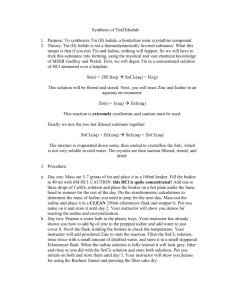

ICHEMM Final Synthesis Report

advertisement