publication - John A. Martin & Associates

advertisement

1

INTRODUCTION................................................................................................................3

1.1

OBJECTIVES ....................................................................................................................3

1.2

METHODOLOGY ..............................................................................................................3

1.3

BUILDING MODELS FOR RESPONSE COMPARISON ...........................................................4

1.3.1

Acquire Structural Plans, Earthquake Ground Motions and Damage Reports ....4

1.3.2

Development of 3-D Models of Buildings ..............................................................6

1.3.3

Run Elastic Time History Analysis ........................................................................7

1.3.4

Comparison of Responses ......................................................................................7

1.3.5

Model 3 Elastic Analysis........................................................................................8

1.3.6

Model 3; Inelastic Analysis....................................................................................8

1.3.7

Summary of Responses...........................................................................................8

1.4

BUILDING EVALUATION USING PREVAILING PRACTICE UBC-97 AND FEMA-273..........9

1.4.1

UBC-97 ..................................................................................................................9

1.4.2

Evaluation Using FEMA 273...............................................................................16

2

ANALYSIS OF AN EIGHT STORY OFFICE BUILDING, NORTH HOLLYWOOD,

CALIFORNIA............................................................................................................................25

2.1

BUILDING DESCRIPTION ................................................................................................25

2.2

THE SAP2000 COMPUTER MODELS..............................................................................28

2.3

MASS CALCULATIONS ...................................................................................................29

2.4

MODAL PERIODS ...........................................................................................................31

2.5

EARTHQUAKE GROUND MOTIONS .................................................................................34

2.6

TIME HISTORY ANALYSES.............................................................................................34

2.6.1

Model 1 and Model 2 ...........................................................................................34

2.6.2

Model 3 ................................................................................................................38

2.6.3

Elastic Demand Ratios and Demand Capacity Ratios ........................................40

2.7

COMPARISON OF ACTUAL DAMAGE WITH PREDICTED DAMAGE ...................................40

2.8

EVALUATION WITH PREVAILING PRACTICE – UBC-97 AND FEMA-273.......................43

2.8.1

Analysis Using UBC-97 .......................................................................................43

2.8.2

Analysis Using FEMA 273...................................................................................47

2.9

SUMMARY .....................................................................................................................57

3

ANALYSIS OF A TEN STORY OFFICE BUILDING, TARZANA, CALIFORNIA 58

3.1

BUILDING DESCRIPTION ................................................................................................58

3.2

THE SAP2000 COMPUTER MODEL ...............................................................................61

3.3

THE IDARC2D-V.5 COMPUTER MODEL .......................................................................61

3.4

MASS CALCULATIONS ...................................................................................................64

3.5

MODAL PERIODS ...........................................................................................................65

3.6

EARTHQUAKE GROUND MOTIONS .................................................................................67

3.7

TIME HISTORY ANALYSES.............................................................................................69

3.7.1

Model 1 and Model 2. ..........................................................................................70

3.7.2

Model 3 ................................................................................................................73

3.7.3

Demand Capacity Ratios .....................................................................................76

3.8

COMPARISON OF ACTUAL DAMAGE WITH PREDICTED DAMAGE. ..................................76

3.9

EVALUATION USING PREVAILING PRACTICE UBC-97 AND FEMA-273 ........................79

1

3.9.1

Analysis Using UBC-97 .......................................................................................79

3.9.2

Analysis Using FEMA 273...................................................................................83

3.9.3

Acceptance Criteria .............................................................................................88

3.10 SUMMARY .....................................................................................................................92

4

ANALYSIS OF A SIXTEEN STORY BUILDING, SHERMAN OAKS, CALIFORNIA

93

4.1

BUILDING DESCRIPTION ................................................................................................93

4.2

THE SAP2000 COMPUTER MODELS..............................................................................97

4.3

MASS CALCULATIONS ...................................................................................................99

4.4

MODAL PERIODS .........................................................................................................101

4.5

EARTHQUAKE GROUND MOTIONS ...............................................................................102

4.6

TIME HISTORY ANALYSES...........................................................................................103

4.6.1

Model 1 and Model 2 .........................................................................................103

4.6.2

Model 3 ..............................................................................................................107

4.6.3

Elastic Demand Ratios.......................................................................................109

4.7

COMPARISON OF OBSERVED AND PREDICTED DAMAGE .............................................110

4.8

EVALUATION WITH PREVAILING PRACTICE – UBC-97 AND FEMA-273.....................111

4.8.1

Analysis Using UBC-97 .....................................................................................111

4.8.2

Analysis Using FEMA 273.................................................................................116

4.9

SUMMARY ...................................................................................................................125

5

ANALYSIS OF A TWENTY STORY BUILDING, ENCINO, CALIFORNIA ........126

5.1

BUILDING DESCRIPTION ..............................................................................................126

5.2

THE SAP2000 COMPUTER MODELS............................................................................128

5.3

MASS CALCULATIONS .................................................................................................131

5.4

MODAL PERIODS .........................................................................................................133

5.5

EARTHQUAKE GROUND MOTIONS ...............................................................................134

5.6

OBSERVED DAMAGE ...................................................................................................135

5.7

TIME HISTORY ANALYSIS ...........................................................................................138

5.7.1

Model 1 and Model 2 .........................................................................................138

5.7.2

Model 3 ..............................................................................................................139

5.7.3

Elastic Demand Ratios.......................................................................................145

5.7.4

Demand/Plastic-Moment Ratios ........................................................................146

5.8

EVALUATION WITH PREVAILING PRACTICE – UBC-97 AND FEMA-273.....................146

5.8.1

Analysis Using UBC-97 .....................................................................................146

5.8.2

Analysis Using FEMA-273 ................................................................................150

5.9

SUMMARY ...................................................................................................................156

6

SUMMARY AND RECOMMENDATIONS.................................................................158

6.1

6.2

6.3

6.4

6.5

GENERAL MODELING ASSUMPTIONS ...........................................................................158

COMPARISON OF MAXIMUM ROOF DISPLACEMENTS ...................................................159

COMPARISON OF INTER-STORY DRIFTS .......................................................................161

COMPARISON OF BASE SHEARS ...................................................................................163

DAMAGE STRESS RATIOS ............................................................................................164

2

1

1.1

INTRODUCTION

Objectives

The purpose of this study is to evaluate the seismic performance of four instrumented steel

buildings during the 1994 Northridge earthquake. Based on the findings from the analysis,

modifications to the conventional analysis and code design procedures are to be suggested to

enhance the reliability of current analysis and design techniques. For this study, the code design

methods of UBC-97 according to LRFD and FEMA-273 were used.

1.2

Methodology

The methodology adopted for this study was as follows:

•

The four buildings used in this study were chosen by CSMIP, they are the a) North

Hollywood Building, b) Tarzana Building, c) Sherman Oaks Building, and d) Encino

Building. The description of each building is given in each building’s individual chapter.

•

The buildings were inspected after the earthquake for potential damage using the procedures

outlined by SAC in its interim guidelines (FEMA 267, 1995). The investigators who worked

on the respective buildings were consulted with and through them structural plans and repair

drawings were acquired. Their observations were documented giving valuable information

on the building and damaged observed after the earthquake.

•

The strong-motion records from the Northridge Earthquake for the buildings were made

available by CSMIP.

