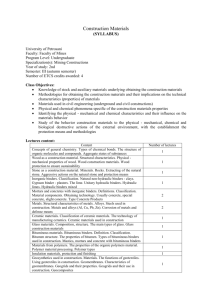

hand book for road works

advertisement