MAPUA INSTITUTE OF TECHNOLOGY School of Chemical

advertisement

AgriWaste Paper Industry

MAPUA INSTITUTE OF TECHNOLOGY

School of Chemical Engineering and Chemistry

MANUFACTURE OF BOND PAPER FROM CORN

STOVER

A Design Proposal Submitted in Partial Fulfillment of the Requirements for the Degree

of Science in Chemical Engineering

De Guzman, Andrea Mella B.

Esperanza, Jailene O.

Lomat, Rouselle Jade J.

Rescober, Elbenson P.

September 22, 2005

1

AgriWaste Paper Industry

ACKNOWLEDGEMENT

We would like to acknowledge and express our greatest indebt ness and gratitude to

the following people, whose without their support, this paper would have not been

accomplished.

To Engr. Winston Flora for entertaining our questions during consultations and for

supervising us throughout the accomplishment of this paper.

To all our families, for being our strength at times when we want to give up and for

being our inspirations to strive for the best.

To all our friends and classmates who have been very kind in lending some of their

references material.

To Manny and Winnie who have been very supportive and helpful to complete this

paper.

And most especially to the Lord Almighty for giving us the guidance and wisdom.

To all of you, we give our sincerest gratitude and love.

Andrea, Jailene, Jade, Elben

2

AgriWaste Paper Industry

Table of Contents

i

ii

INTRODUCTION

History of Pulp and Paper

Manufacturing in the Philippines

The Paper Industry Future

Paper- Uses and Applications

The Corn Production

The Corn Plant and its Type

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

1

2

3

3

4

4

5

EXECUTIVE SUMMARY

Name of the Company

Logo of the Company

Vision

Mission

Objectives of the Project

Statement of the Project

SWOT Analysis

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

7

7

7

7

7

8

8

9

MARKET STUDY

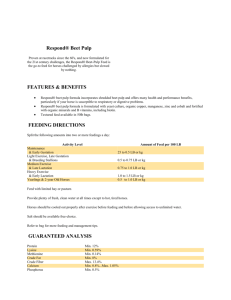

Product Description

Bond Paper

Name of the Product

Properties of the Product

Uses of the Product

Major Users of the Product

Product Distribution

Areas of Dispersion

Selling Price Analysis

Price of the Product

Target Market

Historical and Projected Demand

Analysis of Projected Demand

Market Share

Factors Affecting the Market

Marketing Plans and Programs

Marketing Strategies

Means of Transportation

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

10

10

10

10

10

11

11

11

12

12

13

13

13

15

15

17

18

18

19

TECHNICAL STUDY

Description of Raw Materials

Properties, Collection and Storage of

Corn Stovers

……………………………………………………………...

……………………………………………………………...

20

20

20

Letter of transmittal

Acknowledgement

……………………………………………………………...

3

AgriWaste Paper Industry

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

21

24

28

31

33

34

39

40

41

49

50

54

ORGANIZATIONAL AND FINANCIAL

STUDY

Organizational Chart

Job Description

Policies, Rules and Procedures

Organizational Chart

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

55

56

62

63

FINANCIAL STUDY

……………………………………………………………...

63

ENVIRONMENTAL STUDY

Wastewater Treatment Plant

Environmental Impact Assessment

Environmental Policy

Material Safety Data Sheet (MSDS) Of

Bond Paper

Recommendation

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

……………………………………………………………...

94

94

96

103

104

Chemical Requirements

Manufacturing Process

Stock Preparation

Material Balance Major Assumptions

Overall Material Balance Assumptions

Detailed Material Balance

Energy Balance

Process Flowchart

Equipment Specifications

Equipment Layout

Plant Description

Equipment Optimization

……………………………………………………………...

……………………………………………………………...

106

Appendices

LIST OF TABLES AND GRAPHS

…………………………………………

…………………………………………

…………………………………………

…………………………………………

…………………………………………

…………………………………………

…………………………………………

………………………………………….

Table 2.1 : Properties of Bond Paper

Table 2.2 : Price List of Some Market Competitors

Table 2.3 : Market Share Projection

Table 3.1 : Non-wood Plant Fiber Characteristics

Table 4.1 : Equipment Specifications

Table 4.2 : Equipment Optimization

Table 6.1 : Pre-operating Expense

4

10

12

16

21

21

41

5

63

AgriWaste Paper Industry

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

……………………………………….....

………………………………………….

Table 6.2 : Pre-operating Salaries

Table 6.3 : Interim Interest Expense

Table 6.4 : Land and Building Cost

Table 6.5 : Taxes and Licenses

Table 6.6 : Office & Laboratory Supplies

Table 6.7 : Equipment Cost

Table 6.8 : Delivery Cost

Table 6.9 : Communication Consumption

Table 7.0 : Electricity Consumption

Table 7.1 : Salaries and Wages

Table 7.2 : Packaging Cost

Table 7.3 : Repair and Maintenance

Table 7.4 : Fuel Projection

Table 7.5 : Waste Water

Table 7.6 : Solid Waste

Table 7.7 : Water Projection

Table 7.8 : Electricity Projection

Table 7.9 : Price Inventory of Raw Material

Table 8.0 : Price Inventory of Finished Goods

Table 8.1 : Total Project Cost

Table 8.2 : Cost of Sales

Table 8.3 : Marketing and Administrative Expense

Table 8.4 : Balance Sheet

Table 8.5 : Breakeven

Table 8.6 : Cash Flow

Table 8.7 : Projected Income Statement

Table 8.8 : Rate of Return

Table 8.9 : Schedule of Amortization

Table 9.0 : Payback

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

83

84

85

86

87

88

89

90

91

92

93

LIST OF FIGURES

Figure 1: Logo of the Company

Figure 2: Product Distribution

Figure 3 : Historical Demand of Bond Paper

Figure 4: Projected Demand of Bond Paper

Figure 5 : Overall Material Balance

Figure 6 : Detailed Material Balance

Figure 7 : Equipment Pictures

Figure 8 : Location Map

Figure 9 : Organizational Chart

Figure 10: GANTT Chart

Figure 11: Equipment Layout

Figure 12: Plant Layout

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

………………………………………………..

5

7

11

14

14

33

34

41

50

55

63

49

52

AgriWaste Paper Industry

INTRODUCTION

Today’s world is undoubtedly the world of industrial development. The

Philippines in order to cope up with the growing world of science and technology

has joined in the race of stability and have created industrial plants and improved

within our country not only in the industrial centers but also in the less urban areas.

The growth of industries had created a demand for technical men and women

to design, construct, and operate industrial plant.

Through the research and

development programs, new technology of using alternative raw materials that are

less expensive but highly competitive to the world market specifically to the

exportation activities have been developed.

The pulp and paper industry plays a major role in the viewpoint of mass

communication, education and industrial economic growth. The art of paper making

is centuries old. Its development closely follows the trend of economic growth and

also population growth. On the other hand, the available environmental resource

depleted each year specifically the timber resources for the paper manufacture.

Thus, through some enormous research work several papermaking techniques

using agricultural residues such as bagasse, rice husk, jute sticks, grasses, corn

stovers etc. has given a clear view in the paper mill industry and now rapidly

becoming popular to be used as source of raw materials for papermaking.

The use of agricultural residues and other waste materials which are

traditionally thrown away or burnt are presently used and studied to prevent

degradation of the natural ecosystem, to reduce the load of fresh fibers from timber

resources, and also to reduce the waste disposal.