•

Analytical models for each building were created and analyzed using elastic/linear and/or

inelastic/nonlinear analysis techniques. The models were calibrated based on the

comparisons with the recorded building response and the actual building performance. The

comparisons included, but were not limited to, building periods, drifts, higher-mode

response, time histories and location of damaged joints if any.

3

•

Conclusions were made based on the extent of damage and modeling techniques adopted for

each building which included damping, higher mode effects and panel zone effectiveness.

•

The buildings were evaluated against current building design guidelines and practices,

namely the UBC-97 code and the FEMA-273 rehabilitation guidelines. The model which

best simulated the actual response observed in the field was used for this evaluation.

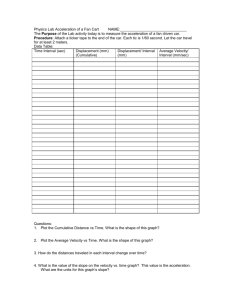

1.3

Building Models for Response Comparison

The outline of the procedure adopted for the building response comparison is shown in the

flowchart in Figure 1-1. The actual procedures used for each building are described in the

following chapters. Each of these chapters describes in detail a particular building as well as the

steps taken to construct, calibrate and study the analytical models used in this study.

1.3.1 Acquire Structural Plans, Earthquake Ground Motions and Damage Reports

The North Hollywood building was inspected by Myers Nelson Houghton Inc. The Sherman

Oaks building was inspected and repaired by Englekirk and Sabol Consulting Structural

Engineers. The Encino building was evaluated and repaired by Kariotis & Associates Structural

Engineers. The Tarzana building was inspected and repaired by John A. Martin and Associates.

Interviews were setup with the respective firms where their observations and type of damage to

each building was documented. Structural plans and damage reports were obtained.

The strong-motion records were given by CSMIP for each building. The motions included

displacements, velocities and accelerations in the North-South, East-West, and Vertical

directions. The motions were recorded by accelerometers located on the ground, at mid level,

and on the roof of each building.

4

Building Response Comparison

Acquire Model Plans, Time History Records,

Damage Reports and Repair Drawings

Develop 3-D Models

Model 1 (No rigid-end zones)

Model 2 (Full rigid End Zones)

Run Elastic Time-History Analysis

Is Actual Response bounded by the

Model 1 and Model 2 Responses?

Adjust Rigid End Zones and

Re-Run Time-History Analysis

NO

Develop Inelastic Model

Run Inelastic

Time-History Analysis

YES

YES

Elastic Analysis?

NO

Does the existing model time-trace

correlate well with the actual recording?

Adjust Hysteretic Parameters

NO

YES

Does the existing model amplitudes

correlate well with the actual recording?

NO

Adjust Modal Damping and

Re-Run Time-History Analysis

YES

Model 3

- Check Story Drifts

- Compare Stresses with Actual Damage

- Summarize Findings and Modeling Assumptions

- Evaluate with Prevailing Practice

Figure 1-1: Procedure used for the Comparison Building Response.

5

1.3.2 Development of 3-D Models of Buildings

Three-dimensional models of the lateral resisting system for all four buildings were constructed

for use with the computer program SAP2000. Two models were created for the elastic timehistory analysis that had different rigid end zone assignments. The first model (Model 1) utilized

all of the rigid end zones and the second model (Model 2) assumed no rigid end zones.

The primary lateral resisting system for all the buildings consisted of Special Moment Resisting

Frames (SMRF). One of the buildings had shear walls and cross braces at the lower levels and

were modeled as a part of the lateral resisting system. Gravity framing was excluded in the

model, as it was proven (Chapter 2) that it did not contribute significantly to the lateral

resistance. The mass and gravity loads from the gravity framing however were included. It was

verified for the North Hollywood building that their contribution to the lateral stiffness of the

building was minimal (the difference in the responses was between 2 and 5%). The response

comparisons for the other buildings looked good and did not warrant further investigation of the

influence of the gravity framing.

The influence of vertical ground motion was investigated for the Tarzana building (Chapter 3).

Again, the added modeling requirements necessary to include the effects of vertical ground

motion in the analysis, proved insignificant in terms of stress increases or displacement

responses. Thus, the effects of vertical ground motion were ignored in the analysis.

For the SAP2000 models, columns and beams were modeled as FRAME elements while the

shear walls were modeled as SHELL elements. Each member was assigned gravity loads. The

gravity loads consisted of the self-weight of the member and any supported dead load that

corresponded to the weight of the structure distributed to that member.

The mass, mass moment of inertia and center of mass were calculated and included for each of

the 3-D models. The calculations were made by the computer program JAMA-SDS (MMI). The

mass included the weight of the floor slab, framing member, partition loads, ceiling loads and

mechanical loads. The mass of the building was lumped at the center of mass on each floor. The

6

mass moments of inertia were applied at the center of mass for rotational inertia forces about the

vertical axis. The floor slab system was modeled using a rigid diaphragm formulation.

1.3.3

Run Elastic Time History Analysis

Model 1 and Model 2 were analyzed for the elastic time-history analysis that had different rigid

end zone assignments. The accelerations recorded at the ground level during the 1994

Northridge Earthquake were used as the input ground accelerations for the time-history analyses

These accelerations included components in the three principal axes of the buildings. The effects

of vertical excitation were investigated and it was concluded to be insignificant. Therefore, the

vertical component of the ground motion was not used in the analyses. Details on this

investigation are given for the Tarzana building (Chapter 3). Thus only the two horizontal

components were used in the time-history-analysis. Throughout this report, the North-South

direction is also referred to as “180” and the East-West direction is also referred to as “90”

The results from time-history analysis of Models 1 and 2 were compared against the actual

recorded responses from the Northridge earthquake. For three of the four buildings (Tarzana,

North Hollywood, and Sherman Oaks) the precise location of the seismographs/accelerometers

was unavailable therefore they were assumed to be located at the center of mass of the respective

floors. . The torsional response from the analyses were checked and found to be insignificant.

The actual torsion from the earthquake could not be determined, as there was only one sensor at a

particular floor, and the torsional component of the response was not recorded.

1.3.4 Comparison of Responses

A comparison between the acceleration, velocity and displacement responses for Model 1 and

Model 2 and the actual recorded responses was performed. When the actual recorded timehistory was bounded from the analysis results for Model 1 and Model 2 then the response was

identified as elastic and the required calibration was made by modifying the length of the rigid

zones. On the contrary, when the actual time-history appeared to be more flexible than Model 2,

this was a clear indication of inelastic behavior. Therefore, inelastic analysis had to be

performed calibrating both the rigid zone length and the structural hysteretic characteristics.

7

1.3.5

Model 3 Elastic Analysis

Model 3 was calibrated to match the earthquake response by an iterative process that consisted of

three basic steps: a) run the elastic analysis, b) compare the results, and c) adjust the rigid zones

and modal damping until the results matched the recorded response.

1.3.6 Model 3; Inelastic Analysis.

Inelastic models were developed only for those buildings that did not fall in the elastic range, as

described earlier. For this study it was the Tarzana building. The computer program used for the

inelastic analysis was IDARC2D-v.5. The details of the inelastic analysis setup are given in

Chapter 3. Since this program has limited 3D capabilities, a combination of two 2D models, one

for each direction, was prepared.

