Application Note: Virtex-II Families

R

XAPP688 (v1.2) May 3, 2004

Creating High-Speed Memory Interfaces

with Virtex-II and Virtex-II Pro FPGAs

Author: Nagesh Gupta, Maria George

Summary

Designing high-speed memory interfaces is a challenging task. Xilinx has invested time and

effort to make it simple to design such interfaces using the Virtex-II™ and Virtex-II Pro™

FPGAs. This application note discusses the challenges presented by this task together with

various techniques that can be used to overcome them, while illustrating the key concepts in

implementing any memory interface. All examples used in this application note assume a

DDR-1 interface on an XC2VP20FF1152-6 Virtex-II Pro FPGA. The interface speed is

200 MHz.

Introduction

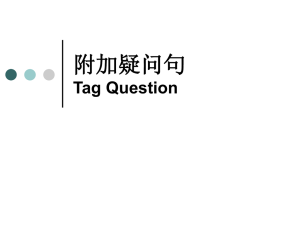

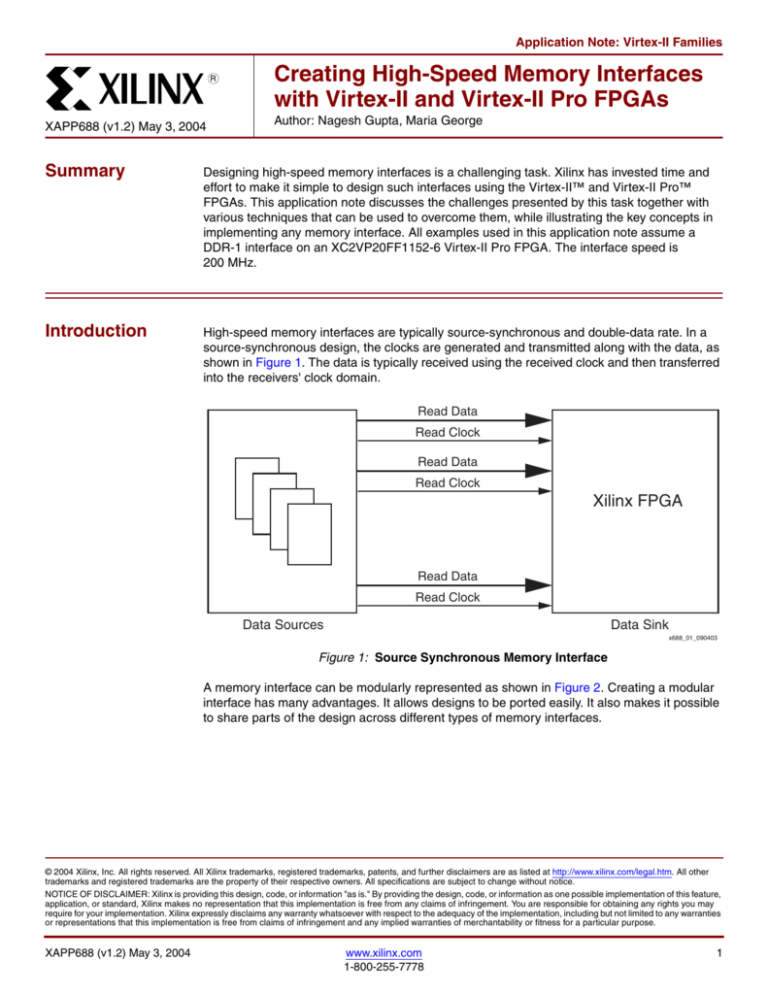

High-speed memory interfaces are typically source-synchronous and double-data rate. In a

source-synchronous design, the clocks are generated and transmitted along with the data, as

shown in Figure 1. The data is typically received using the received clock and then transferred

into the receivers' clock domain.

Read Data

Read Clock

Read Data

Read Clock

Xilinx FPGA

Read Data

Read Clock

Data Sources

Data Sink

x688_01_090403

Figure 1: Source Synchronous Memory Interface

A memory interface can be modularly represented as shown in Figure 2. Creating a modular

interface has many advantages. It allows designs to be ported easily. It also makes it possible

to share parts of the design across different types of memory interfaces.

© 2004 Xilinx, Inc. All rights reserved. All Xilinx trademarks, registered trademarks, patents, and further disclaimers are as listed at http://www.xilinx.com/legal.htm. All other

trademarks and registered trademarks are the property of their respective owners. All specifications are subject to change without notice.

