Process Analysis for Esterification and Two

advertisement

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

41

Process Analysis for Esterification and Two-step

Transesterification in the Biodiesel Production

Plant

Winardi Sani1 , Khalid Hasnan2 , Mohd Zainal Md Yusof3

Abstract—

Esterification and transesterification reacting

vessels are the core unit operations of typical industrial biodiesel

production plants. Feedstock with a high free fatty acid is

esterified first in an acid condition before continuing to the

transesterification under presence of an alkaline catalyst. Process

analysis is an important tool to a plant engineer in the biodiesel

plant operation to estimate the conversion of the palm oil to

biodiesel and the yield. This paper describes the process analysis

for the methanolysis of crude palm oil through the esterification

and the subsequent two-step transesterification in the biodiesel

production plant with a capacity of 1000 kg per batch. Physical

pretreatment of the crude palm oil (CPO) is necessary to remove

the unsaponifiable and other undesired trace components to

become bleached palm oil (BPO). Conversion at 85% (w/w) of

free fatty acid (FFA) to biodiesel has been achieved in the

esterification of BPO with methanol under acid catalyst reaction.

The first transesterification is able to produce up to 88% (w/w)

conversion of triglycerides (TG) to biodiesel. The remaining TG

is carried out in the second step of the transesterification to

complete the reaction toward achieving a high methyl ester

content. Analytical method using gas chromatography is used for

validation against the theoretical results. GC analysis results

conforms the conversion estimated by the process analyses based

on the material balance, especially in the esterification and firststep transesterification, 81% and 88%, respectively. After one

hour retention time of the second-step transesterification, 95%

conversion of TG to biodiesel has been achieved. The process

analysis applied at the equilibrium states shows consequently in

accordance with the GC analysis results. Therefore, it offers a

useful compendium to a plant engineer for better understanding

of the biodiesel processes.

Index

Term—

Biodiesel,

Esterification,

transesterification, Material balance.

Two-step

I.

INTRODUCTION

Biodiesel has attracted the attention of many researchers and

engineers more than two decades worldwide to prolong the

lifetime of the fossil-based fuel. Issues in the environments,

the limited reserves of petroleum, and the high cost of

1

[Winardi Sani is with the Department of Mechanical Engineering T echnology

(Plant), Faculty of Engineering T echnology, Universiti T un Hussein Onn

Malaysia, 86400 Parit Raja, Batu Pahat, Johor, Malaysia

winardi@uthm.edu,my]

2

3

biodiesel as well as the oil price fluctuation in the market,

among other things, are the major driving forces in conducting

research and development in the renewable energy sector

either in the lab scale or the industrial one. The pilot plant in

UTHM with a capacity at one metric ton (MT) and operated

in batch mode under a supervisory control and data acquisition

(SCADA) system, has been constructed to strengthen a

promising research in area of renewable energy. Crude palm

oil (CPO) is chosen as the dominant feedstock due to the

abundance of this crop in the State of Johor which is also the

biggest producer of palm oil in the Peninsular of Malaysia

with around 0.7 Mha of the plantation area for the palm trees.