The iterative process used to calibrate Model 3 consisted of following three basic steps: a) run the

inelastic analysis, b) compare the results and c) adjust the hysteretic parameters and modal

damping until the results matched the recorded response.

1.3.7 Summary of Responses

The responses from Model 3 were examined to determine the accuracy of predicting zones of

high stress, draw conclusions on the validity of modeling techniques and to illustrate the ease or

difficulties in calibrating procedure. The methods used to determine areas of overstress in the

buildings are described in this section, however the conclusions on the modeling techniques are

discussed in the main conclusions of this report.

Elastic Demand Ratios (EDR) were calculated for each member, to determine any overstressed

areas within the buildings. The equations used to calculate the EDR are described in Section

1.4.1.5.1. The Elastic Demand Ratios are ratios of the recorded forces in each member divided

by the capacity of each member. These checks were used to correlate the overstressed areas

(ratios above unity) with the damaged areas from the Northridge earthquake. The Elastic

Demand Ratios were calculated for the load combination that actually existed in the building at

the time of the earthquake. This is the dead load of the building, with partition loads and the

maximum earthquake loads from the time history analysis. Moment and axial member capacities

8

were calculated according to the Load and Resistant Factor Design (LRFD) method [3]. The

expected yield strengths were used in the calculation of the member capacities.

The demand/plastic-moment ratios were an additional calculation performed to determine any

overstresses in the building members. The demand/plastic ratios are the maximum moments

from the combination of earthquake and gravity loads divided by the plastic moment capacity of

the element and should not be confused with the LRFD elastic demand ratios. The expected

yield strengths were used in the calculation of the member capacities.

1.4

Building Evaluation using Prevailing Practice UBC-97 and FEMA-273

All four buildings were analyzed according to UBC-97 [1] and FEMA-273 [2], to check for

compliance with current design standards. The results are used as a guide to identify the

potential for damage. The actual results will be presented later when each building is discussed

in detail.

1.4.1 UBC-97

Reference to Tables, and Equation numbers in italics correspond to those in UBC-97.

The UBC-97 design method used in this study is described in this section. The topics discussed

are the lateral forces applied to the buildings, the calculation of elastic demand ratios, the drift

limit calculations and the seismic special provisions required for structural steel moment

connections. A summary of the steps taken for the UBC-97 analysis is shown in the flow chart in

Figure 1-2.

1.4.1.1 Static Base Shear

The Design Static Base Shear was calculated for all four buildings according to Section 1630.2

formula 30-4:

V=

CV I

W,

RT

9

where I is the Importance Factor according to Table 16-K, Cv is the seismic coefficient

according to Table 16-R, R (Table 16-N) is a coefficient representing the inherent over strength

and global ductility capacity, and T is the period of the structure. The following values were used

for all four buildings.

a) An R value of 8.5 as the lateral resistance is provided from a steel moment-resisting

structural system.

b) An importance factor (I) of 1.0 because of regular occupancy

c) A seismic coefficient (Cv) of 0.77, that corresponds to a near source distance of 5 km

and a stiff soil profile SD for three of the buildings. The fourth building (Encino),

used a seismic coefficient (Cv) of 1.024, that corresponds to a near source distance of

2 km or less and a stiff soil profile SD.

d) The period calculated according to Section 1630.2.2 Item 2 Method B was used as the

period of the building (T).

In addition to the equation above, the UBC-97 set limits that this Static Design Base Shear

should not exceed. The Maximum Design Base Shear is set equal to

V=

2.5 C a I

W

R

where Ca is a seismic coefficient corresponding to a seismic factor and soil profile type SE and

V = 0.11 C a I W .

Only for buildings located at Seismic Zone 4 the Maximum Design Base Shear is set equal to

V=

0.8 Z N V I

W.

R

10

Compliance with UBC-97

Calculate Static Base Shear

Is # of Stories ≤5

and H≤

≤65 ft?

YES

YES

Is

BuildingIrr

l ?

NO

NO

NO

Is Building>

240 ft Tall?

YES

Dynamic Analysis

(Response Spectrum)

Static Analysis

Distribute Forces on

to Masses on Each

N-S and E-W

Construct Response Spectrum

Scale Response Spectrum

so that the Base Shear agrees

with the code specifications

Run Static Analysis

Perform

1. Check Drift Limits at Each

Run Dynamic Analysis

Floor Height (h)

∆M ≤ 0.2 h

∆M = 0

2. Create Elastic Force Demand

Ratios and Check ≤ 1.0

3. Check Special and Seismic

Provisions for Steel

Figure 1-2: Flowchart Showing Steps Taken for UBC-97 Analysis

11

1.4.1.2 Static Analysis

For the Tarzana and North Hollywood buildings that were less than 240 feet tall, static analysis

procedures were used and the member forces were calculated by vertically distributing the static

base shears along the height of the buildings. The vertical distribution of the static base shear

applied at each floor was calculated for the static analysis according to Section 1630.5. The

formula (30-15) is shown here:

FX =

(V − Ft ) w X h X

n

∑w

i

hi

i =1

where Ft = 0.07 T V and is applied at the roof.

1.4.1.3 Dynamic Analysis

Dynamic analysis procedures were used for the Encino and Sherman Oaks buildings. The

distribution of the earthquake loads were determined using the Response Spectrum Analysis

method. The design response spectra used for the two buildings were not the same because the

seismic coefficients (Cv) used, described in Section 1.4.1.1 Item C, were different. The design

response spectrum used for the North Hollywood, Tarzana, and Sherman Oaks buildings, is

shown in Figure 1-3 and the design response spectrum used for the Encino building in Figure 14. Both the Encino and Sherman Oaks building had weight irregularities and therefore the

response spectrum was scaled according to Section 1631.5.4 Item 3 so that the calculated base

shear was equal to 100% of the static base shear.

1.4.1.4 Static and Dynamic Analysis Load Combinations

Load combinations that take into consideration the earthquake loading were used in the static and

dynamic analysis. The equations, according to Section 1612.2.1, were:

•

1.2D+1.0E+0.5L

•

0.9D+1.0E

•

0.9D-1.0E

where D stands for Dead Load, E stands for earthquake load, and L stands for live load. The live

load used for the analyses was 50 psf, as UBC-97 requires for office buildings.

12

The earthquake loads were calculated as:

E = ρE h + E v

Where E h is the earthquake force due to the vertical distribution of the static base shear for the

static analysis or the forces from the dynamic response spectra analysis. The

reliability/redundancy factor ρ is described from Equation 30-3 in section 1630.1.1 and E v is the

load effect resulting from the vertical component of the earthquake ground motion and is equal to

0.5CaID.

All four buildings considered the effects of accidental torsion by shifting the center of mass by

5% of the dimension of the buildings for each direction, according to Section 1630.6.

