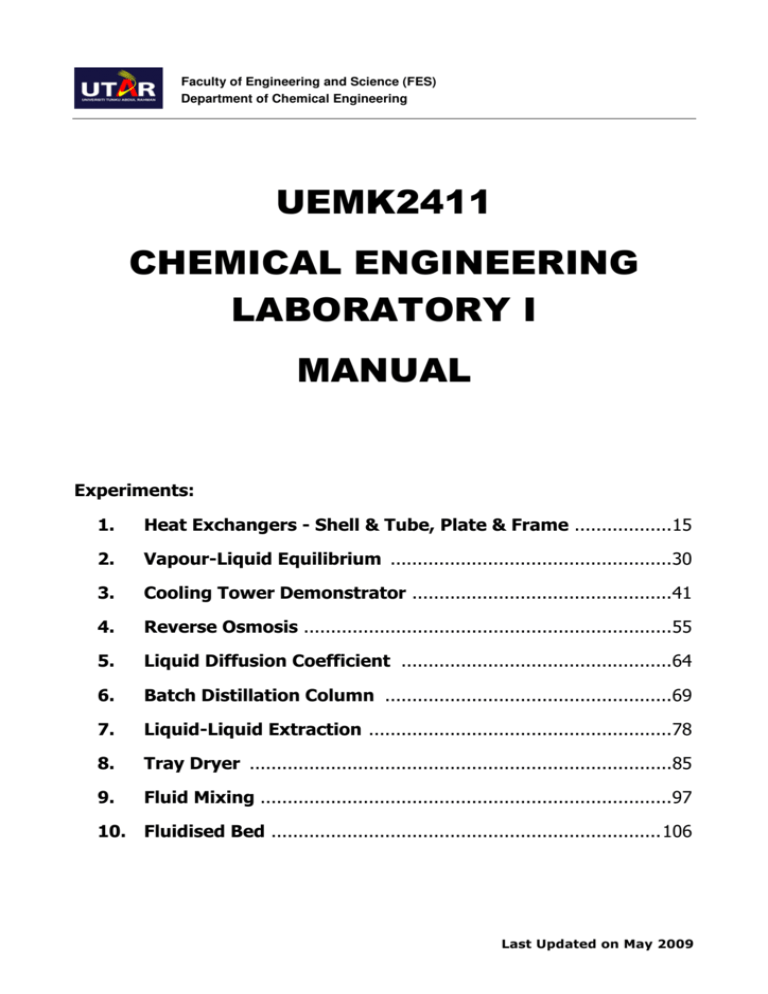

uemk2411 chem ical engineering laboratory i manual

advertisement

Faculty of Engineering and Science (FES)

Department of Chemical Engineering

!" # "

$

%

(

)*

,

! " #' -

.

/

0

! " #! " #

1

2' 2

3

#4

5

&

+

'

#

'

#/ #

% %

Table of Content

1.0

UNIT OBJECTIVES .............................................................................................................3

2.0

UNIT OUTCOMES ...............................................................................................................3

3.0

SUBJECT SYNOPSIS...........................................................................................................3

4.0

LABORATORY SAFETY, RULES AND REGULATIONS ............................................4

4.1

General Rules...............................................................................................................4

4.2

Laboratory Safety Rules ..............................................................................................5

5.0

RESPONSIBILITY OF STUDENTS...................................................................................6

6.0

ASSESSMENTS.....................................................................................................................7

7.0

6.1

Overall Performance in Laboratory during Experiment Session (10 marks) ..............7

6.2

Laboratory Reports (10 marks)....................................................................................8

LABORATORY REPORT WRITING ...............................................................................9

7.1

Content.........................................................................................................................9

7.2

Specification ..............................................................................................................11

7.3

Formatting..................................................................................................................12

Appendix A: Material Safety Data Sheet (MSDS)..................................................................... 114

1.0

UNIT OBJECTIVES

This subject will help the students to develop their skills of collecting, analysing and presenting the

results of data acquired within a well-defined experimental system. The specific objectives are to:

combine elements of theory and practice particularly in thermodynamics, heat and mass

transfer, fluid mechanics and fluid separation

develop competence in conducting experimental work

acquire a "hands-on" laboratory experience

familiarise with laboratory safety procedures

develop and demonstrate a knowledge of experimental error analysis, probability and

statistics

work collaboratively within a group setting

develop skills in handling, manipulating and maintaining basic engineering machinery

develop practical skills to plan and design laboratory experiments

2.0

UNIT OUTCOMES

On completion of this unit, a student should be able to:

collect and analyse experimental data and its relationship to theoretical principles of

fluid mechanics

heat and mass transfer

thermodynamics

fluid separation

prepare a written laboratory reports that clearly present the experimental results, analysis, and

relationship to theory

develop skills in operating common chemical engineering equipment and measurement

apparatus

3.0

SUBJECT SYNOPSIS

A laboratory course in pilot-scale processes involving thermodynamics, heat and mass transfer and

fluid mechanics. Students will acquire the skills in project definition, experimental operation,

analytical procedures, data analysis and technical reports preparation.

4.0

LABORATORY SAFETY, RULES AND REGULATIONS

Laboratory safety is the top priority and this requires all people in the laboratory to be

observing safe practices at all times!

4.1

General Rules

Students must abide the dress code while working in the laboratory.

Laboratory coat must be worn all the time when working in the laboratory.

Only closed toe shoes are allowed in the laboratory. Do not wear sandals, slippers and high

heel shoes inside the laboratory.

Students with long hair must get their hair tied up tidily when doing laboratory work.

Bags and other belongings must be kept at the designated places.

Foods, drinks and smoking are strictly prohibited inside the laboratory.

Noise must be kept to the minimum as a courtesy to respect others.

Students are not allowed to work alone without the supervision of laboratory instructor/officer.

There must be at least 2 persons present in the laboratory at same time.

Students are not allowed to bring any outsiders (non-registered parties) into the laboratory.

Any unauthorized experiment without the knowledge of laboratory instructor is prohibited.

All instrument and equipment must be handled with care.

Workspace has to be cleaned and tidied up after the experiment completed. Instrument and

equipment must be returned orderly after use.

Students are strictly prohibited to take any equipment or any technical manuals out from the

laboratory without the permission of laboratory instructor/officer.

Students are required to instil an instinctive awareness towards property value of laboratory

equipment and to be responsible when using it. Any damages can cause to jeopardise the

success of not only the individual work but also to the university.

Do not attempt to remove and dismantle any parts of the equipment from its original design

without permission.

Students shall be liable for damages of equipment caused by individual negligence. If damages

occurred, an investigation will take place to identify the causes and the names of the involved

students will be recorded for faculty attention.

Please check the notice board regularly and pay attention to laboratory announcements.

Disciplinary action shall be taken against those students who are failed to abide the rules and

regulations.

4.2

Laboratory Safety Rules

It is always a good practice and the responsibility of an individual to keep a tidy working

condition in laboratory.

It is important for each student to follow the procedures given by the laboratory instructor when

conducting laboratory experiment.

Before any experiment starts, students must study the information / precaution steps and

understand the procedures mentioned in the given laboratory sheet.

Students should report immediately to laboratory instructor/officer if the laboratory equipment

is suspected to be malfunctioning or faulty.

Student should report immediately to the laboratory instructor/officer if discovered any

damages on equipment or any hazardous situation.

Students should report immediately to the laboratory instructor/officer if any injury occurred.

If there is a tingling feel when working with electrical devices, stop and switch off the devices

immediately. Place a warning note before reporting to the laboratory instructor/officer and wait

for further instruction.

Do not work with electricity under wet condition in laboratory. Electric shock is a serious fatal

error due to human negligence and may cause death.

Students are required to wear goggles, gloves, apron and mask when handling corrosive or

active chemical agents.

Hazardous chemical agents must be properly stored and labelled in a designated place.

Students must acquire and study the material safety data sheet of a particular chemical agent

before using it.

(Extracted from Student Laboratory Guidelines. Refer to the Guidelines for complete rules & regulations)

5.0

RESPONSIBILITY OF STUDENTS

Attendance is compulsory. Attendance shall be taken during the laboratory session.

Please sign your attendance when you attend the laboratory session.

Laboratory report can only be accepted for submission if the student has attended the

laboratory session.

