Engineering

Change Order

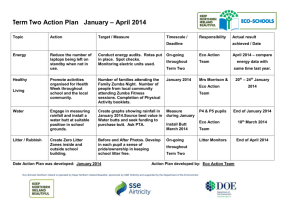

Chapter 1 -

Copyright

Copyright © 2002 - 2003 Horizons International, Inc.

All rights reserved.

Information in this document is subject to change without notice. The software

described in this document is furnished under a license agreement or

nondisclosure agreement. The software may be used or copied only in

accordance with the terms of those agreements. No part of this document may

be reproduced, stored in a retrieval system, or transmitted in any form or by

any means without the prior written permission of Horizons International, Inc.

Horizons International, Inc.

P.O. Box 2056

La Mesa, CA 91943

U.S.A.

www.hzs.com

Version 8.0 - 73.1

Crystal Reports

One of the reporting tools Horizons applications uses is Crystal Reports. With

the report viewer in an application that interfaces with SQL, it is free of charge.

If the reporting tool is accessed through a server the licensing hinges on where

the report processing is occuring. If running in an environment where the

application is on an individual machine accessing an SQL server, then there is

no licensing cost for Crystal Reports.

However, if it is used in a remote terminal server or Citrix environment, and is

installed on a network, Crystal Reports Standard per NAMED user must be

purchased.

Horizons is not responsible for any misuse of licensing procedures.

1

2

Table of Contents

Chapter 1: Introduction

Introduction....................................................................................................................................2

Glossary ..........................................................................................................................................3

Chapter 2:

Overview

Overview of Engineering Change Orders ...................................................................................6

ECO Terminology..........................................................................................................................7

Changes to Horizons Manufacturing Suite – BOM Maintenance ............................................8

Chapter 3:

Using ECO

Using ECO ....................................................................................................................................10

PROCEDURES FOR ECO.........................................................................................................11

Daily Processing Procedures.......................................................................................................12

.......................................................................................................................................................15

Engineering Change Orders window .........................................................................................16

ECO Select window .....................................................................................................................20

ECO Maintenance window .........................................................................................................22

Adding a sub item ................................................................................................................................ 24

Editing a sub item................................................................................................................................. 24

Procedures for Processing Engineering Change Orders..........................................................26

ECO Approvals window..............................................................................................................27

Process Changes................................................................................................................................. 28

Automatic Process-ing of ECOs...........................................................................................................29

Historical BOMs ..........................................................................................................................30

Chapter 4:

ECO Setup

ECO Setup ....................................................................................................................................34

i

Where And When the New ECO and REV Numbers Will Appear ........................................38

Chapter 5:

ECO Hardware Dispositions

ECO Hardware Dispositions.......................................................................................................42

Chapter 6:

ECO Approval User Setup

ECO Approval User Setup..........................................................................................................46

Chapter 7:

HMS Notes Setup

HMS Note Setup...........................................................................................................................50

Chapter 8:

Engineering Change Orders

Engineering Change Orders .......................................................................................................54

Buttons at the Top................................................................................................................................ 54

Fields.................................................................................................................................................... 55

ECO Select....................................................................................................................................60

Buttons at the Top................................................................................................................................ 60

Header Fields....................................................................................................................................... 61

Scrolling Region ................................................................................................................................... 63

ECO Priority Lookup ..................................................................................................................67

Chapter 9:

ECO Lookup

ECO Lookup ................................................................................................................................70

Header Fields....................................................................................................................................... 70

Scrolling Region ................................................................................................................................... 71

Buttons at the Bottom........................................................................................................................... 72

Chapter 10:

ECO Maintenance

ECO Maintenance........................................................................................................................76

ii

Fields To The Right Of Treeview ......................................................................................................... 78

Scrolling Region Below Treeview......................................................................................................... 84

Scrolling Region At The Bottom Of The Screen...................................................................................85

ECO Item Lookup .......................................................................................................................87

Additional ECO Information......................................................................................................90

Buttons at the Top................................................................................................................................ 90

Header Region ..................................................................................................................................... 91

Cpnt Fields ........................................................................................................................................... 92

Component WorkCenters ...........................................................................................................96

Buttons at the Top................................................................................................................................ 96

Fields.................................................................................................................................................... 97

............................................................................................................................................................. 97

Scrolling Region .................................................................................................................................102

Buttons at the Bottom.........................................................................................................................102

ECO Finished Good Defaults....................................................................................................103

Buttons at the Top..............................................................................................................................103

Fields..................................................................................................................................................104

ECO Rev Lookup.......................................................................................................................112

Header Fields.....................................................................................................................................112

Scrolling Region .................................................................................................................................113

Chapter 11:

Approvals

ECO Approval............................................................................................................................116

Buttons At The Top ............................................................................................................................117

Header Region ...................................................................................................................................117

Scrolling Region .................................................................................................................................119

Chapter 12:

Process Changes

Process ECO Changes ...............................................................................................................126

Chapter 13:

Manual Rev Adjust

ECO Manual Rev Adjustment..................................................................................................130

Header Fields.....................................................................................................................................131

Scrolling Region .................................................................................................................................131

iii

Chapter 14:

ECO Reports

ECO Reports ..............................................................................................................................134

Chapter 15:

Remove ECO History

Remove ECO History ................................................................................................................138

Index........................................................................................................................................... 141

Chapter 1: Introduction

Chapter 1:

Introduction

1

Chapter 1: Introduction

Introduction

Welcome to the Horizons Manufacturing Suite (formerly known as Horizons Light

Manufacturing), a software program designed to automate both discrete and process

manufacturers tracking mechanisms. This suite of applications seamlessly integrates with

Microsoft Business Solutions Great Plains Edition or Standard Edition. NOTE: This manual is a

living document that will be updated as additional functionality and code releases become

available.

Layout

HMS | Maintenance | BOM Maintenance

1

2

3

4

2

Chapter 1: Introduction

This manual follows several conventions to make it easier to read. Field names are in bold print,

and window names are italicized. For example, “the Save button on the BOM Maintenance

window”. Furthermore, each window is typically broken up into 4 sections:

1. The Buttons at the Top.

2. The Header Fields pertains to Parent items. Header Fields must be saved by saving the

entire window.

3. The Scrolling Region pertains to component items. The scrolling fields save when Tabbing

from line to line, leaving the Scrolling Region for the Header Fields, or leaving the window.

4. The Buttons at the Bottom.

Cascaded menu items are indicated by pipes. For example, the path to the BOM Maintenance

window is HMS | Maintenance | BOM Maintenance.

3

Chapter 1: Introduction

Glossary

BOM

Bill of Materials. This is the “recipe” that the Work Order follows to build the Finished Good, or

Subassembly (Parent).

Component

The items that make up the Parent. NOTE: A Sub-Assembly is a component of the Parent Item.

ECO

Engineering Change Orders component. ECO allows unlimited revisions of all Bill of Materials,

future, current and historical. This includes selecting historical revisions for a current Work Order

that has been set up to use existing stock.

Finished Good

The end result of a manufacturing process.