Owing to the grandness of the palm oil to the community and

to sustain the inherently local strength, UTHM has taken a

prudent initiative to explore the potential niche area in the

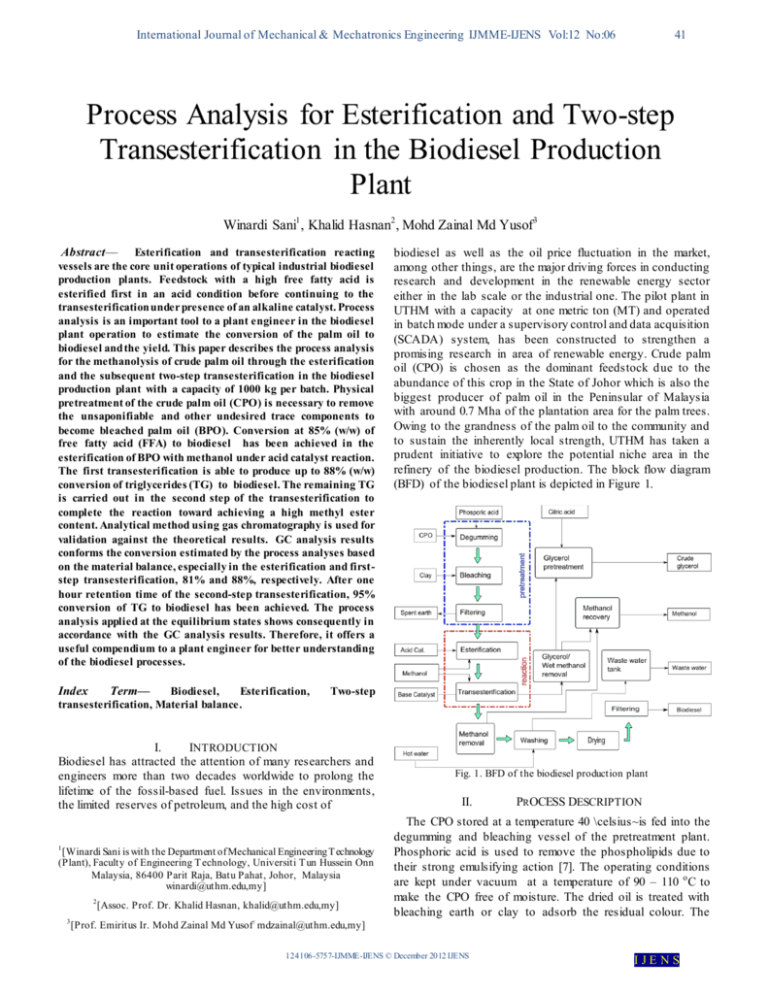

refinery of the biodiesel production. The block flow diagram

(BFD) of the biodiesel plant is depicted in Figure 1.

[Assoc. Prof. Dr. Khalid Hasnan, khalid@uthm.edu,my]

Fig. 1. BFD of the biodiesel production plant

II.

PROCESS DESCRIPTION

The CPO stored at a temperature 40 \celsius~is fed into the

degumming and bleaching vessel of the pretreatment plant.

Phosphoric acid is used to remove the phospholipids due to

their strong emulsifying action [7]. The operating conditions

are kept under vacuum at a temperature of 90 – 110 o C to

make the CPO free of moisture. The dried oil is treated with

bleaching earth or clay to adsorb the residual colour. The

[Prof. Emiritus Ir. Mohd Zainal Md Yusof : mdzainal@uthm.edu,my]

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

mixture of oil is the passed through to the 10 µm filter for

separation of the spent earth from the oil. The obtained oil

refined in the pretreatment plant is a bleached, degummed, dry

crude oil and yellow-reddish in colour. Researchers [4,5,6]

reported that the esterification process is required if the

feedstock has more than 0.5% by weight of free fatty acid.

The transesterification of the oil is used to convert the

remaining oil completely into biodiesel. These two chemical

reactions are the core processes in the biodiesel production.

The downstream processes are employed for the purification

of the crude biodiesel, the recovery of the methanol, and

neutralization of the glycerol byproduct, along with the

treatment of the waste water.treatment of the waste water.

Esterification refers to the alcoholysis of triglycerides or

renewable oil under presence of an acid catalyst, and if an

alkaline catalyst is employed instead of the acid counterpart,

the process is called transesterification [2,9]. The overal

chemical reaction of the transesterification of palm oil is

described by the following stoichiometric equation:

⇔

(1)

where PO, M, G, and E, each represents palm oil, methanol,

glycerol, and methyl ester or biodiesel, respectively.

