A Mathematical Programming Approach to Analyze the ABC Product

advertisement

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

A MATHEMATICAL PROGRAMMING

APPROACH TO ANALYZE THE

ACTIVITY-BASED COSTING

PRODUCT-MIX DECISION WITH

CAPACITY EXPANSIONS

Wen-Hsien Tsai and Thomas W. Lin

ABSTRACT

In recent years, Activity-Based Costing (ABC) has become a popular cost

management technique in both accounting academics and business practice.

It uses a two-stage procedure to assign resource costs to products: first from

resources to activities, then from activities to products. It improves the accuracy of product cost data derived from traditional direct labor-based costing

systems. Product-mix decision analysis is an important part of ABC information. The purpose of this paper is to incorporate the capacity expansion

features into an ABC product-mix decision model by using a mathematical

programming approach. The current traditional ABC product-mix decision

models do not explicitly consider capacity expansions. We developed a new

mixed integer programming product-mix model that maximizes a firm’s

profit with five major types of ABC constraints: (1) unit-level direct material

constraints; (2) unit-level piecewise direct labor constraints; (3) batch-level

activity constraints (e.g. scheduling and setup activities); (4) product-level

Mathematical Programming

Applications of Management Science, Volume 11, 163–178

Copyright © 2004 by Elsevier Ltd.

All rights of reproduction in any form reserved

ISSN: 0276-8976/doi:10.1016/S0276-8976(04)11012-2

163

164

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

activity constraints (e.g. product design); and (5) stepwise facility-level

activity cost with machine hour constraints (e.g. plant guard and management). With the model presented in this paper, we can evaluate the benefits

of simultaneously expanding the various kinds of capacity.

1. INTRODUCTION

In recent years, Activity-Based Costing (ABC) has become a popular cost

management technique in both accounting academics and business practice. ABC

has been gradually adopted to overcome the shortcomings of traditional cost

systems. Through the interactive developments between practical and academic

circles, ABC has been applied to various business functions and different

industries. The latest ABC model is composed of both the cost assignment view

and the process view with activities as the intersection of these two views (Turney,

1992a, pp. 80–89, 1992b). The cost assignment view provides information about

resources, activities, and cost objects. This information can be used to analyze

critical decisions such as pricing, product mix, sourcing, and product design. The

process view provides financial and non-financial information about cost drivers

and performance measures for each activity or process. This information can

be used for activity/process improvements to reduce costs and/or enhance value

to customers.

Thus, product-mix design analysis is an important part of the cost assignment

view of ABC. In the early ABC literature, authors often used realistic numerical

examples to show that the products’ ABC costs will be significantly different from

the ones derived from traditional direct labor-based costing systems. However,

they seldom demonstrated how to select the optimal product-mix. ABC had also

been criticized for its failure to incorporate constraints into production-related

decisions (Kee & Schmidt, 2000; Spoede et al., 1994). In light of this, some

authors (Kee, 1995; Kee & Schmidt, 2000; Malik & Sullivan, 1995; Tsai, 1994;

Yahya-Zadel, 1998) proposed various mathematical programming models to

conduct the product-mix decision analysis under ABC. All of these product-mix

models can be used to select the optimal product-mix that maximizes a firm’s

profit with various constraints.

Kee (1995) integrated ABC with the Theory of Constraints (TOC) in the

product-mix decision analysis. As quoted by Kee and Schmidt (2000) from

Goldratt (1990): “The TOC consists of a set of focusing procedures for identifying

a bottleneck managing the production system with respect to this constraint,

while resources are expended to relieve this limitation on the system. When a

bottleneck is relieved, the firm moves to a higher level of goal attainment and

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

165

one or more new bottlenecks will be encountered. The cycle of managing the

firm with respect to the new bottleneck(s) is repeated, leading to successive

improvements in the firm’s operations and performance.” This means that TOC

successively relieves the bottlenecks and the associated constraints by expanding

the obtainable resources (capacities) or by improving the firm’s operations. The

current traditional ABC product-mix decision models do not explicitly consider

capacity expansions. The feasibility or benefits of capacity expansions has usually

been evaluated by using post-optimal (sensitivity) analysis. It is a tedious job to

successively expand various resources. Sometimes, a manager may end up with a

sub-optimal solution because he/she determines the combination of the expanded

levels of various resources by a trial-and-error method, instead of a systematic

method. Furthermore, it is difficult to simultaneously consider two or more kinds

of capacity expansions by using the current ABC product-mix decision models.