HMS

Horizons Manufacturing Suite. This suite was previously known as Horizons Light

Manufacturing. You might still see references in the software to Horizons Light Manufacturing or

HLM, particularly with reference to specific palette options and window names.

MRP

The Material Requirements Planning component. Based on demand, the system advises

production and purchase needs of Components and Parent Items. There is the capability to

“order” Labor and Overhead.

MPS

Master Production Schedule component. A high level view of overall production by Work Order,

Sales Order, or Forecasts.

Multiple Bins

If Multi Bin is activated under Setup | Inventory | Inventory Control, then mark the Enable

Multiple Bins checkbox. For more information see the Multiple Bins chapter in the Bill of

Materials and Production Entry Manual.

Parent Item

The Parent Item refers to Finished Goods, Sub-Assemblies, and Reverse manufactured goods.

4

Chapter 1: Introduction

Router

The Router Component. Router allows the ability to setup Operations, Cost Centers and Work

Centers, and organize them into steps for each Bill of Materials. Then the routing sequence can be

printed out on a traveler report.

Shop Floor Control

Shop Floor Control component. Shop Floor Control includes the Router component, and adds the

ability to schedule Work Orders, enter time, and issue stock automatically through the Production

Traveler Processing window. Capacity can be seen on the color coded SFC Capacity by Work

Center window. The planner is color coded, and when there is a capacity overage the cell will

show up as red. The HMS Work Order Status window provides details about each Router Step,

Operation, and Work Center function, as well as the actual Status of the order. The Production

Traveler Processing window offers a method of tracking the processing of quantities and time

spent on each step in production.

S/L

Serial/Lot numbers. The Serial/Lot component allows full tracking from the customer that bought

the Finished Good to the component Lot used in making the Finished Good, and the Vendor from

whom it was purchased.

Sub-Assembly

A Parent Item that is used in a Bill of Materials as a component to build another Finished Good.

For example, if a bicycle is the Finished Good, the seat might be a Sub-Assembly. The seat has its

own Bill of Materials and can be produced at the same time as the whole bicycle, or separately.

WIP

The Work In Process component. WIP allows the transfer of materials from one location to

another, and final adjustments to component line items can be made before posting production.

WO

A Work Order or build that is the order to manufacture the Parent Item.

5

Chapter 1: Introduction

6

Chapter 2:

Overview

Chapter 2 - Overview

Overview of Engineering Change Orders

Engineering Change Orders (ECO), makes it possible to create and track

changes to components and Bills of Materials. Revisions with effective dates

are entered by item and applied to Bills of Materials. The records can have a

Priority set which is for user information only and does not affect when a

Revision is implemented. Drawing ID and Drawing Sequence Number can be

entered and any documents (drawings or text) from programs outside of

Dynamics can be attached for future reference. Unlimited Notes are available

for each Engineering Change Order or Item and Revision Number.

The Effective date is the determining factor as to when a Revision is put into

effect. When a new production Work Order is entered for an item or then

Process Changes routine is run then the program will check to see if a new

revision needs to be processed. If there is one then all component changes will

be made to the Bill of Material. Components that are removed or added will be

logged in the Component Change Log regardless of the setting of the Logging

option in HLM Setup. In addition any errors encountered during the Revision

update will be logged.

When Horizons Manufacturing Suite, (HMS), has been in use and Bills of

Materials are entered, then the program will automatically create a list of the

current revisions in the ECO tables when the ECO module is first entered. The

revision will be designated as “!A” unless revisions have been entered in HLM

Item Maintenance or Dynamics Item Maintenance using the HLM Alternate

window.

6

Chapter 2 - Overview

ECO Terminology

When ever the term “Base Item” or “ECO Item” is used in this manual, it

refers to the parent, component or new item that has been selected at Parent /

Cpnt or Replace With fields in the Engineering Change Orders window.

A “Parent based ECO” is one that has a Finished Good in the Parent/Cpnt

field on the Engineering Change Orders window.

A “Component based ECO” is one that has either a component or subassembly in the Parent/Cpnt field on the Engineering Change Orders

window.

Whenever the term “Sub Item” or “Affected Item” is used, it refers to the

item(s) selected in ECO Select or ECO Maintenance screens to be attached to

the ECO Item.

“Implement” means to execute the ECO, at or after it’s effective date, to

become the active BOM in BOM Maintenance and to be used for future

Production Work Orders. The old BOM is now in ECO History.

The following are the items found on the ECO Palette ( | HMS | Maintenance

| ECO Maintenance).

7

Chapter 2 - Overview

Changes to Horizons Manufacturing Suite – BOM

Maintenance

Due to the longer length of the Revision numbers with the Engineering Change

Orders module, longer fields have been added to Horizons Manufacturing

Suite’s BOM Maintenance screen. This, in turn, has squeezed the ECO number

out the main BOM Maintenance screen.

The ECO number for the Parent can be found under the FG Defaults button off

the BOM Maintenance screen.

The ECO number for the components can be found under the Accounts button

off the BOM Maintenance screen – scrolling window header – when the

component is highlighted in the scrolling window.

8

Chapter 3:

Using ECO

Chapter 3 - Using ECO

Using ECO

The ECO Module is designed to allow users to manage and track changes to

Bills of Materials without having to setup new, active Bill of Materials or

Parent Inventory Items. Engineering Change Orders are documents that

describe the changes to an assembly. This can be a replacement, deletion,

addition of parts or a change to an existing part.

10

Chapter 3 - Using ECO

PROCEDURES FOR ECO

Whenever the term “Base Item” or “ECO Item” is used in this manual, it

refers to the parent, component or new item that has been selected at

Parent / Cpnt or Replace With fields in the Engineering Change Orders

window.

A “Parent based ECO” is one that has a Finished Good in the Parent/

Cpnt field on the Engineering Change Orders window.

Setup Procedures

Addressing the ECO Main Setup

Prior to producing a new change order, setup for your procedures needs to be

done in the ECO Setup window. This window is where options can be selected

to instruct the system on how to handle change orders.

Hardware Dispositions

To setup hardware dispositions open the ECO Disposition Setup window by

clicking Hardware Dispositions on the HMS ECO palette. In this window

new dispositions can be added to the list if needed.

The ECO Disposition Setup window is used to setup user-defined headings to

indicate the disposition of items on the old Bill of Materials. This list is

accessed during processing, in ECO Maintenance, through the Detail button to

the right of the Treeview. The Detail button opens the Additional ECO

Information window for items being changed. These Disposition ID’s are

accessed under the magnifying glasses listed under Hardware Disposition in

the lower, right corner. For more information, see Chapter 4: Hardware

Dispositions.

The dispositions currently appear on the ECO Impact report. The first six

dispositions are on the report header by default. Up to 15 may be placed on the

report using the report Legends in the Dynamics Report Writer.

Setup User Approvals

Engineering Change Orders may be approved before they can be processed to

take effect. At least one unrequired user approval should be set up. The ECO

Approval User Setup window is used to define which users are allowed to

approve Engineering Change Orders as well as which users are REQUIRED to

approve Engineering Change Orders so that they may be implemented. When a

user approval is required the Req. checkbox needs to be marked. For more

information see Chapter 11: Approvals.