6

AgriWaste Paper Industry

HISTORY OF PULP AND PAPER MANUFACTURING IN THE PHILIPPINES 1

Before the 1930’s the Philippines imported paper from China, Spain (15651898), and the United States (1898-1946). The country did not have the market to

justify mass production of paper and its’ vast forests were believed unsuitable for

this purpose. The rapid development of the sugar industry and the advancement of

processes for bulk production from straw and bamboo, however, changed the trend

in the 1930’s.

In 1939, the Compania General de Tabacos de Filipinas organized Compania

de Cellulosa de Filipinas. The said company built the country’s first pulp and paper

mill, a 10 tons/day bleached paper mill at Bais, Negros Oriental, based on bagasse

from a sugar mill they controlled in this area (Central Azucarera de Bais). This mill

used the Pomilio process consisting of a mild caustic cook, chlorination with

gaseous chlorine, followed by a conventional bleaching system.

It now has a

capacity of 45 tons/day of bleached writing paper.

In 1950, the government-owned National Development Corporation brought in

a paper machine (20 tons/day) to produce cement bags from imported pulp. This

machine was later transferred to the APO Cement Corporation for the same purpose

and intermittently operated for a few years but was finally shutdown. In 1948, the

San Miguel Corporation started up the first paper corrugator in the country using

imported board.

The popularity of this packaging product immersed swiftly and

created a growing demand for containerboard.

Because of the deteriorating balance of payments position, the government

was forced to institute import controls in the late 1940’s, and these continued

through the 1950’s. Such controls encouraged the establishment of a number of

small paper mills operating on imported pulp or waste paper. The first of these was

the Philippine Paper Mills, Incorporation, which started in 1951 to produce chipboard

from waste paper.

In 1960, a group of local businessmen organized the Bataan Pulp and Paper

Mills, Incorporation, to build a pulp and paper mill based on bamboo. This mill, with

1

Scale Paper Making – International Labor Office Geneva, Technical Memorandum No. 8

7

AgriWaste Paper Industry

a capacity of 75 tons/day of bleaching writing paper started up in 1962 but ran into

serious problems with the supply of raw materials.

In 1950, Bislig Bay Lumber Company, Incorporation, began to operate a

timber concession on the eastern coast of the island Mindanao, which formed the

raw materials’ base for a large-scale pulp and paper mill. Bislig was confident that

the technology could be developed to use the short-fibred Philippine mahogany in

the manufacture of paper and was particularly interested in producing Kraft

Container board for use in the corrugated carton plant of San Miguel Brewery

Incorporation.

A research program was started on the use of Philippine woods for this

purpose. In 1953 Bislig Industries started to implement this project. Bislig Industries,

Incorporation is now known as the Paper Corporation of the Philippines.

In 1973, the United Pulp and Paper Company built an integrated pulp and

paper mill in Bulacan (Luzon) to produce 30930 tons/day of Kraft pulp for cement

bags. This mill uses bagasse pulp manufactured in its own pulp mills and imports

long fiber pulp.

The pulp and paper industry of the Philippines has been badly hit by the

previous recessions. Developed countries have repeatedly dumped paper into the

country at incredibly low prices, which has severely distressed local markets.

However, it can be expected that the pulp and paper industry of the

Philippines will survive the crisis and emerge in a more efficient and stronger

financial condition. Steps are being taken to increase the reserve of raw materials

through an extensive reforestation program, and the country is expected to become

a significant factor in the pulp and paper industry in Asia.

The Paper Industry Future

Education, literacy and industrial growth spur the demand for paper products.

The development of paper industry closely follows the trend of economic growth.

Therefore, as more income is realized in the country, paper consumption and

production are anticipated to rise. Taking into consideration the annual growth of the

8

AgriWaste Paper Industry

country’s population and favorable outlook for the economy, domestic demand for

paper and paper products will be on up trend in the coming years.

Paper- Uses and Applications2

Paper represents a commodity of day to day modern life. It is well known

item which, is only media of communication through writing. It has helped the men

from past in practicing to become literate and educated. It is considered as the most

important and right medium for education. Nowadays, use of paper of different

qualities has become very important in every field of modern life i.e. offices,

education institutes, research and engineering centers, art rooms, book printings,

magazine and newspaper publishing etc.

The Corn Production3

On a worldwide basis, corn is planted on approximately 325 million acres

(132 million hectares), with a harvest of more than 450 million metric tons (17.7

billion bushels; 624 billion liters). This annual harvest is second to wheat, by a

difference of less than 10 percent.

In industry, corn is used in the manufacture of a wide range of nonfood

products. Even the cornstalk and other plant parts have industrial uses. The stock is

processed into building materials, conditioners, paper, explosives, and packing

materials.

The cobs yield furfural, a raw material used in the manufacture of

plastics, nylon, and other materials. The husks are widely used as fillers, and their

tender inner parts are boiled to sugar and then pressed and dried to make cigarette

paper.

2

3

Handbook on Pulp and Paper Industries -SIRI Board of Consultants and Engineers

Colliers Encyclopedia, Volume 7 c.1996 by P.F. Collier and Sons Limited, U.S.A. p.333

9

AgriWaste Paper Industry

The Corn Plant and its Type4

The corn plant has a jointed stalk varying in height from 2 to 20 feet (0.6-6

meters) and in diameter from one half inch to 2 inches (1.3-5 cm). At the base of

each stalk, or internode, are buds that produce lateral branches called ear shoots.

These ear shoots may develop into ears of corn. The leaf consists of the blade, the

sheath, and a collar-like ligules. The leaf blade tapers from the central midrib to the

edges and also to a point at the leaf tip.

The development of the pulp and paper industry closely follows the trend of

economic growth.

Therefore, a small income is realized in the country, paper

consumption and production are anticipated to rise. Taking into account the 2.4 %

average annual growth of the country’s population and the favorable outlook of the

economy, domestic demand for paper and paper products will be on the uptrend in

the coming years.

It is unfortunate though those because of frequent breakdown obsolete plant

equipment, domestic production has not been able to meet rising demand. It only

accounts for 6.5 % of the supply of pulp and paper were the balance is satisfied

through input. If the industry desires to reduce input dependence and conserve

scarce foreign exchange, players would have to invest in new facilities the face of

the challenge of improving product quality and cost competitiveness.

Corn varies in different types. Dent corn is the principal type grown in the

Corn Belt. Flint Corn has no dent or depression in the top of the kernel, and the

endosperm is almost all hard starch. The group is grown primarily in the Northern

United States where it is suited to the shorter growing season because of its earlier

maturity.

Popcorn is a type of flint corn with small kernels that have the property of

bursting when heat is applied. The bursting occurs because of the rapid expansion

of the starch endosperm. In the United States, popcorn is raised in Illinois, Indiana,

Iowa, Kentucky, Nebraska, and Ohio. Flour Sour has no dent in the top of the

kernel, and the endosperm is all soft starch. Because of the soft starch, the kernel

4

Colliers Encyclopedia, Volume 7 c.1996 by P.F. Collier and Sons Limited, U.S.A. p.334

10

AgriWaste Paper Industry

grinds into flour easily.

Flour corn is grown in many of the Central and South

American countries. In sweet corn the endosperm contains dextrin, a sugar-like

substance, with a lesser proportion of starch than the endosperm of other groups of

corn. The kernel may be more or less wrinkled when ripe, depending upon the

stage of maturity when harvested.

11

AgriWaste Paper Industry

EXECUTIVE SUMMARY

NAME OF THE COMPANY

AGRIWASTE PAPER INDUSTRY

AgriWaste Paper Industry is the name chosen for our company simply

because we are producing a quality bond paper product through the utilization of

agricultural waste such as corn stovers.

