Florida Department of Transportation District 4 To Design, Build

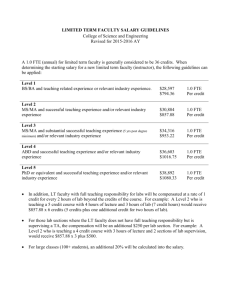

advertisement