11

Chapter 3 - Using ECO

Daily Processing Procedures

There are 2 different scenarios that can be utilized when implementing a new

change order.

1. When a component ECO Item is being replaced with another component

on all parents the Engineering Change Order window, and the ECO Select

window are used.

The Engineering Change Orders window is used to initiate change orders.

By default, the system will automatically apply a Rev Number during the

creation of the change order, however, the user may choose to remove it.

The initial setup of a change order must be performed here. The ECO may

then be edited in the ECO Select and ECO Maintenance windows.

The ECO Select window allows the user, during the initial setup of an

ECO, to specify items that will be affected along with the type of change(s)

to be made. The information in this window is stored in a temporary table

and is deleted when the window is closed. In order for any changes made

here to have an affect, you must click the Process button. This will cause

the changes to show up in the ECO Maintenance window, where further

modifications may be made.

With this type of ECO, the replacing component / subassembly item will

have the new ECO and REV numbers, on the active BOM in BOM

Maintenance. The parents affected by the change will have only the new

REV number, unless the option Apply This ECO # To All Affected Items

is marked in the Engineering Change Orders window before the ECO is

saved.

The following steps need to be followed to initiate an Engineering Change

Order to replace one component with another one.

1) Open the Engineering Change Orders window. The next

change order number will default in the ECO Number field.

Tab through the fields making selections as needed.

2) In the Parent/Cpnt field enter the component that you want to

replace.

3) In the Replace With field input the component that will be used

to replace the Parent/Cpnt item.

4) The Rev. field is populated automatically, but the field can be

modified if necessary.

5) The Effective Date is populated automatically, but can be

changed if necessary.

6) Consider the check boxes, and other options on the window and

make selections accordingly.

12

Chapter 3 - Using ECO

7) A click on the Select button at the top of the window to open

the ECO Select window where all items that will be impacted

with the change will appear in the scrolling area of the window.

8) Mark the Chg. checkbox, and then click the Process button at

the top of the screen to complete initiating the change order.

The system asks if the user wants to open the ECO

Maintenance window. This is an optional choice. In ECO

Maintenance window changes can be seen in the Treeview, and

additional information about the change can be accessed by

clicking buttons to the right of the Treeview. For example:

highlighting a component in the treeview, and then clicking the

Detail button will open the the Additional ECO Information

window. If a Parent Item is highlighted and Parent is the choice

on the pop-up window, then the ECO Finished Good Defaults

window will open. For more information see Chapter 10: ECO

Maintenance.

2. The second scenario occurs when the Parent ECO Item has several

components changed.

1) Open the Engineering Change Orders window. The next

change order number will default in the ECO Number field.

Tab through the fields making selections as needed.

2) Enter a Parent Item in the Parent/Cpnt field.

3) Then click on the Select button to open the ECO Select

window. A list of components that are attached to the parent

item are listed in the scrolling area. Components can be deleted,

and item quantities can be changed in this window. To add

components to the parent item go to the ECO Maintenance

window.

4) When changes have been made click on the Process button at

the top of the window, and following the prompts open the ECO

Maintenance window.

5) In the ECO Maintenance window the changes made in the ECO

Select window can be viewed in the Treeview. A new

component can be added to the Bill of Materials by highlighting

the Parent Item in the tree, and clicking the Select Item button,

and then making a selection from the pop-up window. A

window will open that will allow the addition of new

components to the Parent Item. When an item has been

selected, the Redisplay icon at the upper left corner just above

the treeview will need to be clicked, so the new item can appear

13

Chapter 3 - Using ECO

in the treeview area. Components can also be deleted by

highlighting a component, and clicking on the Delete button.

6) Highlighting a component, and then clicking the Detail button

will open the Additional ECO Information window which gives

further information about the component, and where further

editing to the new component can be done.

Activating Changes

1. Activating changes can be done in 3 ways.

1) Processing can be done in the Process ECO Changes window

according to the Check From This Date field which is linked

with the Effective Date field for each revision in the

Engineering Change Order window. When selections are made

click on the Process button to complete the operation.

2) Immediate manual processing can be done in the ECO Approval

window. Once all of the approval users have been selected, and

a revision has been entered in the ECO Number field, click on

the Execute Now to complete processing.

3) Processing revisions can also be automatically done through the

Production Entry window when the revision Effective Date is

the same as the User Date in the upper lefthand corner of the

Great Plains Toolbar.

NOTE:To view revision history select the History radio on the ECO

Maintenance window. The revision hisory will populate the treeview

area.

14

Chapter 3 - Using ECO

15

Chapter 3 - Using ECO

Engineering Change Orders window

HMS | Maintenance | ECO Maintenance | Engineering Change

Orders

1. Choose or enter an ECO Number.

This number will automatically increment from ECO Setup, but can be

overridden. To apply the users next change to an existing ECO number,

overwrite the incrementing number and type in the existing number. (Do not

try to lookup and select the existing ECO number, or the user will be selecting

the entire ECO record rather than just the number.).

2. Choose or enter a Priority.

This is an information only field that will print on reports.

3. Enter a Description.

The Description entered here will automatically appear in the white text box

below in this screen. This is designed to save time. The text in the ECO

Comment box is easily accessible from many screens, including when viewing

historical ECO’s. The Description is not as easily accessible, although through

zooming, it can be seen in history.

4. Choose or enter the Parent/Cpnt.

16

Chapter 3 - Using ECO

There are several ways an ECO can be used. Enter a component, subassembly

component, subassembly parent, end item parent or a new, unused item,

depending on the changes to be made. The possible changes that can be made

are:

a. Changes to a component / subassembly item that exists on a Bill of

Materials (BOM)

i. When the component will have a change made to it on all BOMs

where it exists.

When an ECO where the component is being changed on multiple BOMs, is

implemented, the component / subassembly item will have the new ECO and

REV numbers, on the active BOM in BOM Maintenance and Item

Maintenance. The sub items, or parents affected by the change, will have

neither the new ECO or REV numbers, unless the option “Apply This ECO To

All Affected Items” is marked in this screen before the ECO is saved.

ii. When the component will be deleted on multiple BOMs or

everywhere it exists.

When an ECO where the component is being deleted on multiple BOMs is

implemented, the component / subassembly item will be gone, and the affected

parents will have new REV number only. The ECO number will only be seen

in ECO History for the old BOM and not in BOM Maintenance, unless the

option Apply This ECO To All Affected Items is marked in this screen before

the ECO is saved.

iii. When the component will be replaced on multiple BOMs or

everywhere it exists.

When an ECO where the component is being replaced on multiple BOMs is

implemented, the replacing component / subassembly item will have the new

ECO and REV numbers on the active BOM in BOM Maintenance. The parents

affected by the change will have only the new REV number, unless the option

Apply This ECO To All Affected Items is marked in this screen before the

ECO is saved.

b. Changes to a new item that does not exist as a component /

subassembly on BOMs

i. When the component will be added to multiple BOMs.