Theoretically, under the appropriate conditions of pressure and

temperature, in the presence of a catalyst, each mole of palm

oil requires three moles of methanol to produce three moles of

biodiesel and one mole of undesired glycerol. Since the

reaction is reversible, the forward direction is in favour toward

the desired product. The esterification process hereby takes

place in one hour with water as the by product. However, this

process also yields the desired biodiesel at a certain extent of

conversion and glycerol as the byproduct. Water and glycerol

resulted from the reaction must be discharged after

completion. The subsequent transesterification is done in two

steps. Removal of glycerol by manually phase separation is

done before proceeding to the second step. At the end of the

transesterification, hot water at 5% (w/w) is introduced gently

to the vessel to capture the remaining glycerol and a vacuum

flashing follows thereafter to ensure the crude biodiesel free of

water. The operating conditions for both processes are at 65 o C

and 2 bar to ascertain the reacting mixture being in liquid

phase. This higher pressure is established by introducing

nitrogen gas to the mechanical-agitated vessels.The

esterification process hereby takes place in one hour with

water as the by product. However, this process also yields the

desired biodiesel at a certain extent of conversion and glycerol

as the byproduct. Water and glycerol resulted from the

reaction must be discharged after completion. The subsequent

transesterification is done in two steps. Removal of glycerol

by manually phase separation is done before proceeding to the

second step. At the end of the transesterification, hot water at

5 % (w/w) is introduced gently to the vessel to capture the

remaining glycerol and a vacuum flashing follows thereafter

to ensure the crude biodiesel being free of water. The

operating conditions for both processes are at 65 o C and 2 bar

to ascertain the reacting mixture being in liquid phase. This

42

higher pressure is established by introducing nitrogen gas to

the mechanical-agitated vessels.

III.

PROCESS SPECIFICATION

This quantifies the amount of the reacting components

necessary for the entire processes of producing biodiesel from

palm oil. The process spefication is indicated in Table 1.

In the esterification of the bleached, degummed palm oil. para

toluenesulfonate, C7 H8 O3 S, abbreviated with PTSA, is

employed for the acid catalyst. Sodium methoxide (NaOCH 3 )

30% acts as the alkaline catalyst in the first and second

transesterification. This specification makes the plant operator

convenient in preparing the chemical materials. Each reaction

occurs in nitrogen blanket which ensures the inherently safe

condition.

T ABLE I

REACT ION SPECIFICAT ION /1000 KG OF OIL

Ratio To Oil

Reaction

Esterification

First

Transesterification

Second

Transesterification

IV.

M eOH [mol]

PTSA[wt %]

3

0.3

NaOM e

[kg]

-

1.25

17.7

1.25

5

MATERIAL AND MODEL

The crude palm oil (CPO) with a food grade is purchased

from the local palm oil refinery. The FFA level as palmitic is

at 3.4 % (w/w) , and the moisture content of 0.2 % (w/w) by

measurement. It means the oil contains 94.6 % (w/w) of

triglycerides and other trace components. [1] reported that the

triglycerides comprises of five different fatty acids, seeTable

2, the average molecular mass M=848.24 kg/kmol. To enable

analysing the mass balance in the chemical reactions, the palm

oil is modeled as tripalmitic due to the major contribution in

the composition. Methyl palmitate or palmitic acid methyl

ester is therefore the biodiesel under this study.

The general chemical reaction in Eq. (1) becomes therefore a

methanolysis of tripalmitin as stated in Figure 2.

Fig. 2. Methaloysis of T ripalmitin

This stoichiometric equation is used to determine the

theoretical yield and the conversion of the triglycerides. The

conversion of the reacting component, $X_i$~is defined as

follows:

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

43

(2)

where n i0 and n i are the moles of the reacting components

before and after reaction in a volume-constant batch reactor V.

V.

A NALYSIS AND RESULTS

For the theoretical analysis purpose, the fatty acid attached in

the glycerol backbone are modeled solely as the

tripalmiticacid. Additionally, GC analysis for methyl ester

content determination of samples during the plant operation is

also applicable for validation. The material balance will be

applied following the operating stage performed in the

esterification

T ABLE II

MOLAR MASS OF PALM OIL

Triglyceride

Chemical

M % [kg/kmol]

structure

Trimyristin

1

C45 H86 O6

7.2316

Tripalmitin

45

C51 H98 O6

363.2940

Tristearin

4

C57 H110 O6

35.6592

Triolein

39

C57 H104 O6

345.3185

Trilinolein

11

C57 H98 O6

96.7323

and transesterification vessels of the actual plant. The process

calculations of this balance is performed based on the mole

unit, and it is however tabulated for convenient in the mass

unit.

