CME 458-459 Winter 14 - Department of Chemical & Materials

advertisement

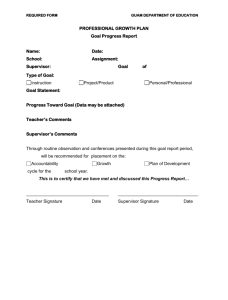

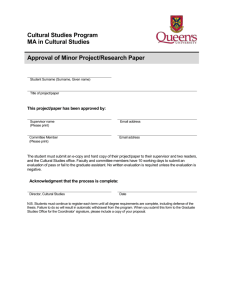

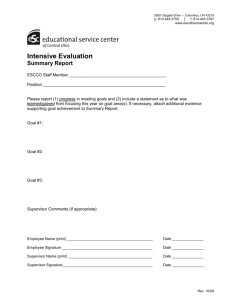

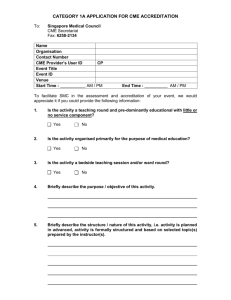

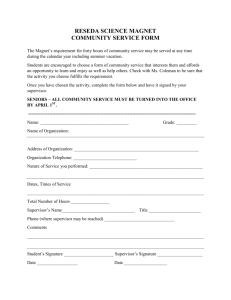

Winter 2014 Department of Chemical and Materials Engineering CME 458 or 459 Special Project Course ** ************************************************************************************ Each of 458 and 459 is a complete self-standing course, and may be taken by either a Chemical or Materials student. If a student takes it once, it is called “CME 458”. The second time it will be called “CME 459”. Both courses cannot be taken in one term. SYLLABUS as December 20, 2013 Policy about course outlines can be found in Section 23.4(2) of the University Calendar. Course description: individual research project under the supervision of an academic faculty member. Credits: 3.5 (each) The course starts: January 6, 2014. The course ends (final report due): April 9, 2014. Required weekly allocated time: to be discussed with the project supervisor; the recommended “in-class” time is at least 5 hr per week + “homework” time Instructor and coordinator The research project is performed under the supervision of an academic faculty member. The list of the CME Faculty members and their contact information can be found at: http://www.cme.engineering.ualberta.ca/FacultyStaff/FacultyAcademicStaff.aspx The course coordinator ensures student’s registration, collects reports and assigns final grades (subject to the Dean’s approval) based on recommendations from the supervisor. Course coordinator: Dr. Natalia Semagina. Office: ECERF building, 7-070C. E-mail: semagina@ualberta.ca. Important dates Progress report deadline: Final report deadline: March 10th 2014, 4 pm. April 9th 2014, 4 pm. Submit to the Assignment box located in CME. If your report is too large to fit in, bring it to Heather Green or Project coordinator before the deadline time. It is student’s responsibility to ensure that the report is received in time. Late submission 10% of the final mark will be deducted if the progress report is not submitted on time. One each business day of delay to submit the Final report results in 10% mark deduction. Winter 2014 Note that the deadline extension is not possible, except for the reasons outlined at the University calendar (section 23.3 “Attendance”, such as incapacitating illness, severe domestic affliction, or religious convictions). Grading principles This is not a pass/fail course. The course coordinator will assign the final grade based on the supervisor’s recommendation and evaluation form, and will submit the grade to the Dean’s office for approval. 100% mark is based on the Final Report evaluation form to be completed by the project supervisor. The Final Report Evaluation raw score will be lowered by 10% for the failure to submit a progress report in time, and by 10% for each working day of delay of the Final report. For the percentage of the report evaluation, refer to the Evaluation form (appendix). A student passes the course with a score of 3 out of 5 or higher (after all applied deductions). A necessary condition to pass the course, along with the total score of 3, is that at least the “satisfactory” mark is assigned in both “Intellectual contribution to the project” and “Analytic content: quality of treatment”. How to register Note: a student cannot register on-line for this course, the registration must be done by Heather Green upon receiving the registration form as explained below. 1. The course is open only to Chemical or Materials students with a GPA of 3.0 or greater during the previous two academic terms. The prerequisite to CME 459 is CME 458. 2. Select a project from the Project List (Appendix), discuss it with a supervisor, complete the registration form (Appendix), obtain signatures from the Supervisor and Course coordinator (for CPC and Oilsands stream students only, the approval signature is also required from appropriate advisor). Return the signed completed form to Heather Green (ECERF, 7th floor, reception area) to complete your registration. 3. If a desired project is not included in the Project List, a student is encouraged to discuss such a project with the professor whom she/he considers best qualified as supervisor of the project. A brief written project description (title and one-page abstract) must be prepared and the project must be approved by the CME 458/459 coordinator (via e-mail). After that, the registration form should be signed and submitted as explained above. 