NOTICE OF DISCLAIMER: Xilinx is providing this design, code, or information "as is." By providing the design, code, or information as one possible implementation of this feature,

application, or standard, Xilinx makes no representation that this implementation is free from any claims of infringement. You are responsible for obtaining any rights you may

require for your implementation. Xilinx expressly disclaims any warranty whatsoever with respect to the adequacy of the implementation, including but not limited to any warranties

or representations that this implementation is free from claims of infringement and any implied warranties of merchantability or fitness for a particular purpose.

XAPP688 (v1.2) May 3, 2004

www.xilinx.com

1-800-255-7778

1

R

Key Challenges

Xilinx FPGA

Arbitration Layer

Application Interface Layer

Control Layer

Physical Layer

Memories

x688_02_090403

Figure 2: Modular Memory Interface Representation

Key Challenges

High-speed controllers and interfaces are challenging to design. Designing high-speed

memory interfaces are particularly challenging due to various factors. Some of the key

challenges are

•

Source-synchronous data transmit (data write function).

•

Source-synchronous data receive (data read function).

While these functions are common in all high-speed interfaces, memory interfaces make it

particularly challenging due to the following factors:

•

Single-ended standards. Memories typically use HSTL or SSTL type input/output standard.

•

Non-free-running clocks. Some memories such as DDR SDRAM provide a non freerunning strobe clock for data reads.

•

Timing parameters. The input and output timing specifications for memories take away

significant amount of the available data valid window.

We have solved these key problems with patent-pending innovations. These innovations have

been proven in hardware and are available for use in the form of reference designs.

Physical Layer

The Physical layer is responsible for transmitting and receiving all the signals to and from the

memories. The major functions of the physical layer include:

•

Write data into the memory.

•

Read data from the memory.

•

Provide all the necessary control signals

•

Transfer the read data clock domain from memory domain to FPGA domain.

The physical layer constitutes a major challenge in memory interface design. This section

elaborates on the different aspects of the physical layer.

2

www.xilinx.com

1-800-255-7778

XAPP688 (v1.2) May 3, 2004

R

Physical Layer

Clocks, Address and Control Signals

The FPGA generates all the clocks and control signals for reads and writes to memory. The

memory clocks are typically generated using a Double Data Rate (DDR) register.

Controller

&

Transmit

Data Path

IOB

VCC

BUFG

Clock0

Clock to

Memory

Clock180

DCM

BUFG

x688_03_090803

Figure 3: Clock Generation for Memory Device

As shown in Figure 3, a Digital Clock Manger (DCM) generates the clock and its inverted

version. Generating the clock this way has a couple advantages:

•

The data, control and clock signals all go through similar delay elements while exiting the

FPGA.

•

Clock duty cycle distortion is minimal when global clock nets are used for the clock and the

180° phase-shifted clock.

All of the address and control signals are registered and output at the IOB. The address and

control signals are registered using a clock that is 180° shifted from the clock signal to the

memory. Such an approach enables the address and control signals to have additional time

margin before they are registered. The address and control signals meet the required timing

with ease. An example timing analysis for a DDR-1 interface implemented using an

XC2VP20FF1152 FPGA, -6 speed grade, is shown inTable 1.

Table 1: Address and Control Signal Margins

Parameter

TCLOCK

Value

Leading-Edge

Uncertainties

Trailing-Edge

Uncertainties

5000

Meaning

Clock period

TCLOCK_SKEW

50

50

50

Minimal skew, since right/left sides are being used

and the bits are close together

TPACKAGE_SKEW

65

65

65

Using same bank reduces package skew

TSETUP

750

750

0

Setup time from memory data sheet

THOLD

750

0

750

Hold time from memory data sheet

TPCB_LAYOUT_SKEW

50

50

50

Skew between layout lines on the board

TPHASE_OFFSET_ERROR

140

140

140

Offset between different phases of the clock. Taken

from the parameter CLKOUT_PHASE

TDUTY_CYCLE_DISTORTION

0

0

0

Duty-cycle distortion does not apply

TJITTER

0

0

0

Since the clock and address are generated using the

same clock, the same jitter exists in both. Therefore,

it does not need to be included

1055

1055

1445

3945

Total Uncertainties

Command Window

XAPP688 (v1.2) May 3, 2004

2500

www.xilinx.com

1-800-255-7778

Worst-case window of 2500 ps

3

R

Physical Layer

Figure 4 illustrates the address and control signal margin.