Fig. 4. M aterial Streams for Esterification

Comp.[%]

A. Esterification

The FFA level of 3.4% (w/w) needs to be reduced to 0.5%

maximum to avoid saponification problem in the

transesterification. Esterification itself is a chemical reaction

similar to the Figure \ref{chapter4:fig:tripalmitintrans}, with

the difference in the catalyst used. Instead of an alkaline

condition, esterification employs an acid catalyst. Converting

the FFA into the biodiesel governs the stoichiometric as

shown in Figure 2.

Fig. 3. Esterification of FFA

Refering to Figure 3, R stands for palmitic acid,

CH3 (CH2 )14 COOH. The reacting vessel VE 201 in Figure 4

illustrates the material streams at the inlet and outlets for the

esterification.

Lowering the FFA level to 0.5\% yields 85.3\% conversion to

the desired product, or it is equivalent to 30.6 kg of biodiesel,

see Table III.

T ABLE III

MAT ERIAL BALANCE FOR FFA REDUCT ION

Inlet Streams [kg]

Outlet

Streams[kg]

1

2

3

FFA

34.0

5

MeOH

96.0

92.4

PTSA

3.0

3.0

Water

2.0

4

FAME

30.6

TOTAL

135.0

135.0

The theoretical conversion of the FFA (M=256 kg/kmol), X,

into biodiesel analyzed through the following relationship:

Material

(3)

The conversion of FFA to biodiesel is 85.3\%, or in other

word, 5 kg of FFA remains in the oil after esterification. The

conversion of the FFA to biodiesel stops at this level due to

water accumulation that hinders toward completion of the

reaction process. Refering to Table 3, 30.6 kg of crude

biodiesel (Fatty Acid Methyl Ester, FAME) is obtained and

water also generated (4 kg) by converting the FFA level down

to 0.5%. Its function is to accelerates the reaction process

without getting involved in the reaction. During the

esterification of FFA to biodiesel, an acid transesterification of

triglyceride takes also place. The material balance of this

process is formed using the stoichiometric equation in Figure

2 but under presence of an acid catalyst. With ΔmTG = 187.14

kg, it yields 81% conversion. FAME is the desired product in

the esterification along with reducing the FFA content. The

first crude biodiesel produced through the esterification comes

from the FFA conversion and the TG reaction. In other words,

m3,FAME = ΔmFFA + ΔmTG . And the theoretical yield, referring

to the definition in [8] is Φ = 80.7%. The yield, Φ is defined

as the weight percentage of the final product relative to the

CPO weight at the initial stage. Water and glycerol are

discharged to the glycerol neutralization vessel by separation.

The main product is then transfered to vessel VE 202 for

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

transesterification reaction.

B. First Transesterification

The acid catalyst resulted from the previous esterification

must be first neutralized. However, the conversion of the TG

to biodiesel takes place at a moderate level. The reaction shall

therefore be completed in the second reaction to th e desired

conversion up to 96.5 % minimum.

44

the conversion of the FFA into s oap in the alkaline condition.

5 kg of FFA produces 5.43 sodium salt that must be remo ved

after transesterification. The amount of the alkaline catalyst

required for the neutralization of the FFA is calculated as

follows:

(6)

C. Neutrailization

The acid condition of the oil mixture in the previous process

must be neutralized before proceeding to the alkaline

transesterification. The alkaline catalyst is employed to

neutralize the existing PTSA (CH3 C6H4 SO3 H). This process

is described in the following stoiochiometric equation:

Methylsulfuric acid sodium salt (M = 134.09 kg/kmol) formed

in the Eq. (1) is soluble in water. Toluene (normal boiling

point at 110.6 o C) is also produced during this reaction and it

will be removed in the vacuum flashing.

PTSA acts as the limiting reactant and it therefore reacts with

the sodium methoxide completely at the end of the process.