4. A CME 458/459 project may not be combined with a Dean’s Research Award as the Award “can’t be concurrent with a project for which credit is received.” Requirements to the reports 1. The Progress Report should be 1-2 pages long, summarize the work done on the project and tasks still to be performed (“list” format is recommended). It is not graded per se, but the failure/delay of submitting it will result in 10% final mark deduction. Its purpose is to track student’s progress. 2. Final Report. There is no required page limit (unless indicated by the supervisor), please make sure that the content matches the evaluation criteria in the evaluation form (Appendix), unless a different report outline was approved by the supervisor and course coordinator. Typically, the report is about 20-30 pages (not including appendices with raw data, if any). For the CME 459 project, please keep in mind that this is a separate report, not cumulative with your previous CME 458 report. If any data from the CME 458 report is used, they should be properly cited and distinguished from the current work. Winter 2014 All reports will be handed in to the course coordinator, Heather Green, or submitted to the Assignment box before the deadline time. The course coordinator will distribute the reports to the appropriate supervisor(s). The late submission will be penalized as discussed above. Academic integrity The University of Alberta is committed to the highest standards of academic integrity and honesty. Students are expected to be familiar with these standards regarding academic honesty and to uphold the policies of the University in this respect. Students are particularly urged to familiarize themselves with the provisions of the Code of Student Behaviour (online at www.uofaweb.ualberta.ca/governance/studentappealsregulations.cfm) and avoid any behaviour which could potentially result in suspicions of cheating, plagiarism, misrepresentation of facts and/or participation in an offence. Academic dishonesty is a serious offence and can result in suspension or expulsion from the University. Audio/video recording Audio or video recording of lectures, labs, seminars or any other teaching environment by students is allowed only with the prior written consent of the instructor or as a part of an approved accommodation plan. Recorded material is to be used solely for personal study, and is not to be used or distributed for any other purpose without prior written consent from the instructor. Winter 2014 CME 458/459 Special Projects in Materials Engineering DEPARTMENT OF CHEMICAL AND MATERIALS ENGINEERING PROJECT SELECTION (REGISTRATION FORM) Indicate which course you will be registering for: CME458 _______ CME 459 ________ Term in which the project is to be completed (circle): Fall Term (Sept-Dec) Winter Term (Jan-April) Spr/Sum Term (May-Aug) Name of Student: ___________________________________ ID No. ________________ No. of Project in Listing: _______ Title of Project: __________________________________________________________________ Supervisor(s): ___________________________________________________________________ (Please print) Signature of Supervisor(s): ________________________________________________________ Signature of Course Coordinator: __________________________________________________ Dr. Natalia Semagina If your Project is not listed, please provide a short written description of the project to the Course Coordinator. __________________________________________________________________________ ** For CPC and Oilsands stream students only, approval is required from appropriate advisor. Please indicate program: Chemical CPC ________ Chemical Oilsands _________ Name: __________________________ Signature: _______________________________ (Please print) (Advisor) Winter 2014 CME 458/459 Special Projects DEPARTMENT OF CHEMICAL AND MATERIALS ENGINEERING Final Report Evaluation Form Project: CME 45___ Term:____________ Student: ______________________________ID: _______________ Supervisor(s) (Print name): __________________________________________________ Co-supervisors: if the work was equally shared, each of you may provide your own evaluation and the coordinator will use the average value. Alternatively, upon agreement, you may submit one Evaluation Form signed by both of you. The Course includes an Engineering design component, which is defined by CEAB as “an ability to design solutions for complex, open‐ended engineering problems and to design systems, components or processes that meet specified needs with appropriate attention to health and safety risks, applicable standards, and economic, environmental, cultural and societal considerations. Engineering design integrates mathematics, natural sciences, engineering sciences, and complementary studies in order to develop elements, systems, and processes to meet specific