Managerial Accounting

Managerial Accounting

201 1

First semester

Takayuki Asada

1

Chapter 2 Job-Order Costing for Manufacturing and Service

Companies

After reading this chapter, you will be able to:

1)Distinguishi between manufacturing and non-manufacturing costs and between product and period costs.

2)Discuss the three inventory accounts of a manufacturing firm.

3)Describe the flow of product costs in a manufacturing firm’s accounts.

4)Discuss the types of product costing systems.

5)Explain the relation between the cost of jobs and the work in process inventory,finished goods inventory,and cost of goods sold accounts.

6)Describe how directs material,direct labor,and manufacturing overhead are assigned to jobs

2

7)Explain the role of a predetermmined overhead rate in applying overhead to jobs.

8)Explain why the difference between actual overhead and overhead allocated to jobs using a predetermined rate is closed to Cost of hoods sold or is apportioned among Work in

Process inventory,Finishied Goods Inventory,and Cost of Goods

Sold.

9)Explain how service companies can use job-order costing to calculate the cost of services provided to customers.

10)Discuss modern manufacturing practices and how they affect product costing.

3

1 Introduction

We discuss the topic of cost management systems.

Historically, there are two types of costing systems,job order costing and process costing .

Since the mid-1980,however,companises have been adoptting activitybased costing for product and customer costing.

Short-case:He(Bob William) is now the new owner of Eastlake Motorboat company,a small(and,heretofore barely profitable)manufacturer of custombuilt wooden motorboats patterned after the classic lake cruisers built in the

1930s through the 1950s.During his first week on the job he had a lunch meeting with his accountant,Nancy Young, and expressed his interest in two key drivers of company success-cost estimation and pricing.

4

2. Cost Classifications for Manufacturing

Firms

1)Manufacturing Costs;Direct and Indirect Cost Categories.

Direct cost is a cost of a resource or activity that is acquired for or used by a single cost object ,while an indirect cost is the cost of a resource that was acquired to be used by more than one cost object.

A job order costing system estimates the costs of manufacturing products for many different jobs required for specific customer orders.

Process costing system is applicable when all units produced during a specified time frame are treated as a one type of output.

5

1)Merchandizing and manufacturing firms are compared in the chart 2-1.

6

2)manufactuirng costs manufacturing costs ( also known as product cost) are all the costs associated with the production of goods. The include three cost categories:direct material,direct labor,and manufacturing overhead.

manufactuirng overhead is the cost of all manufacturing activities other than direct material and direct labor.

3)Non-manufactuirng costs

Nonmanufacturing costs(also known as period costs):Selling costs,General and administrative

Costs

7

4).Product and Period Costs

Product costs are those costs assigned to goods produced

Period costs are identified with accounting periods rather than with good produced

8

3. Product cost information in financial reporting and decision making

Manufacturing companies need product cost information in order to prepare financial statements in accordance with GAAP(generally accepted accounting principles).

GAAP requires that inventory on the balance sheet and cost of good sold on the income statement be presented using full costing informations.

9

4. Balance Sheet Presentation of Product Costs

Product costs are treated as an asset until the finished goods are sold.

Product costs appear on the balance sheet in threee asset accounts related to inventory:

Raw materials, Work in Process, and finished goods.

1)Raw materials:

2) Work in Process inventory

3)Finished goods inventory

EastLake Motorboat company

Balance sheet as of December 31,2006

Assets Liabilities and stockholders’ Equity

Cash 20,000 Account payable 10,000

Account receivable 40,000 Notes payable 60,000

Inventory Longterm debt 100,000

Raw materials 50,000

Work in Process100,000

Fnished goods 60,000 210,000

Equipment(net) 400,000 Total liabilities and

Total asstets 670,000 stockholders’ equity 670,000

10

5. Flow of product costs in Accounts

11

6. Income Statement presentation of product costs

When finished goods are sold,the cost of the inventory sold is considered an expense and must be removed from finished goods inventory and charged to cost of goods sold.

This provides a matching of revenues (sales dollars) with the cost of producing the revenue.

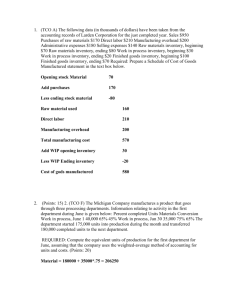

Cost of goods manufactured=(Beginning balance in work in process) + (Current manufacruing costs) - (Ending balance in work in process)

Cost of good sold=(Beginning balance in finished goods) +

(cost of goods manufactured) – (ending balance finished goods)

12

Illustration 2-6 presents a schedule of costs of goods manufactured and a simplified income statement showing cost of ggds for Easklake

Motorboat Copany

13

7.Types o Costing Sytems

Companies use product costing systems(an integrated set of documents

,ledgers,accounts,and accounting procedures) to measure and record the cost of manufactured products. There are two major product cositnf systems;Job-order costing systems and process costing systems.

14

8. Over view of job costs and financial statement accounts

15

9.Job-order Costing Systems

Job-order costing operations begin when a company decides to produce a specific product for stock (that is ,with no specific buyer in mind for the item) or in response to an order for a custom product.

If the company decides to accept the order,a job cost sheet is prepared. A job cost sheet is a form,typically computer generated,used to accumulate the cost of producing the item or items ordered.

1)Direct material cost

2)Direct labor cost

3)Manufactured overhead: Recall that manufacturing overhead costs are not directly traced to goods produced. For that reason,an indirect method of assigning overhead costs to jobs is needed.

16

10.Eastlake Revisited:Using job cost information

Recall from the chapter opening vignette that Bob williams,the new owner of Eastlake Motorboat ,is concerned that his company is underestimating costs and setting prices too low for its custom boats. Using information from job-cost sheets

,his accoutant,Nancy Young,prepared an analysis of estimated and actual cost for four recent jobs.

Using this information ,Bob can see that his hunch is right. Actual cost are higher than estimated.

However,in addition to considering production cost, managers need to consider what customers are willing to pay when setting prices.

17

.

Summary

1)Distinguish between manufacturing and non-manufacturing costs and between product and period costs.

2)Discuss the three inventory accounts of a manufacturing firm.

3)Describe the flow of product costs in a manufacturing firm’s accounts.

4)Discuss the types of product costing systems.

5)Explain the relation between the cost of jobs and the work in process inventory,finished goods inventory,and cost of goods sold accounts.

6)Describe how direct material ,direct labor,and manufacturing overhead are assigned to jobs.

7) Explain the role of a predetermined overhead rate in applying overhead to jobs.

8) Explain why the difference between actual overhead and overhead allocated to jobs using a predetermined rate is closed to cost of goods sold or is apportioned among Work in Process Inventory,Fisnied goods inventory,and cost of goods Sold.

18