Design History File - Molecular Medicine Ireland

advertisement

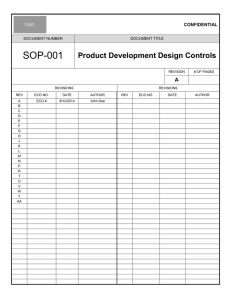

Design History File: Product Name: Company Name: Company Address: Version No: Date...................................... Revision History Version Number [Document Filename] Date COMPANY PROPRIETARY AND CONFIDENTIAL Page 1 of 5 Table of Contents 1.0 Purpose ......................................................................................................................................... 3 2.0 Scope ............................................................................................................................................ 3 3.0 DEFINITIONS ............................................................................................................................... 3 3.1 Design History File (DHF) ................................................................................................... 3 3.2 Design Input ........................................................................................................................ 3 3.3 Design Output ..................................................................................................................... 3 3.4 Design Validation ................................................................................................................ 3 3.5 Device Master Record (DMR) ............................................................................................. 3 3.6 Product ................................................................................................................................ 3 3.7 Product Development .......................................................................................................... 3 3.8 Quality System .................................................................................................................... 3 3.9 Validation............................................................................................................................. 4 3.10 Verification........................................................................................................................... 4 4.0 Responsibilities and Requirements ............................................................................................... 4 4.1 Product Manager ................................................................................................................. 4 4.2 Regulatory Affairs/Quality Systems Director ....................................................................... 4 5.0 References .................................................................................................................................... 4 6.0 Procedure ..................................................................................................................................... 4 6.1 Purpose of Design History File ............................................................................................ 4 6.2 Location of Design History File............................................................................................ 4 6.3 Contents of Design History File ........................................................................................... 5 6.3.1 Product Development Documents ......................................................................... 5 6.3.2 Technical Report Documents ................................................................................. 5 6.4 Maintenance of Design History File..................................................................................... 5 [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 2 of 5 1.0 Purpose This procedure defines the Design History File for containing or referencing the records necessary to demonstrate product development in accordance with the approved design plan and design input requirements. 2.0 Scope This procedure applies to all product development programs funded and managed by [Company Name]. 3.0 DEFINITIONS 3.1 Design History File (DHF) Provide a compilation of records, drawings and descriptions which describes the design history of the finished product. 3.2 Design Input Describe the physical and performance requirements of a product used as a basis for product design and development. 3.3 Design Output The results of a design effort at each design phase and at the end of the total design effort. The finished design output is the basis for the Device Master Record. The total finished design output consists of the product, its packaging and labelling, and the Device Master Record. 3.4 Design Validation This includes objective evidence that the product conforms with product specification to user’s needs and intended use(s). Details of ethnographics review to be included. 3.5 Device Master Record (DMR) A compilation of records containing: the procedures specifications, for a finished product. 3.6 Product Unless otherwise specified, the word "product" in this procedure is used in the more global sense to refer to components, materials, structures, machines, devices, systems, processes, software, or services. 3.7 Product Development The systematic product development process for optimizing time to market, cost, product performance, customer satisfaction, and risk management, by simultaneously integrating all product knowledge and expertise from concept, through manufacturing and customer satisfaction, to the end of the product's life. 3.8 Quality System Outline the organisational structure, responsibilities, procedures, processes, and resources for implementing the quality management system. ISO13485 [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 3 of 5 3.9 Validation Confirmation by examination and provision of objective evidence that the particular requirements for a specific intended use can be consistently fulfilled. And include predicate testing where applicable. 3.10 Verification Confirmation by examination and provision of objective evidence that specified requirements have been fulfilled. 4.0 Responsibilities and Requirements This procedure is intended as a guide. Depending on the complexity of the product and the extent of the design requirements, the Product Manager (appointee) and the Executive Management Team must meet the essential requirements for establishing and maintaining the design history. 4.1 Product Manager The Product Manager (appointee) bears overall responsibility for successful management of the development program and establishing and maintaining the Design History File. 4.2 Regulatory Affairs/Quality Systems Personnel The Regulatory Affairs/Quality Systems (appointee) is responsible for assuring the quality of the product design process, the manufacturing process, the product, and all phases of the Product Development Cycle. The Regulatory Affairs/Quality Systems (appointee) is responsible for maintaining required hard copies of Design History File documents and design history archives of completed product development programs. 5.0 References >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> 6.0 Procedure 6.1 Purpose of Design History File The basic purpose of the Design History File is maintenance of the records that demonstrate development of the product in accordance with the Product Development. Plan (the design plan) and the Marketing Requirements Document (the product design input requirements). Beyond satisfying this regulatory requirement, the Design History File provides other benefits. It contains the information necessary to validate a product design in a known location where it can be maintained throughout the life cycle of the product. It is also a storage base of the technical knowledge supporting the product design. Developers can access the Design History File to develop future models of this product or entirely new products using similar technology. 6.2 Location of Design History File It is usually not possible to maintain all of the design history documentation for a product design in a single location. Typically, developers maintain design history documentation in many places. Design history may include entries in laboratory notebooks, internal memoranda, electronic mail, and other documents stored at various physical locations. However, the Design History File must contain or reference all essential documents verifying development of the product in accordance with design control requirements. [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 4 of 5 [Company Name] maintains electronic design history files in a secure directory on the internal company network. Document Control maintains required hard copies of design history documents in a secure location separate from Device Master Record documentation. Hard copies include documents requiring signature approval and documents managed under production document change control procedures. Document Control maintains completed laboratory notebooks in a secure location in accordance with Laboratory Notebook Procedures. 6.3 Contents of Design History File 6.3.1 Product Development Documents The following are examples of possible types of design history. See Development of Design Output for further descriptions of design history documentation. 6.3.2 Technical Report Documents The following are examples of possible types of technical reports. See Development of Design Output, for further descriptions of technical reports. 6.4 Authorization to Continue Development Marketing Requirements Document Development Report Design Review Documentation Manufacturability Report Meeting Agendas and Minutes Product Development Plan Master Schedule Release to Full Production and Support Test Plans (Reliability, Verification, Validation, etc.) Design Validation Reports Design Verification Reports Error Budget Reports Product Support Reports Reliability Test Reports Risk Analysis Reports Sensitivity Analysis Reports Maintenance of Design History File The Product Manager (or designee) is responsible for maintaining the Design History File. The Team – engineers, Product Development Team, and other developers (include all relevant personnel) provide the Product Manager (or designee) with all design history documentation for filing or referencing in the Design History File. After completing the product Release to Production and the conclusion of a development program, the Product Manager (or designee) releases the design history documentation for that product and program to the Quality Systems Manager. Document Control files include the product design history documentation in the design history archives along with any original hard copies of design history. From this point, the product accumulates design history as part of the change control system. A new product model generates a new program. [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 5 of 5