needs. It is a creative, iterative, and open‐ended process, subject to constraints which may be governed by standards or legislation to varying degrees depending upon the discipline. These constraints may also relate to economic, health, safety, environmental, societal or other interdisciplinary factors”. Evaluation criteria: A student passes the course with a score of 3 out of 5 or higher (after all applied deductions); the final grade will be assigned by the course coordinator. A necessary condition to pass the course, along with the total score of 3, is that at least the “satisfactory” mark is assigned in both “Intellectual contribution to the project” and “Analytic content: quality of treatment”. The Final Report Evaluation raw score will be lowered by 10% for the failure to submit a progress report in time, and by 10% for each working day of delay of the Final report. The course coordinator will assign the final mark and submit it to the Dean’s office for approval. Other comments (if any): The supervisor may suggest a grade. If more than one student is supervised, please indicate the approximate ranking, which the course coordinator will take into consideration Signature(s) of the supervisor(s), date ______________________________________________________________ Winter 2014 ****************** To be completed by the Course Coordinator ***************** Raw score based on the above evaluation:_______________ At least a “satisfactory” mark is assigned in both “Intellectual contribution to the project” and “Analytic content: quality of treatment” Final report handed in in time, with delay _____ days (penalty 10% of the report mark per one working day of delay) Progress report handed in in time, not handed in (penalty 10%) Final mark:___________________ Course coordinator:__________________________________________ Name, signature, date Winter 2014 CME 458-459 PROJECT LIST 2013-2014 If a desired project is not included in the Project List, a student is encouraged to discuss such a project with the professor whom she/he considers best qualified as supervisor of the project. A brief written project description (title and one-page abstract) must be prepared, and the project must be approved by the CME 458/459 coordinator. ************************************************************************** Project 1: Optimum Refining of C5 Naphtha Supervisor: A. de Klerk Type of Project: Numerical Number of Students: 1or 2 The refining pathway of C5 naphtha in a refinery is somewhat dependent on the configuration of the other refinery units. The easiest strategy is to blend the C5 naphtha directly into the motor-gasoline. This has two drawbacks. Firstly, the C5 naphtha has a high vapour pressure and by including it directly into the motorgasoline, it limits blending of butanes into the motor-gasoline. The second drawback is related to the olefin content of the C5 naphtha, since the maximum olefin content in motor-gasoline is regulated. Olefins have a higher octane value than paraffins, but in an olefin-rich refinery it is generally better to include heavier olefins into the motor-gasoline, since the octane difference between olefins and paraffins increases with increasing carbon number. The situation is even more complicated if one considers oxygenated motor-gasoline. At present no guidelines exist for a priori recommending a C5 naphtha refining strategy for refineries rich in olefins and oxygenates. The aim of this project is to provide such a guideline. Project 2: Understanding the problem related to oxidative heteroatom (S, N, O) removal from bitumen Supervisor: A. de Klerk Type of Project: Experimental Number of Students: 1 Bitumen derived from oil sands contain higher amount of heteroatoms e.g. S, N. The content of heteroatoms must be reduced to an acceptable level to meet fuel specifications. The heteroatomic species in bitumen-derived distillate fractions are aromatic in nature and generally more difficult to remove compare to conventional crude oils. Catalytic hydrodesulphurization, hydrodenitrogenation, and hydrodeoxygenation are mostly used techniques to remove the S, N, and O heteroatom, respectively, from bitumen. However, these processes require higher amount of hydrogen and are associated with catalyst fouling/deactivation. The oxidative heteroatom removal is a promising technology that involves oxidation step followed by heteroatom removal step. However, heteroatom containing aromatic ring can be oligomerized/polymerized due to oxidation that might hinder the heteroatom removal process and gum formation or fouling in pipeline can also occur. In order to prove this hypothesis, hetero-aromatic compounds (e.g. thianaphthene, indole, benzofuran) will be oxidized in a glass reactor