1.4.1.5 Calculations of Member Demand Ratios

The Elastic Demand Ratios (EDR) were calculated to determine any overstressed areas within

each building for the load combinations mentioned earlier. Moment and axial member capacities

were calculated according to the Load and Resistant Factor Design (LRFD) methods [3]. The

specified yield strengths of steel were used in the EDR calculations. Elastic force demand ratios

were calculated according to LRFD Equations H1-1a and H1-1b and are shown here:

a) For

Pu

≥ 0.2

ϕPn

M uy

Pu 8 M u x

+

+

ϕPn 9 ϕM nx ϕM n y

≥ 1.0

13

DESIGN RESPONSE SPECTRUM

1.60

Control Periods

T S =C V /(2.5 C V )

T 0 =0.2 T S

Spectral Accelerations (g)

1.40

T0=

0.14

sec

TS=

0.70

sec

PEAK ACCELERATION

2.5 Cα=

1.20

1.10

g

1.00

Damping Ratio ξ= 0.05

0.80

0.60

0.40

0.20

0.14

0.00

0.00

0.70

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

5.50

6.00

Period (sec)

Figure 1-3: UBC-97 Design Response Spectrum (North Hollywood, Tarzana, Sherman Oaks)

DESIGN RESPONSE SPECTRUM

1.60

Control Periods

T S =C V /(2.5 C V )

T 0 =0.2 T S

Spectral Accelerations (g)

1.40

TS=

0.72

sec

T0=

0.14

sec

PEAK ACCELERATION

2.5 Cα=

1.20

1.43

g

1.00

Damping Ratio ξ= 0.05

0.80

0.60

0.40

0.20

0.00

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

Period (sec)

Figure 1-4: UBC-97 Design Response Spectrum (Encino)

14

5.00

5.50

6.00

b) For

Pu

≤ 0.2

ϕPn

M

M uy

Pu

+ ux +

2ϕPn ϕM nx ϕM n y

≥ 1.0

1.4.1.6 Check for Drift Limitations

The story drift limits were calculated according to the Section 1630.10. The maximum

experienced inter-story drift was calculated as the Maximum Inelastic Response Displacement

(∆M) for each floor, and is given in the following equation:

∆ M = 0.7 R ∆ S

where ∆S is the Design Level Response Displacement, which is the total story drift that

corresponds to the design seismic forces as described in Section 1630.2.1. The maximum

Inelastic Response Displacement can not be greater than 2% of the story height.

1.4.1.7 Check for Special Seismic Provisions

To determine if the four buildings met the special seismic provisions in UBC-97 the panel zone

thickness, the need for continuity plates, and the column-beam moment ratio checks were

investigated.

1. The required panel zone thickness was calculated according to the following formula (Chapter

22 Division IV 8.3b Formula 8-2)

t z ≥ (d z + wz ) / 90

2. The equation used to determine if continuity plates were required was calculated from the

following formula (Chapter 22 Division IV 8.5)

Rn = 6.25(t cf ) 2 Fyf and Rn = 1.8Fyf b f tbf

15

3. The Column-Beam Moment ratios were calculated from the equation shown below. One of the

following equations must be satisfied: (Chapter 22 Division IV 8.6)

∑ ( Fyc

− Puc / Ag )

∑ Z b Fyb

≥ 1.0

or

∑ ( F yc − Puc / Ag )

Vn d b H /( H − d b )

≥ 1.0

1.4.2 Evaluation Using FEMA 273

The buildings were checked for the Basic Safety Objective (BSO), as outlined in the FEMA-273.

The BSO requires the building to satisfy two criteria, Life Safety for the BSE-1 level earthquake,

and Collapse Prevention for the BSE-2 level earthquake. A non-linear static procedure was

adopted for all four buildings since the building heights exceeded 100 ft (page 2-31 guidelines).

A summary of the steps taken for the FEMA-273 analysis is shown in the flow chart in Figure 15. The development of the Response Spectrum for each earthquake, the Pushover analysis, and

the acceptance criteria is discussed in this section.

1.4.2.1 Non-linear Static Pushover Analysis

The pushover analysis requires the building to be displaced to a specified target displacement

depending on the magnitude of the earthquake for prescribed load patterns. The target

displacements are calculated from Equation 3-11 of FEMA-273.

1.4.2.2 Mathematical Model

The mathematical model used for the analysis is the best fit model or Model 3. Hinges are

applied to the beams and columns, with force deformation parameters adopted from Table 5-4 of

FEMA-273.

1.4.2.3 Lateral Load Patterns

The following load patterns were used on the buildings for the pushover analysis:

16

a) Uniform Pattern with forces distributed based on the mass at each floor

b) “A lateral load pattern proportional to the story inertia forces consistent with the story

shear distribution calculated by combination of modal responses using Response

Spectrum Analysis of the building including a sufficient number of modes to capture

90% of the total mass”

c) Force (linear) pattern used for the linear static procedure given by the equation:

FX =

w X h Xk

n

∑w h

i

V,

K

i

i =1

where:

k is between 1 and 2, depending on the fundamental period of the building

wi - hi are the floor weights – heights, and

V is the Design Base Shear

Generally FEMA-273 requires at least two of the following combinations for dynamic analysis

(the Uniform Pattern and one of the other two, depending on the building requirements) or just

Linear Distribution Pattern for static analysis. In this project, all patterns were used for a more

complete picture (expect for the Encino building -‘Chapter 5’- where pattern “c” was not used).

17

Design Risk/Performance Category

1.1

Analysis Options

a. Elastic-Static or Dynamic

b. Non-Linear Static (Pushover)

Pushover analysis was used

c. Non-Linear dynamic because Buildings were > 100 feet tall

1.1.1.1 Mathematical Model

•

Modeled Lateral Resisting System of Buildings

(Model 3)

1.1.1.3 Lateral Load Patterns Applied

1. Uniform Distribution FX =

mX

V

∑ mi

m X h Xk

2. Linear Distribution

FX =

3. Modal Distribution

Response Spectra, Modal Analysis/Forces

k

∑ mi h X

V

1.1.1.2 Push to Target Displacement

δ t = C 0 C1C 2 C3 S a (Te2 / 4π 2 ) g for BSE-1 and BSE-2

1.1.1.4 Acceptance Criteria

All Hinges must Meet BSO, Which is

Life Safety for BSE-1 and Collapse

Prevention for BSE-2

YES

NO

Building Meets Fema-273 Criteria

and no Changes to the Building is

Needed

Building Does Not Meet

FEMA-273 Criteria and Must

be Retrofitted

Figure 1-5: Flowchart Showing Steps Taken for FEMA-273 Analysis

18

1.4.2.4 Push to Target Displacement

The target displacement calculated from Equation 3-11 of FEMA-273 as:

2

T

δ t = C0C1C2C3 S a e 2 g

4π

where

C0 is the modification factor to relate spectral displacement and likely roof displacement.

C1 is the modification factor to relate expected maximum inelastic displacements to

displacements calculated for linear elastic responses.

C2 is the modification factor to represent the effect of hysteresis shape on the maximum

displacement response.

C3 is the modification factor to represent increased displacements due to second order

effects.

Sa (g) is the Response spectrum acceleration at the fundamental period and damping ratio

of the building.

The response spectra corresponding to the BSE-1 and BSE-2 level earthquakes were generated

from the corresponding spectral acceleration Sa values for each level earthquake and are shown in

Figure 1-6. The spectral acceleration is derived from the mapped short period response

acceleration parameter SS and the modified mapped response acceleration parameter at “one

second” period S1 for the given site. For the BSE-1 level earthquake, it is taken as the smaller of

the 10% probability of exceedance in 50 years (5% of Critical Damping) and two thirds of the

value for the 2% probability of exceedance in 50 years (section 2.6.1.2). In general, the BSE-1

and the BSE-2 earthquakes are typically taken as 10/50 and 2/50 year events

The Spectral Response Acceleration parameters for the Los Angeles area, for which all four

buildings were located, were taken from maps 29 and 30. The parameter values are:

19

BSE-1

SS = 1.25g , and S1 = 0.50g.

