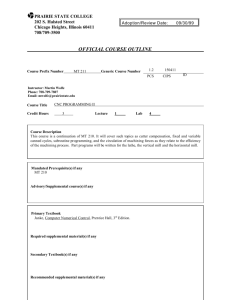

milling machines and milling operations

advertisement