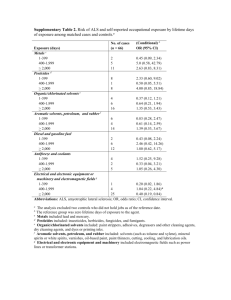

Some Petroleum Solvents - IARC Monographs on the Evaluation of

advertisement