Based on the stoichiometric equation, 1 mole of sodium ion is

required to form the soap. Since the methoxide exists in the

form of sodium methoxide at a concentration of 30 %, 1.336

kg of the alkaline chemical (or 0.95 kg of NaOCH3 ) is

required to thoroughly neutralize 3 kg of the acid catalyst

(PTSA). Table 4 shows the material balance for the reaction

process. 2.34 kg of salt is formed after the neutralization stage,

and it must be removed after the first-step transesterification.

T ABLE IV

MAT ERIAL BALANCE FOR FFA NEUT RALIZAT ION

Inlet Streams [kg]

Material

1

FFA

NaOMe

Salt

Toluene

TOTAL

2

3.00

16.40

19.40

Outlet

Streams[kg]

3

5

15.45

2.34

1.61

19.40

D.Soap Formation by FFA

The dissolution of the sodium methoxide in the methanol

leads to the formation of the methoxide ion and methanol. The

remaining free fatty acid (FFA) resulted from the previous

esterification is then converted by the sodium methoxide to

soap (sodium palmitate, M = 278.41 kg/kmol) according to the

following reaction:

For the material balance calculation, the FFA is used as the

limiting reactant since it must be totally removed and onverted

into soap. The neutralization process produces also methanol.

Table 5gives the results of the material and mass balance for

where the values of the remaining FFA at 0.5 wt. %, M FFA =

256.4 kg/kmol, and M MeOH = 54.02 kg/kmol as well as mTG

=187.43 kg. The sodium ion is present in the sodium metoxide

30% by weight, then:

(7)

In the first step transesterification, the remaining triglycerides

are converted to biodiesel

T ABLE V

MAT ERIAL BALANCE FOR SOAP FORMAT ION

Inlet

Outlet

Streams [kg]

Streams[kg]

1

3

FFA

5.0

NaOMe

15.46

14.41

Soap

0.00

5.43

Methanol

104.00

104.62

TOTAL

124.46

19.40

The following section analyses the biodiesel formation in this

step.

Material

E. Alkaline catalyst and methanol

Sodium methoxide 30\% by weight required to neutralize

the acid catalyst and the FFA has been determined previously.

The methanol content of the alkaline catalyst must be included

when calculating the total methanol needed for the right osing

of the reactants. With 1.25 molar ratio methanol to the initial

TG, the actual molar ratio is above 80 % in methanol excess.

With 1.25 molar ratio methanol to the initial TG, the actual

molar ratio is above 80% in methanol excess. With 187.4251

kg as the remaining triglycerides or it is equivalent to 0.2322

mol (M = 807.3 kmol/kg). The actual amount of methanol in

the reaction is:

(8)

where mTG = 964.0 kg, M TG = 807.0 kg/kmol, and M MeOH =

32.0 kg/kmol. The quantity of the alkaline catalyst is set

through the relationship:

(9)

that is equivalent to 11.333 kg of sodium methoxide 30% (3.4

kg NaOH). The total sodium methoxide necessary is

13.225kg. That is the sum of the catalyst for neutralization and

the actual catalyst in the base condition. The total methanol in

the first transesterification is actually the sum of the methanol

in equation (8) and methanol inherently at 70% in the sodium

methoxide. It corresponds to 57.483 kg or 1.8 mol. The mole

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

ratio of methanol to the oil is then 7.74:1, that means, the

methanol excess is 4.34 mole relative to the theoretical

stoichiometrics, as indicated in Figure 2. The neutralization of

the acid catalyst and the remaining FFA contribute to the low

conversion of the oil to biodiesel. The sodium methoxide

becomes less reactive as alkaline catalyst for the biodiesel

production. It acts first as the neutralizing reactant before as

the catalyst. It prevents the transesterification from

completion. The conversion of the oil to biodiesel therefore

reduces significantly. The total conversion of TG to biodiesel

yields XTG = 88.3%. Table 6 clarifies the overall mass balance

of the first transeterification process to produce the second

crude biodiesel. The glycerol produced during the reaction is

at 11.4% of the consumed triglycerides (74.61 kg).