Student must be punctual to attend laboratory session.

Students who are late for more than 30 minutes will be barred from attending the

laboratory session. Only students with valid reason of medical basis or unforeseen

circumstances can be considered to apply for laboratory replacement.

Students are expected to study the lab sheet before the laboratory session start.

Student must understand all the safety measures / precaution steps before starting any

experiments.

Student must complete the experiment within the allocated duration of laboratory session.

Students are responsible for the condition of their working area at the end of each laboratory

session. All power to the equipment and instruments should be turned off, and cooling water

flows should be shut off. Glassware used should be cleaned and dried.

Students have to pass up their experiment result to laboratory officer on the same day after

every experiment. A copy of the experimental result (with chop) must be attached together

with the laboratory report.

Fabricating results and plagiarism are strictly prohibited. Strict action will be taken if

student is found fabricating results or copy from others.

Students have to pass up their laboratory report 2 weeks after the date of experiment to

laboratory officer.

6.0

ASSESSMENTS

6.1

Overall Performance in Laboratory during Experiment Session (10 marks)

This is a group assessment. Each student performance in the laboratory during the experiment

session will be observed and marks will be given to the group as a whole.

The performance will be assessed based on the following criteria:

Criteria

Description

Safety

Awareness

Adhere to laboratory safety, rules and regulation.

Abide to dress code (lab coat, shoes, long pants etc.)

while working in the laboratory.

Understand all the safety measures / precaution steps

before starting any experiments.

Proper safety equipment such as goggles, gloves etc.

were used when necessary.

Show precautions when handling chemicals.

Punctuality

Attend laboratory session on time.

Preparation

Show understanding in the experiment that are about

to carry out.

Cleanliness and

Responsibility

Workspace is clean and tidied up after the

experiment completed.

Instrument and equipment are returned orderly after

use.

Show instinctive awareness towards property value

of laboratory equipment and instruments and their

responsibility in handling them.

Marks

10

6.2

Laboratory Reports (10 marks)

Laboratory report will be assessed based on the following criteria:

Criteria

Description

Marks

Overall

Presentation

of Report

Organisation of report with the correct format and

necessary information such as titles, figure

explanations.

Report is written in clear and concise English.

2.5

Observations /

Data / Result

Presentation

Valid observations, consistent with event and

demonstrate attention to detail.

Data are presented in an organised manner.

Quality of data reflects student’s ability to perform

experiment successfully and utilise computer

software in analysis (if applicable).

All calculations and graphs are correct.

2.5

Discussion

Discussion shows complete understanding of

experiment and the significance of data.

Logical explanation for problems in the data.

3.5

Conclusion

Summary of key findings in a clear statement.

Clearly show relationships between data and

conclusion.

Express views on the weakness of the experimental

design (if there is any), or what is the implication of

the conclusion.

1.5

TOTAL

10

7.0

LABORATORY REPORT WRITING

Laboratory reports are the most frequent document written by an engineering student. A laboratory

report should not be used to merely record the expected and observed results but demonstrate the

writer’s comprehension of the concept behind the data. A good laboratory report should address

the following questions:

“Why?”

– Why did I do this particular experiment?

“How?”

– How did I actually carry it out?

“What?”

– What did I find? What were my results?

“So What?” – What does my result mean? What is the significance of the result? What are

my conclusions?

!

"# $%& '

$ & & %'($

%

('#(' ) '#

( )( '(($ '$ *

The laboratory report should be written with the same professionalism that would be used to

present the results of a major industrial project. A good report of technical work quantitatively

states significant results of experiments and computations and explains how they were obtained,

what they mean, and how they are useful. The report should be clear, concise, and accurate.

7.1

Content

The laboratory report should follow the following format and all the pages should be numbered

except the cover page.

Section

Max number of

lines / pages

UTAR Laboratory Cover Page

1) Title of Experiment

1 – 2 lines

2) Objectives of Experiment

1 – 5 lines

3) Introduction

Provide a scientific background related to the experiment and

provides the reader with justification for why the work was

carried out.

½ page

Section

Max number of

lines / pages

4) Materials and Equipment

List only the materials/chemicals and equipment/apparatus used in

the experiment.

½ page

5) Results and Calculations

Present the data obtained from the experiment. The data have to

be presented in a clear and understandable manner.

depends on

results and

calculations

All tables must be clearly labelled with numbers and titles.

All necessary calculations based on the raw data should be

provided in this section.

6) Discussion

This is most important section where detailed analysis of the

experimental data should be provided. Factors/issues related to

the obtained results must be explained.

3 pages

Graphic materials based on the experimental data should be

presented and discussed in this section. All graphs must be

clearly labelled with numbers and titles.

Strategies that can use in the discussion:

compare expected results with those obtained

explain the results in terms of theoretical issues

what do the results indicate?

what is the significance of the results?

relate results to the experimental objectives

analyse experimental error

what ambiguities exist?

find logical explanation for problems in the data

what questions might we raise?

7) Conclusion

Based on the discussion provided, summarise the key findings in a

clear statement. Additionally, the conclusion can also be used to

express views on the weakness of the experimental design (if

there is any), or what is the implication of your conclusion.

5 lines

8) References

List all references used in the preparation of the report.

Information obtained from any source, including the Internet, is

covered by copyright law. Any source referred in the report must

be acknowledged, both within the text and at the end of it.

depends on

references

The format should follow the American Psychological

Association (APA) referencing style.

There shall be no appendix for the report. All information should be summarised into the

discussion section.

The laboratory reports should be arranged so as to include the major sections described above, but

students are free to insert additional subsections if they help to organise and clarify material and

information for the reader.

While the results and information contained in the report are of primary importance, students

should not underestimate the importance of a neat, easy-to-follow, well-organised presentation.

Pay attention to the appearance of the graphs, figures and tables, and to the ease with which the

reader can interpret them. Good results can be easily obscured by careless organisation and

presentation.

Students should take note on verb tense. These two points should help in writing the report:

By the time you get to the stage of writing a laboratory report, the experiment is already

finished. Use past tense when talking about the experiment.

Example: “The objectives of the experiment were………”

The report, the theory and permanent equipment still exist; therefore, use present tense:

“The objective of this report is………..”

“Newton’s Law of motion is………….”

“The transmission electron microscope produces micrographs………”

7.2

Specification

Specification

Description

Language

The report should be written in British (UK) English.

Paper

White simile A4 size paper (210 × 297 mm)

Printing

Report must be computer typewritten using word processor and

printed preferably double sided.

Printing must be of high quality. Text and figures must be clear

and legible.

Binding

Staple on top left corner

7.3

Formatting

Formatting

Page Margin

Description

Left margin

: 4.0 cm

Right, Top, Bottom margins : 2.5 cm

Header and Footer margins : 1.5 cm

Typesetting and

Spacing

Font Type

: Times New Roman

Font Size

: 12 pt

Section Title

: Uppercase, Bold, Centred

Subsection Title

: Title Case, Bold, Align left

Symbol for variable : Italic (e.g. m, P, T, v, α, δ, τ )

General Spacing

: 1.5 lines

General alignment for texts in paragraph should be “justified”.

The format for writing units, symbols, numbers etc. in the report follows the International System

of Units (SI). The following sections give some common descriptions of the writing styles. For

complete and thorough information, refer to the SI Brochure available online at

http://www.bipm.org/en/si/si_brochure/.

The use of the correct symbols and names for SI units, and for units in general are mandatory in the

report. In this way ambiguities and misunderstandings in the values of quantities can be avoided.

Style

Numbers

Description

Avoid starting a sentence with a number or symbol.

Number has to be used together with unit; if not it has to be spelled out

(e.g. three cats; not 3 cats).

If the number is between +1 and -1, the decimal marker is always

preceded by a zero (e.g. 0.15; not .15).

Numbers with many digits may be divided into groups of three by a

thin space, in order to facilitate reading. Neither dots nor commas are

inserted in the spaces between the groups (e.g. 43 765 589, 58.159 25;

not 43,765,589; not 58.159,25).

When there are only four digits before or after the decimal marker, it is

customary not to use a space to isolate a single digit (e.g. 5879, 1.5681)

When multiplying numbers, use only the multiplication sign “×” with a

space before and after, not centre dot (⋅⋅) nor the letter “x” or “X” (e.g.

