Biodiesel Implementation

advertisement

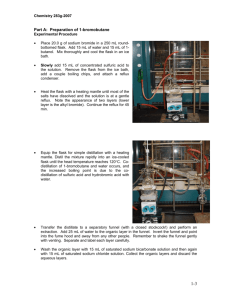

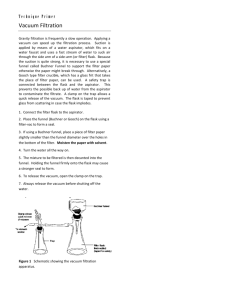

www.sustainicum.at DIRECTIONS FOR IMPLEMENTATION The production of biodiesel Author: E-Mail: Institution: Andreas Hofinger-Horvath Andreas.hofinger@boku.ac.at University of Natural Resources and Life Sciences, Department of Chemistry The production process Although it is not possible to get into the technological or technical issues here, the basic principles of the production of biodiesel have been schematically portrayed. Recycled fats Vegetable Oils Methanol + KOH Methanol Recovery Sulfuric Acid + Methanol Dilute Acid Esterification Transesterification Crude Glycerin Glycerin Refining Glycerin Crude Biodiesel Refining Biodiesel As a starting base, various vegetable oils (such as rapeseed oil or sunflower oil in moderate climates or palm oil), as well as used cooking fats and oils can be used. Triglyceride Methanol Glycerin FAME 1 www.sustainicum.at 1) Used cooking oils and fats present several problems in the preparation. Aside from varying particulate matter and food leftovers, the humidity in connection with high temperatures (e.g. frying fat) can lead to a partial hydrolysis of the triglyceride. During the process various free fatty acids are formed that cannot be directly transformed through a base-catalyzed reaction into methyl ester. In this case the esterification must first go through an acidcatalyzed reaction before the rest of the triglyceride goes through the base-catalyzed transester reaction (transesterification) to be transformed into biodiesel. 2) Pure vegetable oil can be transformed directly into biodiesel through a base-catalyzed transesterification reaction (this application will be shown in our example). Minimal equipment requirements Laboratory: Personal protection gear: Electricity hook-up Water hook-up Safety glasses Lab coat 2 www.sustainicum.at Necessary equipment: Name Number Use Check Iron stand 2 □ Iron ring 1 Synthesis, separation, filtration Separation, filtration Double socket 3 □ Cooling clamp 1 Synthesis, separation, filtration Synthesis Flask clamp 1 Synthesis □ Kleck clip 1 Synthesis □ Adjustable work platform 1 Synthesis □ Magnetizing mixer with heat function 1 Synthesis □ Crystallizing dish 500ml 1 Synthesis □ Reflux condenser 1 Synthesis □ Rubber hose 2 Synthesis □ Round bottom flask 100ml 1 Synthesis □ Magnetic stirrer 1 Synthesis □ Separating funnel 250ml 1 Separation □ Erlenmeyer flask 100ml 3 Separation, filtration □ Rolled-rim glass minimum 10ml 1-3 Filtration, sample storage □ Glass stirrer 1 Filtration □ Glass funnel ca. 6-8cm 1 Separation, filtration □ Folded filter 1 Filtration □ Scale 1 Synthesis □ Pasteur pipettes 1 Synthesis □ Suction cups 1 Synthesis □ Graduated pipette 10ml 1 Synthesis □ Spatula 1 Synthesis □ Cork ring, small 1 Synthesis □ Horn spoon 1 Filtration □ □ □ Necessary chemicals: Name Comments Use Check Rapeseed, sunflower oil As fresh as possible Synthesis □ Methanol Water free Synthesis □ Potassium hydroxide pellets - Synthesis □ Sodium sulfate Water free Drying (filtration) □ 3 www.sustainicum.at Kühlerklemme = cooling clamp; Doppelmuffe = double socket; Kolbenklemme = flask clip; Magnetrührbohne = magnetic stirrer; Magnetrührer mit Heizfunktion = magnetic stirrer with heating function; Eisenstativ = iron stand; Laborboy = adjustable working platform; Wasserbad = water bath; Rundkolben = round bottom flask; Schliffklemme = flask clamp; Rückflusskühler = reflux condensor; Kühlwasser = cool water Figure 1 Setting up the equipment Secure the reflux condenser, cooling clamp, and double socket onto the iron stand so that there remains sufficient space underneath (ca. 50cm). The hoses for the reflux condenser should be attached in such a way that the cold water is drained through the spiral of the reflux condenser (the fresh water should flow down as quickly as possible). According to figure 1, the adjustable work platform should be placed at the foot of the iron stand. Atop the stand, place the magnetic mixer with heat function. Rest the crystalizing dish with water on the mixer. The round bottomed flask is attached with a joint clamp on the under side of the reflux condenser and fixed with a double socketed flask clamp (tension-free mounting!). The round-bottomed flask should hang in the air. Only when the adjustable work platform is lifted should the flask dip into the water bath! The top of the flask must remain clear so that no pressure can build! The set-up must be undertaken exactly as shown in the sketch (iron stand) otherwise the stand will be in danger of tipping over! The separating funnel A separating funnel (figure 2, also separator funnel) is a piece of glass equipment that is used in chemical laboratories to separate non-mixable fluids. At the top, the device has a ground glass joint that can be closed with a stopper and at the bottom with a spigot. If two non-mixable fluids (two phases) are poured in (e.g. water and oil), the fluid with the greater density (in the case of water and oil, the water) collects at the bottom and can be drained into a container. The increasingly narrow 4 www.sustainicum.at form of the funnel