When an ECO where the component is being added to multiple BOMs is

implemented, the new component / subassembly item being added will have

the new ECO and REV numbers, on the active BOM in BOM Maintenance and

Item Maintenance. The parents affected by the change will have the new REV

number only, unless the option Apply This ECO To All Affected Items is

marked in this screen before the ECO is saved.

c. Changes to a subassembly parent item or finished good parent

17

Chapter 3 - Using ECO

i. When the parent will have several changes made to it’s BOM

For example, one component is replaced by an updated new component, and

the scrap% must change on a second component due to the replacing item.

When implemented the parent ECO item, only, will have the new ECO and

REV numbers in the active BOM in BOM Maintenance and Item Maintenance.

This is the case whether the sub item components are being added, deleted,

replaced or changed. The affected components will not have the new ECO

number unless the option Apply This ECO To All Affected Items is marked in

this screen before the ECO is saved.

5. Choose or enter the Replace With item.

Enter a new, unused item at Replace With if an existing BOM component /

subassembly component was entered at Parent / Cpnt above, and the goal is

replace the above item with this item on one or many BOMs.

6. The REV Number will increment automatically unless the user marks the

option in ECO Setup to Disable Revision Sequence Check If this option is

marked, the program will verify that a revision entered is after the last

entered revision. If the REV Number is not in order, an error message will

appear when the ECO is saved.

7. The Effective Date will default to today’s date. The Effective Date must

be unique for each Parent/Cpnt item per ECO. This means that two ECOs

cannot be set up with the same Parent/Cpnt item and the same Effective

Date. An error message will appear when the ECO is saved, if they are not

unique.

8. Enter a Drawing ID and Drawing Seq. #, if desired.

These fields will print on reports but are memo fields only

9. Enter a Change Request #, if desired.

This field will also print on reports.

10. If you are using the ECO for development purposes you may check the

Prototype field. This will keep the ECO from being implemented, even if

it is past the Effective Date

11. If the user would like the sub or affected items selected in ECO Select or

ECO Maintenance to have the new ECO number, mark the Apply This

ECO To All Affected Items option.

See step number 4 above for more details on how this affects where the ECO #

will populate. Normally the users do not want to mark this option as the ECO

system populates the proper screens with the REV and ECO #, as needed. Only

under special circumstances would this option need to be marked.

12. When the user is ready to add sub-items that the ECO will affect, three

methods can be used:

a. Checking the Auto-Add All Parent Items check box.

18

Chapter 3 - Using ECO

b. If the Parent/Cpnt item above is a component or subassembly in

existing BOMs, and the change will affect all existing parents, the user

can add all parents automatically by checking the Auto-Add All

Parent Items checkbox before saving the record. When the record is

saved the parent items will be added as the sub-items of the ECO and

can then be viewed by opening ECO Maintenance (click on the button

called ECO Maint at the top of the screen.).

c. Through the ECO Maint. Button.

Sub items can also be added manually by saving the ECO and accessing ECO

Maintenance. The ECO Maint. button will do both.

d. By clicking the Select button.

19

Chapter 3 - Using ECO

ECO Select window

If you do not want to select all parents, but want to pick and choose, click on

the Select button to open ECO Select where the sub-items can be selected.

HMS | Maintenance | ECO Maintenance | Engineering Change

Orders | Select button

When accessing the ECO Select screen, there are several possible scenarios:

1. When working with a component ECO Item that exists on BOMs:

a. The Parent checkbox is automatically marked (the Cpnts checkbox

will be inactive unless the ECO Item is a subassembly).

b. The parent items to the component ECO Item, which were entered in

the Parent/ Cpnt field in Eng. Change Orders, will list with the

existing Quantity, U of M and Scrap %.

c. If you mark the All Items checkbox, the Quantity will be 0 and the U

of M will be the base U of M. Items to be applied to this ECO can be

marked.

2. When working with a new, unused component ECO Item:

a. The All Items checkbox will need to be marked to list all available

parents to which the new component could be added.

20

Chapter 3 - Using ECO

b. The Quantity and Scrap % will default as zero

3. When working with an end item parent ECO Item:

a. The Cpnts checkbox is automatically marked and Parents checkbox is

inactive.

b. The components (and subassembly components) to the parent ECO

Item, entered in the Parent / Cpnt field in Eng. Change Orders, will

list with the existing Quantity, U of M and Scrap %.

4. When working with a subassembly ECO Item:

a. The Parent checkbox is automatically marked and parents to the

subassembly will list.

b. The Cpnts checkbox will also be active so that the subassembly’s

components may be selected.

Keeping the above scenarios in mind, there are several other steps that may be

performed within the ECO Select window:

5. You may access the BOM to which the ECO item belongs if the item is a

subassembly parent or end item parent via the M button.

6. The C button provides access to a where – used inquiry called Component

Inquiry, regardless what type of item the ECO Item is.

7. Quantity, U of M and/or Scrap % can be entered.

Entering a value in one of these fields will mark the record. When entering a

quantity, the user will be asked if they want to roll this quantity down to all

marked records. This will save time when entering a change to a component in

several parents, for example.

8. Add, Chg, Delete and Add to Parent can also be marked in preparation

for ECO Maintenance. It is easier to make these changes and settings in

ECO Select, than in ECO Maintenance.

9. Click the View Marked button to see only the marked records to be added

to ECO Maintenance.

10. When ready, click the Process button to add all marked items to the ECO.

The user is asked if they want to open ECO Maintenance when the process

is finished.

21

Chapter 3 - Using ECO

ECO Maintenance window

ECO Maintenance allows the user to view and edit current and historical ECOs

and BOMs. Once ECO are saved in Eng. Change Orders, they will appear in

the ECO Maintenance tree view. This window may also be used to add the sub

items w which will be affected by the ECO, rather than using the ECO Select

window.

HMS | Maintenance | ECO Maintenance | ECO Maintenance

The ECO Maintenance window may be used in two ways:

z

As an inquiry screen

z

As an editing tool

When using the ECO Maintenance window as an inquiry screen:

1. The top, left drop down menu determines the type of information displayed

in the white tree view box below. The possible choices are:

a. Engineering Changes – shows only the Engineering Changes which

have been entered in the ECO system.

b. Finished Goods – shows the list of finished goods by Bill of Material in

the tree view window

c. Subassemblies – shows only the sub-assemblies from the Bill of

Materials.

If there are ‘sub items’ that have been selected for an ECO, there will be a “+”

(plus sign) to the left of the ECO #.

22

Chapter 3 - Using ECO

i. Click the plus sign to see a list of the sub items that will be affected

by the change.

ii. Highlight each sub item and view the fields to the right of the white

tree view box to see what changes will be happening.

iii. Click on the Detail button on the right, to see details such as

quantity changes, etc.

ECO Maintenance defaults to the Engineering Changes view, upon opening

the screen.