25 × 5.3; not 25 ⋅ 5.3; not 25 x 5.3).

Style

Units

Description

If possible, use SI units; although other commonly used non-SI units are

also acceptable (e.g. °C for temperature, bar for pressure).

Spacing

One spacing between number and unit (e.g. 5 cm, 50 °C, 30 %; not

5cm; not 50°C; not 30%).

Exception for angular degree (°), minute (′) and second (″) (e.g. 3°, 45′)

which are placed immediately after the number.

Symbols for Units

Use symbol for units and not their abbreviation (e.g. 5 s; not 5 sec.).

Symbols for units are written in upright type i.e. not italic (e.g. m for

metres, g for grams). This is to differentiate them from italic type

symbols used for variables (e.g. m for mass).

Symbols for units are written in lowercase, except for symbols derived

from the name of a person, which start with uppercase. However, the

unit name itself is written in lowercase.

(e.g. the unit for pressure is named after Blaise Pascal; the unit itself is

written as “pascal” whereas the symbol is “Pa”; 5 Pa or 5 pascal; 5 J or

5 joule; 5 N or 5 newton)

Symbols are not pluralised (e.g. 5 kg; not 5 kgs).

Symbols do not have an appended period / full stop (.) unless at the end

of a sentence.

Symbols derived from multiple units by multiplication are joined with a

space or centre dot (⋅⋅) (e.g. N m for N⋅m). Hyphens (-) should not be

used (e.g. not N-m)

[Note: centre dot (⋅⋅) is different from period / full stop (.); centre dot is

available under command Insert > Symbol].

Symbols formed by division of two units are joined with a solidus ( ⁄ )

(slash ( / ) is also acceptable) or given as a negative exponent (e.g. m/s

or m s-1).

Only one solidus should be used (e.g. kg⋅m-1⋅s-2 or kg/(m⋅s2); not

kg/m/s2).

Do not mix unit symbols and unit names within one expression (e.g.

coulomb per kilogram; not coulomb per kg).

Style

SI Prefixes

Description

Factor

101

102

103

106

109

1012

1015

1018

1021

1024

Name

deca

hecto

kilo

mega

giga

tera

peta

exa

zetta

yotta

Symbol

da

h

k

M

G

T

P

E

Z

Y

Factor

10–1

10–2

10–3

10–6

10–9

10–12

10–15

10–18

10–21

10–24

Name

deci

centi

milli

micro

nano

pico

femto

atto

zepto

yocto

Symbol

d

c

m

µ

n

p

f

a

z

y

Prefix symbols are attached to unit symbols without a space or hyphen

(-) between the prefix symbol and the unit symbol (e.g. km; not k m;

not k-m).

The same also apply for prefix names (e.g. kilometre; not kilo metre;

not kilo-metre)

Prefix symbols are written in upright type, i.e. not italic. (e.g. kPa; not

kPa).

All prefix symbols larger than kilo (103) are uppercase; the rest are

lowercase (see table above) (e.g. MW, GHz, kW, mg, nm).

All prefix names are lowercase, except at the beginning of a sentence

(e.g. megawatt, gigahertz, kilowatt, milligram, nanometre)

A prefix is never used in isolation; and compound prefixes are never

used (e.g. 10-9 m is nm or nanometre; not mµm or millimicrometre).

!"

Experiment 1

Heat Exchangers - Shell & Tube, Plate & Frame

1.0

OBJECTIVES OF EXPERIMENT

To study different types of heat exchanger operation.

To collect related experimental data for calculation of heat losses, heat transfer coefficient

and log mean temperature different.

To study the effect of flow rate on heat transfer.

To perform energy balance around a heat exchanger.

To study temperature profiles across a heat exchanger.

2.0

INTRODUCTION

2.1

Shell & Tube Heat Exchanger

Most chemical processes involve heat transfer to and from the process fluids. The most commonly

used heat-transfer equipment is the shell and tube heat exchanger. If the fluids both flow in the

same direction, as shown in Figure 2.1, it is referred to as a parallel-flow type; if they flow in the

opposite directions, then it is a counterflow type.

2.1.1

Heat Balance

For a parallel-flow or counterflow shell and tube heat exchanger with one tube pass and one shell

pass as shown in Figure 2.1 and Figure 2.2, the heat balance is given as:

mt C pt (t2 − t1 ) = msC ps (T1 − T2 ) = q

where mt

ms

Cpt

Cps

t1, t2

T1, T2

q

=

=

=

=

=

=

=

mass flow rate of cold fluid in the tube, kgs-1

mass flow rate of hot fluid in the shell, kgs-1

specific heat of cold fluid in the tube, kJkg-1 °C-1

specific heat of hot fluid in the shell, kJkg-1 °C-1

temperature of cold fluid entering / leaving the tube, °C

temperature of hot fluid entering / leaving the shell, °C

heat exchange rate between fluid, kW

(1)

!"

Fluid T

T2

T1

t1 , mt

t2

T2

∆T2

t2

∆T1

t1

T1 , ms

Heat Transferred

Figure 2.1: Temperature Profile for a Parallel-Flow Heat Exchanger

Fluid T

T2

t2

t1 , mt

∆T1

T1

T2

t2

∆T2

t1

T1 , ms

Heat Transferred

Figure 2.2: Temperature Profile for a Counterflow Heat Exchanger

T2

Fluid T

T1

t2

t1 , mt

T2

t2

t1

T1 , ms

Heat Transferred

Figure 2.3: Temperature Profile for a 1:2 Heat Exchanger

!"

2.1.2

Heat Transfer

The general equation for heat transfer across the tube surface in a shell and tube heat exchanger is

given by

q = U o Ao ∆Tm = U i Ai ∆Tm

(2)

= outside area of the tube, m2

= inside area of the tube, m2

where Ao

Ai

∆Tm

Uo

Ui

= mean temperature difference, °C

= overall heat transfer coefficient based on the outside area of the tube, kWm-2°C-1

= overall heat transfer coefficient based on the inside area of the tube, kWm-2°C-1

The coefficients Uo and Ui are given by:

d ln(d o d i )

d

d

1

1

1

=

+

+ o

+ o + o

U o ho hod

2k w

d i hid d i hi

(3)

di

d

1

1

1 d i ln(d o d i )

= +

+

+

+ i

U i hi hid

2k w

d o hod d o ho

(4)

and

where ho

hi

hod

hid

kw

do

di

=

=

=

=

=

=

=

outside fluid film coefficient, kWm-2 °C-1

inside fluid film coefficient, kWm-2 °C-1

outside dirt coefficient (fouling factor), kWm-2 °C-1

inside dirt coefficient, kWm-2 °C-1

thermal conductivity of the tube wall material, kWm-1 °C-1

tube outside diameter, m

tube inside diameter, m

The mean temperature difference for both parallel and counterflow shell and tube heat exchanger

with single shell pass and single tube pass is normally expressed in terms of log-mean temperature

difference,

∆T1 − ∆T2

∆Tlm =

(5)

∆T1

ln

∆T2

where ∆T1 and ∆T2 are as shown in Figure 2.1 and Figure 2.2.

!"

For a more complex heat exchanger, such as 1:2 heat exchanger (Figure 2.3), an estimate of the true

temperature difference is given by

∆Tm = Ft ∆Tlm

(6)

where Ft is the temperature correction factor as a function of two dimensionless temperature ratios

R and S:

R=

(T1 − T2 )

(t − t )

and S = 2 1

(t 2 − t1 )

(T1 − t1 )

(7)

Having calculated R and S, Ft is then determined from the standard correction factor figures.