T ABLE VI

MAT ERIAL BALANCE FOR T HE 1 ST T RANSEST ERIFICAT ION

Outlet

Streams[kg]

3

MeOH

48.61

TG

112.82

FAME

74.97

Glycerol

34

8.5118

TOTAL

244.91

244.91

After the first transesterification, the crude biodiesel

undergoes a phase separation based on a difference in density.

The reacting vessel VE 202 contains solely the crude biodiesel

and the remaining triglycerides.

Material

Inlet

Streams [kg]

1

57.48

187.4251

F. Second Transesterification

In the same vessel, the second transesterification is

accomplished to complete thoroughly the reaction to a higher

conversion of oil to the biodiesel product. With the desired

remaining triglycerides of 0.2 w/w % maximum , as required

in the EN 14214 standard, the remaining oil after the second

transesterification is then: the uncoverted oil ist 1.92 kg and

can be removed partly by means of the water washing and the

vacuum flashing at the end of the process. The methanol in

excess in chosen hereby, and the triglycerides becomes the

limiting reactant. The amount of the alkaline catalyst being

added reduces to 1.5 w/w % or 5.0 kg of NaOCH3 30%, which

is also specified in Table 1. The second step is accordingly the

ultimate transesterification, where the TG conversion to crude

biodiesel must be at the highest point for the complete

reaction. This is accomplished by the high excess of methanol.

The theoretical conversion at 96.5 % minimum shall

accordingly be also achieved in the real plant operation. Table

7 shows the material balance for the second transesterification.

45

T ABLE VII

MAT ERIAL BALANCE FOR T HE SECOND

T RANSEST ERIFICAT ION

Material

MeOH

TG

FAME

Glycerol

TOTAL

Inlet

Streams [kg]

1

95.78

112.82

34.00

208.60

Outlet

Streams[kg]

3

82.59

1.9179

111.43

12.65

208.60

VI.

GC A NALYSIS

GC analysis to determine the methyl ester content (between

C14 } and C24 ) in biodiesel follows EN14103:2003 method [3].

The FAME analysis is conveyed in a split injection into an

analytical column with a polar stationary phase and a flame

ionization detector (FID. The GC configuration used here is

the PerkinElmer Clarus 500, fitted with a capillary

split/splitless injector and FID. In order to determine the

retention times of the fatty acid methyl esters, methyl

heptadecanoate (C17 ) acting as the internal FAME standard

needs to be run. The ester content expressed as a mass fraction

in percent, is calculated using the following formula:

∑

(10)

where A is the total peak area from the ME, A EI is the peak

area corresponding to C17 , VEI the volume of C14 , and m is the

sample weight. The samples have been taken at a certain time

intervals of 10 or 15 minutes after each process which

retention time of each process during the plant operation is set

at one hour. Three hours are needed for the entire production.

The samples are measured first using the TLC method for

ester content determination. The appropriate samples are

hence selectively prepared for the GC analysis. The results of

this analysis is shown graphically in Figure 4. The values of

the ester content after esterification, the first-step

transesterification, and the second-step transesterification are

81 %, 88%, and 95%, respectively. Referring to the graph, the

chemical equilibrium is achieved both at the end of the

esterification and the end of the first transesterification. The

time dependency of the rate of the concentration change of the

reactants is therefore negligible. The conversion of TG to

biodiesel after one hour operation of the second-step

transesterification is at 95% can be understood that the

reaction is actually incomplete. The curve in the last region

indicates that the tendency to the higher conversion is

possible. By slightly increasing the retention time, the reaction

becomes definitely completed and the ultimate target of the

minimum conversion at 96.5\% can be accordingly achieved.

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS Vol:12 No:06

46

chemically to an equilibrium in which state the conversion of

96.5% minimum shall definitely be achieved.

A CKNOWLEDGMENT

This research study has been funded by the "Fundamental

Research Grand Scheme" from the Higher Education Ministry

of Malaysia (FRGS Vot 1063).

