6.0 Fires and Explosions Chemicals present a very substantial

advertisement

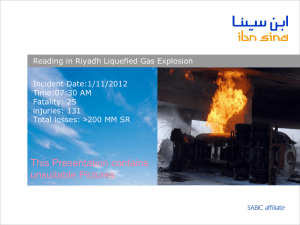

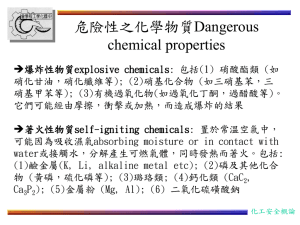

6.0 Fires and Explosions Chemicals present a very substantial hazard due to their potential to generate fires and explosions. The combustion of one gallon of toluene can destroy an ordinary chemistry laboratory in minutes; persons present may be killed. The potential consequences of fires and explosions in pilot plants and process plant environments are even greater. The three most common chemical plant accidents are fires, explosions and toxic releases, in that order. Organic solvents are the most common source of fires and explosions in the chemical industry. Yearly losses due to fires and explosions are substantial. Property losses for explosions in the United States are estimated at over 200million. Additional losses due to business interruptions are estimated to exceed 250million annually. To prevent accidents due to fires and explosions, engineers must be familiar with: • the fire and explosion properties of materials, • the nature of the fire and explosion process, and • procedures to reduce fire and explosion hazards. 6-1 THE FIRE TRIANGLE The essential elements for combustion are fuel, oxidizer, and an ignition source. These elements are illustrated by the fire triangle shown in Figure 6-1. Fire, or burning, is the rapid, exothermic oxidation of an ignited fuel. The fuel can be in solid, liquid or vapor form, but vapor and liquid fuels are generally easier to ignite. The combustion always occurs in the vapor phase; liquids are volatized and solids are decomposed into vapor prior to combustion. When fuel, oxidizer, and an ignition source are present at the necessary levels, burning will occur. The fire triangle tells us a fire will not occur if (1) fuel is not present or is not present in sufficient quantities, (2) an oxidizer is not present or is not present in sufficient quantities, and (3) the ignition source is not energetic enough to initiate the fire. Two common examples of the three components of the fire triangle are wood, air, and a match; or gasoline, air, and a spark. However, other, less obvious combinations of chemicals can lead to fires and explosions. Various fuels, oxidizers and ignition sources common in the chemical industry are: FUELS Liquids Solids Gases Gasoline, acetone, ether, pentane. Plastics, wood dust, fibers, metal particles. Acetylene, propane, carbon monoxide, hydrogen. OXIDIZERS Gases Liquids Solids Oxygen, fluorine, chlorine. Hydrogen peroxide, nitric acid, perchloric acid. Metal peroxides, ammonium nitrate. IGNITION SOURCES Sparks, flames, static electricity, heat 6-2 DISTINCTION BETWEEN FIRES AND EXPLOSIONS The major distinction between fires and explosions is the rate of energy release. Fires release energy slowly, while explosions release energy very rapidly, typically on the order of microseconds. Fires can also result from explosions and explosions can result from fires. 6-3 DISTINCTION BETWEEN FIRES AND EXPLOSIONS Some common definitions related to fires and explosions are given. Combustion or Fire: Combustion or fire is a chemical reaction in which a substance combines with an oxidant and releases energy. Part of the energy released is used to sustain the reaction. Autoignition temperature (AfT): A fixed temperature above which a flammable mixture is capable of extracting enough energy from the environment to self-ignite. Flash Point (FP): The flash point of a liquid is the lowest temperature at which it gives off enough vapor to form an ignitable mixture with air. At the flash point, the vapor will burn, but only briefly; inadequate vapor is produced to maintain combustion. The flash point generally increases with increasing pressure. There are several different experimental methods used to determine flash points. Each method produces a somewhat different value. The two most commonly used methods are open cup and closed cup, depending on the physical configuration of the experimental equipment. The open cup flash point is a few degrees higher then the closed cup. Flammability Limits (LFL and UFL): Vapor-air mixtures will only ignite and burn over a well-specified range of compositions. The mixture will not burn when the composition is lower than the lower flammable limit (LFL); the mixture is too lean rich; that is, when it is above the upper flammable limit (UFL). A mixture is flammable only when the composition is between the LFL