Collaborative Cost Reduction and Component

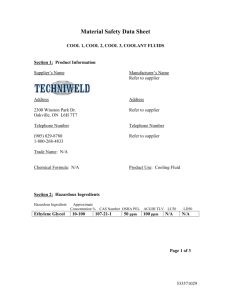

advertisement