Please pdf

advertisement

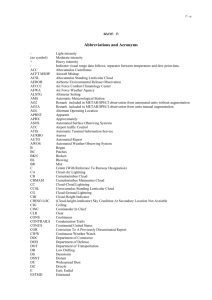

Surveying technical Surveying on a major airstrip upgrade by Clare van Zwieten, PositionIT The rehabilitation of this airstrip has included the construction of 23 000 m3 of raft foundations, the largest ever done in South Africa, in order to provide sufficient support for aircraft landing in the dolomite risk area in which the airstrip is located. A R700-million major construction project to rehabilitate an airstrip outside Pretoria is well underway (see Fig. 1). The project has been split into two phases – rehabilitation of the main runway and rehabilitation of the taxiways and other airside pavements. The airstrip currently handles mainly large transport and commercial aircraft. The upgrade of the runways, taxiways and airside facilities to meet international standards and specifications was necessary to ensure that the airstrip was capable of accommodating its planned future aircraft operations. (Future traffic will include the Airbus A380, the Airbus A400M, the Boeing 747-4002 and other large bodied heavy aircraft.) It is intended that the upgrade will allow the airstrip to continue operations for an additional 30 years [1]. The redesign of the runways and taxiways was undertaken by a joint venture consortium consisting of Ninham Shand, Africon International, Ndodana Consulting Engineers and VGI Consult. The design ensures that the airstrip meets International Civil Aviation Organisation standards, as well as the stringent guidelines regarding infrastructure provision on dolomite. Measures have been incorporated into the design to limit possible sinkhole formation and soil instabilities within the vicinity of the runway and critical taxiways. In addition to the civil upgrades the entire runway lighting system will be upgraded [1]. The runway contractor’s joint venture is made up of Mvela Phanda Construction, Protech Khuthele (incorporating South African Road Testing Services) and Gerolemou Construction. This article will focus primarily on the work allocated to Protech Khuthele and the surveying required to complete the work. Phase one of the project consists of 22 Fig. 1: Aerial view of the airstrip taken in October 2008. rehabilitation of the 3,4 km runway (3,6 km if the runoff areas are taken into consideration). This includes tie-in points for the secondary runway (to be built at a future date) that will eventually cross the main runway. Phase two of the project involves working on the taxiways serving the main runways. Phase three (still in the planning stages) will focus on the upgrading of the secondary runway and parking aprons for the aircraft. At this stage phase one is virtually complete. There are still three out of a total of six bellmouths, to build and a bit of sweeping and cleaning still to do. (A bellmouth occurs when one road ties into another road creating a radius section.) Phase two is about a month-and-a-half from completion. Surveyors Gary Freeman from South African Road Testing Services, a surveying and geotechnical company falling under the Protech Khuthele umbrella, manages the surveying on the project and handles the quantities for the job as well (see Fig. 2). Fig. 2: Gary Freeman (South Africa Road Testing Services) and Jonathan Cornes (Protech Khuthele). He is assisted by Arthur Nkoko, the only full-time surveyor on site. Equipment Model Maker and Road Maker software were used on the project. The Topcon ATG 6 automatic levels and Topcon PositionIT -Aug/Sept 2009 SURVEYING into the same survey control that the design is based on.) The South African Road Testing Services team checked and confirmed the control points and then put in additional points of their own approximately every 100 m. Dynamic compaction Fig. 3: The runway after dynamic compaction has taken place [1]. GTS-230 series total stations were used to check the tolerances. The Topcon mmGPS Machine Control System was used for the layer works. The automatic level and the total station were used in conjunction with the FC 200 Controller and Topsurv software. The mmGPS system uses Pocket 3D and 3DMC Software. Design The design was issued by the consultants. Freeman took the information off the drawings, and captured the details into Model Maker and Road Maker. In order to generate design model and quantities, details from the original ground level (OGL) are required. Freeman did an OGL as an independent check to establish whether there was a discrepancy between this and the previous OGL done for the consultants in order to identify any potential problems upfront. The survey control was handed over to the contractors by the consultants, so there was no need for the survey contractors to