facilitates an accurate separation, i.e. the closing of the spigot shortly before the lighter phase begins to pour out. Schliffstopfen = Ground joint plug; Phasengrenze = phase boundary; Hahn = spigot; Scheidetrichter = separating funnel Figure 2 The inexperienced user often discards the wrong phase, i.e. the phase in which the target molecules are found. It is recommended to keep both phases as long as the desired substance is isolated and characterized. Generally the rule applies: organic phases are mostly lighter than water and therefore on top. If halogen is found on the organic molecule, the organic phase can become heavier and therefore be found on the bottom. If a drop of distilled water is added and the phase in which it disappears is observed, it is possible to quickly identify the watery phase. Experiment Synthesis: according to figure 1 fill the round-bottomed flask with exactly 26.0 g vegetable oil, 7.5 g (= 9.5 ml) methanol and 0.26 g (ca. 3 pieces) potassium hydroxide pellets. Set the 100 ml round bottomed flask on the scale and set the scale to zero by pushing the “tare button.” Carefully pour the first vegetable oil into the flask – add ca. 24 g directly from the bottle. Measure the remaining amount with a graduated pipette in exact dosages. Measure the methanol with a graduated pipette, then set the scale to zero again and finally add three pellets of potassium hydroxide. To conclude, the mix is carefully added with the magnetizing mixer. The 100 ml round bottomed flask is now attached to the stand using keck clips and flask clamps (figure 1, see above). The magnetizing mixer with the sensitive water bath atop is lifted with the help of the working platform until the 100 ml round bottomed flask is sufficiently submerged. The water cooler is turned on now (at the latest!) After turning on the water cooler the heating for the water bath and the magnetizing mixer are turned on. From the point at which the reaction-mix bubbles, the mixture should boil under reflux for 45 minutes. The water bath should be re-filled if needed. After the necessary time (boiling for longer won’t hurt) the magnetizing mixer including the water bath is lowered again so that the round bottomed flask is completely in the air and can cool (ca. 5 minutes 5 www.sustainicum.at until the exterior of the round bottomed flask is slightly warmer than lukewarm). However, it can be observed that a clear solution becomes turbid as it cools. Eisenring = iron ring; Doppelmuffe = double socket; Öl = oil; Wasser = water; Scheidetrichter = separating funnel; Hahn = spigot; Erlenmayerkolben = Erlenmeyer flask Figure 3 Separation: The separating funnel is hung in the iron ring so that the tip of the opening dips into the below-standing Erlenmeyer flask (figure 3). Pay attention that the spigot is closed at first. The turbid solution is slowly poured through a funnel into the upper opening of the separating funnel. Wait until the emulsion has completely segregated (at least five minutes). The bottom phase (watery) is now comprised of glycerin and the upper (organic) of biodiesel. Now let the bottom phase carefully run out first through the opening of the separating funnel spigot into a tared Erlenmeyer flask (EF 1) (figure 3, left right). No part of the upper phase should be allowed to sweep through with the bottom phase!!! Finally the upper phase is drained into a second tared Erlenmeyer flask (EK 2). Measuring the total weight and subtracting the empty weight of both Erlenmeyer flasks defines the output weight. Glycerin output weight Gross weight Erlenmeyer flask (EF 1): Empty weight Erlenmeyer flask (EF 1): Output weight Glycerin: ……………. ……………. ……………. Raw output of biodiesel Gross weight Erlenmeyer flask (EF 2): Empty weight Erlenmeyer flask (EF 2): Output weight biodiesel: ……………. ……………. ……………. 6 www.sustainicum.at Erlenmayerkolben = Erlenmeyer flask; Rohbiodiesel = crude biodiesel; Filterpapier = filter paper; Feststoff = solids; Trichter = funnel; Rollrandglas = rolled-rim glass; Filtrat = filtrate; Stativ = stand; Eisenring = iron ring; Doppelmuffe = double socket Figure 4 Filtration: A spoonful of solid waterless sodium sulfate is added to the Erlenmeyer flasks containing the raw biodiesel and swirled. Continue to add Na2SO4 until the solution is completely clear and the Na2SO4 doesn’t clump when added. In doing so, any water that was unavoidably swept through the spigot during extraction is completely removed (bound by the Na2SO4). The Erlenmeyer flask is set aside for ca. 5 minutes. The glass funnel is hung in the iron ring so that the tip dips into the belowstanding rolled-rim glass (figure 4). The filter paper (recommended are so-called folded filters) is placed in the glass funnel. The now dried solution is filtered out through the folded filter in the tared rolled-rim glass (figure 4). The now damp Na2SO4 should be transferred to the filter. In this way dried biodiesel is obtained. Biodiesel output Gross weight rolled-rim glass: ……………. Empty weight rolled-rim glass: ……………. Output weight biodiesel: ……………. Due to time restraints the refining (cleaning) of the biodiesel is not foreseen. You are holding socalled “crude biodiesel” in your hands. 7