Technical Product Guide for Tricon v10 Systems

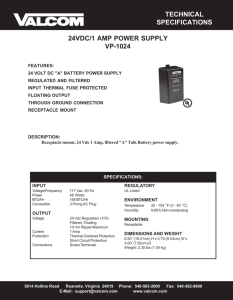

advertisement