bring in their own control. (It is always preferable to tie Fig. 4: Rafts covered in reinforced steel. PositionIT -Aug/Sept 2009 Rehabilitation of the main runway has involved the rebuilding of the runway. The old runway had completely deteriorated to such a point that it could not simply be resurfaced – the underlying foundation layers had failed. The remains of the old runway had to be stripped off and undercut down to the stable layer. Being a dolomite area, there is a high risk of sinkholes forming so dynamic compaction was applied to the main runway and taxiways. The dynamic compaction was done by GCD, a company specialising in geotechnical work. The dynamic compaction involved using a crane to drop a 12 ton weight a distance of 12 m and letting it hit the ground. This process was done every 25 m2. The impact of the weight landing creates stress waves that cause compaction effects deep down compressing anything that has the potential to collapse and thereby enabling the identification of sinkholes. The cable used to hoist the weight, has a weakened section, so if the weight punches through into a big sinkhole, the cable will snap to prevent the weight from pulling the whole crane down into the sinkhole. Fortunately no sinkholes were discovered while conducting the dynamic compression testing on the main runway and taxiways. technical The dynamic compaction left the runway riddled with row upon row of circular indents about 3 m wide which were covered up with bulk fill when the layer works began (see Fig. 3). Specifications for a runway are generally slightly higher than those for roads. Layer works for the main runway consist of a layer of bulk fill averaging 1,2 m in depth, followed up with seven layers made up of roadbed, two layers of selected, two layers of stabilised, bitumen treated base, and asphalt. This part of the project has seen close to a million cubic metres of soil moved. Raft foundations Runways are usually built parallel to the predominant wind direction. Generally the wind tends to blow from one direction and when it changes it often blows in the opposite direction. For this reason runways are designed to allow planes to land from either end. Because of the increased pressures on landing zones and the area having a high sinkhole risk, it was decided to construct raft foundations along the impact zones on either end of the runway i.e. the first and last 500 m sections of the main runway. Raft foundations have been constructed in South Africa previously but never over an area of this size. Raft foundations are a means of increasing the bearing capacity of impact zones. They are designed to distribute the huge impact caused by landing aircraft over a wider area. This was particularly necessary due to the sinkhole risk factor. The rafts were created by cutting trenches into the soil 1 m deep leaving Fig. 5: Raft trenches filled with rainwater. 23 SURVEYING technical Fig. 6: Machine controller and grader working in conjunction with the reclaimer. a waffle pattern of 2,5 x 2,5 m squares across the two 500 m by 45 m landing zone sections of the runway (see Fig.4). There were a total of eight rafts per landing section, with each raft made up of 506 blocks. Reinforced steel was then crisscrossed and set at measured depths in the trenches as stipulated by the specifications provided by the consultants. The specifications provided details on how many steel reinforcing bars were required in each trench, their diameter, their spacing intervals and so forth. The trenches were then filled with concrete. As the work progressed the survey team had to pick up on all the surface finishing, the bottom of the trench finishing and the widths to check tolerances and overuse of concrete. There were reasonably tight tolerances on the raft foundations – width 20 mm, depth 40 mm. When checking the tolerances the survey team used Topcon ATG 6 automatic levels and the Topcon GTS-230 series total stations. Challenges Most of the work on the raft foundations took place between October 2008 and February 2009, the rainy season. The trenches flooded and the trenches sometimes collapsed due to the changing wet and dry cycles (see Fig. 5). In addition, cleaning and clearing the trenches was a difficult process as the trenches could not be accessed by hand. Clearing had to be done using poles and small scoops. It was a very labour intensive job and at one stage there were 250 people working on the raft foundations. Coordinating their activities in the rain was extremely challenging. Gary Freeman from South Africa Road Testing Services had to generate the setting out data for the raft foundations Fig. 8: Layer works at a later stage in the project. 