LOGO OF THE COMPANY

Figure 1.Logo of the Company

The circle represents our objective to become globally competitive in the

market; the corn plant symbolizes our main raw material. The color green represents

our objective to become an environment friendly industry.

VISION

The company shall be recognized as a world class manufacturer of quality

bond paper using global technology with local expertise.

It shall be known as

industry leader not only in the production of quality bond paper and other paper

products but also to the development of creative and innovative people as well.

MISSION

AgriWaste Paper Industry is fully committed to produce bond paper of high

quality and standards cheaper compared to imported bond papers, by providing the

needs of local industries and foreign and to contribute to the improvement of in the

commercial and industrial segments of the society.

12

AgriWaste Paper Industry

OBJECTVES OF THE PROJECT

This study aims to design a small-scale process of paper plant that will

manufacture, produce and sell paper product which is bond paper from agricultural

waste. The company’s project expects to achieve the following objectives:

To be known as the leading manufacturer of quality paper in the

Philippines and also in the world market by providing good quality of bond

paper at low cost to our economy.

.Aims to help in minimizing the waste produced by the agricultural

products such as corn through using the corn stovers as our main source

of pulp.

Aims to necessitate and support the increasing demand of bond paper in

local and global market.

Aims to minimize the importation of bond paper by increasing 7% of our

production every five years.

Aims to help improve the economic status of Santiago City, Isabela and its

neighboring towns and cities by providing additional employment.

STATEMENT OF THE PROJECT

The following statements represent the overall purpose of the company:

To manufacture, distribute, and sell, ready at all times to increase and

improve the production to meet the changes in market demand.

To provide significant contribution to the country’s profit income.

To satisfactory create revenue that will ensure an adequate company

growth rate.

To maintain the highest ethical standards in the conduct of the business.

To facilitate both personal and professional development of the

employees.

To be socially responsible.

13

AgriWaste Paper Industry

SWOT ANALYSIS

Strength

Production of quality bond paper at low cost / moderately priced

On time delivery

Provide employment

Utilize agri-based waste, particularly corn stovers

New breed of entrepreneurs

Customers/clients are

always

satisfied; we

exceed

customers

satisfaction

Support the government in their aim to uplift the economic situation

Weakness

Not well-verse in the field of business

(Shifts to strength is by hiring experienced people in the

business field)

Opportunities

Increasing Demand/High demand for bond paper

Welcome new investors

Open to new trend and market

Welcomes sponsoring project

Availability of a cheaper but of better quality of paper

New development/techniques and technology

Tough competition in the market

The emergence of the imported paper and thin competitive products in

Threats

the field of printing and writing

Peso devaluation – the decline or peso is a great effect in our

company’s profit and other aspects as well, since our equipment will be

imported from other countries.

(Shifts to opportunities is by maintaining good

quality of the product and having lower price that will be an advantage)

14

AgriWaste Paper Industry

MARKET STUDY

PRODUCT DESCRIPTION

Bond Paper

All types of paper are made from pulp containing fibers that form a matted or

felted sheet on a screen when moisture is removed. Nearly all paper is made up of

cellulosed fibers. The bond paper product we will be manufacturing was made from

agricultural fibers of corn stalks (stovers).

1. Name of the Product

AgriWaste Superior Bond Paper

2. Properties of the Product

The bond paper produced would be a bleached and sized paper that is

suitable for writing, printing and other graphic purposes. Some of the characteristics

of our bond paper are its good strength and durability in repeated handling, sized so

as to the prevent spreading of writing ink and render the paper more resistant to

moisture, and bleached so as to improve brightness and clarity. It has also a good

surface quality and erasability.

Table 2.1 Properties of Bond Paper Product

Substrate Type: superior bond paper

Weight

Size

Opacity

Smoothness(BEKK,

sec)

Caliper

Brightness (%,

min.)

160gsm (43lb.) Tint (Lab)

8.5” x 11”

Gloss

>90%

Environmental

Use

45-55

45-55

Storage

Conditions

(boxed)

92

15

93.5, 3.0, –7.0

n/a

15ºC–25ºC (59°F–

77°F),

30–70% RH noncondensing

10ºC–30ºC (50°F–

86°F),

10–80% RH noncondensing

AgriWaste Paper Industry

3. Uses of the Product

The use of the product is for writing, printing and other graphic purposes

which, is characterized to have a good product quality with affordable price.

4. Major Users of the Product

Schools (Private and Public)

Companies/Offices (Private and Public)

Bookstores

5. Product Distribution

The diagram represents the flow of our product distribution to our target

customers.

Process Plant

Warehouse

Marketing

Wholesaler

Bookstores

Commission Agent

Schools

( Private & Public)

Final Consumers

Figure 2.Product distribution

16

Companies/Offices

( Public & Private)

AgriWaste Paper Industry

6. Areas of Dispersion

AgriWaste Paper Industry will be located at Santiago City, Isabela. The bond

paper products will be distributed mostly in public and private companies and public

and private schools, bookstores within the area of Santiago City, and nearby towns

and cities in the Isabela province. Nearby provinces will also be of great interest.

SELLING PRICE ANALYSIS

Establishing a new business means you have to be very competitive in all

areas: quality, economically friendly and an affordable and reasonable price for the

consumer.

To decide the best price for the product, the sales team must know the

competitor’s price if the company can lower or meet the competitors pricing without

sacrificing the quality rendered to the product produce. In order for us to determine

the price of our product, we collected the price list of our major competitors if we can

meet their price.

Table 2.2 Price List of Some Market Competitors5

5

Brand Name of Our Major Competitors

Price / ream (500 pieces)

Best Buy

163. 75

St. James

190.00

Corona

225.00

Advance

200.00

Sterling

210.50

Prices are based on National Bookstores

17

AgriWaste Paper Industry

Aside from collecting our competitors’ price list, we also considered the

following aspects:

Government rules and regulations on price hike

Taxes rendered to our government

Product advertisements and promotions

Comparison of our products to our competitors

Considering the said factors, we have come up that our price per kg will be

Php37.62/kg. Our product will be competitive with the other commercialized quality

bond papers in the market today.

1. Price of the Product

The company’s bond paper production would be 6,062,654 reams per year

and increase of production every five years. The main raw material which is corn

stovers will be obtained free from the farmers but we will be paying for the labor of

collecting the corn stovers for us. The input corn stovers would be 100% and the

selling price of our product will be Php85.02/ream of bond paper.

2. Target Market

The target market of our company will be the fundamental users of our

products

which

consist

of

schools,

companies/offices,

printing/publishing

corporations and other that needs high quality and at low cost bond paper.

HISTORICAL AND PROJECTED DEMAND

AgriWaste Paper Industry will be producing bond paper for the first 10 years.

As the company celebrates its 10 years of operation, other kinds of paper such as

newsprint, onion paper and board paper will be proposed to produce. Importation of

the product will be done to meet the demand of Cagayan Valley Region consumers.

18

AgriWaste Paper Industry

From the Historical and Projected demand, almost 2% of the nationwide consumers

are from Isabela Province.

HISTORICAL DEMAND

Thousands

DEMAND(MT/Year)

900

800

700

600

500

400

300

200

100

1995

1996

1997

1998

1999

2000

2001

2002

2003

Year

Figure 3. Historical Demand of Bond Paper

D em and

(M illion R eam s)

PROJECTED DEMAND

700

600

500

400

300

200

100

0

2006

2008

2010

2012

Year

Figure 4. Projected Demand of Bond Paper

19

2014

2016

2004

AgriWaste Paper Industry

Analysis of Projected Demand

Based on the data gathered, there is an existing demand for bond paper.