using air as an oxidizing agent and di-tertial-butyl peroxide as an initiator. The oxidation products will be analyzed with Fourier transform infrared and gas chromatography- mass spectroscopy, and high performance liquid chromatography. The proposed polymerization/oligomerization process can be shown in reaction below: or N H Oxidation or S O Oligomer/polymer or gum formation Winter 2014 Project 3: Granule Transport Device by Electromagnetically Driven Peristalsis Supervisors: Petr Niktrityuk and Hyun-Joong Chung Type of Project: Experimental and Computational This project is a unique opportunity to experience both experiment and simulation in a single semester. The successful applicant will first fabricate a peristaltic tube with multiple magnets controlled by a computer program. A close guidance from a graduate student will be provided in this stage. The second step is to observe the transport of various granules or colloids. A computer simulation will then be followed to explain the observed phenomena. Project 4: Silk - a reinvented functional material from biological source Supervisor: Hyun-Joong Chung Type of Project: Experimental Silk - an 'old' fabric material that can be obtained from biological source - is recently reinvented to various functional materials, where the application ranges from wound dressing, controlled drug delivery, and biosensors. The scope of the special research project will span various stages of research activity, including literature survey, decision making, experimental design, and actual material synthesis and characterization. The recipient will have unique opportunity to build up a research project on his own with close direct advising from a new faculty advisor. Project 5: Solidification of an aluminum bulk metallic glass Supervisor: H. Henein Type of Project: Experimental Bulk metallic glasses are a new class of materials characterized by their amorphous structure under low cooling rates of solidification. The resultant alloy has high hardness and low ductility. Some of these new classes of alloys are incorporated into new designs of golf clubs. A new Al based bulk amorphous alloy will be atomized and the structure characterized using x-ray, and microscopy techniques. The hardness of the alloy will also be measured. A model of droplet cooling will be used to estimate the droplet cooling rate prior to solidification. The resultant structure and properties will be related to the droplet cooling rate. Engineering objectives: •Develop experimental testing strategy. •Carry out atomization experiments. •Use of various microscopy techniques to characterize the solidified microstructure. •Carry out x-ray diffraction analysis of powders. •Use hardness measurements to estimate the mechanical properties. •Relate mechanical properties to the evolution of microstructure. Project 6: The Effect of Warm Rolling on the Morphology of Cementite in Low alloy Steels Supervisor: H. Henein Type of Project: Experimental Number of Students: 2 Low alloy steels are used for down hole applications in the oil and gas sector. As down hole conditions of oil and natural gas extraction are worsening, producers encounter the presence of hydrogen sulfide with consequences such as sulfide stress cracking (SSC) instigated by hydrogen. There is increasing Winter 2014 evidence that the morphology of cementite in these quench and tempered steels plays a role in the SSC behaviour. The objective of this project is to explore the use of warm rolling as a processing strategy to modify the morphology of cementite. The project will involve carrying out a literature review on the subject, plan and execute an experimental warm rolling test matrix, followed by the quantitative characterization of the microstructure using Optical and SEM microscopy, X-ray diffraction. In addition, other characterization techniques such as hardness measurements may be used as needed. An analysis of the experimental and characterization results will be carried out. Project 7: Modeling Heat Transfer in Light-Actuated Wax/Nanoparticle Composites Supervisor: A. Elias Type of Project: Computational Number of Students: 1 Smart materials are able to sense changes in their surroundings, and undergo a programmed change in properties. We have developed light-responsive wax/nanoparticle composites that are able to undergo large mechanical deformations when they are irradiated with light (due to the melting of the wax). These materials could form the basis for microscaled actuators, including pumps and valves. However, the time scale of the response is an important consideration that must be explored. The response time of our current (mm-scaled) devices is on the order of tens of seconds. It is well-known that when