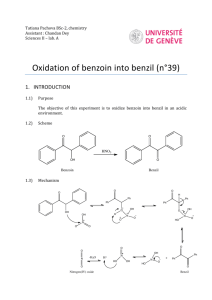

Bismuth(III) Promoted Aerobic Oxidation of Benzoin

advertisement

Org. Chem. J. 2010, 1, 20-25 Bismuth(III) Promoted Aerobic Oxidation of Benzoin Bismuth(III) Promoted Aerobic Oxidation of Benzoin Mohsen Mousavi, a,* and Mohammad Reza Gouyab a b Department of Chemistry, Islamic Azad University, Saveh branch, Saveh, Iran Department of Chemistry, Islamic Azad University, Saveh branch, Young Researchers Club, Saveh, Iran E-mail: drmousavi@hotmail.com Recevied date: March 15, 2010 Abstract Oxidation of benzoin with some mild oxidants was studied in different reaction media. The best result was obtained utilizing Bi5O(OH)9(NO3)4 in boiling acetic acid under air. More investigations revealed a catalytic role for Bi5O(OH)9(NO3)4 in aerobic oxidation of benzoin. Keywords: benzoin; benzil, bismuth, catalyst, oxidation 1. Introduction Benzil is a popular building block in organic synthesis due to its bi-functional character which is utilizable in the synthesis of homo- and heterocyclic compounds1-6 as well as bi-, tri- and tetra-dentate ligands for use in coordination chemistry.7-9 As benzoin is a key intermediate in the synthesis of benzil, it is of great importance to develop a fast, facile and eco-friendly procedure for quantitative conversion of benzoin to benzil. The oxidative cleavage of benzoin and/or benzil to benzoic acid10 makes strong laboratory oxidants, e.g. KMnO4 insufficient for this transformation. The classic reagent for this conversion is nitric acid,11 but it does not provide the product in good yield. In addition, the procedure involves the release of poisonous NO2 gas. In recent years, some mild and catalytic reaction condition are developed for quantitative oxidation of benzoin to benzyl.12,13 Among others, Bi3+ was used as stoichiometric oxidant in the presence of catalytic amounts of Cu2+ ions.14 However, many oxidizing systems suffer from long reaction times and/or requirement of oxidizing agents in molar ratio. Presumably, molecular oxygen is the best choice to use as stoichiometric oxidant, because it is inexpensive, readily available, and ultimately produces benign byproducts such as H2O.15,16 Here, we report an effective catalytic system for oxidation of benzoin by atmospheric O2 at reasonable times. 20 Mousavi et al. Org. Chem. J. 2010, 1, 20-25 2. Results and Discussion At first, some mild oxidants were examined for conversion of benzoin to benzil. Based on the results, presented in Table 1, Bi5O(OH)9(NO3)4 was chosen as preferred reagent for desired transformation. Table 1. Oxidation of benzil by various oxidants in acetic acid at 70 °C. Oxidant Entry Time (min) Yield (%) Type Amount (mmol) 1a non - 360 5 2 b H 2O 2 1 360 35 3 b NH4NO3 1 360 54 4 b K2S2O8 1 360 67 Bi5O(OH)9(NO3)4 0.5 330 100 5 a substrate 2.5 mmol, solvent 7.5 ml; b substrate 1 mmol, solvent 6 ml The reaction in given condition was relatively slow, so we tried to optimize the temperature, solvent and the molar ratio of oxidant. As it is expected, the reaction found to be strongly temperature dependent. At 110 °C, the reaction completed at a reasonable time of 60 minutes, while it is strongly slowed down at room temperature (Table 2). Table 2. Oxidation of benzil (1 mmol) by Bi5O(OH)9(NO3)4 (0.07 mmol) in acetic acid (6 ml) at various temperature. Entry Temperature (°C) Time (min) Yield (%) 1 20 1440 8 2 40 1440 100 3 70 210 100 4 90 130 100 5 110 60 100 The reaction was then carried out in some other traditional organic solvents under reflux. The corresponding results are summarized in Table 3. Some characteristic properties of solvents, including boiling points (Bp), electric dipole moments (μ) and acid dissociation potentials (pKa), are also included in the table to reveal the main affecting parameters. The solvents are arranged in descendant order of dipole moment. There is not any reasonable dependence between the reaction rates and the polarity of solvents, but two other parameters present more detectable influences on the reaction rates. In general, the reactions proceed faster in solvents with higher boiling points. As the reactions are carried out near the boiling points of the solvents, the results imply the influence of temperature on the reaction 21 Org. Chem. J. 2010, 1, 20-25 Bismuth(III) Promoted Aerobic Oxidation of Benzoin Table 3. Oxidation of benzil (1 mmol) by Bi5O(OH)9(NO3)4 (0.07 mmol) in various solvents (6 ml) at their reflux temperatures. Entry Solvent μ (debye) a Bp (°C ) a pKa a