Using the population (see Appendix A) growth rate, an optimistic projected demand

should be expected. Supply is based mainly on local production, which shows a

very healthy pattern of growth in the consumption.

The graph shows a steady increase of projected demand within ten years.

The positive outlook of the graphical projections can be justified by the influence of

the general economic progress of the country, degree of personal disposable

income, population growth, and price competitiveness of accessible paper as

compared to international standards. With the annual increase in demand, there is a

need to step up production to satisfy consumers.

Technical Feasibility

The working process is continuous due to the demand of paper in the

Philippines. The operation will be 24 hours a day and seven times a week. To

ensure the correct implementation of the plant procedure, the company will employ

highly qualified personnel and research workers.

MARKET SHARE

The assumed market share of AgriWaste Paper Industry, as a pioneer of corn

stover bond paper, will be 1.6% of the total Philippine bond paper market in 2007.

After five years of continuous supply, the company will increase its production by 7%

of the year 2011 and another 7% in the year 2016 total bond paper demand

20

AgriWaste Paper Industry

Table 2.3 Market Share Projection

MARKET SHARE

Sales

Year

Population

Phil. (ages

4-69)

Consumption

(pcs

paper/personyear)

Demand

(pcs/

person/year)

Demand

(MT /

Year)

(MT/Year)

2007

75179054

2555

192082481809

868,213

12,559.35

0.0145

2008

76656012

2555

195856109499

885,270

13,701.11

0.0155

2009

78132970

2555

199629737189

902,326

13,701.11

0.0152

2010

79609928

2555

203403364879

919,383

13,701.11

0.0149

2011

81086886

2555

207176992569

936,440

14,660.19

0.0157

2012

82563844

2555

210950620259

953,497

14,660.19

0.0154

2013

84040802

2555

214724247949

970,554

14,660.19

0.0151

2014

85517760

2555

218497875639

987,610

14,660.19

0.0148

2015

86994718

2555

222271503329

1,004,667

14,660.19

0.0146

2016

88471676

2555

226045131019

1,021,724

15,619.27

0.0153

Sources of population: National Statistics Office (NSO)

21

Market

Share

AgriWaste Paper Industry

FACTORS AFFECTING THE MARKET

The following factors may affect the industry market:

Population Growth

The increase in population greatly affects the market of bond paper since the

demand greatly follows the trend of the increasing population. Therefore, there

would be a greater demand for our bond paper products which means there would

be also a step up in our production.

Improved Technology

The significant technological improvements such as the use of electronic

mails in the business transactions of the companies/offices can decline the

demand of bond paper.

On the other hand, with the knowledge on advancement in the technology we

can also improve our company’s process/production which can help us to produce

a better quality and more products to produce.

Emergence of New Competitors

The emergence of new competitors can affect the market of the product since

people have the tendency to compare our bond paper product produced with our

competitors in the market. To ensure the customers trusts, we will produce the

best quality bond paper at lower costs and also establish an effective quality

management system and environmental management systems.

High Costs of Fuel and Energy

Among of the largest cost components in papermaking are its electrical

energy and fuel energy.

On the average, they constitute about 25-30% total

production costs for local paper manufacturer.

Protecting the Industry

Protection for domestic pulp and paper industry are either direct or indirect.

Imported Machineries and Spare Parts

Taxes and duties of machinery, equipment and spare parts not produced

locally should be kept at minimum levels.

22

AgriWaste Paper Industry

MARKETING PLANS AND PROGRAMS

The following marketing plans will guide our company all throughout the

operation:

Selection of major market or product areas for growth and profit

improvement.

Evaluation of market and competitive situation in each selected areas.

Establishments of goals for each area selected.

Determination of the possible strategies to achieve goals.

Implementation of strategies to achieve through plans that conclude

specific programs, completion dates and responsibility assignments.

Aggressive goal centered leadership plan measurements and control

of progress to achieve goal.

Plans to expand its operation by producing book paper in next 15th

year of operation.

MARKETING STRATEGIES

The following strategies will be done to be able to become competitive to the

market:

Product Launching

The product will be launched in the Isabela province which will be developed

by prominent people whose expertise in paper producing technology is of top

caliber.

Conduction of Seminars

Seminars with respect to the bond paper products will be conducted. The

seminar will focus on the Pros and Cons of our products as well as the company

performance.

It also includes some seminars for educational purposes of the

employees.

23

AgriWaste Paper Industry

Distribution of Leaflets and Brochures

Leaflets and brochures will be distributed to large and small users of the

product to ensure knowledge with regards to the quality and price of our product and

also to be able to promote and at the same time advertise our product.

Implementing Bulk Promotion

The company will implement a bulk promotion for our customers. They will be

entitled with great discounts if they will order in large quantities.

Direct Selling Approach

The direct selling of our product will be done through personally meeting the

clients in their respective offices and ask them if possible they will allow us to test

the quality of our product and if they will be satisfied, purchasing will be possible.

Internet Address

Information regarding our product will be available though our website.

MEANS OF TRANSPORTATION

Large Trucks (6-wheeler trucks) are the ones that we will be using to collect

corn stovers in the farm. Our company will be having its own trucks for such activity.

However, if in any case our trucks will not be available (due to motor failure, flat

tires), we plan to contract trucking establishment so that the activity will not be

cancelled or delayed.

For delivering our finished product (bond paper), the company will have

smaller trucks called Isuzu-elf. The main reason for having an “elf truck” is for the

accessibility of passing the narrow roads.

Also in several places in our target

provinces, market places (where dry and wet goods are sold) are not accessible by

huge trucks. Thus, we have to use elf to reach our prospective buyers.

In transporting the bond paper to our valued client is dependent of the

location or site of our target customers. The company will deliver the product within

one week after the placement of order by the customers. In case of exportation, the

product is transported through ships contacted by the company.

24

AgriWaste Paper Industry

TECHNICAL STUDY

DESCRIPTION OF RAW MATERIALS

The production of paper is for most part concentrated in areas that have

abundant supply of fibrous raw materials especially wood but in our case agricultural

waste such as corn stalks (stovers) would be in abundant.

A. Properties, Collection and Storage of Corn Stovers

Corn stalks (stovers), like straws, would probably be harvested in a time

frame consistent with the harvest of the grain, depending on specific harvesting

methods. The harvest of corn is usually twice a year but other provinces can raise

corn all year round.

During rainy season months of July to September the

production supply is minimal. Thus, during its peak harvesting months of summer,

collection of corn stovers must be made so that the amount of raw needed is met.

The storage room must be kept clean and the management must keep

the cleanliness of the area, avoiding personnel smoking around the premises

because it is fire friendly and also to avoid cases such as fire burning.

The bulk density of corn stovers is 0.7216. The theoretical ultimate strength of

primary valence chains of cellulose is calculated as 800 to 2260 kg/mm2, however

the ideal values approaches 100 kg/mm2. Thus, it is just appropriate to estimate that

we can stock corn stovers for as high as 20 meters in height and as many as 2000

cubic meters in volume is acceptable.