BSE-2

SS = 1.75 g, and S1 = 0.75g.

FEMA 273 guidelines require that since we had insufficient or no soil data available, Site Class

E (SE) that corresponds to soft clays should be used. The spectral response acceleration

parameters adjusted for Site Class E from Tables 2-13 and 2-14 (FEMA-273) were set to be Fa=1

and Fv=2. From these values the design short period spectral response acceleration parameter,

SXS and design spectral response acceleration parameter SX1 were calculated as

SXS = 1.17g, and SX1 = 1.0g for BSE-1 and

SXS = 1.75g, and SX1 = 1.5g for BSE-2

The period T0 of the general response spectrum curve in Figure 2-1 of FEMA-273 at an effective

damping of 5% is:

T0 = (SX1BS) / (SXSBS) = 1.0/1.17 = 0.86 seconds for BSE-1 and

T0 = (SX1BS) / (SXSBS) = 1.5/1.75 = 0.86 seconds for BSE-2

The fundamental periods of all four buildings fell in the constant velocity portion of the

spectrum. The response spectra for the site for the BSE-1 and BSE-2 level earthquakes at 5%

damping are given in Figure 1-6. The spectral acceleration Sa from Figure 1-3 is:

Sa = 1.17g, for BSE-1 and

Sa = 1.75g, for BSE-2

1.4.2.5 Acceptance Criteria

The acceptance criteria for the beams and columns assumed as fully restrained are taken

from Table 5-4 of FEMA-273. The maximum plastic rotations corresponding to the LifeSafety (LS) and Collapse Prevention (CP) requirements as well as the hinge properties are

calculated depending on the Width-Thickness ratio (b/t) of each section under the guideline

specifications.

20

Acceleration Response Spectrum for BSE-1

1.40

T0 =

S

S

X 1

BS

T0= 0.86 sec

XS

B1

0.2T0= 0.17 sec

1.20

Sa= 1.17 g

PGA= 0.47 g

Sα (g's)

1.00

Response Spectrum

0.2 T0

T0

Response at T=1 sec

S XS

Sa =

BS

3T

⋅ 0 .4 +

T0

0.80

Sa =

β = 5.0 %

S XS

Sa =

0.60

BS

S X1

B1 T

0.40

0.20

0.00

0.00

1.00

2.00

3.00

4.00

5.00

6.00

Period (sec)

Acceleration Response Spectrum for BSE-2

2.00

T0 =

1.80

T0= 0.86 sec

S

X 1

B

S

XS

B1

S

0.2T0= 0.17 sec

Sa= 1.75 g

PGA= 0.70 g

1.60

Response Spectrum

0.2 T0

T0

Response at T=1 sec

Sa =

1.40

S XS

BS

3T

⋅ 0.4 +

T0

Sα (g's)

1.20

Sa =

β = 5.0 %

1.00

Sa =

0.80

S XS

BS

S X1

B1 T

0.60

0.40

0.20

0.00

0.00

1.00

2.00

3.00

4.00

5.00

Period (sec)

Figure 1-6: FEMA 273 Design Spectra for BSE-1 and BSE-2 Earthquakes

21

6.00

1.4.2.6 Response Comparisons using Demand-Capacity Spectra Response Method

The Demand-Capacity Spectra method for seismic evaluation and retrofit of buildings as outlined

in ATC-40 and the FEMA-273 guidelines, is based on comparing the seismic demand spectrum

with the capacity spectrum of a building. The structural performance or maximum displacement

during a specific seismic event can be well approximated, as the intersection of the pushover

curve (capacity spectrum) with the inelastic demand spectra for a specified damping value,

plotted in Acceleration Displacement Response Spectrum (ADRS) format. The ADRS plot is a

representation of the spectral displacements and the corresponding spectral accelerations for a

specific damping ratio. Using modal analysis it is possible to modify this cure to give the elastic

composite spectrum that represents the BS of the building for different values of roof

displacement. Assuming an elastic structure with well-defined mode shapes (taken as mass

normalized φ Tj [M ]φ j = 1 , where T represents transposition and [M] the mass matrix), the

Maximum Base Shear (BS) can be represented in terms of Spectral Acceleration (Sa(ωj, ξj)) as:

S (ω ξ )

BS = g Γ j2 α j j

g

where:

g is the acceleration due to gravity

Γ j = φ Tj [M ][r ] is the modal participation factor and

[r ]T = {1,1,...,1}

is a unit vector.

Using the same concept the maximum roof displacement (uij) can be represented in terms of

spectral displacement (Sd(ωj, ξj)) as follows:

uij = φij Γ j S d (ω j , ξ j ).

22

Assuming that the first mode is dominant (which is true for all the structures analyzed for this

project) a single mode can be used to define the response and the equations above can be

modified as:

S (ω ξ )

BS = g Γ12 α j j and u1 j = φ1 j Γ1 S d (ω j , ξ j )

g

It is worth mentioning that ( φ1 j Γ1 ) represents the C0 coefficient as defined in FEMA 273

guidelines or the modal story participation factor (PFim) in ATC-40.

In this study, as demonstrated later, three of the four buildings behaved elastically. Thus,for

these buildings there was no need to define the inelastic demand spectrum, since it coincides

with the elastic one. For the case where inelasticity was detected, an inelastic demand spectrum

was necessary.

A rigorous procedure to define an inelastic spectrum, requires multiple time history analyses for a

variety of structures in order to obtain the maximum deformation under the already specified

ground motion. This procedure is analytically described by Reinhorn (1996). Instead, there are

other methods developed to approximate the inelastic spectra from the elastic spectra without the

requirement of the additional time history analyses. Such a method is used for this project and is

described below.

The inelastic spectra is derived from the elastic response spectra through the factor Rµ , which is

defined as

Rµ =

S AE W

Qy g

where:

S AE is the point defined by the pushover curve and the elastic demand spectrum,

W is the weight of the structure,

23

Qy is the yield Base Shear and

g is the acceleration due to gravity

This factor reduces the elastic spectral accelerations to account for the inelasticity in the

structure. The inelastic displacement spectrum can be now defined from the elastic displacement

spectrum as:

S dI =

S dE

Rµ

E

1 c

Sd

(

)

1

+

R

−

1

≥

µ

c

Rµ

where:

S dI is the inelastic spectral displacement,

S dE is the inelastic spectral displacement and

T0a

b

c=

+

is a factor suggested from Krawinkler and Nasser (1992).

a

1 + T0 T0

The factors a, b are specified in the same publication and are functions of the structural post

yielding stiffness of the building as shown in the pushover curves. T0 is the fundamental period

of the structure.

The inelastic acceleration spectrum is also defined from the elastic acceleration spectrum by

using the following equation:

E

SI

S

S aI = a 1 + a d

E

Rµ

S d

R

µ

− 1 ,

where a is the structural post yielding stiffness of the building as shown in the pushover curves.

24

2

2.1

ANALYSIS OF AN EIGHT STORY OFFICE BUILDING,

NORTH HOLLYWOOD, CALIFORNIA

Building Description

This building is an eight-story Steel Moment Resisting Frame (SMRF) office building located at

North Hollywood, California. It is rectangular in plan, with approximate dimensions 71’ X 192’.

