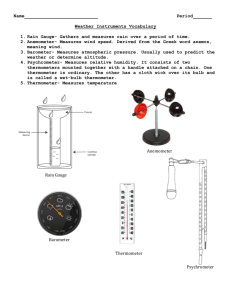

Measurement of temperature

advertisement