In light of this, the purpose of this paper is to incorporate the capacity expansion

features into an ABC product-mix decision model by using a mathematical programming approach. The detailed cost assignment view of ABC is described in

Section 2. Section 3 presents an ABC product-mix decision model with capacity

expansion features. In Section 4, a numerical example is used to demonstrate

how to apply the model. Finally, the discussion and conclusions are presented in

Sections 5 and 6, respectively.

2. COST ASSIGNMENT VIEW OF ABC

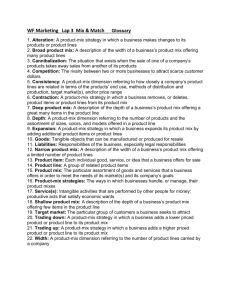

The detailed cost assignment view of ABC is shown in Fig. 1 (Tsai, 1996a; Turney,

1992a, b). ABC assumes that cost objects (e.g. products, product lines, processes,

Fig. 1. The Detailed Cost Assignment View of ABC.

166

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

customers, channels, markets, etc.) create the need for activities, and activities

create the need for resources. Accordingly, ABC uses a two-stage procedure to

assign resource costs to cost objects. In the first stage, resource costs are assigned

to various activities by resource drivers. Resource drivers are the factors chosen to

approximate the consumption of resources by the activities. Each type of resource

traced to an activity becomes a cost element of an activity cost pool. Thus, an

activity cost pool is the total costs associated with an activity. An activity center

is composed of related activities, usually clustered by function or process. In the

second stage, costs in each activity cost pool are distributed to cost objects by an

adequate activity driver which is used to measure the consumption of activities

by the cost objects. In this paper, we regard products as the cost objects. The

total costs of a specific product can be calculated by adding the costs of various

activities assigned to that product. The unit cost of the product is achieved by

dividing the total costs by the quantity of the product.

The resources used in manufacturing companies may include “people,”

“machines,” “facilities,” and “utilities,” while the corresponding resource costs

could be assigned to activities in the first stage of cost assignment view by using

the resource drivers: “time,” “machine hours,” “square footage,” and “kilowatt

hours,” respectively (Brimson, 1991, p. 135). The following are the categories for

manufacturing activities: (1) unit-level activities (performed one time for one unit

of product, e.g. machining, finishing); (2) batch-level activities (performed one

time for a batch of products, e.g. setup, scheduling); (3) product-level activities

(performed to benefit all units of a particular product, e.g. product design); and

(4) facility-level activities (performed to sustain the manufacturing facility, e.g.

plant guard and management) (Cooper, 1990). The costs of different levels of

activities can be traced to products by using the different kinds of activity drivers

in the second stage of cost assignment view. For example, “number of machine

hours” is used for the activity “machining,” “setup hours” for “machine setup,”

and “number of drawings” for “product design.” Usually, the costs of facility-level

activities cannot be traced to products with definite causal relationships and

should be allocated to products with the appropriate allocation bases (Metzger,

1993; Tsai, 1996b). For the purpose of product-mix decisions, we regard the costs

of facility-level activities as the common fixed cost in this paper.

3. ABC PRODUCT-MIX DECISION MODEL

WITH CAPACITY EXPANSIONS

Jadicke (1961) applied a Linear Programming (LP) technique to a Cost-VolumeProfit (CVP) model, called “Product Mix” model in many management accounting

or LP texts, which could aid management in determining the optimal product mix,

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

167

maximizing total profit under some limits (constraints) to production or sales in

the case of multi-product companies. In recent years, some authors (Kee, 1995;

Kee & Schmidt, 2000; Malik & Sullivan, 1995; Tsai, 1994; Yahya-Zadel, 1998)

utilized various mathematical programming approaches to conduct the productmix decision analysis under ABC. In this paper, we will extend their research to

incorporating capacity expansion features into the product-mix decision model

under ABC.