the dimensions of a device are reduced, the surface area to volume ratio increases significantly, enabling rapid heat transfer to occur. The purpose of the proposed project is to explore how reducing the size of our devices will reduce their response time. This work will build on existing experimental data and modeling results. Some previous experience with COMSOL would be greatly beneficial. Project 8: Effect of Boiling Bubble on Degradation of Alloy 800 in Simulated Crevice Chemistries Supervisors: J. L. Luo and A. Afacan Type of Project: Experimental Number of Students: 1 Alloy 800 is the preferred steam generator tube material for CANada Deuterium Uranium (CANDU) reactor. Due to boiling bubble generated on the surface and impurity in water, pitting corrosion problem could occur on Alloy 800 surface. It has been reported that one of the most aggressive species presented in the solution is the S2O32- ion which accelerates corrosion in crevice area of steam generator tubing materials. This project mainly focuses on investigation of the combined effect of S2O32- and boiling bubble on the degradation of passive film on Alloy 800. The influences of temperature and solution flow rate on corrosion behavior will be studied using electrochemical methods. The results will be used to further understand the mechanism of the reduced sulfur-induced corrosion and to develop method for controlling/preventing corrosion. Project 9: Mass Transfer Measurements under Pool Boiling Condition Supervisors: J. L. Luo and A. Afacan Type of Project: Experimental Number of Students: 1 Fluid to solid mass transfer under flow-boiling and two-phase flow are important to a range of phenomena currently relevant to the nuclear industry, e.g., materials degradation of wide range of components, fouling of heat exchangers and steam generators. However, there are limited experimental data measured under these conditions reported in the open literatures. The lack of data can be attributed to the experimental difficulties. The facilities being capable of conducting preferred measurements under two-phase flow boiling are not Winter 2014 available so far and the interpretation of the data is challenging compared to the single-phase equivalents. The objective of the project is to measure the mass transfer under pool boiling condition. An experimental set-up has been designed, constructed and commissioned in our lab to heat up the solution surrounding the specimen to the boiling condition. The project will be focused on investigating the effect of heat flux on mass transfer on nucleate boiling surface under pool boiling conditions using electrochemical technique, which has never been investigated according to the open literature. The results will help us to further understand the mechanism of mass transfer on nucleate boiling surface and to optimize operating conditions for better corrosion control. Project 10: Semiconductivity Conversion of steam generator tubing materials in Sulfate, Thiosulfate and Chloride Solutions Supervisor: J. L. Luo Type of Project: Experimental Number of Students: 1 Corrosion of steam generator (SG) tubing in SG second side crevice environments has been a major concern during the service of nuclear power generating systems. Film degradation is found mostly at the heat-transfer crevices associated with tube supports, where the impurities in the SG feedwater are highly concentrated in the SG crevices and result in an aggressive environment in which sulfate, thiosulfate, chloride ions are present. Thiosulfate and chloride are two detrimental impurities that can cause passivity degradation. This work will mainly focus on investigations of how thiosulfate and chloride affect the semiconductivity of passive films on Alloy 800. The synergistic effect between these thiosulfate and chloride ions on the corrosion behavior of the steam generator tubing materials will also be studied. The correlation between semiconductivity and passivity degradation will be established. These results are necessary for determining the controlling factor for sulfur induced corrosion and designing the inspection duration to reduce/avoid sulfur induced corrosion. Project 11: The Optimization of Ni/YSZ Anode materials for SOFCs via Infiltration Technique Supervisor: Jingli Luo Type of Project: Experimental Number of Students: 2 Solid oxide fuel cells (SOFCs) can convert chemical energy into electricity directly and have good fuel flexibility and high efficiency. As the most widely used anode, the Ni-YSZ showed higher electrochemical performance compared with other anode materials. However, there are still many challenges hindering its commercial implementation, the quite severe dimensional instability of Ni-YSZ anode is one