Clock 180

Address/Control

Memory Clock

Leading Edge

Uncertainties

Trailing Edge

Uncertainties

Leading Edge

Margin

Trailing Edge

Margin

0

1445

3945 5000

time, ps

x688_04_011404

Figure 4: Address and Control Signal Margins

Data Write

The write data and strobe are clocked out of the FPGA. The strobe is center-aligned with

respect to the data. For DDR-1, the strobe is required to be non-free-running. A strobe for

DDR-1 is required only when valid data is being written into the memory. In addition, the DDR-1

strobe is bi-directional. The same strobe is used for reads and writes.

= 0˚

Memory Clock

Generated using

clock180

Command/Address

Generated using

clock90 & clock270

Write Data

In phase with

memory clock

DQS

x688_05_092403

Figure 5: Write Data, Command, Address, Strobe, and Clock Signals

To meet the requirements specified above, the write data is clocked out using a clock that is 90

degrees and 270 degrees shifted from the primary clock going to the memory. The DDR

registers in the IOB are used to clock the write data out. This is shown in Figure 6.

d0

clock270

dn

clock90

x688_06_090803

Figure 6: Using IOB DDR Registers to Drive the Write Data

4

www.xilinx.com

1-800-255-7778

XAPP688 (v1.2) May 3, 2004

R

Physical Layer

Table 2 shows a calculation of the extra margin available for write data capture using the

techniques just described. An illustration of the calculated time margin window is shown in

Figure 7.

Table 2: Write Data Timing Margin Calculation

Parameter

Value

Leading-Edge

Uncertainties

Trailing-Edge

Uncertainties

Meaning

TCLOCK

5000

Clock period

TCLOCK_PHASE

2500

Clock phase

TDCD

250

Duty cycle distortion of clock to memory

TDATA_PERIOD

2250

Total data period, TCLOCK_PHASE – TDCD

TCLOCK_SKEW

50

50

50

Minimal skew, since right/left sides are being used

and the bits are close together

TPACKAGE_SKEW

65

65

65

Skew due to package pins and board layout. This can

be reduced further with tighter layout

TSETUP

450

450

0

Setup time from memory data sheet

THOLD

450

0

450

Hold time from memory data sheet

TPCB_LAYOUT_SKEW

50

50

50

Skew between layout lines on the board

TPHASE_OFFSET_ERROR

140

140

140

Offset error between different clocks from the same

DCM. Taken from the parameter CLKOUT_PHASE

0

0

0

Total Uncertainties

1205

755

755

Worst case for leading and trailing can never happen

simultaneously

Window

740

755

1495

Total worst-case window is 740 ps

TJITTER

The same DCM is used to generate the clock and

data. Hence they jitter together

Leading Edge

Margin

Trailing Edge

Margin

Write Data

DQS

Leading Edge

Uncertainties

Trailing Edge

Uncertainties

0

755

1545

2250

time, ps

x688_07_011404

Figure 7: Write Data Margin

Strobe Delay Circuit

The strobe is delayed such that it falls within the data valid window. There are several

mechanisms that can be used to delay the strobe.

1. Introduce an external board trace delay. This mechanism has been explained in earlier

Xilinx Application Notes such as XAPP253.

2. Use a delay line on the board as opposed to a trace delay. This mechanism is similar to the

external trace delay, but will use a delay line to create the required delay.

XAPP688 (v1.2) May 3, 2004

www.xilinx.com

1-800-255-7778

5

R

Physical Layer

3. Delay a free-running strobe using the DCM. This mechanism can be used in memories

such as QDR-2, FCRAM-2 and RLDRAM-2. The disadvantage of this mechanism is it

requires additional DCM and clocking resources for each strobe. A QDR-2 interface using

this mechanism is explained in XAPP 262.

4. Use an internal delay element with precisely controlled delays. An internal delay element

has been built of LUTs(Look Up Tables) and other resources in the Xilinx FPGA fabric.

Selecting the elements and all routing resources used within the elements defines the

delay values precisely.

Methods (3) and (4) above are the preferred methods. Method (3) cannot be used if the FPGA

is short on clocking resources or if a free-running strobe is not available. Method (4) has been

demonstrated successfully for DDR-1 interface at 200 MHz.

Input

Output

LUT

LUT

LUT

LUT

LUT

LUT

x688_08_090803

Figure 8: Building Delay Elements Using LUTs in a Xilinx FPGA

Figure 8 shows the way in which the LUTs are configured to create selectable delay elements.

The delay value of each MUX element is between 200 and 300 picoseconds. The extra delay of

the strobe with respect to data is calculated using a calibration circuit that ensures that the

strobe is within the worst-case data valid window.