The lateral resistance in the North-South direction comprises of four single bay moment resisting

frames along the centerline, while that in the East-West direction comprises of two bay moment

resisting frames at the North and South edges of the building. A floor plan of the lateral resisting

system as well as the column orientations is shown in Figure 2-1. The member sizes and story

heights for the moment resisting frames in the North-South and East-West directions are shown

in Figure 2-2. Beam column connections are typical pre-Northridge SMRF connections with the

beam complete penetration field welded to the column flange. The panel zones have doubler

plates welded to each side of the column web and continuity plates at the levels of the top and

bottom beam flanges. The moment frame connection detail is shown in Figure 2-3.

The structural steel used is either Grade A36 or Grade A572 (Grade 50) as specified on the

construction drawings. The floor system at all floors except the roof is composed of QL-99-20

steel deck overlaid with 3¼” lightweight concrete. The roof is a combination of a QL-99-20 steel

deck overlaid with 3¼” lightweight concrete and a TUFCOR 24 GA. metal deck with 2¼’’

zonolite.

Seismic sensors are located at the base, the fifth floor and the roof.

25

20’

19’

38’

19’

20’

19’

19’

19’

19’

N

35’ 2’’

35’ 2’’

Figure 2-1: Model Dimensions and Column Orientations.

26

7 X 12’ 6’’=87’ 6’’

17’

17’

7 X 12’ 6’’=87’ 6’’

NS Frames

EW Frame

Figure 2-2: Frame Elevation and Member Sizes.

27

Figure 2-3: Moment Frame Connection Detail

2.2

The SAP2000 Computer Models

The SAP2000 models were created as outlined in the introduction. The additional modeling

assumptions made for this building are:

The columns were assumed fixed at the base because they were supported at the foundation

by individual pile footings. The actual fixity could not be determined, because the base-plate

connection details were not available. This assumption is justified because the response of

the model with its base model showed much better comparisons with the actual recordings

than the model on which the columns were assumed to be pinned at the base.

The unit weight of the penthouse was assumed to be the same as the unit weight of the roof.

The lateral resistance between the 8th floor and the roof in the East-West direction was

provided by diagonal bracing, but the brace sizes were not available in the plans. The braces

due to modeling considerations were replaced with an equivalent 2-bay moment frame, as

seen in Figure 2-1. The relative lateral stiffness at this level was assumed proportional to the

28

stiffness of the 8th floor with proportionality constant equal to the ratio of the mass at the roof

and the 8th floor.

The splice locations were not discretely modeled and the column sections were assumed to

remain constant between two adjacent floors.

The effectiveness of the rigid zones for Model 3 was calibrated at 80% of the full rigid zone

length for the East-West direction frames, and 85% for the North-South direction frames. The

damping ratios used for the fundamental periods of Model 3 were set at 5% for the East-West

direction and 4% for the North-South direction. All higher modes were damped at 10% so that

the contribution of the high frequency response in the acceleration time histories would be

minimal. A summary of the modeling assumptions is presented in Table 2-1.

Table 2-1: Modeling Differences Between the Various Models.

Model

Rigid Zones

Analysis

Model 1

Model 2

All Elements

None

80 % EW

85% NS

Elastic 3D

Elastic 3D

Yield Stress

(ksi)

-

Elastic 3D

-

Model 3

Modal Damping

EW: 5% 1st, all others 10% damped

NS: 4% 1st, all others 10% damped

A visual representation of the three-dimensional SAP2000 model used is shown in Figure 2-4.

2.3

Mass Calculations

The loading criteria used to calculate the masses from the plans or the manufacturer

specifications are given in Table 2-2. Any contribution from the live loads was assumed to be

included in the partition loading. An additional 30-psf skin loading along the perimeter was

considered where applicable. A summary of the results is presented in Table 2-3.

29

Figure 2-4: 3D Model of the Building.

Table 2-2: Dead Loads Considered for the Mass Calculations

Story / Area

Structural Weight

(psf)

Roof Below

Penthouse Floor

47.4

Roof Area

10.4

Typical Floors

46+(8.545…13.4 )

Additional Vertical Loads

(psf)

Partition

20

Ceiling and Mechanical

5

Roofing and Insulating

6

Ceiling and Mechanical

5

Partition

20

Ceiling and Mechanical

5

30

Total

(psf)

72.39

21.4

(79.5…84.4)

Table 2-3: Center of Mass, Mass and Mass Moment of Inertia for Different Levels.

Typical Floor (2-6, avg.)

Level 7

Level 8

Roof

Mass Moment of

Inertia

(kips sec2 in)

1842490

1788245

1853151

962017

Mass

(kips sec2/in)

3.30

3.21

3.33

2.08

Center of Mass

X coord.

Y coord.

(in)

(in)

1165.5

420.24

1165.5

420.24

1165.5

420.24

1092.09

424.09

The floor plan layout showing the center of mass locations, plan openings, and perimeter line

loads is shown in Figure 2-5.

2.4

Modal Periods

The modal periods of the building for the three different models along with their mass

participation factors are given in Table 2-4. Model 3, had a fundamental period of 2.57 seconds

in the East-West and 2.19 in the North-South direction. The natural frequencies of the building

were obtained from the actual recorded responses using the transfer functions of the story

accelerations normalized by the superimposed input base motion in the frequency domain (Figure

2-6). The Mode 8 (3rd mode in the NS direction) could not be identified. A possible reason

might be the relatively high damping (see method requirements as described in the Tarzana

building). The modal periods calculated using this method matched well with the periods

obtained from the modal analysis of Model 3. The maximum difference was 7.3% on the third

mode in the East-West direction. The analytical results of this study are shown in Table 2-5.

31

4th Floor

Typical Floor

8th Floor

Roof

Figure 2-5: JAMA-SDS (MMI) calculations.

Table 2-4: Modal Periods for the Selected Computer Models.

Model

1

Model

2

Model

3

Mode

Period

1

(sec)

2.513

4

7

1

4

7

1

4

7

1.008

0.570

2.790

1.114

0.638

2.565

1.028

0.583

East-West

Modal

Cumulative Modal

Participation

Participation

Factor

Factor

(%)

(%)

76.39

76.39

12.86

5.39

75.74

12.74

5.46

76.26

12.84

5.41

89.28

94.80

75.74

88.50

94.12

76.26

89.13

94.67

32

Mode

Period

2

(sec)

2.145

5

8

2

5

8

2

5

8

0.728

0.399

2.427

0.829

0.464

2.185

0.742

0.408

North-South

Modal

Cumulative Modal

Participation

Participation

Factor

Factor

(%)

79.52

79.52

13.85

3.79

78.91

13.53

4.10

79.44

13.80

3.84

93.37

97.16

78.91

92.44

96.54

79.44

93.24

97.08

Table 2-5: Comparison of the Modal Periods for Model 3 and the Period Obtained from the

Recorded Response Using the FFT Method.

Mode

1

4

7

East-West

Modal

Modal Periods

Periods

(FFT Analysis)

(SAP2000)

(sec)

(sec)

2.565

2.6

1.028

1.039

0.583

0.540

Diff.