Time ( min) Yield (%) 1 Dimethyl sulfoxide 3.96 189 - 165 100 2 Acetonitrile 3.93 81.6 - 360 36 3 Dimethylformamide 3.82 153 - 340 100 4 Methanol 1.70 64.5 15.5 360 28 5 Acetic acid 1.70 117.9 4.76 130 100 6 Formic acid 1.43 101 3.75 300 32b 7 Toluene 0.38 110.6 - 360 58 a The data are derived from .17 b The reaction was complicated by the simultaneous formation of both benzil and benzoic acid, the given yield is for benzil. rates. However, there is not a direct relationship between boiling points of solvents and the reactions rates; since the reaction in acetic acid take places faster than solvents with higher boiling points. This comparison suggests the acidity of solvent as the second parameter which mainly affects the reaction rates. In order to disclose the role of acidity, independent of temperature, some reactions were performed in solvents with different pKa at a constant temperature. The results, presented in Table 4, apparently confirm the positive effect of acidity, which is measured by acid dissociation potential (pKa). The higher reaction rate in acetic acid compare to that of propionic acid, may be attributed to the solubility of Bi5O(OH)9(NO3)4. The reagent is insoluble in most organic solvents, but slightly soluble in acidic solvents especially at higher temperatures. The solubility in acetic acid is higher than propionic acid. Therefore, besides the involvement of H+ in the reaction mechanism, part of the accelerating role of acidic solvents is owed to the solubility of reagent. Table 4. Oxidation of benzil (1 mmol) by Bi5O(OH)9(NO3)4 (0.07 mmol) in various solvents (6 ml) at 80 °C. Entry Solvent pKa Time (min) Yield (%) 1 Acetic acid 4.76 135 100 2 Propionic acid 4.87 210 100 3 dimethylformamid - 480 100 Further investigations, comprising the variation of the molar ratio of oxidant to substrate, revealed more mechanistic aspect of the reaction. The reaction equation (Equation 1) indicates that at least 0.1 mmol Bi5O(OH)9(NO3)4 is required per conversion of one mmol benzoin to benzil. However, a stepwise decrease in the molar ratio of oxidant, from 0.2 to 0.02, only caused a retard in reaction rates (Table 5). 19PhCOCH(OH)Ph + 2Bi5O(OH)9(NO3)4 → 19PhCOCOPh + 10Bi + 28H2O + 8NO2 22 (1) Mousavi et al. Org. Chem. J. 2010, 1, 20-25 Table 5. Oxidation of benzil (1 mmol) by various amounts of Bi5O(OH)9(NO3)4 in acetic acid (6 ml) at 80 °C Entry Oxidant (mmol) Time (min) Yield (%) 1 0.2 130 100 2 0.07 135 100 3 0.06 150 100 4 0.05 165 100 5 0.04 350 100 6 0.02 375 100 Even more, a decrease in molar ratio of oxidant from 0.2 to 0.07 mmol caused minor changes in reaction rates. A plot of reaction times versus molar ratio of added oxidant shows a significant change in curve by decreasing the molar ratio from 0.05 to 0.04 mmol (Fig. 1). Therefore, at least part of the reaction proceeds without consuming the supplied oxidant. As the reactions are carried out under air, the atmospheric O2 may be regarded as the second oxidant presented in the system. In fact, there are other evidences which emphasis on the role of atmospheric O2 as final oxidant and suggest a catalytic role for Bi3+. This concept may be shown by equations 2 and 3. As it is 3PhCOCH(OH)Ph + 2Bi3+ + 6H2O → 3PhCOCOPh + 2Bi0 + 6H3O+ (2) 4Bi0 + 3O2 + 12H3O+ → 4Bi3+ + 18H2O (3) 400 350 Time (min) 300 250 200 150 100 50 0 0 0.05 0.1 0.15 0.2 0.25 Oxidant (mmol) Figure 1. The plot of reaction time versus molar ratio of oxidant (tick line), and the variation of reaction times (Δt) versus molar ratio of oxidant (dashed line). suggested by equations 2 and 3, the first step of reaction depends on the concentration of Bi3+, while the second step depends on the concentration of H+ (pH value) and dissolved O2. So, it may be concluded that at high concentrations of Bi3+ (more than 0.05 mmol in 6 ml acetic acid) the second step, which is responsible for recovery 23 Org. Chem. J. 2010, 1, 20-25 Bismuth(III) Promoted Aerobic Oxidation of Benzoin of Bi3+, has minor influence on the reaction rate. Inversely, at low concentrations of Bi3+ (less than 0.04 mmol in 6 ml acetic acid) the reaction requires the second step to regenerate the necessary Bi3+. The rate of the second step is limited by concentration of H+ and the oxygen supply in solution. The involvement of bismuth in oxidation procedure was clearly evident by appearance of a black precipitation of Bi0 during the reaction course, which disappeared by an air flow or stronger stirring of mixture. Thus, the break down in relation curve