and the UFL. Commonly used units are volume percent fuel (percent of fuel plus air). Lower explosive limit (LEL) and upper explosive limit (UEL) are used interchangeably with LFL and UFL. Explosion: An explosion is a rapid expansion of gases resulting in a rapidly moving pressure or shock wave. The expansion can be mechanical (via the sudden rupture of a pressurized vessel) or it can be the result of a rapid chemical reaction. Explosion damage is caused by the pressure or shock wave. Deflagration: An explosion with a resulting shock wave moving at a speed less then' the speed of sound in the unreacted medium. Detonation: An explosion with a resulting shock wave moving at a speed greater than the speed of sound in the unreacted medium. Confined explosion: An explosion occurring within a vessel or a building. These are most common and usually result in injury to the building inhabitants and extensive damage. Unconfined explosion: Unconfined explosions occur in the open. This type of explosion is usually the result of a flammable gas spill. The gas is dispersed and mixed with air until it comes in contact with an ignition source. Boiling liquid expanding vapor explosion (BLEVE): A BLEVE occurs if a vessel ruptures which contains a liquid at a temperature above its atmospheric-pressure boiling point. This type of explosion occurs when an external fire heats the contents of a tank of volatile material. As the tank contents heat, the vapor pressure of the liquid within the tank increases and the tank's structural integrity is reduced due to the heating. If the tank ruptures the hot liquid volatilizes explosively. Dust explosion: This explosion results from the rapid combustion of fine solid particles. Many solid materials (including common metals such as iron and aluminum) become very flammable when reduced to a fine powder. 6-4 FLAMMABILITY CHARACTERISTICS OF LIQUIDS AND VAPORS Flammability characteristics of some important organic chemicals (liquids and gases) are shown in Table 6.1. Liquids The flash point (FP) is one of the major physical properties used to determine the fire and explosion hazards of liquids. Flash points for pure components are easily determined experimentally. Table 6-1 lists flash points for a number of substances. Flash points can be estimated for multicomponent mixtures if only one component is flammable and if the flash point of the flammable is known. In this case the flash point temperature is estimated by determining the temperature at which the vapor pressure of the flammable in the mixture is equal to the pure component vapor pressure at its flash point. Experimentally determined flash points are recommended for multicomponent mixtures with more than one flammable component. Example 6-1 Methanol has a flash point of 11℃ and its vapor pressure at this temperature is 53 mm Hg. What is the flash point of a solution containing 75% methanol and 25% water by weight? Solution The mole fractions of each component are needed to apply Raoult's Law. Assuming a basis of 100 pounds of solution Raoult's law is used to compute the vapor pressure (psat) of pure methanol, based on the partial pressure required to flash. p = xpsat psat= p / x = 53/0.63 = 84.1 mm Hg Using a graph of the vapor pressure versus temperature, shown on Figure 6-2, the flash point of the solution is 17°C Vapors Flammable limits for vapors are determined experimentally. Vapor-air mixtures of known concentration are added to a closed vessel and then ignited. The maximum explosion pressure is measured. This test is repeated with different concentrations to establish the range of flammability for the specific gas. Figure 6-3 shows the results of one such experimental run; this particular substance has an LFL of 2.2 per cent and a UFL of 7.8 per cent. Vapor Mixtures Frequently LFLs and UFLs for mixtures are needed. These mixture limits are computed using the Le Chatelier equation' Where LFL; is the lower flammable limit for component i in volume % of component i in fuel and air, yi is the mole fraction of component i on a combustible basis, and n is the number of combustible species. Similarly, Where UFL; is the upper flammable limit for component i in volume % of component i in fuel and air. The Le Chatelier's equation is an empirically derived equation which is not universally applicable. The limitations are covered in the literature. Example 6-2 What is the LFL and UFL of a gas mixture composed of 0.8% hexane, 2.0% methane, and 0.5% ethylene by volume? Solution The mole fractions on a fuel only basis are calculated below. The LFL and UFL data are obtained from Table 6-1. Equation 6-1 is used to determine the LFL of the mixture. Equation 6-2 is used to determine the UFL of the mixtures, Since the above mixture contains 3.3% total combustibles, it is flammable. 