CITY OF ORLANDO ENGINEERING STANDARDS MANUAL

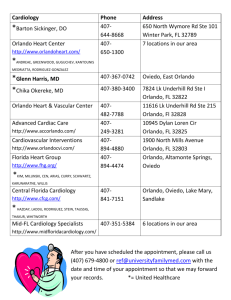

advertisement