3.1. Assumptions

The ABC product-mix decision model presented in this paper has several

assumptions. First, the activities in a multi-product company have been classified

as unit-level, batch-level, product-level, and facility-level activities, and the

related resource drivers and activity drivers have been chosen by the company’s

ABC team through an ABC study. Second, the data on actual running activity

cost per activity driver for each activity (Tyson et al., 1989) has been collected

and used in the model. Third, the unit selling prices and the unit direct material

costs are constant within the relevant range. Fourth, only the facility-level activity

cost is regarded as the common fixed cost, and its cost function is a stepwise

function that varies with machine hour. Fifth, renting additional machines can

expand machine hour resources. Sixth, using overtime work or additional night

shifts with higher wage rates can expand direct labor resources.

3.2. Capacity Expansion Features

3.2.1. Stepwise Facility-Level Activity Cost

Because the total cost of facility-level activities (e.g. plant guard and management)

cannot be traced to products with definite causal relationships, we regard it as the

common fixed cost and assume that its cost function is a stepwise function (as

shown in Fig. 2) which varies with machine hours, observed from a prior cost

behavior analysis. The total facility-level activity cost is F0 under the current

capacity H0 machine hours. If the capacity is successively expanded to H1 , H2 , . . .

Ht machine hours, the total facility-level activity cost increases to F1 , F2 , . . . Ft ,

respectively. Let Xi be the production quantity of product i and ih the requirement

of machine hours for one unit of product i. As a result, the total facility-level activity

cost and the associated machine hour constraints are (Tsai & Lin, 1990):

Total facility-level activity cost =

t

k=0

F k k

(1)

168

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

Fig. 2. Stepwise Facility-Level Activity Cost.

Constraints:

n

ih X i ≤

i=1

t

t

H k k

(2)

k=0

k = 1

(3)

k=0

where (0 , 1 , . . . t ) is an SOS1 set of 0–1 variables within which exactly one

variable must be non-zero (Beale & Tomlin, 1970; Williams, 1985). When q = 1

(q = 0), we know that the capacity needs to be expanded to the qth level, i.e. Hq

machine hours.

3.2.2. Piecewise Direct Labor Cost

In this paper, we assume that using overtime work or additional night shifts with

higher wage rates can expand direct labor resources. Thus, the total direct labor

cost function will be a piecewise linear function as shown in Fig. 3. The available

Fig. 3. Piecewise Direct Labor Cost.

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

169

normal direct labor hour is G1 and the direct labor hour can be expanded to G2 ;

the total direct labor cost is L1 and L2 at G1 and G2 , respectively. As a result, the

total direct labor cost and the associated constraints are (Tsai & Lin, 1990):

Total Direct Labor Cost = L 1 1 + L 2 2

(4)

Constraints:

TL = G 1 1 + G 2 2

(5)

0 − 1 ≤ 0

(6)

1 − 1 − 2 ≤ 0

(7)

2 − 2 ≤ 0

(8)

0 + 1 + 2 = 1

(9)

1 + 2 = 1

(10)

where (1 , 1 ) is an SOS1 set of 0–1 variables within which exactly one variable

must be non-zero; (0 , 1 , 2 ) is an SOS2 set of non-negative variables within

which at most two adjacent variables, in the order given to the set, can be non-zero

(Beale & Tomlin, 1970; Williams, 1985); TL is the total direct labor hour we need

and its function depends on the case under study.

If 1 = 1, then 2 = 0 [from Eq. (10)], 2 = 0 [from Eq. (8)], 0 , 1 ≤ 1

[from Eqs (6) and (7)], and 0 + 1 = 1 [from Eq. (9)]. Thus, from Eqs (4) and

(5) we know that total direct labor cost and total labor hour needed are L1 1 and

G1 1 , respectively; this means that we will not need the overtime work.

If 2 = 1, then 1 = 0 [from Eq. (10)], 0 = 0 [from Eq. (6)], 1 , 2 ≤ 1

[from Eqs (7) and (8)], and 1 + 2 = 1 [from Eq. (9)]. Thus, from Eqs (4)

and (5) we know that total direct labor cost and total labor hour needed are

L 1 1 + L 2 2 and G 1 1 + G 2 2 , respectively; this means that we will need the

overtime work.