2. The Show radio buttons are used in conjunction with the View drop down

to determine what type of data is showing in the tree view.

a. The Planned radio button relates only to the Engineering Changes

choice in the View drop down menu. ECO Maintenance defaults to the

“Planned” radio button upon opening.

b. The In Use and History radio buttons relate to all three drop downs

choices:

i. In Use shows the current BOMs.

ii. History will show all historical BOMs that are the result of ECO

changes being implemented. Any time an ECO is processed, a copy

of the BOM, before and after, is made or updated.

3. When the Finished Goods drop down option is selected along with the

History radio button, the user can view Historical BOMs for only end item

parent numbers. These BOMs are sorted by the parent number with the

REV number listed. The plus sign, to the left of the Item Number, can be

clicked to see the components as they were at that time. Click on the Detail

button on the right to see details such as quantity changes, etc.

4. When the Subassemblies drop down option is selected along with the

History radio button, the user can view Historical BOMs for only

subassembly items and sort by the Subassembly number with the REV

number listed. The plus sign to the left of the Item Number can be clicked

to see the components as they were at that time. Click on the Detail button

on the right, to see details such as quantity changes, etc.

5. When the Engineering Changes drop down option is selected along with

the History, the user can view all Historical BOMs by ECO number with

the REV number and ECO Item listed. The plus sign to the left of the Item

Number can be clicked to see the sub items that were affected with that

ECO. Click on the Detail button on the right, to see details such as quantity

changes, etc.

6. The Parent Items window, in the picture of ECO Maintenance above - just

below the tree view, shows either the parents of the item highlighted in the

tree view, or all the past Revisions of that item. Click on the button at the

23

Chapter 3 - Using ECO

lower, right corner of the Parent Items window to make the toggle change.

In the picture of ECO Maintenance above, this button says Revisions.

When clicked it changes to Parent Items and the heading of the window

changes to Item Revisions. Click on the button again, and it changes back.

When using ECO Maintenance as an editing tool:

When working with Planned ECOs, the user can add or edit directly in the

ECO Maintenance window, provided the ECO has been saved in the

Engineering Change Orders window

Adding a

sub item

1. First select the ECO in the white tree view box.

2. Then the click the Select Items button to add the required items.

3. Once the item has been selected using the Select Items button, you may

either:

a. Mark the new sub item for deleting by clicking the Delete checkbox

b. Click the Detail button to make changes.

4. Once all is correct for the new item, click the Save button.

Editing a

sub item

For sub items added previously, the user can edit each ECO’s sub-items.

1. First open the ECO in the tree view by clicking on the Plus Sign to the left

of the ECO Number.

2. Highlight one of the sub items that list.

3. Click on the Detail button on the right.

This will either open the Additional ECO Information or ECO Finished Good

Defaults windows, depending on the type of item highlighted in the tree view.

In these windows the BOM Setup fields can be changed for the new BOM.

4. Once changes are complete, click the Save button.

If changes were made in the ECO Select screen, the user will be able to see

them in the “Details” button and further edit them if desired.

NOTE:the following steps may be completed when either adding or editing a

sub item.

5. When the ECO sub-item is a parent item, as in a replace type ECO, a New

Parent Rev will be automatically entered.

This will be the next Rev for that item. It is necessary for each Parent change to

have a new revision or else a historical BOM of the previous component

structure will not be kept in the ECO history – it will be overwritten by the new

change. This field is active and can be edited, if desired.

6. If desired, you may enter Manufacturers Parts numbers in the

Manufacturers Part Number window at the bottom of the screen.

24

Chapter 3 - Using ECO

This window is used to enter Manufacturers Parts by Revision Number for

each item that is highlighted in the ECO Tree window. These parts do not have

an effective date of their own. When a user looks up MPN’s for an existing

item in the standard MPN window in BOM Maintenance, on the active BOM,

they will see these entries, made through the ECO Maintenance screen, as

well. The controlling factor here is whether the item being edited in ECO, has

been added to the BOM yet. If it has not, the parts entries are not valid until the

item is a part of a BOM when the ECO is implemented to become the active

BOM.

7. You may use the E button next to the Browse Buttons, at the top left of the

screen, to zoom to the Engineering Change Orders window and display the

record highlighted in the ECO Maintenance tree view.

25

Chapter 3 - Using ECO

Procedures for Processing Engineering Change

Orders

Once the above steps for creating and editing the ECO have been completed,

the ECO must be implemented. ECOs may be processed three ways:

1. By hand, individually using the Approvals screen.

2. By hand, individually or as a group using the Process Changes screen.

3. Automatically using Production Work Orders as the ECO’s Effective date

come due.

26

Chapter 3 - Using ECO

ECO Approvals window

HMS | Maintenance | ECO Maintenance | Approvals

The Approvals window is provided to allow all designated users the ability to

comment on and approve an ECO. The users are set up in the Approval User

Setup window. Each user can be Required to approve before the ECO can be

processed, and they can be assigned a Department for reporting purposes.

1. Lookup the ECO to approve via the lookup icon at the ECO Number

field. Once ECO Lookup is open, mark the Unapproved Only and

Unprocessed Only checkboxes as needed to filter the ECOs listed.

2. To view details such as notes and item setup open ECO Maintenance via

the ECO Maint. button at the top of the screen.

3. Review the changes which the ECO will be making.

a. The ECO Item appears with a red ‘P’ for “Primary” in the scrolling

window in the bottom half of the ECO Approvals screen.

b. The Revision numbers will list as the numbers that will be used when

the ECO is implemented.

c. The new Cpnt Quantity should be listed correctly based on changes

made in the Details button in ECO Maintenance.

27

Chapter 3 - Using ECO

d. The Add and Delete comments and checks should be correct based on

the changes made in ECO Maintenance.

4. The ECO system tracks which user is logged into Dynamics or eEnterprise.

All the approving user has to do is click the Approve (or Un-Approve)

button.

5. Once approved, a date will appear next to that user’s name in the Approval

List. In this way, management can tell who has approved and who hasn’t.

6. Each user may enter their own comments about the ECO. To see a

particular users comments, highlight that user in the Approvers List.

7. Once all required approvers have approved, the system will allow the

Approved For Production box to be checked. This will then reflect in

ECO Maintenance and on reports for that ECO.

8. The ECO can be processed immediately in this window by clicking on the

Execute Now button. The Approved For Production box must be

checked first. The Effective Date will be changed to today’s date.

9. Once the ECO is processed, the Processed date will fill in with today’s

date. In this way viewers can tell if an ECO has been made active in BOM

Maintenance.

Process

Changes

HMS | Maintenance | ECO Maintenance | Process Changes

Once the Approved For Production box is available to be marked for an ECO

in ECO Approvals, it can also be processed in the Process Changes window.

This window will process any ECOs where the Effective Date is today or

earlier. When looking up at From Item and To Item, be sure to mark the

Unapproved Only and Unprocessed Only checkboxes as needed to filter the

ECOs listed.

28

Chapter 3 - Using ECO

Automatic

Processing of

ECOs

If neither the ECO Approvals nor the Process Changes screens are used, ECOs

will automatically be processed when a Work Order is entered for a Parent

Item where the parent or one of its components has an ECO with an effective

date of today.

