The Economic Benefits of the North American Rare Earths Industry

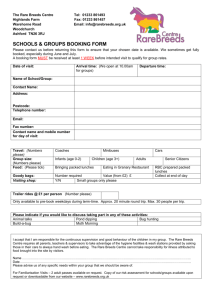

advertisement