3.3. Description of the Model

The ABC product-mix decision model with capacity expansions is as follows:

Maximize = Total Revenue − Total Direct Material Cost

− Total Direct Labor Cost − Total Unit-, Batch-, Product& Facility-Level Activity Costs

170

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

=

n

pi Xi −

i=1

−

s

n c m a im X i − (L 1 1 + L 2 2 ) −

d j ␦ij B ij −

i=1 j∈B

d j ij X i

i=1 j∈U

i=1 m=1

n n n d j ij R i −

i=1 j∈P

t

F k k

(11)

k=0

Subject to:

Unit-Level Direct Material Constraints:

n

a im X i ≤ Q m ,

m = 1, 2, . . . s

(12)

i=1

Piecewise Unit-Level Direct Labor Constraints:

TL = G 1 1 + G 2 2

(13)

0 − 1 ≤ 0

(14)

1 − 1 − 2 ≤ 0

(15)

2 − 2 ≤ 0

(16)

0 + 1 + 2 = 1

(17)

1 + 2 = 1

(18)

Stepwise Facility-Level Machine Hour Constraints:

n

ih X i −

i=1

t

t

H k k ≤ 0,

(19)

k=0

k = 1

(20)

k=0

Batch-Level Activity Constraints:

X i ≤ ij B ij ,

n

i = 1, 2, . . . n;

␦ij B ij ≤ T j ,

j∈B

j∈B

(21)

(22)

i=1

Product-Level Activity Constraints:

Xi ≤ Di Ri ,

i = 1, 2, . . . n

(23)

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

n

ij R i ≤ V j ,

j∈P

171

(24)

i=1

X i ≥ 0,

i = 1, 2, . . . n

(25)

(0 , 1 , 2 ) : An SOS2 set of non-negative variables.

(26)

(1 , 2 ) : An SOS1 set of 0–1 variables

(27)

(0 , 1 , . . . t ) : An SOS1 set of 0–1 variables

(28)

R i : 0–1 variables,

i = 1, 2, . . . n

B ij : Non-negative integer variables,

(29)

i = 1, 2, . . . n,

j∈B

(30)

where

Xi =

pi =

Cm =

aim =

Qm =

dj =

ij =

␦ij =

B ij =

ij =

Tj =

ij =

Ri =

Vj =

Di =

The production quantity of product i;

The unit selling price of product i;

The unit cost of the mth material;

The requirement of the mth material for one unit of product i;

The available quantity of the mth material;

The actual running activity cost per activity driver for activity j;

The requirement of the activity driver of unit-level activity j ( j ∈ U) for

one unit of product i;

The requirement of the activity driver of batch-level activity j ( j ∈ B) for

product i;

The number of batches of batch-level activity j ( j ∈ B) for product i;

The number of units per batch of batch-level activity j ( j ∈ B) for product

i;

The capacity limit of the activity driver of batch-level activity j ( j ∈ B);

The requirement of the activity driver of product-level activity j ( j ∈ P) for

product i;

The indicator for producing product i (Ri = 1) or not producing product i

(Ri = 0);

The capacity limit of the activity driver of product-level activity j ( j ∈ P);

The maximum demand of product i;

Other variables and parameters are as mentioned before.

Equation (11) represents the total profit function , and Eqs (12)–(24) are the

constraints associated with various resources and activities. Equation (12) is the

direct material constraint. Equations (13)–(18) are the direct labor constraints

described in Section 3.2.2. Equations (19) and (20) are the machine hour

constraints described in Section 3.2.1.

172

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

Equations (21) and (22) are the constraints associated with batch-level activities,

where Eq. (22) is the capacity constraint for batch-level activity j ( j ∈ B). For

example, we use “setup hours” as the activity driver of the batch-level activity

“setup” because each product needs different setup hours. In this case, Tj are the

available setup hours, ␦ij are the needed setup hours for product i, B ij is the number

of setup needed for product i, and ij is the average number of units in each setup

batch. In fact, there may be different number of units in each setup batch for a

specific product. However, we can use the average number of units for the purpose

of planning. On the other hand, we may use “number of batches” as the activity

driver of the batch-level activity “setup” because the setup hours needed is the

same for each product. In this situation, ␦ij can be set to 1 and Tj is the available

number of setup.

