Operation Process Charts and Grading Rubrics End Table Drawer

advertisement

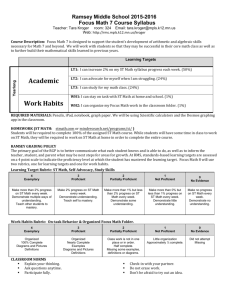

Operation Process Charts and Grading Rubrics End Table Drawer Student Name:________________________________ Period:________ End Table DRAWER FRONT Operation Process Chart & Rubric DRAWER FRONT OPERATION PROCESS CHART Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the BACK APRON’s final dimensions. (see your squaring the DRAWER FRONT sheet) 1 Multiple Multiple 2. Drill opening for handle 1 Drill Press 3. Make ¼” groove ¾” up from bottom side of the front 1 Table Saw w/ fence 4. Router 1/8” round over on outside edges and ends 1 Router table 5. Sand as needed 100grit to 220 grit all surfaces. 1 Orbital Sander 6. Submit to instructor for Assessment DRAWER FRONT RUBRIC The Student demonstrated basic measuring concepts. Mastery 5 Level of Evidence Thickness (3/4”) All Dimensions are precise Proficient 4 Width (4 3/16”) Not Proficient 3..2..1..0 Length (14 15/16”) Lost points Task ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Router Process done correctly All corners are router with 1/8” round over bit consistently covering the entire table tops Groove placement is correct Handle location is correct The groove allows the bottom piece to fit snuggly, and is ¼” deep and ¾” from the bottom. Handle hole is located in the center of the face. Proficient 4 Total Points Lost -1 -3 Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Most corners have gone through the Router process correctly: o Corners are router to 1/8” o Round over runs consistently over the entire table top Grooves are slightly off : o Plywood doesn’t fit o Not 1/4” deep o Not ¾” from bottom Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Some corners have gone through the Router process correctly: o Corners are router to 1/8” o Round over runs consistently over the entire table top Grooves are mostly off : o Plywood doesn’t fit o Not 1/4” deep o Not ¾” from bottom Handle hole is slightly off : o Not centered Handle hole is mostly off : o Not centered Total Points Possible Total Points Received 5 -5 Not Proficient 3..2..1..0 ¼” dado blade 1/8” round over bit Abrasive Paper as needed Pnts of 5 Comments Pnts of 5 Comments The Student demonstrated proper finishing techniques. Level of Evidence Mastery 5 Evidence of proper sanding techniques There are no imperfections. Proficient 4 Some imperfections: o Scratch marks o Blade Marks o End grains pitted Not Proficient 3..2..1..0 Many imperfections: o Scratch marks o Blade Marks o End grains pitted Total Points of 20/ Student Name:________________________________ Period:________ End Table DRAWER SIDES Operation Process Chart & Rubric DRAWER SIDES OPERATION PROCESS CHART Task Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the SIDE APRONS’ final dimensions. (see squaring the SIDE APRONS sheet) 2 Multiple Multiple 2. Create a ¼” wide; ¼” deep groove ¾” up from the bottom. 2 Table Saw w/ Fence 3. Sand as needed 100grit to 220 grit all surfaces. 1 Orbital Sander Dado Blade Abrasive Paper as needed 4. Submit to instructor for Formal Assessment The Student demonstrated basic measuring concepts. 5 Points Level of Evidence All Dimensions are precise 1/2” x 4 - 3/16” x 14” Mastery 5 Thickness (1/2”) Proficient 4 Width (4 - 3/16”) Not Proficient 3..2..1..0 Length (14”) ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Groove placement is correct The groove allows the bottom piece to fit snuggly, and is ¼” deep and ¾” from the bottom. Proficient 4 Lost points DRAWER SIDES RUBRIC -1 -3 Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Mastery 5 Proficient 4 Evidence of proper sanding techniques There are no imperfections. Some imperfections: o Scratch marks o Blade Marks o End grains pitted Total Points Received Pnts Rec. of 5 Comments Pnts Rec. 5 Comments Grooves are mostly off : o Plywood doesn’t fit o Not 1/4” deep o Not ¾” from bottom The Student demonstrated proper finishing techniques. Level of Evidence Total Points Possible 5 -5 Not Proficient 3..2..1..0 Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Grooves are slightly off : o Plywood doesn’t fit o Not 1/4” deep o Not ¾” from bottom Total Points Lost Not Proficient 3..2..1..0 Many imperfections: o Scratch marks o Blade Marks o End grains pitted Total Points of 20 / Student Name:________________________________ Period:________ End Table DRAWER BACK Operation Process Chart & Rubric DRAWER BACK OPERATION PROCESS CHART Task Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the DRAWER BACK’s final dimensions. (see your squaring the DRAWER BACK sheet) 1 Multiple Multiple 2. Sand as needed 100grit to 220 grit all surfaces. 1 Orbital Sander 3. Submit to instructor for Formal Assessment Abrasive Paper as needed The Student demonstrated basic measuring concepts. Level of Evidence All Dimensions are precise Mastery 5 Thickness (3/4”) Proficient 4 Width (3 7/16”) Not Proficient 3..2..1..0 Length (14”) ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Proficient 4 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Lost points DRAWER BACK RUBRIC -1 -3 Not Proficient 3..2..1..0 Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Mastery 5 Evidence of proper sanding techniques There are no imperfections. Proficient 4 Some imperfections: o Scratch marks o Blade Marks o End grains pitted Not Proficient 3..2..1..0 Many imperfections: o Scratch marks o Blade Marks o End grains pitted Total Points of 15/ Total Points Possible Total Points Received 5 -5 The Student demonstrated proper finishing techniques. Level of Evidence Total Points Lost Pnts Rec. of 5 Comments Pnts Rec. 5 Comments