of examples. When the anode is unintentionally exposed to air during operation, the oxidation of Ni to NiO will occur. And the mechanical cracking and performance drop will be triggered due to the expansion of anode volume. As the alternative to resolve this problem, the infiltration has been developed by impregnating small amount of Ni particles into the porous electrolyte matrix. In this project, the suitable electrode scaffoldings with acceptable stability and conductivity for infiltration process will be selected and its property will be characterized. Based on these, the best anode catalyst composition will be determined. The output of this project will help us find the optimum anode materials and form the base to support the next stage research during which the control of the morphology of active materials will be studied. Winter 2014 Project 12: Study of the Dynamics of Reacting Systems using Extent-based Methods and Computational Singular Perturbation Supervisors: V. Prasad and A. de Klerk Type of Project: Computational Number of Students: 1 In systems with a large number of chemical reactions, it is often difficult to understand the time scales at which different reactions and modes operate, and to find conditions that activate specific subsystems of reactions. It is even more challenging to obtain this information in open systems such as flow reactors, and when mass transfer effects are also present. There are two techniques that can be used to solve this problem: the transformation of the equations describing the reactions and mass transfer into extents of each reaction and mass transfer process. This decouples each of the reaction and mass transfer affects. Once this transformation is performed, computational singular perturbation (CSP) may be used to break up the model of the chemical reaction system into sub-systems of reactions that operate at different time scales. Once this is done, input manipulations can be designed in order to activate desired reaction subsystems and suppress undesirable reactions. In this project, the objective is use the extent-based methods and CSP together study the dynamic behaviour of ammonia decomposition and Fischer-Tropsch synthesis, and to use the understanding of the behaviour to devise dynamic operating strategies that optimize objectives such as conversion, selectivity or product profiles. The work involves combining existing Matlab code for the extent-based transformation and CSP, and for ammonia decomposition and Fischer-Tropsch chemistry, and conducting simulations to understand and optimize operating conditions. Project 13: Monitoring of welding processes Supervisors: V. Prasad and P. Mendez Type of Project: Computational, potentially some experimental work Number of Students: 1 Welding is a complex process that is used in many critical applications. Most often, testing the quality of the welds produced is done through destructive testing of representative However, it would be beneficial to develop a method to infer the quality of welds from machine parameters and data collected in real time. The objective of this project is to analyze dynamic data obtained on flash-butt welding processes, and to develop methods to identify potentially unsatisfactory welds from the statistical analysis. Another aspect of the project is to perform frequency domain and wavelet analysis of gas metal arc welding data to classify droplet behaviour in the welding. There is the potential for performing some experiments related to the gas metal arc welding. Thus, the work is primarily computational, and involves statistical analysis using Matlab programming. Project 14: Video capture of liquid/liquid dispersion mechanisms in stirred tanks Supervisor: Suzanne M. Kresta (with Marcio Machado and Nitin Arora) Type of Project: Experimental Liquid/liquid dispersion in stirred tanks is important in a range of industrial applications such as: cosmetics, pharmaceutical and oil sands. The results for an oil-phase continuous system are different from the results for a water-phase continuous system, even in the same mixing equipment, due to the differences in surface charge. However there are no reported images and movies of this important difference which might help us to model and understand the phenomenon. Some work has been done in our research group in order to provide Winter 2014 good quality images and movies showing the dispersion of one sparingly miscible fluid into another. Our next step is to look at differences between the two systems at the point of phase inversion. Two different stirred tank geometries and several impellers will be tested and the results will be used for validation of mathematical models and design of new experimental procedures.