Equations (23) and (24) are the constraints associated with product-level

activities. Equation (23) is the market demand constraint and Eq. (24) is the

capacity constraint for product-level activity j ( j ∈ P). For example, we may

use “number of drawings” as the activity driver of the product-level activity

“product design.” In this case, Vj is the available number of drawings for the

firm’s capacity, and ij is the number of drawings needed for product i.

4. A NUMERICAL EXAMPLE

In this section, we present a numerical example. Assume that a manufacturing

company is considering producing product 1, product 2, and product 3 (i = 1, 2,

3) and that these products need two kinds of the same direct material (m = 1, 2).

We also assume that it needs five main activities in producing these three products:

two unit-level activities, Machining and Finishing (U = {1, 2}), two batch-level

activities, Scheduling and Setup (B = {3, 4}), and one product-level activity,

Product Design (P = {5}).

The related data for this example are shown in Table 1.

From Table 1, we know that the total facility-level activity cost is $40,000

under the current capacity H 0 = 3,000 machine hours and that the capacity can

be expanded to H 1 = 4,000 or H 2 = 5,000 machine hours by renting additional

machines with the total facility-level activity cost increasing to F 1 = $55,000

or F 2 = $70,000, respectively. Besides, the available normal direct labor hour is

G 1 = 7,000 hours with the normal wage rate of $1.2/hr and the direct labor hour

can be expanded to G 2 = 9,000 hours with the overtime wage rate of $1.8/hr.

Further, assume that two unit-level activities, Machining and Finishing, need direct

labor, and Machining activity needs 1/2 i1 labor hour for one unit of product i;

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Product (i)

Maximum demand

Selling price

Direct material

1

2

3

Di

pi

ai1

ai2

1,000

130

8

5

1,000

90

6

2

2,000

110

4

3

i1

i2

2

3

2

1

1

2

␦i3

i3

␦i4

i4

1

120

2

10

1

120

2

10

1

60

4

30

T3 = 60

20

10

30

V5 = 55

m=1

m=2

Activity driver

Machine hours

Labor hours

c1 = 3

c2 = 4

Cost/driver dj

$2

$1

Production

Orders

Setup

Hours

$100

Drawings

$400

i5

Facility-level cost

Cost

Machine hrs

F0 = $40,000

H0 = 3,000

F1 = $55,000

H1 = 4,000

F2 = $70,000

H2 = 5,000

Direct labor constraint

Cost

Labor hrs

Wage rate

L1 = $8,400

G1 = 7,000

r1 = $1.2/hr

L2 = $12,000

G2 = 9,000

r2 = $1.8/hr

Unit-level activity

Machining

Finishing

j

1

2

Batch-level activity

Scheduling

3

Setup

Product-level activity

Design

4

5

$150

Available Capacity

Q1 = 15,000

Q2 = 12,000

T4 = 50

A Mathematical Programming Approach to Analyze the Activity-Based Costing

Table 1. Example Data.

173

174

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

these two activities utilize the same group of multi-function workers. Thus, Eq. (13)

will be:

n 1

i 1 + i2 X i = G 1 1 + G 2 2

(31)

2

i=1

By using Eqs (11)–(31), the product-mix decision model for the example is

formulated as follows:

Maximize

= 79X 1 + 59X 2 + 82X 3 − 8,4001 − 12,0002 − 100B 13 − 100B 23

− 100B 33 − 300B 14 − 300B 24 − 600B 34 − 8,000R 1 − 4,000R 2

− 12,000R 3 − 40,0000 − 55,0001 − 70,0002

Subject to:

Unit-Level Direct Material Constraints:

8X 1 + 6X 2 + 4X 3 ≤ 15,000

5X 1 + 2X 2 + 3X 3 ≤ 12,000

Piecewise Unit-Level Direct Labor Constraints:

4X 1 + 2X 2 + 2.5X 3 − 7,0001 − 9,0002 = 0

0 − 1 ≤ 0

1 − 1 − 2 ≤ 0

2 − 2 ≤ 0

0 + 1 + 2 = 1

1 + 2 = 1

Stepwise Facility-Level Machine Hour Constraints:

2X 1 + 2X 2 + X 3 − 3,0000 − 4,0001 − 5,0002 ≤ 0

0 + 1 + 2 = 1

Batch-Level Activity Constraints:

Scheduling

X 1 − 120B 13 ≤ 0

X 2 − 120B 23 ≤ 0

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

175

X 3 − 60B 33 ≤ 0

B 13 + B 23 + B 33 ≤ 60

Setup

X 1 − 10B 14 ≤ 0

X 2 − 10B 24 ≤ 0

X 3 − 30B 34 ≤ 0

2B 14 + 2B 24 + 4B 34 ≤ 500

Product-Level Activity Constraints:

Design

X 1 − 1,000R 1 ≤ 0

X 2 − 1,000R 2 ≤ 0

X 3 − 2,000R 3 ≤ 0

20R 1 + 10R 2 + 30R 3 ≤ 55

where Xi , B ij ≥ 0, i = 1, 2, 3, j ∈ B; 0 , 1 , 2 ≥ 0; Ri , 1 , 2 , k = 0, 1, i = 1,

2, 3, k = 0, 1, 2. This is a Mixed-Integer Programming (MIP) model. We solve

this problem by utilizing the software, LINDO (Schrage, 1987), and obtain the

following optimal solution:

X1 = 875

0 = 0

1 = 0

B13 = 8

B14 = 88

R1 = 1

0 = 0

X2 = 0

1 = 0.25

2 = 1

B23 = 0

B24 = 0

R2 = 0

1 = 1

X3 = 2,000

2 = 0.75

B33

B34

R3

2

= 34

= 67

=1

=0

Accordingly, the optimal product-mix is (X1 , X2 , X3 ) = (875, 0, 2000), which

requires 15,000 units (=8 × 875 + 6 × 0 + 4 × 2,000) of the first kind of

material, 10,375 units (=5 × 875 + 2 × 0 + 3 × 2,000) of the second kind of

material, 3,750 (=2 × 875 + 2 × 0 + 1 × 2,000) machine hours, and 8,500

(=4 × 875 + 2 × 0 + 2.5 × 2,000) direct labor hours. The total profit is

$76,225. This means that the machine capacity is expanded to 4,000 hours (i.e.

there are 250 excess machine hours) by renting machines, and that the direct labor

capacity is expanded to 8,500 labor hours by adding 1,500 overtime hours.

176

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

5. DISCUSSION

In the model shown in this paper, we only considered the capacity expansions for

machine hours and direct labor hours. In future research, we also can consider

the capacity expansions for various levels of activities by using a similar process

of model formulation. In addition to capacity expansions, we can further improve

this product-mix model by relaxing the strong assumption: “the unit selling

prices and the unit direct material costs are constant within the relevant range.”

This may be achieved by using piecewise linear functions to approximate the

non-linear revenue or the non-linear direct material costs (Tsai & Lin, 1990).

The future research can also build a product-mix model to evaluate the impact

on profits or product mixes of decreasing unit activity costs through ABC activity

improvements.

6. CONCLUSIONS

In recent years, activity-based costing has become a popular cost management

technique in both accounting academics and business practice. ABC uses a

two-stage procedure to assign resource costs to products: first from resources

to activities, then from activities to cost objects (products). It improves the

accuracy of product cost data derived from the traditional volume or unit-based

(e.g. direct labor hours) costing systems. One of the special features of ABC

is that it uses both volume-based (i.e. unit-level) and non-volume-based (i.e.

batch-level, product-level, or facility-level) drivers to assign activity costs to

products according to the nature of activities. Product-mix decision analysis is an

important part of the ABC information. To extend the existing research literature,

this paper incorporates capacity expansion features into a ABC product-mix

decision model by using a mathematical programming approach.