2.1.3

Tube-Side Heat Transfer Coefficient, hi

For turbulent flow, Sieder-Tate equation can be used:

Nu = C Re 0.8 Pr 0.33 (

f

/ w )0.14

= Reynolds Number

= ρ f u t d e / µ f =Gt d e / µ f

Nu

= Nusselt Number

= hi d e / k f

Pr

= Prandtl Number

= Cpµ f / k f

de

= equivalent (or hydraulic) diameter, m

where Re

Gt

µf

µw

f

ut

Cp

C

kf

=

=

=

=

=

=

=

=

=

=

(8)

4 × (cross-sectional area of flow) / wetted perimeter

di for tubes

mass velocity, mass flow per unit area, kg/s·m2

fluid viscosity of bulk fluid temperature, Nsm-2

fluid viscosity at the wall, Nsm-2

fluid density, kgm-3

fluid velocity in tube, ms-1

fluid specific heat, heat capacity, J/kg°C

0.023 for non-viscous liquids

0.027 for viscous liquids

= fluid thermal conductivity, W/m°C

For laminar flow (Re < 2000), the following correlation is used:

Nu = 1.86(Re . Pr) 0.33 (d e / L) 0.33 ( µ f µ w ) 0.14

where L = tube length, m.

(9)

!"

2.1.4

Tube-Side Pressure Drop, ∆Pt

The tube-side pressure drop is given by:

[

∆Pt = N p 8 j f ( L / d i )( µ µ w )

where ∆Pt

Np

jf

L

ut

m

2.1.5

=

=

=

=

=

=

=

−m

]

+ 2.5

ρ f u t2

2

(10)

tube-side pressure drop, N/m2

number of tube-side passes

tube dimensionless friction factor (Figure C.3 in Appendix C)

length of one tube, m

tube-side velocity, m/s

0.25 for laminar, Re < 2100

0.14 for turbulent, Re > 2100

Shell-Side Heat Transfer Coefficient, hs (Kern’s Method)

In order to determine the heat transfer coefficient for fluid film in shell, the cross-sectional area of

flow As is first calculate for hypothetical row of tubes of the shell as follows:

As = ( pt − d o ) Ds l B / pt

where do

pt

Ds

lB

=

=

=

=

(11)

tube outside diameter, m

tube pitch, m

shell inside diameter, m

distance between baffle, m

Then, the shell-side mass velocity, Gs and linear velocity, us are calculated as follows:

where W s

f

Gs = Ws As

(12)

u s = Gs ρ f

(13)

= fluid flow rate on the shell-side, kg/s

= shell-side fluid density, kg/m3

!"

The shell equivalent diameter, de is given by

4( p t2 − πd o2 / 4) 1.27 2

de =

=

p t − 0.785d o2

do

πd o

(For square pitch arrangement)

(

)

pt

1

× 0.87 pt − πd o2 / 4

2

2

1.10 2

de =

=

pt − 0.917d o2

πd o / 2

do

(For equilateral triangular pitch arrangement)

4

(

(14)

)

(15)

Thus, Reynolds number in shell is given by:

Re =

Gpde

µf

=

us d e ρ f

(16)

µf

Baffle cut, Bc, is used to specify the dimensions of a segmental baffle. It is the height of the

segment removed to form the baffle, expressed as a percentage of the baffle disc diameter.

Using this Reynolds number and given Bc value, the heat transfer factor, jh value can be determined

from figure. The heat transfer coefficient for fluid film in shell can then be calculated from:

Nu =

2.1.6

hs d e

0.14

= j h Re Pr 0.33 (µ f µ w )

kf

(17)

Shell-Side Pressure Drop, ∆Ps (Kern’s Method)

The shell-side pressure drop is given by:

∆Ps = 8 j f ( Ds / d e )( L / l B )

where

Ps =

jf

=

lB

=

us

=

ρ u s2

2

(µ

f

µ w )−0.14

shell pressure drop, N/m2

shell dimensionless friction factor from Figure C.5

distance between baffle, m

shell-side velocity, m/s

(18)

!"

2.2

Plate Heat Exchanger

Plate heat exchangers are used extensively in the food and beverage industries due to the fact that

they are easily taken apart for cleaning and inspection. Their used in other industries will depend

on the relative cost as compared to other types of heat exchanger such as the shell and tube heat

exchangers.

The general equation for heat transfer across a surface is:

Q = UA∆Tm

where Q

U

A

(12)

= heat transfer per unit time, W

= the overall heat transfer coefficient, W/m2 °C

= heat transfer area, m2

∆Tm = the mean temperature difference, the temperature driving force, °C

For counter-current arrangement, the temperature difference correction factor Ft will be close to 1.

Therefore,

∆Tm = ∆Tlm

where ∆Tlm = log mean temperature difference =

T1

T2

t1

t2

=

=

=

=

(T1 − t 2 ) − (T2 − t1 )

(T − t )

ln 1 2

(T2 − t1 )

(13)

(14)

inlet hot water temperature

outlet hot water temperature

inlet cold water temperature

outlet cold water temperature

From heat balance,

Q = mC p ∆T

where m

Cp

∆T

= mass flow rate of fluid in the plates, kgs-1

= specific heat of fluid in the plates, kJ kg-1 °C-1

= temperature difference of fluid entering/leaving the plates, °C

(15)

!"

One may use the equation for forced-convective heat transfer in conduits to the plate heat

exchangers by applying appropriate constant C and indices a, b, and c. For the purpose of

designing the exchanger, a typical equation as given below is useful for making a preliminary

estimate of the area required:

hp de

kf

where hp

= 0.26 Re

0.65

Pr

µf

µw

0.4

0.14

(16)

= plate film coefficient

Re

=

Pr

=

Gp

Af

de

Cp

=

=

=

=

G p de

(17)

µ

Cpµ

(18)

kf

mass flow rate per unit cross-sectional area = W/Af

cross-sectional area for flow

equivalent (hydraulic) diameter = twice the gap between the plates

fluid specific heat, heat capacity

The flow arrangement in a plate heat exchanger is much closer to true counter-current flow than in

a shell and tube heat exchanger. Therefore, the mean temperature difference will generally be

higher in a plate heat exchanger. For a series arrangement the logarithmic mean temperature

difference correction factor Ft will be close to 1.

The plate pressure drop can be estimated using a form of the equation for flow in a conduit:

∆Pp = 8 j f

L p ρu 2p

de

2

(19)

where Lp = the path length

up = Gp/ρ

For preliminary calculations the following relationship can be used for turbulent flow:

j f = 1.25 Re −0.3

(20)

The transition from laminar to turbulent flow will normally occur at a Reynolds number of 100 to

400, depending on the plate design. With some designs, turbulence can be achieved at very low

Reynolds numbers, which makes plate heat exchangers very suitable for use with viscous fluid.

!"

Figure 2.4: Single Pass Flow Plate Heat Exchanger Diagram

3.0

EQUIPMENT – HEAT EXCHANGER

The Heat Exchanger Apparatus provides avenue to collect the necessary experimental data for the

calculation of heat losses, heat transfer coefficient, log mean temperature difference, etc. The

effect of flow rate on the heat transfer rate and the temperature profile can also be studied and may

be applied for complex industrial heat exchangers.

Figure 2.5: Schematic Diagram for Heat Exchanger Training Apparatus

!"

This unit consists of four different types of heat exchangers and two sump tanks for hot and cold

water source. The hot tank is fitted with an immersion type heater that is protected against possible

over heating. Each tank has a centrifugal pump which is protected from dry-run by electronic level

switches.

The four heat exchangers supplied with the unit are:

a) Shell and Tube Heat Exchanger

b) Spiral Heat Exchanger

c) Concentric (Double Pipe) Heat Exchanger

d) Plate Heat Exchanger

All necessary electronic sensors are fitted at respective locations for measuring the inlet and outlet

temperatures of the hot and cold water, and also the flow rates of the hot and cold water streams.

Digital indicators are provided on the control panel to read the appropriate data.

3.1

Process Instruments Configuration

3.1.1

Temperature Controller

The first line displays the liquid temperature in the tank while the second line displays the set value.

Adjust the set value as follows:

Press the ENT button, and then press UP or DOWN arrow key continuously until almost

near the desired set value.

Press UP or DOWN arrow key one by one until desired set value is reached. Notice that the

least digit point is flashing.

Press ENT to register the data. Notice that the least digit point goes off.

3.1.2

Valve Arrangements

Table 2.1: Valves Arrangement for Flow Selection

OPEN

CLOSE

Co-Current

V1, V12, V15, V18, V28

V16, V17, V27, V29, V30

Counter-Current

V1, V12, V16, V17, V28

V15, V18, V27, V29, V30

!"