Mode

(%)

1.3

1.1

7.3

2

5

8

North-South

Modal

Modal Periods

Periods

(FFT Analysis)

(SAP2000)

(sec)

(sec)

2.189

2.111

0.746

0.771

0.412

Not Identified

Torsional Modes

Figure 2-6: FFT Analyses.

33

Diff.

(%)

3.6

3.2

2.5

Earthquake Ground Motions

The earthquake ground motions used in this study are the actual ground motions recorded at the

base of the building during the 1994 Northridge Earthquake. These motions include components

in the North-South, East-West and Vertical directions shown in Figure 2-7.

Acceleration Record at Level 0 (ground - 90)

Acceleration Record at Level 0 (ground - UP)

700

500

500

500

300

300

300

-100

-300

-500

2

2

100

Acceleration (cm/sec )

700

Acceleration (cm/sec )

2

Acceleration (cm/sec )

Acceleration Record at Level 0 (ground - 180)

700

100

-100

-300

-500

-700

10

20

30

40

50

60

-300

-500

-700

0

100

-100

-700

0

10

20

30

40

50

Time (sec)

Time (sec)

North-South Component

East-West Component

60

0

5

10

15

20

25

30

35

40

45

50

Time (sec)

Vertical Component

Figure 2-7: Ground Motion Components.

2.6

Time History Analyses

Linear dynamic time history analyses were performed on all the three models (see Table 2-1).

The time histories of the acceleration, velocity and displacement responses for the individual

models are presented in Figures 2-8 through 2-16.

2.6.1 Model 1 and Model 2

By comparing the time-history responses for Model 2 with the actual structural responses

(Figures 2-11 through 2-13), it is clear that this model is more flexible than the actual structure.

This is also evident by the fact that the fundamental periods calculated from the transfer function

method were 2.60 seconds for the East-West direction and 2.11 seconds for the North-South

direction, while from the modal analysis of Model 2 these values were 2.79 seconds and 2.43

seconds respectively. Thus, the assumption of no rigid zones is clearly inaccurate for this

building.

The model assuming full rigid zones (Model 1) gave much better results (Figures 2-8 through 210). There is however a sharp spike in the acceleration responses at the roof both in the NorthSouth and the East-West directions. This difference in amplitude also appears in the

34

displacement response at the roof shown in Figure 2-10, but to a much lesser degree. The

acceleration, velocity, and displacement responses also show a slight difference in the period of

vibration toward the tail end of the response. The fundamental periods from the transfer function

method compared better with those calculated from the modal analysis of Model 1, which were

2.51 seconds in the East-West direction and 2.14 seconds in the North-South direction.

Acceleration Record at Level 5 (90)

700

500

500

300

300

2

Acceleration (cm/sec )

2

Acceleration (cm/sec )

Acceleration Record at Level 5 (180)

700

100

-100

-300

100

-100

-300

Recorded History

Recorded History

-500

-500

Model 1

Model 1

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

50

60

Acceleration Record at Roof (90)

700

700

500

500

300

300

2

Acceleration (cm/sec )

2

40

Time (sec)

Acceleration Record at Roof (180)

Acceleration (cm/sec )

30

100

-100

-300

100

-100

-300

Recorded History

Recorded history

-500

-500

Model 1

Model 1

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

Time (sec)

Figure 2-8: Acceleration Records for Model 1.

35

40

50

60

Relative Velocity Record at Level 5 (90)

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec)

Relative Velocity Record at Level 5 (180)

100

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded History

-80

Model 1

Model 1

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Velocity Record at Roof (180)

Relative Velocity Record at Roof (90)

100

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec)

30

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded history

-80

Model 1

Model 1

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

40

50

60

Time (sec)

Figure 2-9: Velocity Records for Model 1.

Relative Displacement Record at Level 5 (90)

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

Relative Displacement Record at Level 5 (180)

25

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded History

-20

-20

Model 1

Model 1

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Displacement Record at Roof (180)

Relative Displacement Record at Roof (90)

25

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

30

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded history

-20

-20

Model 1

Model 1

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

Time (sec)

Figure 2-10: Displacement Records for Model 1.

36

40

50

60

Acceleration Record at Level 5 (90)

700

500

500

300

300

2

Acceleration (cm/sec )

2

Acceleration (cm/sec )

Acceleration Record at Level 5 (180)

700

100

-100

-300

100

-100

-300

Recorded History

Recorded History

-500

-500

Model 2

Model 2

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

Acceleration Record at Roof (180)

40

50

60

Acceleration Record at Roof (90)

700

700

500

500

300

300

2

Acceleration (cm/sec )

2

Acceleration (cm/sec )

30

Time (sec)

100

-100

-300

100

-100

-300

Recorded History

Recorded history

-500

-500

Model 2

Model 2

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

40

50

60

Time (sec)

Figure 2-11: Acceleration Records for Model 2.

Relative Velocity Record at Level 5 (90)

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec)

Relative Velocity Record at Level 5 (180)

100

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded History

-80

Model 2

Model 2

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Velocity Record at Roof (180)

Relative Velocity Record at Roof (90)

100

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec)

30

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded history

-80

Model 2

Model 2

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

Time (sec)

Figure 2-12: Velocity Records for Model 2.

37

40

50

60

Relative Displacement Record at Level 5 (90)

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

Relative Displacement Record at Level 5 (180)

25

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded History

-20

-20

Model 2

Model 2

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Displacement Record at Roof (180)

Relative Displacement Record at Roof (90)

25

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

30

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded history

-20

-20

Model 2

Model 2

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

40

50

60

Time (sec)

Figure 2-13: Displacement Records for Model 2.

2.6.2 Model 3

The results for the best fit model (Model 3) are shown in Figures 2-14 to 2-16. The fundamental

periods calculated from modal analysis were 2.56 seconds for the East-West direction and 2.18

seconds for the North-South direction. These periods had 1.3% and 3.6% difference respectively

from the periods calculated from the transfer function method. The time history responses also

closely match the recorded responses. Thus from the results of the time history analysis, the

building appears to have behaved elastically.

38

Acceleration Record at Level 5 (90)

700

500

500

300

300

2

Acceleration (cm/sec )

2

Acceleration (cm/sec )

Acceleration Record at Level 5 (180)

700

100

-100

-300

100

-100

-300

Recorded History

Recorded History

-500

-500

Model 3

Model 3

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

Acceleration Record at Roof (180)

40

50

60

Acceleration Record at Roof (90)

700

700

500

500

300

300

2

Acceleration (cm/sec )

2

Acceleration (cm/sec )

30

Time (sec)

100

-100

-300

100

-100

-300

Recorded History

Recorded history

-500

-500

Model 3

Model 3

-700

-700

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

40

50

60

Time (sec)

Figure 2-14: Acceleration Records for Model 3.

Relative Velocity Record at Level 5 (90)

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec )

Relative Velocity Record at Level 5 (180)

100

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded History

-80

Model 3

Model 3

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Velocity Record at Roof (180)

Relative Velocity Record at Roof (90)

100

100

80

80

60

60

40

40

Velocity (cm/sec)

Velocity (cm/sec)

30

20

0

-20

-40

20

0

-20

-40

-60

-60

Recorded History

-80

Recorded history

-80

Model 3

Model 3

-100

-100

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

Time (sec)

Figure 2-15: Velocity Records for Model 3.