The total extra delay in the strobe path (compared to the data path) should fall within the valid

data window. Calculation of the valid data window is described in data read section.

Data Read

Receiving the source-synchronous data from memory is the most interesting part of the

memory interface. There are several novel techniques we have developed in this area.

Memory read data is edge aligned with a source-synchronous clock. In case of DDR-1, the

clock is a non-free running strobe. The challenge is to receive the data using the strobe and

transfer it to the FPGA clock domain. Since the memory clock is not free running, there can only

be one stage of registers using this clock.

The input side of the data bits uses exactly the same resources as used by the input side of the

strobe. This ensures matched delays on the strobe and data signals until the strobe is delayed

in the strobe delay circuit. That is one of the reason why this design captures the data directly

into registers in the FPGA fabric. A separate circuit transfers the output of these registers into

FIFOs clocked using the FPGA clock.

Data Capture

Data is captured using the delayed strobe mentioned previously. Data is directly captured in the

FPGA fabric slices. By using novel techniqies, it is possible to keep the captured data valid for

two entire clock cycles. The timing calculation for data capture is shown in Table 3. An

illustration of the calculated data valid window is shown in Figure 9.

6

www.xilinx.com

1-800-255-7778

XAPP688 (v1.2) May 3, 2004

R

Physical Layer

Table 3: Data Valid Window Calculation

Parameter

Value

Leading-Edge

Uncertainties

Trailing-Edge

Uncertainties

Meaning

TCLOCK

5000

Clock period

TPHASE

2500

Clock phase

TMEM_DCD

250

Duty cycle distortion from memory DLL

TDATA_PERIOD

2250

Total data period, TPHASE – TMEM_DCD

TDQSQ

500

500

0

Strobe-to-data distortion

TPACKAGE_SKEW

65

65

65

This parameter depends on the exact package. Since

the 8 data bits are close together, skew is less than

this

TSETUP

240

240

0

Setup time from Virtex-II Pro data sheet for -6 part.

Taken from TDICK parameter.

THOLD

–50

0

–50

Hold time from Virtex-II Pro data sheet. Taken from

TCKDI parameter.

TJITTER

100

0

0

Data and strobe jitter together, since they are

generated off the same clock

TLOCAL_CLOCK_LINE

25

25

25

Observed skew is lower than this value, since loading

is light and all bits are close together

TPCB_LAYOUT_SKEW

50

50

50

Skew between data lines on the board

TQHS

450

0

450

Hold skew factor for DQ

880

540

880

1710

Uncertainties

Window

830

Worst-case window of 830 ps

Leading Edge

Margin

Trailing Edge

Margin

Read Data

Read DQS

Leading Edge

Uncertainties

0

880

1710 2250

time, ps

Trailing Edge

Uncertainties

x688_10_050304

Figure 9: Data Valid Window

XAPP688 (v1.2) May 3, 2004

www.xilinx.com

1-800-255-7778

7

R

Physical Layer

A timing diagram of data capture is shown in Figure 10.

Delayed Strobe

Data

word0

Register 0

word1

word2

word3

word4

word5

word0

Register 1

word6

word7

word8

word9

word10

word4

word1

Register 2

word5

word2

Register 3

word6

word3

word7

x688_18a_011504

Figure 10: Data Capture Timing

Data Recapture

Data recapture is the process of transferring the data into the FPGA clock domain. The

recapture circuit works for any system-level timing. No system-level calculations are required

for the circuit to work. The extended period for which each piece of data is valid makes the task

of recapture easier. The data is directly transferred from the data capture registers into

separate FIFOs.

Delay Calibration Circuit

The delay calibration circuit selects the number of delay elements to be used to create extra

delay through the strobe line. The delay calibration circuit calculates the delay of a circuit that

is identical in all respects to the strobe delay circuit. All aspects of delay are considered for

calibration. This includes all the component delays, as well as the route delays. The calibration

circuit selects the number of delay elements to be used at any given time. After the required

number of delay elements is determined, the calibration circuit asserts the appropriate select

lines to the strobe delay circuit. The select lines of the strobe delay circuit can be changed only

when no read data is being received.

Selecting the required number of delay elements as shown avoids any uncertainty due to

process, voltage, and temperature (PVT) variance. The positive and negative hysterisys for

transition from selecting one set of delay elements to another set is configurable. The number

of contiguous selection transitions required to make the transition is also configurable.