Corn stalks (stovers) cellulose content (35-45%5) ranges significantly

depending on variety and regional conditions and a pulp yields of 30-40%.7

6

7

Bulk density is http.www.denscs.com/cornstalk.com

Rymsza, Thomas A., “Agricultural Residues in Pulp and Paper Discussion Paper”

25

AgriWaste Paper Industry

Table 3.1 Non-wood Plant Fiber Characteristics8

Fiber Source

Fiber dimensions of various non-woods

Length (microns)

Diameter (microns)

Max

Min

Ave

Max

Min

Ave

Corn Stalks (Stovers)

2800

680

1260

20

10

16

L/D

Ratio

8:01

B. Chemical Requirements

1. Powdered alum

Alum is the common name for aluminum sulphate. Technically, the term

should be restricted to one of the double salts of aluminum sulphate and alkali

sulphate, such as potassium aluminum sulphate, K2SO4Al2(SO4)324H2O, which

originally was used in paper making because it was the purest form of alum. Alum is

soluble in water and is generally used in solutions containing from 2 to 3.5 lb. per

gal. The iron-free alum is use for the best grades of paper.9

Alum is usually added to correct the pH value. It is added to the paper stock

in order to increase its acidity to approximately pH 5. It is essential additive for good

refining adequate sizing, or rosin dispersion. It is also affects press performance by

reducing the tendency of paper to adhere to the top press roll.

It is commonly supplied in solid block form, but should be dissolved in water

and used in liquid form at a constant density. This chemical is also used for water

treatment in order to induce flocculation. Average consumption is 5 to 8 percent by

weight of the final product (bond paper).10

8

Hurter, Robert W., “Agricultural Residues”, TAPPI 1997 Non-wood Fibers Short Course &

Hurter, A.M., “Utilization of Annual Plants and Agricultural Residues for the Production of Pulp and

Paper”, Non-wood Plant Fiber Pulping Progress Report #19, TAPPI Press, pp. 49-70

9

http://www.perigee.net/~jrjohns/aluma.html

10

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

26

AgriWaste Paper Industry

2. Rosin

Rosin is water-repellent substance obtained from the gum (oleoresin) of the

southern pine, chiefly from the long leaf species. It is available in solid form and it

must be brought to a liquid emulsion before use. When it is distilled from the gum

that exudes from the living tree, it is called gum resin. However, when it is extracted

from the pine-stump wood or other resinous wood by the steam and solvent process

it is known as wood rosin.11

Rosin has a very low melting point and it is good sizing agent; contains 90%

resin acid (abietic acid) and 10% neutral material. It is also susceptible to chemical

or physical treatment that will make it readily soluble or mixable in water. It improves

printing or writing properties by controlling ink penetration.

The average

consumption is proportional to the consumption of alum.12

3. Sodium Hydroxide (Caustic Soda)

It is used in the manufacture of many organic and inorganic compounds, also

in soap making, paper making, rayon, detergents; in refining petroleum and

vegetable oils; and in reclaiming rubber. NaOH is prepared by the electrolysis of

aqueous NaCl and KCl solutions and it is a strong base and very soluble in water.13

Sodium Hydroxide is extensively used as a cooking chemical in paper mills. It

is available in solid form and also in liquid form at 50% concentration. The amount

of sodium hydroxide varies according to raw materials used.

For cotton linters,

jutes, etc. caustic soda is used around 5% of the total raw materials and for rice

straw and bagasse around 12 to 14%.ε

11

http://www.wikipedia.com.wiki/rosin

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

13

http://encyclopedia.thefreedictionary.com/Sodium+hydroxide

ε

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

12

27

AgriWaste Paper Industry

4. Sodium Hypochlorite

Sodium Hypochlorite is the preferred method of shock treatment because it is

readily soluble and rapidly increases the free chlorine content of the water. Just as

importantly the chlorine level drops quickly, especially in strong sunlight, to a level in

which bathers can return into the water.

Sodium Hypochlorite is ideal for shock dosing as it is a strong oxidizing agent.

This enables it to destroy combined chlorines, the source of irritation and odor

complaints. Sodium Hypochlorite contains 65% available chlorine.14

Sodium Hypochlorite is usually used as a bleaching agent in paper pants. The

purpose of sodium hypochlorite in bleaching the pulp is to convert the lignin in the

pulp to compounds that are soluble in water or alkali. It is used to obtain better color

stability and to reduce the viscosity of the cellulose for the case of dissolving pulp.15

5. Starch

Starch is used to improve the quality of writing and printing papers or the

stiffness of water-based corrugating medium. It is most effectively applied, in liquid

form at about 30 to 40 % concentration, to the surface of the paper through a size

press. More often starch can also be used in a less effective manner as an additive

to paper stock. It is also added to give firmness, stiffness, and strength particularly

to the surface of the sheet.16

Starch must be cooked and prepared in liquid form before use. Ready prepared starch is available and used extensively in developed countries but is not

likely to be used by the small mill in developing countries.

Starch requirement ranges from 3 to 12 percent by weight of paper,

depending on the quality to be achieved. 17

6. Talc

14

http://encyclopedia.thefreedictionary.com/Sodium+Hypochlorite

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

16

http://www.lsbu.ac.uk/water/hysta.html

17

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

15

28

AgriWaste Paper Industry

Talc is hydrated magnesium silicate. It serves as a substitute for clay in

similar proportions. It improves the opacity, brightness, and finish of writing and

printing papers. The amount required ranges from 10 to 15% by weight of the

paper.18

MANUFACTURING PROCESS

Paper is a sheet of interlaced fibers – usually cellulose fibers from plants that

are formed by pulping the fibers and causing them to felt, to mat, to form a solid

surface. Paper is said to be of high quality when the pulp used is of good quality

composed primarily of cellulose fibers.

Papermaking is a continuous process, an unbroken line of production that

begins with wood or non-wood fibers (such as of corn stovers) and ends with the cut

sheet of paper.

The lignin, the material that holds corn stovers cells is dissolved, and the

cellulose fibers are to be separated primarily because it is very complex and causes

color reaction with age. Chemical process is usually done in the pulping process

which was used to remove the lignin content of the non-wood fibers, and the

chemical solution consists of caustic soda is digested through a digester. Cooking

time may be as long as 2 to 3 hours depending on the recovery potential of the raw

material and the pulp characteristics. Therefore, we can say that pulping is the most

meticulous process in papermaking because it is the primary component of our

product – paper. If chemical pulping stages are wrong, the manufacturer will not be

able to produce quality paper products. Thus, we will concentrate primarily on the

chemical pulping processing stage.

FIBER PREPARATION

18

Handbook on Pulp and Paper Industries-SIRI Board of Consultants and Engineers

29

AgriWaste Paper Industry

Corn Stover Preparation

From the warehouse house, the corn stovers will be transported using forklift

and then be loaded manually into the mouth of the shedder and shredded to a

uniform length and transferred to though belt conveyor in the duster to be dusted

before loading into the digester. The removal of dust is record in order to ensure

good pulp quality; dust losses of around 0.3 % will be expected. The stovers will be

cut into pieces for 20 to 30 mm. long in order to facilitate the flowing of the chopped,

dusted stovers will then be transferred to the digester through an elevated belt

conveyor.

PULPING STAGE

Digestion

In the digestion process, it consists of cooking the prepared material in the

presence of sodium hydroxide (caustic soda) to isolate the cellulose fiber from the

lignin and other constituents of the corn stovers without causing much damage to

the fibers. Lignin acts as the binding materials and non-fibrous in character and

therefore must be eliminated in the process. Various pulping chemicals are used to

dissolve the lignin selectively and separate the fibers. In chemical pulping, the lignin

and other impurities are removed.

The materials in the continuous digester are screw-propelled through the

cooking zone because stringy vegetable materials do not flow naturally and

mechanical propulsion is therefore required to ensure constant feed.19

The process begins when the prepared corn stovers are loaded into the

digester through conveyors. The cooking of corn stovers chips is carried out at

temperatures of 170 degree Celsius and 0.4 MPa in the digester at 12% caustic

19

J. Newell Stephenson, “Pulp and Paper Manufacture, Volume 2”, c.1951, Joint Executive

Committee of Vocational Education Committees of the Pulp and Paper Industries, USA, 1951.