6-5 MINIMUM OXYGEN CONCENTRATION (MOC) AND INERTING The LFL is based on fuel in air. However, oxygen is the key ingredient and there is a minimum oxygen concentration required to propagate a flame. This is an especially useful result, because explosions and fires are preventable by reducing the oxygen concentration regardless of the concentration of the fuel. This concept is the basis for a common procedure called inerting Below the MOC, the reaction cannot generate enough energy to heat the entire mixture of gases (including the inerts) to the extent required for the self propagation of the flame. The MOC has units of per cent oxygen in air plus fuel. If experimental data are not available, the MOC is estimated using the stoichiometry of the combustion reaction and the LFL. This procedure works for many hydrocarbons. Example 6-3 Estimate the MOC for butane (C4HIO). Solution The stoichiometry for this reaction is C4H10 + 6.5O2 4CO2 + 5H2O The LFL for butane (from Table 6-1) is 1.6% by volume. From the stoichiometry, By substitution The combustion of butane is preventable by adding nitrogen, carbon dioxide or even water vapor until the oxygen concentration is below 10.4 %. The addition of water, however, is not recommended because any condition which condenses water would move the oxygen concentration back into the flammable region. 6-6 IGNITION ENERGY The minimum ignition energy (MIE) is the minimum energy input required to initiate combustion. All flammables (including dusts) have minimum ignition energies. The MIE depends on the specific chemical or mixture, the concentration, pressure, and temperature. A few MIEs are given in Table 6-2. Experimental data indicates that • The MIE decreases with an increase in pressure, • The MIE of dusts are, in general, at energy levels comparable to combustible gases, and • An increase in the nitrogen concentration increases the MIEs. Many hydrocarbons have MIEs of about 0.25 mJ. This is low when compared to sources of ignition. For example, a static discharge of 22 mJ is initiated by walking across a rug, and an ordinary spark plug has a discharge energy of 25 mJ. Electrostatic discharges, as a result of fluid flow, also have energy levels exceeding the MIEs of flammables and can provide an ignition source, contributing to plant explosions 6-7 AUTOOXIDATION Autooxidation is the process of slow oxidation with accompanying evolution of heat, sometimes leading to autoignition if the energy is not removed from the system. Liquids with relatively low volatility are particularly susceptible to this oroblem. Liquids with high volatility are less susceptible to autoignition because they self cool as a result of evaporation. Many fires are initiated as a result of autooxidation, referred to as spontaneous combustion. Some examples of autooxidation with a potential for spontaneous combustion include: • Oils on a rag in a warm storage area, • Insulation on a steam pipe saturated with certain polymers, and • Filter aid saturated with certain polymers. Cases have been recorded where ten year old filter aid residues were ignited when the land-filled material was bulldozed, allowing autooxidation and eventual autoignition. These examples illustrate why special precautions must be taken to prevent fires due to autooxidation and autoignition. 6-8 ADIABATIC COMPRESSION An additional means of ignition is adiabatic compression. For example, gasoline and air in an automobile cylinder will ignite if the vapors are compressed to an adiabatic temperature which exceeds the autoignition temperature. This is the cause of preignition knock in engines which are running too hot and too lean. It is also the reason why some over-heated engines continue to run after the ignition is turned off. Several large accidents were caused by flammable vapors being sucked into the intake of air compressors; subsequent compression resulted in autoignition. A compressor is particularly susceptible to autoignition if it has a fouled after-cooler. Safeguards must be included in the process design to prevent undesirable fires due to adiabatic compression. 