During operation, the temperature of the die can cause the delay elements to get slower. If this

happens, the number of selected delay elements changes automatically.

8

www.xilinx.com

1-800-255-7778

XAPP688 (v1.2) May 3, 2004

R

Control Layer and Application Interface Layer

Control Layer

and Application

Interface Layer

The control and application layers are simple to design in the Xilinx FPGA fabric. The control

layer is responsible to generate all control signals according to a memory protocol. The

application interface layer is used to transfer data and commands between the user application

and the memory interface blocks. A simple user application interface is as shown in Figure 11.

User Application

Read Data FIFO

Write Data FIFO

Command FIFO

(Could Be Separate for

Read and Write Commands)

x688_16_090803

Figure 11: User Application Interface

Tools

Implementation of the interface described in this application note is quite intricate. There are

several instances where very precise routing delays and placements are required. To enable

customers to design effectively using the methods described, a tool is provided that works with

various Virtex-II and Virtex-II Pro devices and generates all the required constraints for the

design. The tool can also generate the recommended pinouts for the data bus. The constraints

generated by the tool must be consistent with the RTL and the RTL hierarchy.

Implementation

This section describes various implementation considerations. Some differences exist between

different memory types. The techniques described in this application are applicable in general

to all of the different memory types. This section talks about the differences between different

memories and how the techniques can be applied to different memories.

Board Design Considerations

Board design considerations for a memory interface are not very different from designing other

high-speed interfaces. Several Xilinx application notes describe the intricacies of building highspeed boards. XAPP623 describes advanced techniques in power system design. Xilinx user

guide UG060 describes a memory board designed for Virtex-II Pro using most of the

techniques described in this application note.

DDR-1 SDRAM Interface

DDR-1 is arguably the most complex memory interface. All of the examples in this application

note were for DDR-1. DDR-1 controller has been illustrated in other Xilinx application notes

such as XAPP253.

XAPP688 (v1.2) May 3, 2004

www.xilinx.com

1-800-255-7778

9

R

References

QDR-2 SRAM Interface

QDR-2/DDR-2 SRAM is different in many aspects compared to DDR-1 SDRAM. This interface

is described in detail in XAPP262. The controller is much simpler, since there is no need for

separate row and column addresses.

The physical layer is simpler since these memories have a contiguous or free-running strobe. A

contiguous strobe can be easily used to capture the data in multiple stages and finally into an

asynchronous FIFO. One complexity is the lack of a data valid signal. The absence of a data

valid signal leaves the state machine to predict when valid data will be available to register. The

state machine predicts the return of valid data by counting the number of cycles after the read

command is issued. However, the input and output buffer speeds of different FPGAs or different

speed grades of FPGAs can potentially cause the data to return at different cycle boundaries.

This reduces the maximum frequency of operation for this kind of interface.

Another novel innovation solves this problem, and makes it possible to determine the exact time

when valid data will be received.

RLDRAM-2/FCRAM-2 Interfaces

Both RLDRAM-2 and FCRAM-2 interfaces are relatively simple. The controller design for either

of these memories is comparable in complexity to QDR-2 controller. There are no separate row

and column addresses to deal with. In addition, the strobes are contiguous and there is a

separate valid signal that indicates the arrival of valid data.

Xilinx will publish an RLDRAM-2 interface application note shortly.

References

1. Xilinx Application Notes XAPP253, XAPP609, XAPP262, XAPP678C, and XAPP688C.

2. Micron data sheet for DDR-1 DIMMs, MT4VDDT1664 A.

3. Micron data sheets for DDR-1 MT46V16M16.

Conclusion

The innovative techniques described in this application note make it easy to design any

memory interface with Xilinx Virtex-II and Virtex-II Pro FPGAs.

Revision

History

The following table shows the revision history for this document.

10

Date

Version

Revision

01/15/04

1.0

Initial Xilinx release.

02/02/04

1.1

Removed Figure 12 (screenshot of unreleased tool).

03/01/04

1.1.1

Table 2: Corrected description for TSETUP and THOLD.

05/03/04

1.2

• Table 1 and Table 2: Added derivation of parameter to "Meaning"

column for TPHASE_OFFSET_ERROR .

• Table 3: Added derivation of parameters to "Meaning" column and

revised parameter values for TSETUP and THOLD. Recalculated

derived values (Uncertainties and Window).

• Figure 9: Modified data window parameters in accord with

changes in Table 3.

www.xilinx.com

1-800-255-7778

XAPP688 (v1.2) May 3, 2004