30

AgriWaste Paper Industry

soda solution (white liquor)20. A boiler is used to supply steam for the digester. The

proportion of caustic soda solution to pulp will be 1:4. Caustic soda consumption for

corn stovers pulping amounted to 12 percent by weight of bone-dry stovers input.

During the cooking process, the lignin and some hemi-cellulose molecules of the

corn stovers are break into smaller ones. After sometime, the lignin and hemicellulose contents have been removed. The charging liquor which is made up from

the caustic solution, some returned spent cooking liquor (termed “black” liquor”) and

hot water. The white liquor turned to black due to the dissolved impurities.

Blow tank

After cooking, the content of the digester is discharged through a valve at the

bottom of the digester. The pulp is transported through pipes using pumps, next,

transferred into the towering blow tank. The stock enters tangentially at such high

speed that it hugs the wall of the separator while the steam escapes to the center

and out through the ventilator. The pulp softened by the cooking process smashed

to the walls of the blow tank.

On blowing the charge the sudden release of pressure causes violent

evolution of steam from the moisture in the chips, and this, together with the

mechanical action of passing through the pipe, causes complete disintegration into

the fibrous state. The separator is usually placed at an elevation higher than the top

of the digesters and the stock therefore drops by gravity to the washing equipment.

At this point it contains the fiber, all the alkali originally added, the organic matter

dissolved during the cook, and a large amount of water, both from the liquor added

and from condensed steam.

20

J. Newell Stephenson, “Preparation and treatment of Wood Pulp”, Mc Graw Hill Book Company

Inc., New York, 1950.

31

AgriWaste Paper Industry

Washing

From the blow tank, the pulp and accompanying black liquor is usually

coarse-screened in order to remove uncooked particles (or shives), which should not

exceed 5 percent of the mixture. The rejects can be either returned to the digester

for further cooking or mechanically processed to an acceptable condition by

“refining”.

However, for mills of very small capacity the quantity of rejects is

insufficient to justify investments in a refiner. In order to obtain good quality pulp, a

three stage, counter-flow washing is used.

This procedure should also reduce

chemical losses if the mill is equipped with a chemical recovery unit.

Washers are open surface cylinders, covered with a wire mesh and rotating in

vats. The unwashed pulp is fed to the vat and picked up by the cylinder. The liquor

is drained away through the surface wire-mesh. The black liquor drained from the

first washer contains all the non-cellulose matter and chemical residues removed

from the pulp. It is passed to a filtrate tank for disposal or chemical recovery except

for a fraction, which is used for the making of the cooking liquor supplied to the

digester.

Washers can be either very simple and inexpensive or somewhat complicated

and costly but more effective. The most satisfactory units operate under vacuum and

require a special construction. Drainage is, in this case, improved and the on-going

pulp contains less chemical or organic impurities. Washers used in small mills can

be elevated in order to achieve the vacuum required barometrically. This procedure

reduces capital costs and power consumption.

Washing is necessary to prevent undesirable matter goes forward with the

pulp and adversely affects the bleaching quality and, ultimately, the quality of the

paper produced.

32

AgriWaste Paper Industry

Screening

The consistency of pulp leaving the washers varies, depending on the

effectiveness of the washer. The next stage is screening in order to remove particles

unsuitable for the paper process.

Also, the extra water was removed before the

bleaching process proceeds to ensure that the available chlorine in sodium

hypochlorite will immediately used in the pulp.

There are several types of screens suitable for small mills. However, the best

types are fully enclosed pressurized or centrifugal screens. After screening, the pulp

is ready for the bleaching process.

STOCK PREPARATION

Stock is treated in a beater or a refiner to give it desired characteristics for

paper formation. In a common type of beater, the fibers are mixed and pounded

between a large metal drum and a bed plate along the bottom of the beater. Beating

shortens the fibers and causes them to swell and fibrillate (fray along the sides and

at the ends). Beaten fibers form a tighter bond, and therefore a stronger paper, than

fibers that have not been beaten.

Bleaching

Bleaching is normally carried out on a three-stage basis. However, very small

mills may operate with a single-stage bleaching only. The bleaching process

removes the residual non-cellulose material from the pulp since it cannot be

removed by cooking without a lowering of both pulp quality and yield. Chemical

grade pulp contains 3-5% lignin. The residual lignin and other matters left on the

fibers caused the dark color of the pulp. This pulp could not be used immediately as

to produce a white grade paper product. Thus, a bleaching process must be carried

out to whiten the pulp.

Care must be observed so as to prevent the cellulose

degradation. Sodium hypochlorite will be used as bleaching chemical.

33

AgriWaste Paper Industry

Refining

The refiner is designed to fibrillate the cellulose fibers. Paper that has

been made from refined pulp has a greater resistance to tearing and bursting than

that from unrefined pulp.

In this process, the addition of various additives such as rosin, alum,

starch and talc are performed. The sizing of paper (prevention of ink penetration) is

accomplished by adding rosin and alum. The talc is also added to improve the

quality of paper in terms of opacity, brightness and finish of the sheet. Starch is

added to give firmness, stiffness, and strength particularly to the surface of the

sheet.

Paper Machine

This huge machine is fed the stock, which is about 99 % water, and

produces a finished roll paper. The most widely used machine is the Fourdrinier

machine after the two brothers who perfected it. The stock is pumped into the first

part of the machine, the head box. Here the stock is given a final mixing, and

turbulence is removed so that the flow into the rest of the machine is smooth and

even. The stock leaves the head box through the slice, an unjustable nozzle that

controls the flow of stock onto a wire mesh.

The wire mesh, sometimes called the Fourdrinier wire, is the mold for

forming a continuous sheet of paper, or web. The wire is an endless belt that acts as

conveyor belt. As stock is put on one end, the wire moves along and shakes to

interlace, or felt the fibers. Water drains out through the opening of the mesh. As it

approaches or reaches the end of the wire, the web may pass under a roller which

compact the fibers. From the wire, the web of paper, which is about 80% water, is

carried to press section of the machine. From presser, paper is transferred to the

dryer, a series of metal rollers.

34

AgriWaste Paper Industry

Packaging

The last stage in papermaking is creating a sheet size by means of paper

cutters. The dried huge sheet of papers will be passed through the paper cutter for

the desired bond paper size of 8.5” x 11”.

35

AgriWaste Paper Industry

MATERIAL BALANCE MAJOR ASSUMPTIONS

Duster

Dust removed – 0.3% of pulp fed

Mixer1

NaOH – 12% solution

4 tons- of pulp

ton of NaOH solution

Digester

Corn Stover composition:

• lignin (35%)

• cellulose (65%)

Washer1

Water added – 70% of the pulp fed

Black Liquor composition

• All NaOH fed

• 35% of Corn Stover fed

• 67% of total Water fed

Screens

Water removed - 75% of total Water Input

Bleacher

1 ton NaOCl solution

100 tons pulp

NaOCl solution Bleaching Agent (15% NaOCl, 85% Inert)

Washer2

Water Added – 70% of pulp fed

Water removed = 5% pulp, all NaOCl solution, 70% total H2O (wastes)

