CIBSE Hong Kong Branch 25th Anniversary

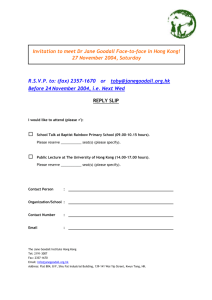

advertisement