39

40

50

60

Relative Displacement Record at Level 5 (90)

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

Relative Displacement Record at Level 5 (180)

25

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded History

-20

-20

Model 3

Model 3

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

40

50

60

Time (sec)

Relative Displacement Record at Roof (180)

Relative Displacement Record at Roof (90)

25

25

20

20

15

15

10

10

Displacement (cm )

Displacement (cm )

30

5

0

-5

-10

5

0

-5

-10

-15

-15

Recorded History

Recorded history

-20

-20

Model 3

Model 3

-25

-25

0

10

20

30

40

50

60

0

10

20

Time (sec)

30

40

50

60

Time (sec)

Figure 2-16: Displacement Records for Model 3.

2.6.3 Elastic Demand Ratios and Demand Capacity Ratios

The Elastic Demand Ratios (EDR) were calculated for this building using the load combination

of the time history and the dead load. The expected yield strengths for the different types of

structural steel were used. The analysis showed a number of locations where potential damage

could occur, since there were a large number of beam sections with the EDR exceeding 1 (Table

2-6). In addition, there are also yielding in several column elements (Figure 2-17).

The demand capacity ratios which is the moment demand for the load combination described

above to moment capacity based on expected yield strengths also showed a number of locations

where potential damage could have occurred.

2.7

Comparison of Actual Damage with Predicted Damage

In this building there are 92 moment resisting frame connections, 64 of which are in the NorthSouth and 28 in the East-West direction of the building. The building was inspected for damage

40

after the earthquake with 11 connections tested in the North-South direction and 6 in the EastWest direction using visual and ultrasonic examination. The inspection results showed no

detectable defects or damage caused by the earthquake. The same conclusion is drawn from the

displacement responses (Figure 2-16) where the elastic SAP2000 analysis coincides with the real

recordings.

This is however contrary to the results from the EDR and Demand/Capacity ratios. The only

logical conclusion that can be drawn at this time for this building is that the quality of the welds

was good and inelastic yielding did occur at some of the beam column connections but was

slight. The inelasticity was probably absorbed in the damping that was used, which was 5% in

the 1st mode for the East-West direction, and 4% in the 1st mode for the North-South direction.

41

Table 2-6: SAP2000 Stress Checks for Beam Elements after Time History Analysis

Element Stress Ratio

15

16

17

18

19

20

21

22

103

104

105

106

107

108

109

110

2nd Story

0.693

0.68

0.918

0.916

0.916

0.917

0.703

0.699

6th story

1.059

1.081

0.991

0.984

0.984

0.988

1.052

1.074

Demand /

Demand /

Demand /

Demand /

Element Stress Ratio

Element Stress Ratio

Element Stress Ratio

Capacity

Capacity

Capacity

Capacity

4th story

3rd story

5th story

0.72

37

0.795

0.83

59

0.836

0.88

81

1.088

1.06

0.70

38

0.788

0.83

60

0.86

0.90

82

1.107

1.08

0.94

39

0.892

0.92

61

0.723

0.75

83

0.849

0.88

0.94

40

0.889

0.92

62

0.727

0.75

84

0.844

0.88

0.94

41

0.889

0.92

63

0.727

0.75

85

0.844

0.88

0.94

42

0.89

0.92

64

0.725

0.75

86

0.847

0.88

0.73

43

0.806

0.85

65

0.807

0.84

87

1.08

1.01

0.72

44

0.804

0.84

66

0.825

0.86

88

1.098

1.04

7th story

8th story

Roof

1.04

125

1.383

1.23

147

1.55

1.37

169

0.198

0.04

1.07

126

1.391

1.25

148

1.477

1.32

170

0.198

0.04

1.03

127

1.071

1.10

149

0.796

0.82

171

0.358

0.37

1.02

128

1.061

1.09

150

0.783

0.81

172

0.348

0.36

1.02

129

1.061

1.09

151

0.783

0.81

173

0.348

0.36

1.03

130

1.066

1.10

152

0.79

0.81

174

0.353

0.36

0.99

131

1.371

1.17

153

1.543

1.32

175

0.198

0.04

1.02

132

1.378

1.19

154

1.47

1.27

176

0.198

0.04

Figure 2-17 Stress Ratios calculated from SAP2000 after time history analysis.

42

2.8

2.8.1

Evaluation with Prevailing Practice – UBC-97 and FEMA-273

Analysis Using UBC-97

In order to investigate how current methods for analysis and design meet the seismic demands,

the building was examined for compliance with the UBC-97 code. Design Static Analysis

procedures were used because the building was categorized as regular and its height was less

than 240 ft.

The Design Base Shear was calculated by the method outlined in the introduction and verified to

be within the acceptable range specified in UBC-97 as described in section 1630.2.1. The values

used for all the above parameters are reported in Table 2.7.

The distribution of the static base shear applied at each level is calculated according to the static

procedure and given in Table 2-7. These loads amplified by the appropriate redundancy factors

give the lateral earthquake forces applied to this building and are given in Table 2-7.

Table 2-7: UBC-97 Summary Table, Parameters and Forces

Site Parameters

Z

0.4

Ca

0.44

Cv

0.77

SEISMIC ZONE: 4

OCCUPANCY CATEGORY: Standard Occupancy

REGULAR STRUCTURE

BUILDING HEIGHT: 104.5 feet

BASE SHEAR VEW= 589.83 kips

BASE SHEAR VNS= 589.83 kips

I

Nv

Structural Parameters

R

8.5

TEW (sec)

1.49

TNS (sec)

1.49

1.00

W (kips)

9708.06

1.20

-- STATIC ANALYSIS -Base Shear Distribution, Earthquake Loads and Overturning Moments

applied to the structure

Lateral Loads

(kips)

Redundancy

Factors

Earthquake Forces

OTM

(kips)

(kips-feet)

FNS

FEW

ρNS

ρEW

NS

EW

NS

EW

Level

139.58

110.18

91.78

78.56

63.90

50.00

35.22

20.60

139.58

110.18

91.78

78.56

63.90

50.00

35.22

20.60

1.31

1.50

183.06

144.51

120.38

103.03

83.81

65.58

46.20

27.02

209.36

165.28

137.67

117.83

95.85

75.00

52.84

30.91

1744.70

4866.70

9135.99

14387.24

20437.24

27112.23

34227.54

44254.63

1744.70

4866.70

9135.99

14387.24

20437.24

27112.23

34227.54

44254.63

Roof

7

6

5

4

3

2

1

43

From Table 2-7, the influence of the redundancy factors in this building is evident. Although the

same base shear is distributed in both directions from the UBC-97 Static Analysis, the final

lateral distribution of the equivalent seismic forces are higher in the East-West Direction (ρ=1.5)

of the building than in the North-South Direction (ρ=1.31). It is important to note that UBC-97

suggests redundancy factors less than 1.25. Therefore, this building does not satisfy the

redundancy checks as recommended in the UBC-97.

2.8.1.1 Check for Drift Limitations

UBC-97 story drift limitations are not satisfied for any of the stories. Analytically, the results for

all stories are presented in Table 2-8.

Table 2-8: UBC-97 Summary Displacements and Drift Limit Checks.

Maximum Inelastic

Response Displacements

INTERSTORY DRIFT RATIO

∆M

(% of story height)

(in)

Level

NS

EW

Roof

7

6

5

4

3

2

1

40.75

37.18

32.35

26.81

21.12