36

AgriWaste Paper Industry

Refiner

Alum – 10% of pulp fed

Rosin – 10% of pulp fed

Mixer2

8 tons of pulp

Talc =

1 tons talc

Starch – 12% of pulp fed

Fourdrinnier Machine

Water evaporated from the wet pulp – 94.5 % water fed

Packaging

Waste Paper – 2% paper fed

37

AgriWaste Paper Industry

OVERALL MATERIAL BALANCE

Figure 5. Overall Material Balance

38

AgriWaste Paper Industry

DETAILED MATERIAL BALANCE

Basis: 39.76 MT/day

39

AgriWaste Paper Industry

40

AgriWaste Paper Industry

SCREEN

INPUT = 52.32 MT

MT

%

Wet Pulp

52.32

100

OUTPUT = 32.52 MT

MT

%

Pulp

32.52

100

OUTPUT = 19.80

MT

%

Waste Water 19.80 100

41

AgriWaste Paper Industry

42

AgriWaste Paper Industry

43

AgriWaste Paper Industry

ENERGY BALANCE

Q = mCp∆T = m(Hv – Hl)

Digester

mcorn stover Cpcorn stover ∆T + mwater CpH20 ∆T + mNaOH CpNaOH ∆T

msteam =

(Hv – Hl)

msteam =

{(39.88 MT)(1.33978)kJ/mole-K(170-25)K + (8.77 MT)(4.16868) kJ/moleK (170-25)K + (1.20MT)(.00451402) kJ/mole-K (170-25)K}

(2793.3-104.89)kJ/mole

msteam =

4.87 MT

Fourdrinnier Machine

mcorn stover Cpcorn stover ∆T + mwater CpH20 ∆T

msteam =

(Hv – Hl)

{(24.63MT)(1.33978) kJ/mole-K (170-25)K+(55.01MT)(4.1868 kJ/moleK)(170-25)K+2260.872)}

(2793.3-104.89)kJ/mole

msteam =

msteam =

60.47 MT

Boiler (Diesel)

mcorn stover Cpcorn stover ∆T + mwater CpH∆T

mDiesel =

mDiesel =

mDiesel =

(Hv – Hl)/heating valueDiesel

{(24.63MT)(1.33978) kJ/mole-K (170-25)K+(55.01MT)(4.1868 kJ/moleK)(170-25)K+2260.872)}

(2793.3-104.89)kJ/mole/(46000)

2.65 MT

44

AgriWaste Paper Industry

PROCESS FLOWCHART

45

AgriWaste Paper Industry

EQUIPMENT SPECIFICATIONS

Hours per day

Percent full

24.000

0.650

Shredder

feed (MT)

density(MT/m3)

feed (MT/hour)

feed volume (m3)

corn stovers

input

40.000

1.560

1.667

1.068

total

40.000

1.068

volume of equipment

1.644

Quantity

Capacity

Height

Length

Width

Power Requirement

Dimensions

pc/s

m3

m

m

m

kW

1.000

1.644

1.677

1.400

0.700

1.119

Material of Construction:

•

•

•

Low alloy cast Grid Lock, Lower Grid Bars & Lower Breaker Bar

Low alloy cast Top Discharge Grid (incorporating variable

faceplate)

Stainless steel blade and body

Duster

feed (MT)

density(MT/m3)

feed (MT/hour)

feed volume (m3)

corn stovers

input

40.000

1.560

1.667

1.068

total

40.000

1.068

volume of equipment

1.644

Dimensions

Quantity

1.000

pc/s

Capacity

1.644

m3

Height

1.667

m

Length

1.400

m

Width

0.700

m

Power Requirement

1.119

kW

Material of Construction:

•

Stainless steel construction in compact design with trough type

trays

46

AgriWaste Paper Industry

input

NaOH

water

total

volume of equipment

feed (MT)

1.196

8.774

9.970

Mixer1

density(MT/m3)

1.040

1.000

Quantity

Capacity

Height

Diameter

Power requirement

1.000

0.636

1.480

0.740

0.559

feed (MT/hour)

0.050

0.366

feed volume (m3)

0.048

0.366

0.413

0.636

Dimensions

pc/s

m3

M

M

kW

Material of Construction:

designed as a compact, water pressure-tight unit including

propeller and integrally cast installation bracket for the

attachment on the square guide tube

•

Motor housing and propeller made

stainless steel

•

Digester

input

feed (MT)

density(MT/m3)

feed (MT/hour)

feed volume (m3)

corn stovers

39.880

1.560

1.662

1.065

caustic soda

1.196

1.040

0.050

0.048

water

8.774

1.000

0.366

0.366

total

49.850

1.479

volume of equipment

2.275

Dimensions

Quantity

3.000

pc/s

Capacity

2.275

m3

Height

2.263

m

Diameter

1.131

m

Material of Construction:

•

Incoloy alloy 800 is used, must have high strength and resist

oxidation, carburization, and other harmful effects of hightemperature exposure.

47

AgriWaste Paper Industry

Boiler

feed (MT)

density(MT/m3)

feed (MT/hour)

feed volume (m3)

water

input

65.333

1.000

2.722

2.722

total

65.333

2.722

volume of equipment

4.188

Dimensions

Quantity

1.000

pc/s

Capacity

4.188

m3

Height

2.773

m

Diameter

1.414

m

Material of Construction:

•

Novel steel construction solid-fuel firing boiler for civil

heating applications comprises a space portion defined by

side, bottom, cover, front and rear walls forming therein

an interspace for water to be heated

Blow Tank

input

pulp

feed (MT)

49.850

total

49.850

density(MT/m3)

0.720

feed (MT/hour)

2.077

2.885

volume of equipment

4.438

Dimensions

Quantity

1.000

pc/s

Capacity

4.438

m3

Height

2.287

m

Diameter

1.352

m

Material of Construction:

•

feed volume (m3)

2.885

Solid stainless steel

48

AgriWaste Paper Industry

Washers 1

pulp

input

feed (MT)

49.850

density(MT/m3)

0.720

feed (MT/hour)

2.077

feed volume (m3)

2.885

water

71.214

1.000

2.967

2.967

total

121.064

5.852

volume of equipment

9.003

Dimensions

Quantity

1.000

pc/s

Capacity

9.003

m3

Height

1.470

m

Length

3.500

m

Width

1.750

m

Power Requirement

2.24

kW

Material of Construction:

•

Stainless Steel with plastic segments

Screens

feed (MT)

density(MT/m3)

feed (MT/hour)

feed volume (m3)

pulp

input

25.922

0.720

1.080

1.500

water

26.696

1.000

1.100

1.100

total

52.318

2.600

volume of equipment

4.000

Dimensions

Quantity

1.000

pc/s

Capacity

4.000

m3

Height

1.280

m

Length

2.500

m

Width

1.250

m

Power Requirement

0.746

kW

Material of Construction:

•

Stainless steel construction and four blade hydrofoil spider

49

AgriWaste Paper Industry

input

pulp

sodium hypochlorite sol'n

total

volume of equipment

feed (MT)

32.521

1.987

34.508

Bleacher

density(MT/m3)

0.720

1.097

feed (MT/hour)

1.355

1.097

feed volume (m3)

1.882

0.075

1.957

3.012

Dimensions

Quantity

1.000

pc/s

Capacity

3.012

m3

Height

2.485

m

Diameter

1.242

m

Power Requirement

1.119

kW

Material of Construction:

•

Stainless steel

input

pulp

sodium hypochlorite soln

water

total

volume of equipment

feed (MT)

34.508

49.298

0.000

83.806

Washer 2

density(MT/m3)

0.720

1.097

1.000

Dimensions

Quantity

1.000

pc/s

Capacity

5.953

m3

Height

1.416

m

Length

2.900

m

Width

1.450

m

Power Requirement

1.119

kW

Material of Construction:

•

Stainless Steel with plastic segments

50

feed (MT/hour)

1.428

2.054

0.000

feed volume (m3)