REFERENCES

[1]

[2]

[3]

[4]

Fig. 4. Ester Content Profile

The sampes have been taken at a certain time intervals, 10 or

15 minutes after each process which retention time of each

process during the plant operation is set at one hour. Three

hours are needed for the entire production. The samples are

measured first using the TLC method for ester content

determination. The appropriate samples are hence selectiv ely

prepared for the GC analysis. The results of this analysis is

shown graphically in Fig. 4. The values of the ester content

after esterification, first-step transesterification, and secondstep transesterification are 81%, 88 %, and 95%, respectively.

Referring to the graph, the chemical equilibrium is achieved

both at the end of the esterification and the end of the first

transesterification. The time dependency of the rate of the

concentration change of the reactants is therefore negligible.

The conversion of TG to biodiesel after one hour operation of

the second-step transesterification is at 95% can be understood

that the reaction is actually incomplete. The curve in the last

region indicates that the tendency to the higher conversion is

probably still possible. By slightly increasing the retention

time, the reaction becomes definitely completed and the

ultimate target of the minimum conversion at 96.5% can be

accordingly achieved.

[5]

[6]

[7]

[8]

[9]

Yusof Basiron, Bailey's Industrial Oil and Fat Products Palm Oil, John

Wiley & Sons Inc. 2005 Vol, 6

Ayhan Demirbas, Biodiesel: a realistic fuel alternative for diesel

engines, Springer-Verlag London Limited, British Library Cataloguing

in Publication Data, 2008

EN14103:2003, Technical Committee CEN/TC 307, Fatty Acid Methyl

Ester (FAME), , Determination of Ester and Linolenic Acid Methyl

Ester Contents, EN14103:2003, CEN, Rue De Stassart 36 B - 1050,

Brussels, Apr 2003

Cheng Sit Foon and Choo Yuen May and Ma Ah Ngan and Chuah

Cheng Hock, Kinetics Study On Transesterfication Of Palm Oil, Journal

of Oil Palm Research, 2004.

Bernard Freedman and Royden O. Butterfield and Everett H. Pryde,

Variables affecting the yields of fatty esters from transesterified

vegetable oils, JAOCS, Vol, 61, pp 163 – 1643, 1984

Jo Van Gerpen, Biodiesel processing and productiontitle, Journal of

Fuel Processing T echnology, ElseVier, 2005, Vol. 86, pp 97 -1107..

In-Chul Kima and Jong-Ho Kim and Kew-Ho Lee and Tae-Moon T ak,

Phospholipids separation (degumming) from crude vegetable oil

by polyimide ultrafiltration membrane, Journal of Membrane Science,

Elsevier, no. 205, pp 113- 123, February 2002.

Octave Levenspiel, Chemical Reaction Engineering, Department of

Chemical Engineering Oregon State University, John Wiley & Sons,

ISBN 0-471-25424-X, 1999.

Jo Van Gerpen and Gerhard Knothe, The Biodiesel

Handbook, Fuel Properties Chapter, AOCS Press, 2005.

VII.

CONCLUSION

The process analysis is the significant tool for a plant engineer

for proper running biodiesel production plant to estimate the

product quality and yield. Starting from the pretreatment of

the CPO to bleached palm oil (BPO), and the subsequent

processes such as esterification, transesterification, and

purification as well as the methanol recovery have been

described to illustrate the important unit operations in the

biodiesel production plants. The conversion of 81% after

esterification and 88 % after first-transesterification measured

in the GC analysis conforms the estimated value resulted from

process analyses based-on material balance. Palmitic acid is

used for TG model since it is the major component in the fatty

acid profile for palm oil. The ultimate target of 96.5%

conversion of TG to biodiesel, can be achieved by a slightly

increasing the retention time of the second-step

transesterification in the actual plant operation. The process

analysis for the last step can be done when the reaction comes

124106-5757-IJMME-IJENS © December 2012 IJENS

IJE NS

![FOCI[3] - Clemson Sustainable Biofuels](http://s2.studylib.net/store/data/005791040_2-3405d51e06eba48ee2e076f677a28aa2-300x300.png)