at 0.05 mmol concentration of Bi5O(OH)9(NO3)4 may be attributed to a change in rate control from the first step to the second step (Equations 2 and 3, respectively). More investigations provided further evidences which support the above concept. A reaction carried out with limited amounts of Bi5O(OH)9(NO3)4 in acetic acid under an N2 atmosphere, led to the formation of the black precipitate of Bi0, and the reaction was not completed even after a day. Furthermore, a white precipitate, which usually remained at the end of reactions, was identified as a Bi3+ derivative by treatment with SnCl2 in a 4 molar sodium hydroxide solution. Finally, the oxidation of benzoin in boiling acetic acid could proceed without adding oxidant (Table 6). Comparing the results of two reactions, in the presence or absence of Bi5O(OH)9(NO3)4, provides a measure of catalytic activity of Bi3+. The advantage of a catalyst is more evident at lower temperatures, as it may be concluded by a comparison between Table 6 and Table 1. Table 6. Oxidation of benzil (1 mmol) by various amounts of Bi5O(OH)9(NO3)4 in acetic acid (6 ml) at 110 °C. Entry Oxidant (mmol) Temp (°C) Time ( min) Yield (%)a 1 0.1 110 60 100 2 0 110 210 100 3. Experimental All chemicals and solvents were purchased from commercial chemical companies, and used as received. The reactions were carried out at a two necked flasks equipped by a condenser. The products were separated by column chromatography, using a regularly packed silica gel 40 column and eluted by a 1: 19 mixture of ethylacetate and hexane. The identities of products were examined via comparison of their melting points and IR spectra with those of authentic samples. 4. Conclusion The results of our investigations revealed the catalytic activity of Bi3+ in aerobic oxidation of benzoin. Though it is not surprising for benzoin to be oxidized by air, our catalytic system based on of Bi3+/H+ is capable of lowering the duration of the slow reaction to reasonable times. The formation of a black precipitate during the reaction procedure clearly indicates the reduction of Bi3+ to Bi0 along with the oxidation of benzoin. Disappearance of black precipitate on vigorous stirring implies the regeneration of Bi3+ from Bi0, by oxidizing effect of air. Combination of two redox reactions leads to a catalytic cycle for oxidation of benzoin by atmospheric O2 (scheme 1). 24 Mousavi et al. Org. Chem. J. 2010, 1, 20-25 Scheme 1 The involvement of H+ in the catalytic cycle explains the higher reaction rates in acidic solvents. Because of the biphasic nature of aerobic oxidation, the apparent rates and repeatability of reactions is affected by the shape and the size of vessel and the quality of stirring. Acknowledgement Financial support from Islamic Azad University, Saveh branch, the Young Researchers Club is gratefully acknowledged. References and Notes 1. Ogata, H.; Kawasaki, A.; Sugiura, F. J. Org. Chem. 1969, 34, 3981-3985. 2. Prasad, G.; Giri, B. P.; Mehrotra, K. N. J. Org. Chem. 1982, 47, 2353-2354. 3. Marjani, K.; Asgarian, J.; Mousavi, M. J. Chem. Res. 2007, 548-551. 4. Marjani, K.; Sharifi Moghadam, M.; Arazi, O.; Mousavi, M. Acta Crystallogr., 2007, E63, o3519. 5. Marjani, K.; Mousavi, M.; Ashouri, A.; Arazi, O.; Bourghani, S.; Asgari, M. J. Chem. Res. 2008, 398-401. 6. Sannicolo, F. J. Org. Chem. 1983, 48, 2924-2925. 7. Arquero, A.; Canadas, M.; Martinez-Ripoll, M.; Mendiola, M. A.; Rodriguez, A. Tetrahedron, 1998, 54, 11271-11284. 8. Jones, L. A.; Hancock, C. K.; Seligman, R. B. J. Org. Chem. 1961, 26, 228-232. 9. Raman, N.; Ravichandran, S.; Thangaraja, C. J. Chem. Sci. 2004, 116, 215-219. 10. Fieser, L. F.; Williamson, K. L. Organic Experiments, 8th Ed.; Houghton Mifflin Company: New York, 1998. 11. Pavia, D. L.; Lampman, G. M.; Kriz, G. S.; Engel, R. G. Introduction to Organic Laboratory Techniques, A Microscale Approach; Sunders College Publishing: Philadelphia, 1990. 12. Schultz, A.; Giannis, A. Synthesis, 2006, DOI: 10.1055/s-2005924764. 13. Mirjalili, B. F.; Zolfigol, M. A.; Bamoniri, A.; Zaghaghi, Z.; Hazar, A. Acta. Chim. Slov. 2003, 50, 563-568. 14. Tymonoko, S. A.; Nattier, B. A.; Mohan, R. S. Tetrahedron Lett. 1999, 40, 7657.-7659 15. Schultz, M. J.; Sigman, M. S. Tetrahedron 2006, 62, 8227-8241. 16. Heravi, M. M.; Zadsirjan, V.; Bakhtiari, K.; Oskooie, H. A.; Bamoharram, F. F. Catalysis Commun. 2008, 8, 315-318. 17. Lide, D. R. ed. CRC Hand book of Chemistry and Physic, 87th Ed, Internet Version, Taylor and Francis: Boca Raton, FL, 2007. 25