1.997

1.872

0.000

3.869

5.953

AgriWaste Paper Industry

input

pulp

alum

rosin

talc

starch

water

total

volume of equipment

feed (MT)

41.395

2.463

2.463

4.226

2.955

38.244

91.745

Refiner

density(MT/m3)

0.561

0.881

1.073

1.746

0.561

1.000

feed (MT/hour)

1.725

0.103

0.103

0.176

0.123

1594

feed volume (m3)

3.174

0.116

0.096

0.101

0.219

1.594

5.200

8.001

Dimensions

Quantity

1.000

pc/s

Capacity

8.001

m3

Height

3.441

m

Diameter

1.721

m

Power Requirement

0.746

kW

Material of Construction:

•

Welded stainless steel

input

starch

talc

water

total

volume of equipment

Quantity

Capacity

Height

Diameter

Power Requirement

feed (MT)

4.226

2.463

5.914

12.603

Mixer2

density(MT/m3)

0.561

1.746

1.000

1.000

0.952

1.693

0.846

0.559

Dimensions

pc/s

m3

m

m

kW

Materials of Construction:

designed as a compact, water pressure-tight unit including

propeller and integrally cast installation bracket for the

attachment on the square guide tube

•

Motor housing and propeller made

stainless steel

•

51

feed (MT/hour)

0.176

0.103

0.246

feed volume (m3)

0.314

0.059

0.246

0.619

0. 0.952397403

AgriWaste Paper Industry

input

Treated pulp

total

volume of equipment

feed (MT)

91.745

91.745

Fourdrinier Machine

density(MT/m3)

0.720

feed (MT/hour)

3.823

feed volume (m3)

5.309

5.309

8.168

feed (MT/hour)

0.103

feed volume (m3)

0.085

0.085

0.131

Dimensions

Quantity

1.000

pc/s

Capacity

8.168

m3

Height

0.454

m

Length

6.000

m

Width

3.000

m

Power Requirement

2.237

kW

Material of Construction:

•

Open stainless steel head box; cantilevered stainless

fourdrinier with top granite rolls and rubber lined bottom

rolls, forming box, plain foils suction foils and suction boxes,

cantilevered suction couch, wire return rolls, wire stretch,

wire guides.

input

paper

total

volume of equipment

feed (MT)

2.463

2.463

Packaging

density(MT/m3)

1.201

Dimensions

Quantity

1.000

pc/s

Capacity

0.131

m3

Height

0.046

m

Length

2.400

m

Width

1.200

m

Power Requirement

0.75

kW

Materials of Construction:

•

Stainless steel body and sharp stainless steel blade

52

AgriWaste Paper Industry

Water Tank

input

feed (MT)

density(MT/m3)

feed (MT/day)

water

232.863

1.000

232.863

total

232.683

feed volume (m3)

232.863

232.863

volume of equipment

358.250

Water Tank

Quantity

5.000

pc/s

Capacity

71.650

m3

Height

7.146

m

Diameter

3.762

m

Material of Construction:

•

Tanks made of corrugated low carbon galvanized steel, lined with

hot bonded food-grade polymer

NaOCl Tank

input

NaOCl solution

total

feed (MT)

1.987

density(MT/m3)

1.097

feed (MT/2wks)

59.621

1.987

feed volume (m3)

54.349

54.349

volume of equipment

83.613

NaOCl Tank

Quantity

1.000

pc/s

Capacity

83.613

m3

Height

7.523

m

Diameter

3.762

m

Material of Construction:

• High density liner polyethylene tanks, modeled tank use for

aggressive corrosive chemicals

53

AgriWaste Paper Industry

Figure 11. Equipment Layout

54

AgriWaste Paper Industry

PLANT DESCRIPTION

Location

Choosing for the best plant site is very difficult. There are several influences that

we have to consider in selecting the most suitable site. Among which are the availability

of raw materials; climate; utilities such as transportation, communication, water

resource; wastewater disposal and dry waste disposal; and most especially the human

labor cost.

We have decided to construct our plant in Santiago City, Isabela. The availability

of the raw material is our main reason of selecting the site, since Isabela have much

production of corn based on the data gathered in the Bureau of Agricultural Statistics

(see Appendix C). Moreover, another source of raw material is the nearby province

Cagayan, which only takes 3 hours getting there. From the data that we have gathered

from Bureau of Agricultural Statistics, the Cagayan Valley Region (Region 2) is one of

the largest corn producers in the country.

Also, the accessibility of transportation facilities, the roads and the highways are

in good quality so it offers some advantages for the delivery of raw materials and

finished goods. Furthermore, the cost is minimal for labor and there is an adequate

supply of human resources. Provincial taxes are also low.

Figure 8. Plant Location Map

55

AgriWaste Paper Industry

Plant Size

The total land area of our plant is 6,496.36 m2. The plant has the perimeter of

322.40 m with the length and width of 80.6 m. The total building area is 4,942 m2 and a

free space of 1,554.20 m2. The plant follows the building and space ratio of 70% and

30% respectively. AgriWaste Paper Industry will consist of the following:

Administration Building (2 floors) – 278 m2

General Manager Office w/ Executive Secretary Room & Rest Room

HR, Purchasing and Cashier Department

Marketing and Finance Department

Canteen

Clinic

Reception Area or Lobby

Company Files Room

Conference Room

Seminar Room (for future expansion)

Comfort Rooms

Process Plant – 956.02 m2

Boiler House

Repair and Maintenance Room

Production Office w/ CR (Plant Head & Process Engineers)

Laboratory w/ CR (Quality Control Head & Lab Analysts)

Comfort Room

Warehouse (Raw Materials) – 2,995.14 m2

Office

Fillers Storage

Warehouse (Finished Goods) – 237 m2

Office w/ Comfort Room

Power House – 64 m2

Guard House w/ CR – 12 m2

Waste Water Treatment Plant – 400 m2

56

AgriWaste Paper Industry

Figure 12. Plant Layout

57

AgriWaste Paper Industry

Figure 12a. Plant Layout

58

AgriWaste Paper Industry

Figure 12b. Plant Layout

59

AgriWaste Paper Industry

ORGANIZATIONAL AND FINANCIAL STUDY

ORGANIZATIONAL CHART

In a business operation, the whole of the industry consists of various subsystems

and activities.

The company has been proposed that a chosen organizational

structure will be designed to accomplish effectively the objective of the company.

The company will adopt the basic form of organization which is through

departmentalization. The group work took into account the various tasks of the

subsystems so that there will be no overloading or under loading of works so as to

optimize each person’s capacity to do the works.

AgriWaste Paper Industry consists of 86 employees, working on eight hours per

day basis. For the personnel in the production like production workers, process

engineers, repair and maintenance, warehouse assistance, forklift operators and the

security personnel and nurses, shifting schedules will be implemented to

accommodate the continuous production of bond paper.

Figure 9. Organizational Chart

60

AgriWaste Paper Industry

JOB DESCRIPTION

General Manager

Functions

The general manager of the company shall initiate the organization’s objectives

and policies as well as formulate plans and programs. He/She is responsible for the

overall direction and control of the company’s entire operation. Also, he/she is liable for

the Quality Management System and achievement of its objectives as signified in the

quality policy. The General Manager also analyzes the act, decision and relation

needed. He/She is directly responsible to the board or the successful achievement of

organization’s objectives. It thus becomes the central task of the manager to reconcile

differences in approach, timing, effort, interest and to harmonize individual goals to

contribute to organizational goal.

Qualifications

Male/Female, between 40 to 50 years of age. At least 10 years of excellent

experience in managerial work.

Executive Secretary

Functions