Table 2.2: Valves Arrangement for Heat Exchanger Selection

OPEN

Shell & Tube Heat Exchanger V4, V5, V19, V20

Spiral Heat Exchanger

V6, V7, V21, V22

Concentric Heat Exchanger

V8, V9, V23, V24

Plate Heat Exchanger

V10, V11, V25, V26

Valve V3

: to vary hot water flow rate

Valve V14

: to vary cold water flow rate

CLOSE

V6 - V11, V21 - V26

V4, V5, V8 - V11,

V19, V20, V23 - V26

V4 - V7, V10, V11,

V19 to V22, V25, V26

V4 - V9, V19 to V24

Valve V2 & V13 : flow bypass for water pump. These valves should be partially opened

all the time. If the water flow rates are not stable, reduce the bypass.

3.1.3

Flow Measurements

FT1: Hot water flow rate

FT2: Cold water flow rate

The flow rates are digitally displayed in LPM.

3.1.4

3.1.5

Temperature Measurements

Counter-Current

Co-Current

TT1: Hot water inlet temperature

TT1: Hot water inlet temperature

TT2: Hot water outlet temperature

TT2: Hot water outlet temperature

TT3: Cold water inlet temperature

TT3: Cold water outlet temperature

TT4: Cold water outlet temperature

TT4: Cold water inlet temperature

Operating Limits

Temperature: maximum 70ºC

!"

4.0

OPERATING PROCEDURES

4.1

Pre-experiment Procedures

1.

Read and understand the theory of heat exchanger.

2.

Read and understand the equipment used in the experiment (heat exchanger apparatus).

3.

Read the safety precautions before conducting the experiment.

4.2

General Start-Up Procedures

1.

Perform a quick inspection to make sure that the equipment is in a proper working condition.

2.

Be sure that all valves are initially closed, except V1 and V12.

3.

Fill up hot water tank via a water supply hose connected to valve V27. Once the tank is full,

close the valve.

4.

Fill up the cold-water tank by opening valve V28 and leave the valve opened for continuous

water supply.

5.

Connect a drain hose to the cold water drain point.

6.

Switch on the main power.

7.

Switch on the hot water tank heater and set the temperature to 50°C. (Note: Recommended

maximum temperature set point is 70°C)

8.

Allow the water temperature in the hot water tank to reach the set point.

9.

The equipment is now ready.

4.3

General Shutdown Procedures

1.

Switch off the heater and wait until the hot water temperature drops below 40°C.

2.

Switch off pump P1 and pump P2.

3.

Switch off the main power.

4.

Drain off all the water in the process lines. Retain water in the hot and cold water tanks for

next laboratory session. (Note: If the equipment is not to be run for a long period, drain all

water completely.)

5.

Close all valves.

5.0

SAFETY PRECAUTIONS

Always check and rectify any leak.

Always make sure that the heater is fully immersed in the water.

Do not touch the hot components of the unit.

Be extremely careful when handling liquid at high temperature.

Always switch off the heater and allow the liquid to cool down before draining.

!"

6.0

EXPERIMENTS

6.1

Experiment 1A: Counter-Current Shell & Tube Heat Exchanger

In this experiment, cold water enters the shell at room temperature while hot water enters the tubes

in the opposite direction. Students shall vary the hot water and cold water flow rates and record the

inlet and outlet temperatures of both the hot water and cold water streams at steady state.

1.

Perform the general start-up procedures as per Section 4.2.

2.

Switch the valves to counter-current Shell & Tube Heat Exchanger arrangement (refer to

Section 3.1).

3.

Switch on pumps P1 and P2.

4.

Open and adjust valves V3 and V14 to obtain the desired flow rates for hot water and cold

water streams, respectively.

5.

Allow the system to reach steady state for 10 minutes.

6.

Record FT1, FT2, TT1, TT2, TT3 and TT4.

7.

Record the pressure drop for both the shell-side and tube-side.

8.

Repeat Step 4 to Step 7 for different combinations of flow rate FT1 and FT2 as shown in the

table below.

6.1.1

Experimental Datasheet

FT1

(LPM)

10

10

10

10

10

FT2

(LPM)

2

4

6

8

10

TT1

(°C)

TT2

(°C)

TT3

(°C)

TT4

(°C)

DP

(mmHg)

DP

(mmH2O)

FT1

(LPM)

2

4

6

8

10

FT2

(LPM)

10

10

10

10

10

TT1

(°C)

TT2

(°C)

TT3

(°C)

TT4

(°C)

DP

(mmHg)

DP

(mmH2O)

!"

6.2

Experiment 1B: Co-Current Shell & Tube Heat Exchanger

By using the same setup as Experiment 1A, repeat the experiment for co-current flow (cold water

enters the shell at room temperature while hot water enters the tubes in the same direction).

If there is air trap in the shell-side, switch the valves to counter-current and bleed the air with

high water flow rate. Then switch the valves position back to co-current position.

6.3

Experiment 2A: Counter-Current Plate Heat Exchanger

By using the same setup as Experiment 1A, repeat the experiment for plate heat exchanger

(counter-current flow).

6.3.1

Experimental Datasheet

FT1

(LPM)

8.0

8.0

8.0

8.0

8.0

6.4

FT2

(LPM)

2.0

4.0

6.0

8.0

10.0

TT1

(°C)

TT2

(°C)

TT3

(°C)

TT4

(°C)

FT1

(LPM)

2.0

4.0

6.0

8.0

10.0

FT2

(LPM)

8.0

8.0

8.0

8.0

8.0

TT1

(°C)

TT2

(°C)

TT3

(°C)

TT4

(°C)

Experiment 2B: Co-Current Plate Heat Exchanger

By using the same setup as Experiment 2A, repeat the experiment for co-current flow (cold water

enters the shell at room temperature while hot water enters the tubes in the same direction).

Results:

FT1

(LPM)

7.5

7.5

7.5

7.5

7.5

FT2

(LPM)

2.0

4.0

6.0

8.0

9.5

TT1

(°C)

TT2

(°C)

TT3

(°C)

TT4

(°C)

FT1

(LPM)

2.0

4.0

6.0

8.0

9.5

FT2

(LPM)

7.5

7.5

7.5

7.5

7.5

TT1

(°C)

Shutdown the equipment as per general shutdown procedures in Section 4.3.

TT2

(°C)

TT3

(°C)

TT4

(°C)

!"

7.0

RESULTS ANALYSIS AND DISCUSSIONS

Discuss all your results. The questions below only serve as a guideline. Your discussion should

not only limited to these questions.

1.

Calculate the heat transfer and heat loss for energy balance study.

2.

Calculate the LMTD.

3.

Calculate heat transfer coefficients.

4.

Calculate the pressure drop and compare with the experimental result.

5.

Perform temperature profile study and the flow rate effects on heat transfer.

!"

Experiment 2

Vapour-Liquid Equilibrium (VLE)

1.0

OBJECTIVES OF EXPERIMENT

To find VLE relationship for binary mixture.

To plot the equilibrium curve.

2.0

INTRODUCTION

Vapour-liquid equilibrium (VLE) is defined by the condition where a liquid and its vapour phase

are in equilibrium with each other. Under this state or condition, there is no net change in vapourliquid phases thus the rate of evaporation (liquid to vapour) is equal to the rate of condensation

(vapour to liquid).

In theory, the state of equilibrium would take forever to be reached but such equilibrium can be

practically achieved within a closed system where the liquid and vapour are allowed to stand in

contact with each other long enough with literally no interference or only slight interference from

the exteriors.

2.1

Theory

The concentration of a vapour in contact with its liquid, especially at equilibrium, is often given by

the vapour pressure. The equilibrium vapour pressure of a liquid is very much dependent on

temperature. In the state of equilibrium, a liquid mixture with individual components in certain

composition will have an equilibrium vapour in which the partial pressures of the vapour

components will have certain set values depending on all of the liquid component compositions and

the temperature. This is also true in reverse whereby a vapour with components at certain

composition or partial pressure is in equilibrium with its liquid, thus the component composition of

its liquid will be dependent on the vapour composition and the temperature.

The equilibrium composition of each component in the vapour phase is often different from the

composition of its liquid phase without a correlation. Such equilibrium phase data can be

determined from a simple experiment with multicomponents of vapour-liquid mixtures. Most

binary component mixtures'equilibrium data can be found in texts and references. In certain cases,

estimation or prediction of equilibrium data behaviour can be done using theories such as Dalton'

s

Law, Raoult’ s Law or Henry'

s Law.

