21 13 23 15 26 16 29 18 32 20 37 23 25 98.0 0.038 40 46 29 98.4 0.048 50 31 57 36 98.7 0.061 63 39 72 45 49 98.9 0.077 79 91 57 99.1 0.097 99 62 114 71 125 78 99.2 0.122 (Adapted from: Enology Briefs I (#1), Feb/Mar 1982. University of California Cooperative Extension) Free SO2 consists of 3 species: molecular SO2 (directly active in preventing oxidation and spoilage), and two ions, HSO3 and SO3, which comprise the major portion of the free SO2 but are much less reactive than molecular SO2. The percentage of free SO2 that exists as molecular SO2 goes down as pH goes up (see 2nd column), so that for the same amount of free SO2, wines with higher pH have less molecular SO2, and therefore less SO2 protection. The last 2 columns show free SO2 levels needed at different pH’s to achieve two levels of molecular SO2, 0.5 ppm and 0.8 ppm, the normal range for SO2 in wine. The molecular SO2 level can be extrapolated from the chart or calculated by using this formula: molecular SO2 = free SO2 + (1 + 10pH -1.8) The SO2 levels shown on this chart are NOT appropriate for all wines in all circumstances, so they should NOT be considered recommendations. A molecular SO2 of 0.8 ppm, while an acceptable maximum for some wines, is too high for many wines. Molecular SO2 below 0.8 ppm, (0.4-0.7 ppm), is preferable when wine is consumed. Wineries adjusting to a standard free SO2 level instead of monitoring molecular SO2 will have varying SO2 impact on their wines; adjusting to molecular SO2 provides consistent SO2 management. In general, a lower molecular SO2 is suggested for reds than whites, around 0.4-0.5 ppm at bottling. Wines with higher pH, red or white, may require too high a level of total SO2 to achieve reasonable molecular SO2 levels. Rather than have excessive bound SO2 (over 100 ppm), wineries must rely on a combination of factors, including susceptibility to spoilage or oxidation, to help select a manageable level of SO2 for higher pH wines. Some pH problems can be relieved by adjusting pH downward with tartaric acid. Above comments courtesy of Lisa Van de Water Call our knowledgable sales staff for technical assistance Orders: 800.585.5562 | bsgwine.com 57