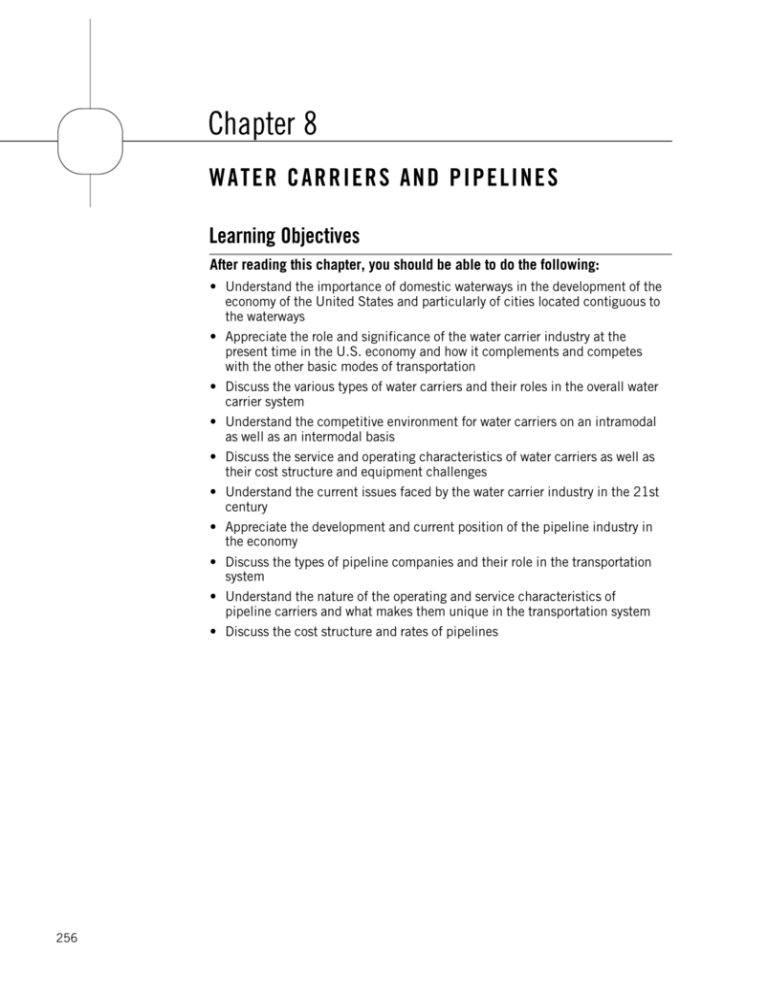

Chapter 8

advertisement