In multicomponent mixtures, the compositions of each component are compared in both the liquid

and vapour phases where the compositions are expressed in mole fractions. A mole fraction is the

number of moles of a certain component divided by the total number of moles of all components in

the mixture in either the liquid or vapour phase. VLE data are often produced and shown in two

component systems (binary) and three component systems (ternary). However, VLE data can exist

in higher order of components but would be complex and difficult to illustrate graphically.

!"

2.2

Related Process Parameters

2.2.1

Vapour Pressure

Vapour pressure is defined as the pressure exerted by the gaseous phase under equilibrium state. It

depends significantly on the surrounding temperature. In addition, it is known as partial pressure of

a component when there is a mixture of gases present within the vapour.

A vapour with components at certain concentration will have a corresponding equilibrium liquid

concentration. The concentration or partial pressure of the liquid components will have certain set

of values depending on the vapour component concentrations and the operating temperature.

Similarly, this also applies to liquid with components.

For ideal gas the partial pressure of Component 1 (p1) is given by Dalton'

s law,

p1 = y1 P1

(1)

Raoult'

s Law expressed the partial pressure in terms of vapour pressure of the liquid where

p1 = x1 P1vap

(2)

However, this law is only applicable to ideal solutions with high value of x1. Generally a point is

reached where the vapour pressure no longer follows the ideal relationship as x1 gradually

decreases.

Both Dalton and Raoult'

s Laws can be combined to yield an equation that relates the vapour and

liquid compositions:

x P vap

y1 = 1 1

(3)

P

For a dilute real solution, Henry'

s Law is used to determine the partial pressure of the component:

p1 = K x1

where K is the Henry'

s constant but it is not equal to the vapour pressure of pure solute.

(4)

!"

2.2.2

Non-ideal Behaviour

For non-ideal system whereby the mixtures no longer obey Raoult'

s law or Henry'

s law, activity

vap

coefficient, γ is used to relate x1, y1, P1 and P as follows:

x1γ 1 P1vap

y1 =

P

(5)

The liquid phase activity coefficients depend on temperature, pressure and concentration.

2.2.3

Temperature

Temperature has an effect on the VLE of a system since at different temperatures there will be a

corresponding set of liquid and vapour compositions under a constant pressure. These two

compositions are in equilibrium with one another at that particular point.

For an ideal binary mixture, the relationship between T-x-y at a constant pressure can be

represented in a plot called the phase diagram as depicted in Figure 2.1 below:

Temperature

vapour

T

liquid

x1

y1

Figure 2.1: Phase Diagram

At a particular temperature T1, there will be a corresponding equilibrium composition x1 and y1 for

the liquid and vapour phase respectively.

!"

2.2.4

Relative Volatility

Relative volatility, α12 is an indication on how easily or difficult a particular separation will be. It

is a measure of the difference volatilities between two components (1 and 2). Ideally, relative

volatility can be defined as the ratio of fraction of a component in the vapour phase to that in the

liquid phase where it could be represented as follows:

α 12 =

y1 / x1

y 2 / x2

(6)

For a binary mixture, the relation can be simplified to:

y1 =

α 12 x1

1 + (α 12 − 1)x1

(7)

This relation is only valid when α12 is constant. In actual cases, it varies with temperature

(increases as temperature falls). Yet it remains remarkably steady for many systems.

2.3

Theory on Refractive Index

When a chopstick is dipped in water in a glass, it looks bent. If the chopstick is dipped in thick

sugar water, it looks more bent. This phenomenon arises from the refraction of light beam.

An-increase in concentration of a solution will yield a higher refractive index. When the refractive

index of air at the atmospheric pressure is “ 1” and a beam of light penetrates a certain medium %,

the ratio between the sine of refraction angle β and the sine of incident angle α a to the normal line

is called the refractive index of the medium.

α

n =1

nX =

sin α

sin β

air

medium X

β

Figure 2.1: Refraction of Light Beam

Since refractive index varies depending on wavelength of light and temperature, it is expressed as

t

nD , where n = refractive index, t = temperature, D = D-ray of sodium (589 nm).

!"

When the refractive index of water whose temperature is 20°C is measured with D-ray, it is

expressed as: nD20 = 1.33299 or usually expressed as nD = 1.33299.

The result for the refractometer calibration for 2-propanol-water is given in the table below:

Table 2.1: Refractometer Calibration for 2-propanol-Water System

Water (ml)

200

2-Propanol (ml)

10

20

30

40

50

60

70

80

100

120

140

160

180

200

240

280

320

360

400

440

480

500

550

600

700

Mole fraction

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.20

1.40

1.60

1.80

2.00

2.20

2.40

2.50

2.75

3.00

3.50

Average RI

1.334700

1.337167

1.340333

1.343833

1.344800

1.346667

1.348867

1.350633

1.353667

1.356133

1.358467

1.360033

1.361800

1.362800

1.365300

1.367000

1.367900

1.369800

1.370967

1.371367

1.372000

1.372467

1.373233

1.373667

1.374800

!"

3.0

EQUIPMENT – VAPOUR-LIQUID EQUILIBRIUM APPARATUS

The vapour-liquid equilibrium apparatus is designed to study the vapour and liquid equilibrium of

mixtures. The composition relationship between vapour and liquid equilibrium for binary and

multicomponent mixtures at atmospheric and elevated pressures can be determined.

The unit comprised of a main insulated evaporator made of stainless steel connected to an overhead

condenser. The cooling water flow rate into the condenser can be regulated with a gate valve and is

measured with a flow meter. A coil heater provides the necessary heat to evaporate the liquid

mixture with preset temperatures controlled by a digital temperature controller. Vapour rises to the

top of the unit is then condensed in the condenser.

Vapour and liquid products are collected in a stainless steel vessel located at the sampling port

lines. A feed port for dosing and sampling ports are provided. Digital meters are installed on the

control panel to display the temperatures and pressures in the system. A pressure relief valve is

connected to the unit to ensure the system will not be over-pressured at all time. Full jacket

insulation ensures minimal heat loss within the unit.

Temperature Meter

and Controller

Pressure Relief Valve

Condenser

Pressure Meter

Evaporator Inlet

Insulated Stainless

Steel Evaporator

Control

Panel

Vapour Sampling

Cooling Water

Inlet Valve

Cooling Water Drain

Liquid Sampling

and Drain

Figure 3.1: Vapour-Liquid Equilibrium Apparatus

4.0

OPERATING PROCEDURES

4.1

Pre-experiment Procedures

1.

Read and understand the theory of vapour-liquid equilibrium.

2.

Read and understand the equipment used in the experiment (VLE apparatus).

3.

Read the safety precautions and chemical hazards before conducting the experiment.

!"

4.

Read the Material Safety Data Sheet (MSDS) for the chemicals used in the experiment in

Appendix A – 2-propanol.

5.

Prepare the following apparatus and materials needed for the experiment:

Refractometer

Beakers

Syringe / Dripper

Prepare 7 L of 25 v/v% 2-propanol-water mixture

5.0

CHEMICAL HAZARDS, SAFETY AND PRECAUTIONS

5.1

Chemical Hazards (refer MSDS in Appendix A for more details)

Propanol is very flammable. It evaporates readily, so it is possible for dangerous levels of

vapour to build up, perhaps reaching a point at which an explosion is possible if a source of

ignition is present.

If propanol is in contact with oxygen over a long period, explosive peroxides may be formed.

These typically have a higher boiling point than propanol, so may become concentrated in the

liquid if propanol is distilled. Therefore, bottles of propanol, once opened, should not be stored

indefinitely, in order to avoid any risk of peroxide formation.

2-propanol is very flammable. It can be ignited by flames, but also by contact with items such

as hot plates or hot air guns.

5.2

Safety Precautions

Always wear safety glasses, mask and gloves when handling chemicals. Do not allow the

solution to come into contact with your skin or eyes.

Should any chemicals come into contact with the body, rinse off immediately with plenty of

water and inform the laboratory instructor/officer. Seek medical treatment if symptoms persist.

