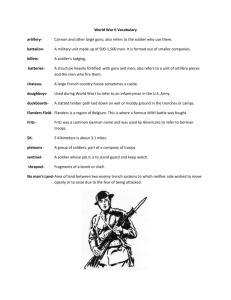

Soldier's Manual and Trainer's Guide

advertisement