29

Chapter 3 - Using ECO

Historical BOMs

Creating Production from Historical BOMs

Should it be necessary, it is possible to use a Historical BOM in Production

Entry. A Historical BOM is one that has been superseded by a BOM that was

changed via an Engineering Change Order.

This is accomplished from within the Production Entry screen by entering the

Revision Number for the Finished Good on the Work Order at the Rev field in

the upper right corner of the screen. You may also enter Rev numbers for any

Subassemblies (in the Production Subassembly Options window – use the blue

S prompt to access). The components will be compiled from the ECO history

BOM if all the data is complete in ECO Maintenance. If there are any records

missing there may be an error after Calculating the work order stating that

some items were removed. The user will need to first run check links on the

BOM Components tables and then check the historical ECO and make changes

if necessary.

Editing Historical BOMs

Historical BOMs can be edited by marking the option in ECO Setup called

Edit Existing ECO BOMs. This will open up most fields in ECO

Maintenance to editing.

NOTE:The users must be careful when making changes to make sure they do

not upset relationships between tables. The user should make a backup

of their HLM tables before doing any editing.

1. Simply bring up the Historical BOM by marking the History radio button

at the top right of ECO Maintenance.

2. Choose either Finished Goods or Subassemblies in the drop down at the

top left.

3. Once found, open it in the tree view via the Plus Sign, highlight the

affected component sub item, and click Detail to modify. This will open

the Additional ECO Information window if it is a subassembly, and the

ECO Finished Goods Default window if the item is a Parent Item.

4. Subassemblies can be edited in the Additional ECO Information window.

The fields at the bottom of the window correspond with the original BOM

fields in BOM Maintenance. If the item is a Parent options can be changed

in the ECO Finished Goods Default window.

5. If a component is missing, highlight the ECO Item (the item with the “+”

next to it) and click Select Item to lookup and add the item. Then click

Detail to enter the necessary information for the item that is being added

Note that this process is basically the same as editing a Planned ECO as

outlined above.

30

Chapter 3 - Using ECO

Changes to “In Use” BOMs

Any changes made to a current Bill of Materials in BOM Maintenance, will

update the BOM in ECO. When an ECO is processed a copy of the new BOM,

as well as the old, is made in ECO.

31

Chapter 3 - Using ECO

32

Chapter 4:

ECO Setup

Chapter 4 - ECO Setup

ECO Setup

The ECO Setup window provides the initial setup for the ECO module.

HMS | Maintenance | ECO Maintenance | ECO Setup

OK

The OK button closes the ECO Setup window.

Next ECO number

The Next ECO Number field is a six to twelve character alphanumeric field

which is used to set the starting point for ECO numbers. The system will

automatically increment the ECO number during processing, starting with the

number entered here. However, this number may be manually overridden when

creating a change order.

It is important to note that the ECO Number may consist of letters, numbers or

both. When numbers are being used, they should be placed at the END of the

format to ensure that they will increment properly. Additionally, ECO numbers

must be able to handle a change of the number of digits. For example, an ECO

number beginning with 12 will be considered to be greater than one beginning

with 100. Place zeros in front of the number to keep this from happening. For

example, use 0012 and 0100 in the above example to maintain proper order

34

Chapter 4 - ECO Setup

Revision Number Format

Because the ECO number is alphanumeric, the Revision Number Format

field is used to tell the system which format is being used so that it will

increment the numbers properly. There are three possible choices:

z

Letters will only allow letters. This format will increment automatically.

z

Numbers will only allow numbers. This format will increment

automatically.

z

Both Letters & Numbers will allow a mix. When using Letters &

Numbers be sure the number portion is at the end of the format. Otherwise

the number will not increment.

Revision numbers will increment automatically only when an ECO is entered

with the same item as a previous ECO. An ECO with a different Parent/Cpnt

item number will not cause the Revision number to increment.

Initial Rev Number

The Initial Rev Number field is used to tell the system the number to begin

incrementing from. Depending on the selection for Revision Number Format

above, this field may be numeric only, alpha only or alpha-numeric. In

processing, this default number can be overridden. As with ECO Numbers,

Revisions beginning with numbers must be able to handle a change of the

number of digits. For example, a Revision number beginning with 12 will be

considered to be greater than one beginning with 100. Place zeros in front of

the number to keep this from happening. For example, use 0012 and 0100 in

the above example to maintain proper order.

The next Revision number increments by number or letter from the greatest

one, in alphanumeric order, found in the system. It looks in the Engineering

Change Orders window (HLM_ECOs table), ECO Finished Good history, the

ECO Master (at both the Item Revision field and the New Parent Revision,

since Sub-Assemblies may have Revisions in both fields), and HMS Item

Maintenance. Once the system has looked at all of these locations, it chooses

the Rev number that is highest in alphabetical order and increments from that

number.

NOTE:ECO Setup allows the user to select the basic Revision Number format,

but the incrementing does not depend on this. The last Revision found

will be checked to see if it ends in a number or a letter and the

appropriate incrementing method will be used on that basis.

If a Revision ends in a number, the number must be capable of being

incremented. If the ending number after the last letter is all nines, the number

will start over at 1. The user should set up the Rev Number format so that it

will accommodate more than the largest number of changes that will ever be

made.

If the Revision ends in a letter, the Revision number will only be incremented

if the it is all letters (no numbers or periods). If it ends in a letter and is not all

letters then a blank Revision number will be returned.

35

Chapter 4 - ECO Setup

If a format includes periods and ends in a number then only the part of the Rev

after the last period will be incremented. The user must update any other

segments.

Remove ‘Delete’ Cpnts From Router Setup

When HMS Router is registered, marking this checkbox will remove items that

are marked to delete during an ECO change of revision, from the ‘Item List’

assigned to Router Steps.

# Of Items To Show In Treeview At One Time

For those companies with complex, multi-level Bills of Materials, this option

can help by allowing you to set how many items you will see at once in the

Treeview in ECO Maintenance, thereby reducing the time it takes to populate

the Treeview window.

Disable Revision Sequence Check

When an Effective Date or Rev Number is entered in the Engineering

Change Order window or the ECO Approval window, the system will

automatically check the sequencing of Revisions compared to the Effective

Date. Marking Disable Revision Sequence Check causes the system to not

perform this check. Mark this checkbox if you do not care whether the

Effective Dates are out of order from the Revision numbers.

NOTE:In order for the Sequence Check to be successful, the Revision

Numbers must be in alphanumeric order.

Edit Existing ECO Boms

A checkmark in Edit Existing ECO BoMs allows the user to edit existing

ECO BOMs in ECO Maintenance, even after the ECO has been approved.

Any fields relating to the ECO BOM can then be altered, including adding or

deleting items, changing Rev Numbers, ECO Numbers or Effective Dates. An

entire BOM can be copied and then altered to create history or records that

need to be in the system.

Auto-Approve BOMs When ECO Processed

When the Require Approval to Use Finish Good in Production option is

selected in HMS Setup, Bills of Material must be marked as approved in the

Finished Goods Approval window (accessed through HMS | Transactions |

BOM Approval) in order to be used in Production Entry.