The current traditional ABC product-mix decision models do not explicitly

consider capacity expansions. This paper contributes to the management sciences

and accounting literature by developing a new mixed integer programming

product-mix model that maximizes a firm’s profit with five major types of ABC

constraints: (1) unit-level direct material constraints; (2) unit-level piecewise

direct labor constraints; (3) batch-level activity constraints (e.g. scheduling and

setup activities); (4) product-level activity constraints (e.g. product design);

and (5) stepwise facility-level activity cost with machine hour constraints

(e.g. plant guard and management). With the model presented in this paper,

we could evaluate the benefit of simultaneously expanding the various kinds

of capacity.

A Mathematical Programming Approach to Analyze the Activity-Based Costing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

177

ACKNOWLEDGMENT

This research was supported by the National Science Council of the Republic of

China under grant NSC90–2416-H-008–001.

REFERENCES

Beale, E. M. L., & Tomlin, J. A. (1970). Special facilities in a general mathematical programming

system for nonconvex problems using ordered sets of variables. In: J. Lawrence (Ed.),

Proceedings of the 5th International Conference on Operational Research (pp. 447–454).

London: Tavistock.

Brimson, J. A. (1991). Activity accounting – An activity-based costing approach. New York, NY:

Wiley.

Cooper, R. (1990). Cost classification in unit-based and activity-based manufacturing cost systems.

Journal of Cost Management, 4(3), 4–14.

Goldratt, E. (1990). What is this thing called theory of constraints and how should it be implemented?

Croton-on-Hudson, NY: North River Press.

Jadicke, R. K. (1961). Improving breakeven analysis by linear programming techniques. NAA Bulletin,

5–12.

Kee, R. (1995, December). Integrating activity-based costing with the theory of constraints to enhance

production-related decision making. Accounting Horizons, 9(4), 48–61.

Kee, R., & Schmidt, C. (2000). A comparative analysis of utilizing activity-based costing and the

theory of constraints for making product-mix decisions. International Journal of Production

Economics, 63(1), 1–17.

Malik, S. A., & Sullivan, W. G. (1995). Impact of ABC information on product mix and costing

decisions. IEEE Transactions on Engineering Management, 42(2), 171–176.

Metzger, L. M. (1993). The power to compete: The new math of precision management. National

Public Accountant, 38(5), 14–16, 30–32.

Schrage, L. (1987). Linear, integer, and quadratic programming with LINDO-user’s manual (3rd ed.).

Redwood City, CA: Scientific Press.

Spoede, C., Henke, E., & Umble, M. (1994). Using activity analysis to locate profitability drivers:

ABC can support a theory of constraints management process. Management Accounting,

75(11), 43–48.

Tsai, W.-H. (1994). Product-mix decision model under activity-based costing. Proceedings of 1994

Japan – U.S.A. Symposium on Flexible Automation, Vol. I, Institute of Systems, Control and

Information Engineers, Kobe, Japan, July 11–18, pp. 87–90.

Tsai, W.-H. (1996a). A technical note on using work sampling to estimate the effort on activities under activity-based costing. International Journal of Production Economics, 43(1),

11–16.

Tsai, W.-H. (1996b). Activity-based costing model for joint products. Computers & Industrial

Engineering, 31(3/4), 725–729.

Tsai, W.-H., & Lin, T.-M. (1990, July). Nonlinear multiproduct CVP analysis with 0–1 mixed integer

programming. Engineering Costs and Production Economics, 20(1), 81–91.

Turney, P. B. B. (1992a). COMMON CENTS-The ABC performance breakthrough, how to succeed

with activity-based costing. Hillsboro, OR: Cost Technology.

178

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

WEN-HSIEN TSAI AND THOMAS W. LIN

Turney, P. B. B. (1992b). What an activity-based cost model looks like. Journal of Cost Management,

5(4), 54–60.

Tyson, T., Weisenfeld, L., & Stout, D. (1989). Running actual costs vs. standard costs. Management

Accounting, 71(2), 54, 56.

Williams, H. P. (1985). Model building in mathematical programming (2nd ed., pp. 173–177). New

York, NY: Wiley.

Yahya-Zadel, M. (1998). Product-mix decisions under activity-based costing with resource constraints

and non-proportional activity costs. Journal of Applied Business Research, 14(4), 39–45.