6-9 IGNITION SOURCES As illustrated by the fire triangle, fires and explosions are preventable by eliminating ignition sources. Various ignition sources were tabulated for over 25,000 fires by the Factory Mutual Engineering Corporation and are summarized in Table 6-3. The sources of ignition are numerous; consequently it is impossible to identify and eliminate them all. The main reason for rendering a flammable liquid inert, for example, is to prevent a fire or explosion by ignition from an unidentified source. Although all sources of ignition are not likely to be identified, engineers must still continue to identify and eliminate them. Some very special situations might occur in a process facility where it is impossible to avoid flammable mixtures. In these cases a very thorough safety analysis is required to eliminate all possible ignition sources in each of the units where flammable gases are present. 6-10 SPRAYS AND MISTS Static electricity is generated when mists of sprays pass through orifices. A charge may accumulate and discharge in a spark. If flammable vapors are present, a fire or explosion will occur. Mists and sprays also affect flammability limits. For suspensions with drop diameters less than 0.01 mm, 'the lower flammability limit is virtually the same as the substance in vapor form. This is true even at low temperatures where the liquid is nonvolatile and no vapor is present. Mists of this type are formed by condensation. 6-11 EXPLOSIONS Explosion behavior depends on a large number of parameters. A summary of the more important parameters is shown in Table 6-4. Detonation and Deflagration Explosions are either detonations or deflagrations; the difference depends on the speed of the shock wave emanating from the explosion. Suppose a combustible mixture is placed within a long pipe. A small spark, flame, or other ignition source initiates the reaction at one end of the pipe. After ignition, a flame or reaction front moves down the pipe. In front of the flame front is a pressure or shock wave. If the pressure wave moves faster than the speed of sound in the unreacted medium the explosion is a detonation; if it moves at a speed less than the speed of sound it is a deflagration. Confined Explosions A confined explosion occurs in a confined space, such as, a' vessel or a building. The two most common confined explosion scenarios involve explosive vapors and explosive dusts. Empirical studies have shown that the nature of the explosion is a function of several experimentally determined characterisitics. These characteristics are dependent on the explosive material used and include flammability or explosive limits, the rate of pressure rise after the flammable mixture is ignited, and the maximum pressure after ignition. Explosion characteristics. The explosion characteristics determined using the vapor and dust explosion apparatus are used in the following way. 1. The limits of flammability or explosivity are used to determine the safe concentrations for operation or the quantity of inert required to control the concentration within safe' regions. 2. The maximum rate of pressure rise is indicative of the robustness of an explosion. Thus, the explosive behavior of different materials can be compared on a relative basis. It is also used to design a vent for relieving a vessel during an explosion before the pressure ruptures the vessel, or to establish the time interval for adding an explosion suppressant (water, carbon dioxide, or Halon) to stop the combustion process. A plot of the log of the maximum pressure slope versus the log of the vessel volume frequently produces a straight line of slope -1/3 This relationship is called the "Cubic Law." (dp / dt )max V 1/ 3 constant K g (dp / dt )max V 1/ 3 K St (6-3) (6-4) where Kg and Kst are called the deflagration indices for gas and dust respectively. As the robustness of an explosion increases, the deflagration indices Kg and Kst increase. The cubic law states that the pressure front takes longer to propagate through a larger vessel. A few values for Kg and Kst are given in Tables 6-5 and 6-6. Dusts are further classified into four classes, depending on the value of the deflagration index. These St classes are shown in Table 6-6. Dust explosions demonstrate --unique behavior. These explosions occur if finely divided particles of solid material are dispersed in air and ignited. The dust particles can be either an unwanted by-product or the product itself. Explosions involving dusts are most common in the flour milling, grain storage, and coal mining industries. Accidents