If this feature is in use, marking the Auto-Approve BOMs When ECO

Processed field causes the new Bill of Material that is created when an ECO is

processed, to be automatically marked as approved in Finished Goods

Approval. This makes the new BOM immediately available for use in

Production Entry.

36

Chapter 4 - ECO Setup

NOTE:When the HMS Setup option Require Approval to Use Finish Good

in Production is not marked, selecting Auto-Approve BOMs When

ECO Processed does not mark the BOM for approval in Finished

Goods Approval, since no approval is required.

# of BOMs per FG Item to retain in ECO History

The # of BOMs per FG Item to retain in ECO History field allows the user

to limit the number of historical Bills of Material that the system retains in the

database. The system can be set to hold up to 99,999,999,999,999 historical

BOMs per Finished Good item. This is used primarily in systems where a large

number of Engineering changes are made, causing disk space to become an

issue. A zero in this field indicates that the system is to retain ALL historical

BOMs.

When a number greater than zero appears in this field and an ECO containing a

Parent Item is processed, the system performs the following steps:

1. Check to see if there are any historical BOMs for the Parent Item(s)

affected.

2. If there are, the system will determine how many historical BOMs there are

for that Parent Item.

3. If there are more than the number listed here, the system will delete any

historical BOMs in excess of this number and so that only the number of

BOMs listed here remain.

Note that which specific BOMs are going to be retained is determined by the

Revision number associated with them. The system keeps the BOMs whose

Revision number is highest in alphanumeric order.

37

Where And When the New ECO and REV Numbers Will

Appear

There are several possible scenarios when discussing where and when the ECO

and Revision numbers appear:

Component ECO where the component is being changed on multiple BOMs

When this type of ECO is implemented, the component / subassembly item

will have the new ECO and REV numbers on the active BOM in BOM

Maintenance and in HMS Item Maintenance. The sub items, or parents affected

by the change, will have neither the new ECO or REV numbers, unless the

option Apply This ECO # To All Affected Items is marked in Engineering

Change Orders before the ECO is saved.

Component ECO where the component is being deleted on multiple BOMs

When this type of ECO is implemented, the component / subassembly item

will be gone, and the affected parents will have new REV number only. The

ECO number will only be seen in ECO History for the old Bill Of Material and

NOT in BOM Maintenance, unless the option Apply This ECO # To All

Affected Items is marked Engineering Change Orders before the ECO is

saved.

Component ECO where the component is being replaced on multiple BOMs

With this type of ECO, the replacing component / subassembly item will have

the new ECO and REV numbers, on the active BOM in BOM Maintenance.

The parents affected by the change will have only the new REV number, unless

the option Apply This ECO # To All Affected Items is marked in the

Engineering Change Orders window before the ECO is saved.

Component ECO where the component is being added to multiple

BOMs

With this type of ECO, the new component / subassembly item being added

will have the new ECO and REV numbers on the active BOM in BOM

Maintenance and HMS Item Maintenance. The parents affected by the change

will have the new REV number only, unless the option Apply This ECO # To

All Affected Items is marked in the Engineering Change Order window

before the ECO is saved.

Parent Item ECO

With this type of ECO, only the Parent Item will have the new ECO and REV

numbers in the active BOM in BOM Maintenance and HMS Item Maintenance.

This is the case whether the sub item components are being added, deleted,

Chapter 4 - ECO Setup

replaced or changed. The affected components will not have the new ECO

number unless the option Apply This ECO # To All Affected Items is marked

in this screen before the ECO is saved.

39

Chapter 4 - ECO Setup

40

Chapter 5:

ECO Hardware

Dispositions

Chapter 5 - ECO Hardware Dispositions

ECO Hardware Dispositions

The ECO Disposition Setup window is used to setup user-defined headings to

indicate the disposition of items on the old Bill of Materials. This list is

accessed during processing, in ECO Maintenance, through the Detail button to

the right of the Treeview. The Detail button opens the Additional ECO

Information window for item being changed. These Disposition ID’s are

accessed under the magnifying glasses listed under Hardware Disposition in

the lower, right corner. For more information, see the Hardware Disposition

field.

The dispositions currently appear on the ECO Impact report. The first six

dispositions are on the report header by default. Up to 15 may be placed on the

report using the report Legends in the Dynamics Report Writer.

HMS | Maintenance | ECO Maintenance | Hardware Dispositions

OK

The OK button closes the ECO Disposition Setup window.

#

The # field is an alphanumeric field that is used to hold the identifier that

represents the Disposition ID. The information in this field will be displayed

in the Hardware Disposition fields in Additional ECO Information and will

also print in the detail section of the ECO Impact report.

42

Chapter 5 - ECO Hardware Dispositions

Disposition ID

The Disposition ID is the actual identifier of the Disposition and is a required

field. The Disposition IDs will print in the header on the ECO Impact report, as

well, as a key to the identifiers in the # field.

Description

The Description field is a fifty character field that allows the user to provide a

description of the hardware disposition. This is an information only field.

Drop Down menu

The unlabeled drop down menu in the lower left corner of the window is used

to sort the Hardware Dispositions. There are two possible sort options:

z

By Name - this is the default sort option. This option sorts the dispositions

in ascending alphanumeric order by Disposition ID.

z

By Number - sorts the dispositions in ascending alphanumeric order by the

# field.

Note icon

The note icon in the lower right corner of the window allows the user to attach

a note to the ECO Disposition Setup window.

43

Chapter 5 - ECO Hardware Dispositions

44

Chapter 6:

ECO Approval User Setup

Chapter 6 - ECO Approval User Setup

ECO Approval User Setup

Engineering Change Orders must be approved before they can be processed to

take effect. The ECO Approval User Setup window is used to define which

users are allowed to approve Engineering Change Orders as well as which

users are REQUIRED to approve Engineering Change Orders so that they may

be implemented.

HMS | Maintenance | ECO Maintenance | Approval User Setup

Save

When clicked, the Save button saves the approval user assignments.

Clear

The Clear button clears the ECO Approval User Setup window without saving

any changes.

Delete

Clicking Delete permanently removes the approval user assignment displayed.

Once deleted, the user will no longer be able to approve change orders.

Approval User ID

This is the User ID for the people that need to approve ECOs’. The user must

be logged in under their ID in order to activate approval of an ECO in ECO

Approval.

Req.

Marking this box will make this user required to approve ECOs’. The user

must be logged in under their User ID to make approvals for their ID.

User Name

The User Name field displays the user name associated with the Approval

User ID.

46

Chapter 6 - ECO Approval User Setup

Department

The Department field is used to enter the department this user is in. This

information will print on reports.

47

Chapter 6 - ECO Approval User Setup

48

Chapter 7:

HMS Notes Setup

Chapter 7 - HMS Notes Setup

HMS Note Setup

An unlimited number of Note IDs may be setup by entering a Note ID and

then clicking the note icon, to the left of the Note ID field. A description of the

note may be entered in the Description field.

Note IDs may also be setup on the fly in the Engineering Change Orders

window at the ECO Number field as well as in ECO Maintenance for the

fields ECO Number and Revision Number.