24 Fig. 7: Processing of a cement stabilised layer. which involved a lot of painstaking, tedious work when you take into account that there were 16 rafts in total, each consisting of 506 blocks. Freeman used Model Maker software to generate all the grid points for the rafts. His site surveyor, Arthur Nkoko then had to set out these grid points. Service tunnel At km 2,2 on the runway a service tunnel was constructed to provide access to services such as communications and electricity. Once the excavation had been done, the concrete tunnel structure was assembled into position and the void was back filled and the layer works done according to the layer specifications for the rest of the runway. Layer works via machine control As the job progressed, the decision was made to acquire a Topcon Machine Control System – the first in South Africa. The mmGPS system has a Fig. 9: Plan view of the runway in Model Maker with the contours plotted and all the necessary setting out detail. PositionIT -Aug/Sept 2009 SURVEYING technical Conclusion Fig. 10: Screen control in the grader cab. 1 arc second accuracy and its ability to enable the faster cutting of levels and to work in conjunction with a reclaimer, has contributed to a faster pace on the contract, improved accuracy, increased productivity, as well as savings on diesel (see Fig. 6). Cutting layers the conventional way with a good grader operator usually results in 15 mm accuracy in contrast to the Machine Control System which provides accuracy of between 3 and 5 mm. The traditional approach to layer works would usually involve the grader stabilising 600 m3 a day, however with the Topcon Machine Control System and the reclaimer, the team is now stablising over 3000 m3 a day. A week’s output is now being accomplished in a day (see Figs. 7 and 8). Fig. 11: Base station for the Machine Control System. There is no need for the operator to get out and do any checks. If the Machine Control System had not been brought in, the surveying on this job would have been far more challenging. First, four or five surveyors would have been needed instead of one. Secondly those surveyors would have had to knock in profile poles at a grid of 10 x 10 m, which would have required additional labour, and they would have had to maintain the profile poles as well. The huge number of survey poles on site would have created restrictions for the operators who would have had to keep a constant watch out for the survey poles. All of this would have involved extra labour, material, time and cost. The main runway, which is now on average 1 m higher that the old runway, is expected to be completed by 23 September 2009 and flights are due to resume in October 2009. Further contracts planned at this air strip include the upgrade of the secondary runway, the finalisation of the runway and taxiway lighting and the construction of the new Airbus A400M facility. The new Airbus A400M facility is expected to include the construction of a new flight lane and hardstands, the construction of appropriate hangars to house eight Airbus A400M aircraft, including a maintenance hangar and wash bay, and new logistics buildings [1]. Acknowledgements I would like to thank Gary Freeman (Manager: South Africa Road Testing Services) and Jonathan Cornes (Contracts Director: Protech Khuthele) for their assistance with this article. References [1] www.af.mil.za/NEWS/2008/068.htm Contact Gary Freeman, South African Road Testing Services, Tel 083 645-5204, gary@pkh.co.za Without the system, it would have been necessary to have four or five full-time surveyors on site, whereas now it is possible to operate with just one full-time surveyor on site. Before the Machine Control System was brought in, the site was an expanse of survey poles. With the machine control, the team now only has two poles in place every 200 m and they are purely there for independent checking. In the four months that it has been in operation, the Machine Control System has paid itself off by increasing the tolerance accuracy on the layer works. For example, a 5 mm improvement on accuracy has potentially saved the contractors R1,4-million in excess use of bitumen treated base. The system is user friendly and easy to set up. The design is generated in Model Maker (see Fig. 9) and then uploaded to the Machine Control System with the GPS transmitting corrections. (A rotating laser provides coverage of 300 m from the machine and up to four lasers can be set up on the system providing distance coverage of up to 2,4 km and a vertical height of 10 m per machine.) The grader operator then points the grader in any direction and the system in the cab controls the grader blade (see Fig. 10). PositionIT -Aug/Sept 2009 25