Ensure that there is no source of ignition, such as a Bunsen burner, gas flame, hot plate, hot air

gun or hot water pipe near the working area.

Propanol releases irritating vapours; avoid inhalation and work in a well-ventilated area.

Good ventilation is essential so that it is not possible for high concentrations of alcohol vapour

to form.

Dispose of all unused chemicals in an appropriate manner after the experiment. Under no

circumstances should the chemicals be allowed to flow into sinks or drains.

Wash your hands thoroughly with soap after the experiment.

Do not switch on the heater if there is no liquid in the evaporator.

Do not pressurise the apparatus for more than 10 bars.

Do not boil the liquid in the apparatus for more than 200°C.

Do not touch the evaporator (it is hot) and condenser when conducting the experiment.

!"

Be careful when pouring the test liquid into the evaporator vessel.

Be careful when taking the sample from the sampling port as the product is hot.

6.0

EXPERIMENTS

6.1

Experiment 1A: Vapour-Liquid Equilibrium

1.

Close the liquid sampling and drain valve.

2.

Open the vapour sampling valve and the evaporator inlet valve.

3.

Pour 2-propanol-water mixture into the evaporator. (Caution: The person who pours the

mixture should wear a face shield.)

4.

Close the vapour sampling valve and the evaporator inlet valve.

5.

Turn on the power supply and main power switch at the front of the control panel.

6.

Set the temperature to 75°C.

7.

Connect the cooling water drain port to drain.

8.

Connect the laboratory water supply to the cooling water supply port. Tighten it with clip.

9.

Switch on the heater power supply located at the control panel.

10. Turn on the water supply and allow the water to flow into the condenser. Set the water flow

rate to 12 LPM.

11. Keep an eye on the temperature. When the temperature reaches the set point, wait for another

5 minutes to allow the system to reach equilibrium, and then record down the temperature and

pressure.

12. Take a sample solution from the vapour sampling port and the liquid sampling port.

(Caution: Be careful when taking the sample from the valves.)

13. Label the samples (i.e. temperature, pressure, x-component, y-component).

14. Close both vapour and liquid sampling valves.

15. Use a refractometer to determine the samples'refractive index (RI). (Reminder: You must take

a few readings to obtain the average reading.)

16. Repeat Step 11 to Step 15 with 5°C increment until the set temperature reaches 95°C.

!"

6.2

Experiment 1B: Refractive Index (RI) Measurement of Liquid Sample

1.

Open the secondary prism of the refractometer and drip 2 or 3 drops of sample liquid onto the

centre part of the main prism surface. Gently close the secondary prism. The sample will

spreads between the main prism and secondary prim as a thin film.

2.

While observing through the eyepiece, gently turn the measurement knob until the boundary

line appears in the field of refraction view. At that time, the boundary line may be coloured

and unclear because it is not yet achromatised.

3.

Turn the measurement knob in a wide range so as to set it at a point where the field of

refraction view clearly changes from bright field to dark field or vice versa. The brightness of

the field can be adjusted with the illumination selector switch in the upper part of the digital

thermometer.

4.

Turn the colour compensator knob to achromatise the boundary line so that the line appears

clearly in the field. Turn the measurement knob again to set the boundary line at the

intersection of the cross hairs.

5.

The upper scale is for reading refractive index (nD) while the lower scale is for Brix percent.

Since the minimal graduation unit for refractive index is 0.001, the scale can be read at a unit

of 0.0001 with the eye.

CAUTION!

Measured value for liquid sample changes depending on the change of temperature. Therefore,

samples'temperature must be kept constant.

Do not wet the refractometer with sample liquid unreasonably. If the refractometer gets wet

excessively, it may cause malfunction and breakdown of the refractometer.

Do not tap or pick at the prism surface with a metal spoon, tweezers, etc. because the prism

surface is made of optical glass. If the prism surface is scratched, the refractometer may fail in

measurement.

When measurement is complete, wipe up sample from the prism surface and its surroundings

with soft tissues moistened with water first, and then wipe the wet parts with dry tissues to dry

them up.

After measurement of a sample of a high molecular compound (e.g. oil, fat etc) wipe the prism

surface with tissues moistened with alcohol or neutral detergent first and then wipe it up again

with dry tissues to dry up.

On ending a day'

s measurement, turn off the power switch.

!"

Results:

Mixture

Condenser water flow rate

Temperature

Pressure

(bar)

(°C)

Reading 1

Reading 2

Reading 3

Average

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Temperature

(°C)

Pressure

(bar)

Average

Reading

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Vapour RI

Liquid RI

Temperature (°C)

Pressure (bar)

Corresponding

Mole Fraction

Vapour (y)

Liquid (x)

Vapour (y)

Liquid (x)

Vapour (y)

Liquid (x)

Vapour (y)

Liquid (x)

Vapour (y)

Liquid (x)

Vapour (y)

Liquid (x)

Vapour Mole Fraction (y)

Reading

Liquid Mole Fraction (x)

!"

7.0

RESULTS ANALYSIS AND DISCUSSIONS

Discuss all your results. The questions below only serve as a guideline. Your discussion should

not only limited to these questions.

1.

Sketch a schematic diagram, including all valves and sensors/controllers, for the VLE unit used

in the experiment. Label all valves and instruments.

2.

Plot a graph of vapour composition (y) versus liquid composition (x) and discuss the findings.

3.

Plot a T-x-y graph and discuss the findings.

!"

Experiment 3

Cooling Tower Demonstrator

1.0

OBJECTIVES OF EXPERIMENT

To determine the “ end state” properties of air and water from tables or charts.

To determine energy and mass balances using steady flow equation on selected system.

To investigate the effect of cooling load on “ Wet Bulb Approach” .

To investigate the effect of air velocity on: (a) Wet Bulb Approach, (b) pressure drop through

the packing.

2.0

INTRODUCTION

Consider an air stream passing over the surface of a warm water droplet or film. Assuming that the

water is hotter than the air, then the water will be cooled down by radiation, conduction and

convection, and evaporation. The radiation effect is normally very small and may be neglected.

Conduction and convection will depend on the temperature difference, the surface area, air velocity,

etc. The effect of evaporation is the most significant where cooling takes place as water molecules

diffuse from the surface into the surrounding air.

2.1

Evaporation from a Wet Surface

When considering evaporation from a wet surface into the surrounding air, the rate is determined

by the difference between the vapour pressure at the liquid surface and the vapour pressure in the

surrounding air. The vapour pressure at the liquid surface is basically the saturation pressure

corresponding with the surface temperature, whereas the total pressure of the air and its absolute

humidity determines the vapour pressure in the surrounding air. Such evaporation process in an

enclosed space shall continue until the two vapour pressures are equal. In other words, until the air

is saturated and its temperature equals the surface.

However, if unsaturated air is constantly supplied, the wet surface will reach an equilibrium

temperature at which the cooling effect due to the evaporation equals the heat transfer to the liquid

by conduction and convection from the air, which under these conditions; will be at a higher

temperature. Under adiabatic conditions, this equilibrium temperature is the wet bulb temperature.

For a cooling tower of infinite size and with an adequate air flow, the water leaving will be at the

wet bulb temperature of the incoming air. Therefore, the difference between the temperature of the

water leaving a cooling tower and the local wet bulb temperature is an indication of the

effectiveness of the cooling tower. Thus, “ approach to wet bulb” an important parameter of cooling

towers, which is the difference between the temperature of the water leaving the tower and the wet

bulb temperature of the entering air.

!"

2.2

Cooling Tower Performance

A study on the performance of a cooling tower is to verify the effect of the following factors on the

cooling tower performance:

water flow rates

water temperatures

air flow rate

inlet air relative humidity

The effect of these factors will be studied in depth by varying them. In this way, we can gain an

overall view of the operation of the cooling tower.

2.3

Thermodynamic Property

In order to understand the working principle and performance of a cooling tower, a basic

knowledge of thermodynamic is essential. A brief review on some of the thermodynamic

properties is presented below.

2.3.1

Specific Enthalpy

At water triple point (i.e. 0.00602 atm and 0.01°C), the specific enthalpy of saturated water is

assumed to be zero, which is taken as datum. The specific enthalpy of saturated water (hi) at a

range of temperatures above the datum condition can be obtained from thermodynamic tables.