Each note may contain 32,000 kilobytes of text and attached pictures or

documents. Any notes applied will follow the Engineering Change Order or

Revision to history.

HMS | Maintenance | ECO Maintenance | HMS Notes Setup

Save

Clicking the Save button saves the Note ID that is being displayed and clears

the HMS Note Setup window.

Clear

The Clear button, when clicked, clears the HMS Note Setup window without

saving. Any changes made will be lost.

Delete

By clicking the Delete button, the user may permanently delete from the

database the Note ID displayed along with any notes associated with it. Any

pictures or external documents that were attached to the note will not be lost.

Note ID

The Note ID is a user-defined identifier for the note. This ID can be up to

fifteen characters long. The actual text of the note is entered by clicking the

note icon to the left of the field. When there are no notes entered for the Note

ID, the icon will appear as a blank page

icon will appear as a page with lines

.

50

. When there are notes present, the

Chapter 7 - HMS Notes Setup

Description

The Description field is a fifty character text field used to enter a description

of the Note ID.

51

Chapter 7 - HMS Notes Setup

52

Chapter 8:

Engineering Change

Orders

Chapter 8 - Engineering Change Orders

Engineering Change Orders

The Engineering Change Orders window is used to initiate change orders. By

default, the system will automatically apply a Rev Number during the creation

of the change order, however, the user may choose to remove it. The initial

setup of a change order must be performed here. The ECO may then be edited

in the ECO Select and ECO Maintenance windows.

HMS | Maintenance | ECO Maintenance | Engineering Change

Orders

Buttons at

the Top

Save

The Save button, when clicked, saves the change order. The Parent/Cpnt and

Effective Date fields must be completed prior to saving.

Clear

The Clear button clears the window and increments the ECO Number to the

next available number. However, if the ECO has not yet been saved, the system

will ask whether to Save or Discard any changes made before clearing. If the

user chooses to Discard, any changes will be lost.

Delete

Removes the ECO Number and the detail information of the ECO (e.g. adds,

deletes, etc.) from the ECO database. If the ECO is deleted PRIOR to being

processed, the ECO will NOT be visible in history and the Rev and ECO

numbers will not take effect. If the ECO is deleted AFTER being processed,

54

Chapter 8 - Engineering Change Orders

the ECO will be visible in history and the ECO and Rev numbers will still be in

use in the Bill of Material and Production Entry until a new ECO for the item

is created.

NOTE:Once an ECO is marked Approved For Production in the ECO

Approval window, the system will not allow the ECO to be deleted

until this checkbox is cleared.

ECO Maint.

This button allows access to the ECO Maintenance screen for further setup of

the ECO. For more information, see the section on ECO Maintenance.

Select

Opens the ECO Select window where details of the change order may be set.

For example, it is possible to set item to be added, changed or deleted.

However, other information, such as Hardware Dispositions and Component

Work Center information must be entered in the ECO Maintenance window.

For more information, see the section on ECO Select.

Print Icon

When clicked, the Print icon

opens the ECO Reports window, where

various reports pertaining to Engineering Change Orders may be printed. For

more information, see the section on ECO Reports.

Fields

ECO Number

The ECO Number is the record number assigned by the system to the changes

being made. Multiple changes may be made to an item on a single ECO. For

example, a component item may be added to a Parent assembly while, on the

same ECO record, an existing item of that Parent assembly may be deleted.

The ECO Number will increment automatically, but may be manually

overridden.

Priority

This is an information only field which is used to indicate the significance of

the change order. This information appears on the ECO Data Report and the

Engineering Change Order report.

New priorities may be added through two methods:

1. By entering them here in the Priority field. The system will then open a

dialog box asking if you want to add the new priority. If the answer is Yes,

the new Priority is saved to the database. If you choose Lookup, the ECO

Priority Lookup window is opened so that you may choose an existing

Priority.

2. By clicking on the blue Priority prompt. This opens the Priority Setup

window, which looks exactly like the ECO Priority Lookup window,

except that new records can be added or deleted in the List window. To

55

Chapter 8 - Engineering Change Orders

Delete, highlight the priority to delete, choose Edit from the menu bar at

the top of the screen, and choose Delete Row.

Description

The Description is used to enter a description of this ECO. During the initial

creation of an ECO, the text entered here will also populate the ECO

Comment area below. If there isn’t enough room here, this field should be

used to enter a summary which can then be expanded in the ECO Comment

area below.

Processed

This field displays the date on which the ECO was processed by the system. A

date of 0/0/0000 indicates that the ECO record has not yet been processed.

Parent/Cpnt

The Parent/Cpnt field contains the item for which the changes are to be made.

This item will then be associated with the ECO and Rev numbers on the Bill of

Materials and any subsequent work orders. For more information, see the

section on Where And When the New ECO and REV Numbers Will Appear.

This item may be a Finished Good, Sub-Assembly or Component item. The

type of item entered will determine the default display information in the ECO

Select window. For more information, see the section on ECO Select.

The Lookup icon, which is only available prior to saving the ECO, opens the

Items window when clicked. This may be used to select any item from

inventory as the object of the change order.

There are several different types of changes that may be made, depending on

the type of item entered here:

If the item is a Component or Sub-Assembly item that exists on a Bill of

Materials, the item may be changed, deleted or replaced on

z

If the component will have a change made to it on all BOMs where it

exists.

z

If the component will be deleted on multiple BOMs or everywhere it exists.

z

If the component will be replaced on multiple BOMs or everywhere it

exists.

At Parent / Cpnt enter a new item that does not exist as a component /

subassembly on BOMs

z

If the component will be added to multiple BOMs.

At Parent / Cpnt enter a subassembly parent item or end item/finished good

parent

z

56

If the parent will have several changes made to its BOM. For example, one

component is replaced by an updated new component, and the scrap %

must change on a second component due to the replacing item.

Chapter 8 - Engineering Change Orders

M button

The M button, when clicked, opens the BOM Maintenance window for the

item in the Parent/Cpnt field, if that item is either a Finished Good or SubAssembly. If the item is a Component, a dialog box will appear stating that the

item selected is not a Finished Good or Sub-Assembly.

C button

The C button opens the Component Inquiry window which may be used to

display the various Bills of Material in which an item resides.

Replace With

The Replace With field is used to enter an item to use as a replacement for the

item in the Parent/Cpnt field. This field should only be used when the item in

the Parent/Cpnt field is either a Component or Sub-Assembly item that

already exists on a BOM, since these are the only types of items that can be

replaced on Bills of Material.

The Lookup icon next to the Replace With field is used to select an item from

inventory to use as the Replace With item. This button is only available prior

to saving the ECO.

Rev Number

When the Parent/Cpnt item is selected, the next Rev Number in sequence

FOR THAT ITEM will be automatically entered, if the past Revision number

can be incremented. If this is the first Revision for an item, the default from

ECO Setup will be used. It is not necessary to use the Revision that the system

comes up with. It can be cleared and entered at Approval time or different one

may be entered. A check will be made to determine that the Rev is unique for

the item and that it is in sequence if the option Disable Revision Sequence