involving dust explosions can be quite substantial; a series of grain silo explosions in Westwego near New Orleans in 1977 killed thirty-five people. An initial dust explosion can cause secondary explosions. The primary explosion sends a shock wave through the plant, stirring up additional dust which may result in a secondary explosion. In this fashion the explosion "leapfrogs" its way through a plant. Many times the secondary explosions are more damaging than the primary. To be explosive, a dust mixture must have the following characteristics. • The particles must be below a certain minimum size: • The particle loading must be between certain limits. • The dust loading must be reasonably uniform. For most dusts, the lower explosion limit is between 20 and 60 gm/m3 and the upper explosion limit between 2 and 6 kg/m3. Vapor Cloud Explosions (VCE) The most dangerous and destructive explosions in the chemical process industries are vapor cloud explosions (VCE). These explosions occur by a sequence of steps: 1. Sudden release of a large quantity of flammable vapor. Typically this occurs when a vessel, containing a superheated and pressurized liquid, ruptures. 2. Dispersion of the vapor throughout the plant site while mixing with air. 3. Ignition of the resulting vapor cloud. The accident at Flixborough, England is a classic example of a vapor cloud explosion. A sudden failure of a 20-inch cyclohexane line between reactors led to vaporization of an estimated 30-tons of cyclohexane. The vapor cloud dispersed throughout the plant site and was ignited by an unknown source 45-seconds after the release. The entire plant site was leveled and 28 people were killed. A summary of twenty-nine vapor cloud explosions over the period 1974 through 1986 shows property losses for each event of between $5,000,000 to $100,000,000 and 140 fatalities (an average of almost 13 per year). Some of the parameters that affect VCE behavior· are Quantity of material released, Fraction of material vaporized, Probability of ignition of the cloud, Distance travelled by the cloud prior to ignition, Time delay before ignition of cloud, Probability of explosion rather than fire, Existence of a threshold quantity of material, Efficiency of explosion, and Location of ignition source with respect to release. Methods which are used for preventing VCEs include keeping low inventories of volatile, flammable materials; using process conditions which minimize flashing if a vessel or pipeline is ruptured; using analyzers to detect leaks at very low concentrations; and installing automated block valves to shut systems down while the spill is in the incipient stage of development. Boiling Liquid Expanding Vapor Explosions (BLEVE)· A boiling liquid expanding vapor explosion (BLEVE, pronounced ble'.-vee) is a special type of accident that can release large quantities of materials. If the materials are flammable, a VCE might result; if toxic, a large area might be subjected to toxic materials. For either situation, the energy released by the BLEVE process itself can result in considerable damage. A BLEVE occurs when a tank containing a liquid held above its atmospheric pressure boiling point ruptures; resulting in the explosive vaporization of a large fraction of the tank contents. BLEVEs are caused by the sudden failure of the container due to any cause. The most common type of BLEVE is caused by fire. The steps are as follows. 1. A fire develops adjacent to a tank containing a liquid. 2. The fire heats the walls of the tank. 3. 4. 5. The tank walls below liquid level are cooled by the liquid, increasing the liquid temperature and the pressure in the tank. If the flames reach the tank walls or roof where there is only vapor and no liquid to remove the heat, the tank metal temperature rises until it loses it structural strength. The tank ruptures, explosively vaporizing its contents. If the liquid is flammable and a fire is the cause of the BLEVE, it may ignite as the tank ruptures. Often, the boiling and burning liquid behaves as a rocket fuel, propelling vessel parts for great distances. If the BLEVE is not caused by a fire, a vapor cloud might form, resulting in a VCE. The vapors might also be hazardous to personnel via skin burns or toxic effects. When a BLEVE occurs in a vessel, only a fraction of the liquid vaporizes; the amount depends on the physical and thermodynamic conditions of the vessel contents. The fraction vaporized is estimated using Raoult’s Equation and the Antoine Equation.