The specific enthalpy of compressed liquid is given by

h = h f + v f ( p − psat )

(1)

The correction for pressure is negligible for the operating conditions of a cooling tower, thus h ≈ hf

at a given temperature.

2.3.2

Specific Heat Capacity, Cp

Specific heat capacity, Cp is defined as the rate of change of enthalpy with respect to temperature

(often called the specific heat at constant pressure). For the purpose of experiment, we may use the

following relationship:

∆h = C p ∆T

(2)

h = C pT

(3)

and

where Cp for water is taken as 4.18 kJ/kg⋅°C.

!"

2.3.3

Dalton's and Gibbs Laws

It is commonly known that air consists of a mixture of dry air (O2, N2 and other gases) and water

vapour. Dalton and Gibbs Laws describe the behaviour of such a mixture as:

The total pressure of the air is equal to the sum of the pressures at which the dry air and the

water vapour each and alone would exert if they were to occupy the volume of the mixture at

the temperature of the mixture.

The dry air and the water vapour respectively obey their normal property relationships at their

partial pressures.

The enthalpy of the mixture may be found by adding together the enthalpies at which the dry air

and water vapour each would have as the sole occupant of the space occupied by the mixture

and at the same temperature.

2.3.4

Humidity and Saturation

Absolute or Specific Humidity, ω =

Relative Humidity, φ =

Mass of water vapour

Mass of dry air

Partial pressure of water vapour in Air

Saturation pressure of water vapour at the same temperature

Percentage Saturation =

Mass of water vapour in given volume of Air

Mass of same vol. of sat. water vapour at the same temperature

(4)

(5)

(6)

At high humidity conditions, it can be shown that there is not much difference between the relative

humidity and the percentage saturation and thus we shall regard them as the same.

2.3.5

Psychometric Chart

The psychometric chart is very useful in determining the properties of air/water vapour mixture.

Among the properties that can be defined with psychometric chart are Dry Bulb Temperature, Wet

Bulb Temperature, Relative Humidity, Humidity Ratio, Specific Volume and Specific Enthalpy.

Knowing any two of these properties, the other properties can be easily identified from the chart

provided the air pressure is approximately 1 atm.

!"

2.4

Orifice Calibration

Psychometric chart can be used to determine the value of the specific volume. However, the values

given in the chart are for 1 kg of dry air at the stated total pressure. For every kilogram of dry air,

there is w kg of water vapour, yielding the total mass of (1 + w) kg. Thus, the actual specific

volume of the air/vapour mixture is given by:

va =

vab

1+ ω

(7)

The mass flow rate of air and steam mixture through the orifice is given by

m&= 0.0137

x

va

x(1 + ω )

= 0.0137

vab

(8)

where m& = mass flow rate of air/vapour mixture

va = actual specific volume

vab = specific volume of air at the outlet

x

= orifice differential, mm H2O

ω = humidity ratio of mixture

The mass flow rate of dry air is given by

m&a =

=

1

× mass flow rate of air/vapour mixture

1+ ω

1

x(1 + ω )

× 0.0137

1+ ω

vab

= 0.0137

(9)

x

vab (1 + ω )

A simplification can be made since in this application, the value of ω is unlikely to exceed 0.025.

As such, neglecting wb would not yield significant error.

!"

2.5

Application of Steady Flow Energy Equation

Consider System A for a cooling tower as defined in

Figure 2.1. It can be seen that for this system, indicated

by the boundary line,

heat transfer at the load tank and possibly a small

quantity to surroundings

work transfer at the pump

low humidity air enters at point A

high humidity air leaves at point B

make-up enters at point E, the same amount as

the moisture increase in the air stream

Figure 2.1: System A

From the steady flow equation,

Q − P = H out − H in

= ma hda + ms hs − (mg hda + ms hs ) A − mE hE

(10)

The pump power, P is a work input, therefore it is negative.

If the enthalpy of the air includes the enthalpy of the steam associated with it, and this quantity is in

terms of per unit mass of dry air, the equation may then be written as:

Q − P = m&a (hB − hA ) − m&E hE

(11)

The mass flow rate of dry air, ma through a cooling tower is constant, whereas the mass flow rate of

moist air increases as the result of evaporation process. The term m&E hE can usually be neglected

since its value is relatively small.

Under steady state conditions, by conservation of mass, the mass flow rate of dry air and of water

(as liquid or vapour) must be the same at inlet and outlet to any system. Therefore,

(m&a ) A = (m&a )B

and (m&a )A + m&E = (m&a )B or m&E = (m&a )B − (m&a )A

!"

The ratio of steam to air is known for the initial and final state points on the psychrometric charts.

Therefore,

(m&s )A = m&aω A

and (m&s )B = m&aω B

m&E = m&a (ω B − ω A )

(12)

Let re-define the cooling tower system to be as in

Figure 2.2 where the process heat and pump work

does not cross the boundary of the system.

In this case warm water enters the system at point C

and cool water leaves at point D.

Figure 2.2: System B

Again from the steady flow energy equation, Q − P = H out − H in , where P = 0.

Q& may have a small value due to heat transfer between the unit and its surroundings:

Q = m&a hB + mw hD − (m&a hA + m&w hC + m&E hE )

Rearranging,

(18)

Q = m&a (hB − h A ) − m&w (hD − hC ) − m&E hE

(

)

Q = m&a hB − h A − m&w C p (t D − t C ) − m&E hE

Again, the term m&E hE can be neglected.

(19)

!"

3.0

EQUIPMENT – WATER COOLING TOWER

The water cooling tower is designed to demonstrate the construction, design and operational

characteristics of a modern cooling system. The unit resembles a full size forced draught cooling

tower and it is actually an “ open system” through which two streams of fluid (in this case air and

water) pass and in which there is a heat transfer from one stream to the other. The unit is selfcontained supplied with a heating load and a circulating pump.

3.1

Load Tank

The stainless steel load tank has a capacity of 9 litres. It is fitted with two cartridge heaters, 0.5 kW

and 1.0 kW each, to provide a total of 1.5 kW of cooling load. A make-up tank is fixed on top of

the load tank. A float type valve at the bottom of the make-up tank is used to control the amount of

water flowing into the load tank.

A centrifugal type pump (work input = 40 W) is supplied for circulating water from the load tank

through a flow meter to the top of the column, into a basin and back to the load tank. A

temperature sensor and temperature controller is fitted at the load tank to prevent overheating. A

level switch is fitted at the load tank so that the heater and pump will be switched off if a low level

condition occurs.

3.2

Air Distribution Chamber

The stainless steel air distribution chamber comes with a water collecting basin and a one-side inlet

centrifugal fan. The fan has a capacity of approximately 235 CFM of air flow. The air flow rate is

adjusted by means of an intake damper.

3.3

Tower and Packing

The tower is made of clear acrylic with a square cross-sectional area of 225 cm2 (15 cm × 15 cm)

and a height of 60 cm. The packing density of tower is 110 m2/m3 for Column A and 77 m2/m3 for

Column B. It comes with eight decks of inclined packing. A top column that fitted on top of the

tower comes with a sharp-edged orifice, a droplet arrester and a water distribution system.

3.4

Operation Processes

3.4.1

Water Circuit

Water temperature in load tank will be increased before the water is pumped through the control

valve and flow meter to the column cap. Before entering the cap, the water inlet temperature is

measured. The water is then uniformly distributed over the top packing deck. This creates a large

thin film of water, which will be exposed to the air stream.

The water will be cooled as it flows downward through the packing due to evaporation process.

The cooled water falls into the basin below the lowest deck and return to the load tank where it is

heated again before recirculation. The outlet temperature is measured at a point just before the

water flows back into the load tank.

!"

Evaporation causes the water level in the load tank to fall. The amount of water lost by evaporation

will be automatically compensated by equal amount of water from the make up tank. At steadystate, this compensation rate equals the rate of evaporation plus any small airborne droplets

discharge with the air.

3.4.2

Air Circuit

A one-side inlet centrifugal fan draws the air from the atmosphere into the distribution chamber.

The air flow rate can be varied by means of an intake damper. The air passes the dry and wet bulb

temperature sensors before it enters the bottom of the tower. As the air stream passes through the

packing, its moisture content increases and the water temperature drops. The air passed another